Field Tuff FTF-05GOR User manