HGI Generators VRP80-TIN12-TL User manual

Ravenstor Road

Wirksworth

Derbyshire

DE4 4FY

ENGLAND

Sales Tel:

+44 (0) 1629 824 284

Sales Fax: +44 (0) 1629 824 613

Email: [email protected]

Website: www.hgigenerators.com

Operation and Maintenance Manual

Petrol Generator

8.0 - 9.6 kW Air Cooled

for build numbers:

VRP80-TIN12-TL, VRP96D-TL, VRP96T-TL

Publication No: 498-1019

© Harrington Generators International Limited

All rights reserved. No part of this publication may be reproduced in any material form (including photography or storing in

any medium by electronic means or other) without the written permission of the copyright holder except in accordance with

the provisions of the Copyright, Designs and Patents Act 1988.

Applications for the copyright holder’s written permission to reproduce any part of this publication should be addressed to

Harrington Generators International Limited at the address above.

Any reference to trademarked product names used within this publication is owned by their respective companies.

Harrington Generators International Limited reserves the right to change the contents of this document without prior notice.

Change Control

Date Version Author Reason for change

Jun 15 Provisional MC Draft for Review by Ken Croft

Jun 15 A MC Updated following review and released

Jan 17 B MC Upd Warranty Iss H

Oct 17 C MC Upd Warranty

Harrington Generators International

498-1019Petrol Generator

Contents

Contents

INTRODUCTION............................................................................................. 1

CERTIFICATION............................................................................................. 3

EC Declaration of Conformity ...................................................................... 3

SPECIFICATION............................................................................................. 4

Model Specification....................................................................................... 4

SAFETY .......................................................................................................... 5

A few words about safety ............................................................................. 5

Operator Responsibility................................................................................ 5

Precautions.................................................................................................... 6

Earthing ...................................................................................................... 6

OPERATION ................................................................................................... 7

Generator Layout........................................................................................... 7

Engine Component Identification................................................................ 7

Pre-Operation Checks................................................................................... 8

Starting........................................................................................................... 9

Stopping....................................................................................................... 10

FAULT FINDING ........................................................................................... 12

MAINTENANCE............................................................................................ 13

Maintenance Schedule................................................................................ 13

Safety Precautions...................................................................................... 14

Maintenance Routine .................................................................................. 14

Harrington Generators International

498-1019 Petrol Generator

Contents

PARTS AND SERVICE................................................................................. 17

Contact Details ............................................................................................ 17

Warranty Statement..................................................................................... 17

Functional Spares ....................................................................................... 17

TRANSPORTATION ..................................................................................... 18

STORAGE..................................................................................................... 18

WIRING......................................................................................................... 19

MANUFACTURER’S SERVICE AND USER GUIDES LINKS...................... 20

Vanguard 350000 Series Engine Operators Manual................................. 20

Mecc Alte S20FS/T20F User Manual ......................................................... 20

Harrington Generators International

1 498-1019Petrol Generator

Introduction

Introduction

Thank you for purchasing a quality generator, carefully

manufactured to the highest standards by one of the

World’s leading generator manufacturers, Harington

Generators International (HGI).

This range of Dual Voltage 110V/230V/400V

are generally used for industrial use and are

not CE marked for European Noise Directive.

Before operating the generator, read this manual and

make sure that all personnel who operate the equipment

have access to the manual (and any additional

documentation supplied with it) and are fully aware with

the operation and functionality of the generator prior to

use.

Misuse of the instructions may invalidate the product

warranty and lead to potential accidents.

This manual is an essential part of the generator and

should be kept with the generator at all times. Make

sure that the manual is available to all users throughout

the generator’s life-span.

If in doubt about the functionality of any of the equipment

within this document please contact HGI or seek other

expert advice.

Every effort has been made to ensure that the

information given in this manual is correct at the time of

publishing. However, it may be superseded due to our

continuous improvement processes.

HGI Limited manufacture a wide range of generating

sets and accessories, including generators approved

for use in Telecoms, Railway and Military applications

where quality and reliability are essential. These

include:

• Petrol Generators

• Petrol Welders

• Gas & Water ECE3 (TIN12)

• Trackside

• Tractor PTO

• Super Silent Diesel Generators (3000rpm)

• Super Silent Diesel Generators (1500rpm

• Automatic Mains Failure Control Systems

• Welf-Air Generators

• Compact Welf-Air Generators

• Super Compact Welf-Air Generators

• Super Silent Diesel Welders

For further information call us now on :

+44 (0)1629 824 284

our experienced and knowledgeable sales staff will be

happy to advise you and provide a detailed quotation

for all your generator requirements or visit our website

www.HGIgenerators.com

VRP96

Harrington Generators International

498-1019 2 Petrol Generator

Harrington Generators International

3 498-1019Petrol Generator

Certification

Certification

EC Declaration of Conformity

In accordance with ISO/IEC 17050-1:2004 Conformity Assessment - Suppliers’ Declaration of Conformity

We: Harrington Generators International Ltd.

Ravenstor Road, Wirksworth, Derbyshire DE4 4FY

Declare that

Equipment 110V/230V Dual Voltage or 400V/230V Petrol Generators

Model Name VRP80-TIN12-T VRP96D-TL VRP96T-TL

Electrical Power Pel 8.0 kW e 9.6 kW e 9.6 kW e

Conforms to the protection requirements of the following EC Council Directives:

2006/42/EC Machinery Directive

2006/95/EC Low Voltage Directive

2014/30/EU EMC Directive

2000/14/EC Noise Emission in the Environment by Equipment for use Outdoors Directive Annex V111

97/68/EC Measures against the emission of gaseous and particulate pollutants from internal

combustion engines to be installed in non-road machinery.

European level Stage 3A (for engines above the minimum kW power threshold).

And has been designed and manufactured to the following standards:

BS5000 Part 3 Rotating electrical machines of particular types or for particular applications.

Generators to be driven by reciprocating internal combustion engines.

EN60204-1 Safety of machinery. Electrical equipment of machines. General requirements.

EN12601 Reciprocating internal combustion engine driven generating sets. Safety.

BS EN61000-6-1 EMC. Generic Standards. Immunity for residential, commercial and light-industrial

environments.

BS EN61000-6-2 EMC. Generic Standards. Immunity for industrial environments.

BS EN61000-6-3 EMC. Generic Standards. Emission standard for residential, commercial and

light-industrial environments.

BS EN61000-6-4 EMC. Generic Standards. Emission standard for industrial environments.

BS ISO 3744 Acoustics. Determination of sound power levels of noise sources using sound pressure.

Notified Body for 2000/14/EC Noise HORIBA MIRA UK

Emission in the Environment by Watling Street

Equipment for use Outdoors Directive Nuneaton

Warwickshire CV10 0UT

Notified Body Number: 00888

I declare that as the authorised representative, the above information in relation the supply and manufacture of

this product is in conformity with the stated standards and other related documents following the provision of the

above EC Directives.

Signed C. Coulton

Jan 2017 Quality Manager

Harrington Generators International

498-1019 4 Petrol Generator

Specification

Specification

Engine: Nominal Power 12.5kW

Vanguard 350000 Series 570cc

OHV V Twin Cylinder

Engine Speed 3000 rpm

Frame: Mild Steel, Polyester Powder Coat Finish

Trolley Mounted

Dimensions: 1055 x 675 x 755 l x w x h (mm)

Fuel Tank Options: Standard 8.5 litre capacity

Performance Class: ISO 8528 LTP G1 Limited Running hours for general purpose electrical supply

Model Specification

VRP80-TIN12-T

Output: 8.0 kW (10.0 kVA)

Output Voltage: 110V CTE

Alternator: S20FS-160/A - 2-pole brushless, self exciting, capacitor controlled

Weight (kg)1125

Hours Run22.8

VRP96D-TL

Output: 9.6 kW (12.0 kVA)

Output Voltage: 110 / 230V

Alternator: S20FS-160/A - 2-pole brushless, self exciting, capacitor controlled

Weight (kg)1130

Hours Run22.5

VRP96T-TL

Output: 9.6 kW (12.0 kVA)

Output Voltage 230 / 400V

Alternator: T20F-200/A - transformer controlled with brushes

Weight (kg)1138

Hours Run22.5

1Dry Weight approx without fuel and oil

2 Hours Run @ ¾ Load (approximate figures only)

Harrington Generators International

5 498-1019Petrol Generator

Safety

Safety

A few words about safety

Your safety and the safety of others are very important and using this generator safely is an important

responsibility.

HGI have designed this generator to give safe and dependable service if operated in accordance to these

instructions. Please ensure that you read this owner’s manual and understand the functionality of the generator

before using your generator. You can help prevent accidents and harm to yourself and nearby personnel by

being familiar with the controls, and by observing safe operating procedures.

The warnings and safety instructions appearing in this guide are not meant to cover every eventuality and

hazards associated with operating or maintaining a generator. You must use your own good judgement, care

and caution.

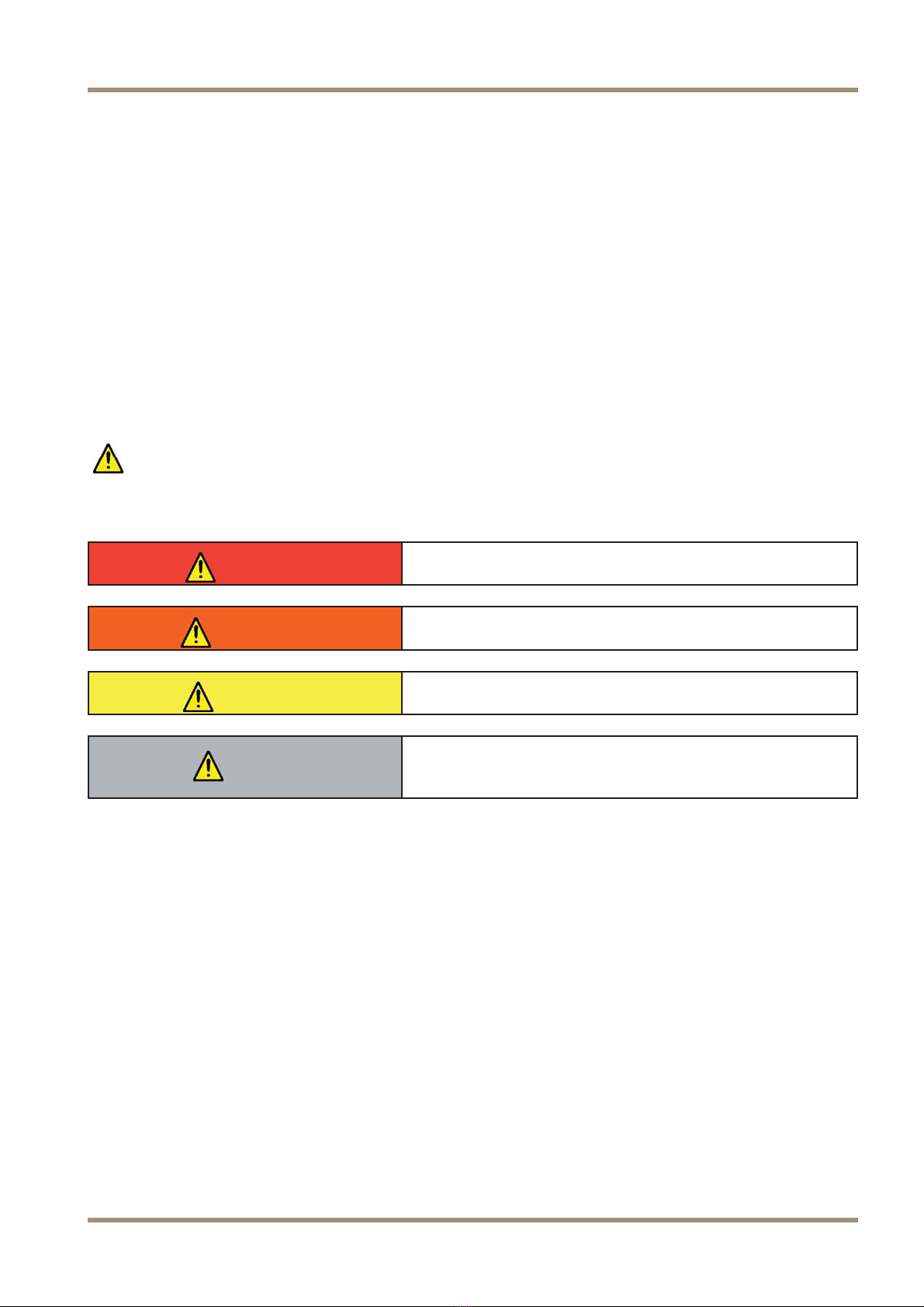

This is the safety alert symbol. It is used to alert you to potential hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

There are four types of safety alert messages used in this manual:

DANGER Danger refers to immediate hazards which WILL

result in severe personal injury or death.

WARNING Warning refers to a hazard or unsafe method or practice which

CAN result in severe personal injury or possible death.

CAUTION Caution refers to a hazard or unsafe method or practice

which CAN result in personal injury.

NOTICE Notice refers to a method or practice which can result in product

damage, or to draw attention to additional information or

explanations.

Operator Responsibility

• Know how to stop the generator quickly in case of emergency.

• Understand the use of all generator controls, output sockets, and connections.

• Be sure that anyone who operates the generator receives proper instruction.

If you have any doubts about the safe operation of this equipment, please contact HGI or a competent operator

or qualified technician.

Petrol Generator

Precautions

The generator can constitute a hazard to users, nearby personnel and property unless the following precautions

are observed during operation:

• Ensure that you know how to stop the engine in an emergency.

• Exhaust fumes are poisonous and can kill.

- Do not operate the generator in a confined area.

- Ensure that the area surrounding the machine has no restrictions that would prevent an adequate flow

of clean, ambient air.

• The generator should be operated in an open space with free air flow on all sides, at least one

metre from other equipment and buildings. The surrounding area should be clear of any combustible

material.

• Fuel is highly flammable, when refuelling:

- Do not run the engine.

- Do not smoke.

- Avoid overfilling the fuel tank.

- Wipe up any fuel spilt on the machine and move the equipment away from the area where fuel has

been spilt.

- Store fuel in approved containers only and do not expose to direct sunlight.

• Parts of the engine, and particularly the exhaust system will get very hot during use, and will remain hot

for some time after the generator has stopped.

• Do not use the equipment with loose or missing components or guards.

• Additional care should be applied if using the generator in damp or wet conditions.

• The throttle control lever is preset to the correct engine speed and must not be adjusted, otherwise

damage to equipment or the generator may be caused and will invalidate the warranty.

• Regularly inspect the condition of trailing cables and integrity of connectors. Only use correctly rated cable

and standard plugs of suitable capacity for the application.

• During servicing, follow HSE recommendations regarding the handling and disposal of contaminated oil

products.

Earthing

The earth pins of the output socket(s) are electrically connected to the metalwork of the generator.

VRP80-TIN12-TL 110V CTE with centre tap to earth.

VRP96D-TL has the neutral connection floating and not tied to earth.

VRP96T-TL has a star neutral point which is floating and not tied to earth.

Further advice on earthing can be found in the following Health & Safety Executive publications (available from

HMSO):

• GS27 Protection Against Electric Shock

• GS24 Electricity on Construction Site

• PM53 Emergency Private Generation

Harrington Generators International

7 498-1019Petrol Generator

Operation

Operation

The guidelines for operating the generator outlined in the section refer to both the standard frame generators

and the trolley mounted generators. However, diagramatically the images refer to the standard frame.

Generator Layout

Engine Component Identification

Muffler

Choke

Lever

Oil Drain Plug

Oil Filler

Air Cleaner

Fuel Tank

Engine

Frame

Auxiliary

Sockets

Alternator

Anti Vibrational Mountings

Tool and

Lead Tray

Control

Panel

Recoil Starter

Air Cleaner

Throttle

Spark

Plug

Engine

Switch Dipstick

Oil Filter

* not exact model shown

for illustration only

Harrington Generators International

498-1019 8 Petrol Generator

Operation

Pre-Operation Checks

Engine Oil

Check the oil level BEFORE EACH USE with the

generator on a level surface and the engine stopped.

Use 4-stroke fully synthetic motor oil that meets or

exceeds the requirements for API service classification

SF, SG, SH, or SJ or later (or equivalent). Always

check the API SERVICE label on the oil container to

be sure it includes the letter SJ or later (or equivalent).

SAE 10W-30 is recommended for general, all

temperature use. Other viscosities shown in the chart

may be used when the average temperature in your

area is within the indicated range.

To check the oil level:

1. Remove the oil filler cap and wipe the dipstick

clean.

Oil Dip Stick

Oil Fill

2. Insert the dipstick into the oil filler neck but do not

screw it in.

3. If the level is low, fill to the full level mark on the

dipstick

Full

Oil Capacity: 1.4 Litres

Fuel

WARNING

Petrol is highly flammable and explosive.

You can be burned or seriously injured when

handling fuel.

Stop the engine and keep heat, sparks, and flame

away.

Handle fuel only outdoors.

Wipe up spills immediately.

With the engine stopped, remove the fuel tank cap

and check the fuel level.

Refill the fuel tank if the fuel level is low. Refuel care-

fully to avoid spilling fuel.

Do not fill above the bottom of the fuel tank neck.

NOTICE

Fuel can damage paint and plastic. Be careful not to

spill fuel when filling your fuel tank. Damage caused

by spilled fuel is not covered under warranty.

After refuelling tighten the fuel cap securely.

Harrington Generators International

9 498-1019Petrol Generator

Operation

NOTICE

If the fuel tank is empty and dry it will take up to

10 minutes for fresh fuel to prime the filters and

carburettor.

Fully fill the tank to speed this up.

Fuel Capacity 8.5 Litres

Throttle

The throttle control lever is preset to the correct engine

speed and must not be adjusted, otherwise damage

to equipment or the generator may be caused and will

invalidate any warranty.

General

Check that the generator is located on level ground

and in an open space with free air flow on all sides, at

least one metre from other equipment and buildings,

and clear of any combustible material.

Starting

WARNING

Please check that all equipment is disconnected

from the generator prior to starting.

WARNING

Carbon monoxide gas is toxic. Breathing it can

cause unconsciousness and even kill. Avoid any

enclosed areas, partially enclosed areas or activities

that may expose you to carbon monoxide.

1. Perform the Pre-Operation Checks.

2. Make sure that all appliances are disconnected

from the output sockets.

3. Turn the fuel shut off valve (located next to the

starter key)to the ON position.

Fuel Shut

Off Valve

Electric

Start Switch

4. Move the choke control to the choke position

NB: The choke may not be required if the engine

is warm or the air temperature is high.

5. Insert the Key and turn the electric start switch

to the START position until the generator starts.

Return the switch to the RUN position.

If the engine failes to start after three attempts

start fault finding procedures.

6. If the choke lever was moved to the choke

position to start the engine, gradually move it to

the RUN position as the engine warms up.

7. Allow the engine to warm up for 1 minute before

connecting any load to the generator output.

Harrington Generators International

498-1019 10 Petrol Generator

Operation

Output Sockets

The output sockets are located on the Top Box above

the alternator.

The socket arrangement available for connecting load

to is dependant upon the model:

Model Top

Box Sockets

VRP80-TIN12-TL

TB005

110V CTE 2 x 16A,

1 x 32A, 1 x 63A

63A Main MCB

VRP96D-TL TB-

6DV9

110V 2 X 16A, 1 x 32A

230V 2 X 16A, 1 x 32A

32A Main MCB

VRP96T-TL

TB3TP

230V 2 x 16A

3Ph 1 x 32A

10A Main MCB

On VRP80-TIN12-T models earthing of the output is

centre tapped to earth, protected by MCBs. 15A MCBs

protecting 16A sockets and 30A MCBs protecting the

32A sockets.

On VRP96D-TL the neutral is floating.

Select the voltage required using the

voltage selector switch on the top box.

On VRP96T-TL the neutral/star point is floating.

Connect the equipment to be powered (load) into the

socket receptacles on the generator top box.

NOTICE

Do not overload the generator as this will cause

overheating, and shorten the life of the generator.

Check that the total load from all equipment connected

does not exceed the generator rating. The output

may be protected against severe overload by circuit

breakers, when fitted.

There is an M8 brass stud on the frame which should

be connected to an external earth point or to an earth

spike. An earth spike can be supplied as an optional

extra and should be driven at least 600 mm into soil.

High Altitude Operation

The generator is capable of operating up to 1000m

without significant power reduction.

At higher altitudes, the standard carburettor air-fuel

mixture will be excessively rich. Performance will

decrease, and fuel consumption will increase.

For high altitude operation install a smaller diameter

main fuel jet in the carburettor and readjust the

pilot screw. If you always operate the engine at

high altitudes, have these carburettor modifications

performed by a reputable service company or contact

HGI.

Even with suitable carburettor jetting, engine

horsepower will decrease approximately 3.5% for each

300m increase in altitude. The effect of altitude on

horsepower will be greater than this if no carburettor

modification is made.

NOTICE

Operation of the engine at an altitude lower than

the carburettor is jetted for may result in reduced

performance, overheating, and serious engine

damage caused by an excessively lean air/fuel

mixture.

Stopping

To stop the engine in an emergency, simply turn the

engine key to the OFF position. Under normal condi-

tions, use the following procedure:

1. Switch off and disconnect the load from the

generator’s output sockets.

2. Allow the generator to run off load for 2 minutes to

cool down.

3. Turn the Key switch to the OFF position

4. Move the Fuel Shut Off Valve to the CLOSED

position.

CAUTION

Leaving the fuel shut off valve in the ON position

after stopping can cause the engine to flood and

impair starting.

Harrington Generators International

11 498-1019Petrol Generator

Operation

NOTICE

If the fuel shut off valve is left ON for transport the

movement may bounce the carburettor float and

allow fuel to flood the engine.

Always ensure that the fuel shut off valve is turned

to CLOSED when not in use.

Harrington Generators International

498-1019 12 Petrol Generator

Fault Finding

Fault Finding

IMPORTANT:

If the following checks and investigations can be completed without the use of tools then the User can safely un-

dertake them. If tools are needed then ONLY trained technicians can undertake the work safely. Wiring diagrams

can be obtained from HGI to help with electrical fault finding.

Symptom Cause and Remedy

Engine will not start • Check the Choke is in the correct position

• Check that there is fuel in the tank

• Blocked Fuel Filters

• Engine Flooded

• Is there enough oil in the engine

• No Spark - incorrectly gapped spark plug

• Blocked Air Filter

• Incorrectly set engine speed.

• Low Oil Level

Engine starts but stops on load • Fuel starvation - check filters

• Choke incorrectly set

• Dirty Air Filter

• Engine Speed incorrectly set

• Low Oil Level

No electrical output • Breakers have been switched off / tripped

• Load is faulty

• Diodes on alternator have failed

• Alternator capacitor has failed

• Alternator has lost magnetism

• Faulty alternator windings

NOTICE FLOODED ENGINES

If the fuel valve is left ON whilst the machine is not in use the engine can flood. If this occurs the following

procedure can alleviate starting problems :

• Turn the Fuel Valve OFF

• Drain the Carburettor bowl

• Remove the Spark Plug and inspect for flooded cylinder - correct if necessary

• Remove Oil Filler Cap (Dipstick) and inspect the oil. Drain oil and refill if necessary.

If in doubt contact HGI Service or consult with your dealer.

Harrington Generators International

13 498-1019Petrol Generator

Maintenance

Maintenance

Good maintenance is essential for safe, economical, and trouble free operation. This not only ensures that your

engine is at its optimum in fuel efficiency, but maintains the engine in order to minimize the risk of breakdowns.

This will save you money in the long run, as worn items can be spotted sooner, saving further problems.

Maintenance Schedule

The maintenance schedule applies to normal operating conditions. If you operate your generator under severe

conditions, such as sustained high-load or high-temperature operation, or use it in unusually dusty conditions,

consult your servicing dealer for recommendations applicable to your individual needs and use.

Service

Period

Item Every 8 hrs

or Daily

Every 25hrs

or Every

Season

50hrs or

Every

Season

100 hrs

or Every

Season Yearly

Check fuel level º

Check oil level º

Change oil º (1) º

Change oil filter (if equipped) º

Service air cleaner pre-cleaner º (2) º

Service air cleaner cartridge º (2)

Clean cooling system º (2)

Clean/replace spark plugs º

Clean/replace in-line fuel filter (if

equipped) º

Check valve clearance º

Alternator Every Year

Battery Every Year

Electrical Every Year

Frame Every Year

1. Change Oil after first 5-8 hours of use and then every 50hrs or season. Change oil every 25hrs if using

under heavy load or in high temperatures.

2. Service more frequently if used in dusty areas.

3. Only by trained personnel.

If you’d like to make an appointment for HGI to service your generator using our in house 26-point health

checker guide then please contact the Service Department.

Harrington Generators International

498-1019 14 Petrol Generator

Maintenance

Safety Precautions

Some of the most important safety precautions follow.

However, we cannot warn you of every conceivable

hazard that can arise in performing maintenance. Only

you can decide whether or not you should perform a

given task.

WARNING

Failure to properly follow maintenance instructions

and precautions can cause serious injury or death.

Always follow the procedures and precautions in the

operations manual. Where third party equipment is

incorporated into the generator always refer to their

guides for familiarisation

• Make sure the engine is off before you begin any

maintenance or repairs. This will eliminate several

potential hazards:

• Read the instructions before you begin, and make

sure you have the tools and skills required.

• To reduce the possibility of fire or explosion, be

careful when working around petrol. Use only a

nonflammable solvent, not petrol, to clean parts.

Keep cigarettes, sparks, and flames away from all

fuel-related parts.

Maintenance Routine

The following procedures refer to the common mainte-

nance items for servicing your generator.

Fuel Level Check

Refer to Pre-Start Checks.

Oil Level Check

Refer to Pre-Start Checks.

Engine Oil Change

Change Oil after the first 5-8 hours of use and then

every 50hrs or season. Change oil every 25hrs if

using under heavy load or in high temperatures.

Recommended oil of grade 10W30 or better.

Drain the oil in the engine while the engine is warm.

Warm oil drains quickly and completely.

1. Place the generator on a level surface, and place

a suitable container under the drain plug bolt.

2. Disconnect spark plug leads and keep away from

spark plugs. Disconnect battery at the negative

terminal.

3. Remove the oil filler cap, drain plug bolt, and

drain plug washer to drain the oil into the suitable

container.

Oil Drain

Plug

4. Follow HSE recommendations regarding the

handling and disposal of contaminated oil

products.

5. Reinstall drain plug and tighten. Remove oil filler

cap.

6. Fill with recommended oil to the top of the oil filler

neck. Replace oil filler cap.

Change Oil Filter

Change oil filter after every 100 hours or every

season.

1. Drain engine oil and remove oil filter.

2. Before installing new filter, lightly oil filter gasket

with fresh, clean oil.

3. Screw filter on by hand until gasket contacts oil

filter adapter. Tighten 1/2 to 3/4 turn more.

4. Add fresh oil. Fill to FULL line on dipstick.

5. Start and run engine at idle to check for leaks.

6. Stop engine. Re-check oil level. Add oil if required.

Service Air Filter Pre-Cleaner

A dirty air filter will restrict air flow to the carburettor,

reducing engine performance. If the engine is

operated in dusty areas, clean the air cleaner

more often than specified in the MAINTENANCE

SCHEDULE.

Harrington Generators International

15 498-1019Petrol Generator

Maintenance

NOTICE

Operating the engine without the air filters or with

the filter installed loosely will allow dirt to enter the

engine, causing rapid engine wear. Install the air

filters securely.

All engines have a round air cleaner cartridge. In

addition, some engines have a pre-cleaner.

To clean pre-cleaner (if equipped), separate it from

cartridge and wash in liquid detergent and water.

Squeeze dry in a clean cloth.

Service Air Cleaner Cartridge

1. Remove knobs and cover.

2. Remove nut, plate and carefully lift air cleaner as-

sembly (pre-cleaner and cartridge) off stud.

3. Reinstall clean (or new) air cleaner assembly

firmly in base. Reinstall plate (top side marked

“UP”) and nut.

4. Reinstall cover. Tighten knobs securely.

Clean Air Cooling System

Debris may clog the engine’s air cooling system.

Remove blower housing and clean area shown to

prevent overheating and engine damage.

NOTICE

Do not use water to clean engine parts.

Water could contaminate fuel system. Use a brush

or dry cloth.

Clean / Replace Spark Plugs

CAUTION

If the engine has been running, the engine will be

very hot. Allow it to cool before proceeding.

Remove the spark plug lead, and then remove the

spark plugs using a spark plug wrench.

Check the spark plug for damage and replace if

necessary, or

Check the gap with a wire gauge. If necessary, reset

the gap.

Re-Install and tighten the spark plug.

PLUG GAP: 0.76 mm (0.03 in)

TORQUE SETTING: 180 lb-in (20 Nm)

Harrington Generators International

498-1019 16 Petrol Generator

Maintenance

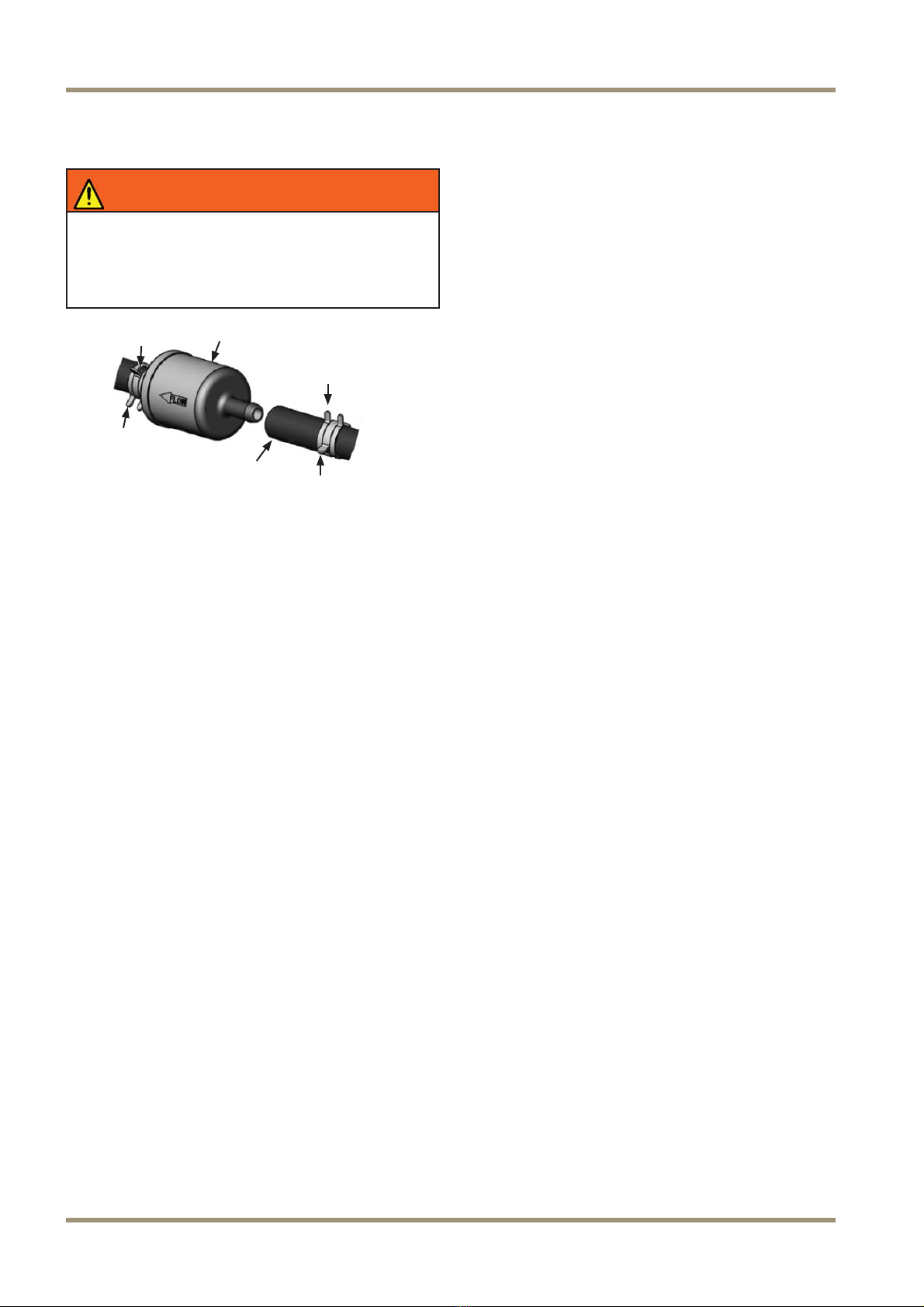

Clean / Replace Inline Fuel Filter

WARNING

Petrol is highly flammable and explosive. You can

be burned or seriously injured when handling fuel.

• Keep heat, sparks, and flame away.

• Handle fuel only outdoors.

• Wipe up spills immediately.

A

C

B

D

B

C

1. Before replacing the fuel filter, if equipped, drain

the fuel tank or close the fuel shut-off valve.

Otherwise, fuel can leak out and cause a fire or

explosion.

2. Clamp hose (D) on either side of the filter.

3. Use pliers to squeeze tabs (B) on the clamps (C),

then slide the clamps away from the fuel filter.

Twist and pull the fuel lines (D) off the fuel filter.

4. Check the fuel lines for cracks or leaks. Replace if

necessary.

5. Replace the fuel filter with an original equipment

replacement filter.

6. Secure the fuel lines with the clamps as shown

and remove the temporary clamps.

Valve Clearance

Valve Clearances should be checked every year. The

clearance should be:

Intake Valve Clearance:

0.004 - 0.006 in (0.10 - 0.15 mm)

Exhaust Valve Clearance:

0.004 - 0.006 in (0.10 - 0.15 mm)

Refit the rocker cover with a new gasket.

Alternator

Ensure that the cooling air vents do not become

blocked by dirt, debris etc.

Check the brushes and slip rings for wear every 12

months or 250/300 hours operation and replace if

worn (brush – type alternators only).

Battery

Electric start models only. The battery is a

maintenance free unit and should not require the

electrolyte being topped up.

Check that the positive and negative terminals are

tight and secure, and free from corrosion. Lightly coat

them with petroleum jelly or similar to protect from

corrosion.

Electrical

• Inspect sockets, and replace if damaged or

contact pins are burnt.

• Check all wiring is secure and not damaged.

• Check the output voltage and frequency are

correct.

• Check the earth continuity between the socket

earth pins and the generator frame.

Frame

Check frame for rust and take necessary action if

unsound.

Check security of fixings and fasteners on the

machine.

Ensure earthing point is sound, clean any rust or oil

deposits.

Generally inspect for fuel and oil leaks

Visually inspect anti vibration mounts for signs of

failing or damage and check fixing bolts are secure.

Check wheels and axles for signs of failing.

This manual suits for next models

2

Table of contents

Other HGI Generators Portable Generator manuals

Popular Portable Generator manuals by other brands

DEI

DEI PVX-4000-2kV Operation manual

Peak Scientific

Peak Scientific MS Bench SCI 1 Service manual

Champion Global Power Equipment

Champion Global Power Equipment 100559 Operator's manual

Agilent Technologies

Agilent Technologies E8306A manual

Pulsar

Pulsar PGD105TiSCO Operator's manual

Wavetek

Wavetek 1001A instruction manual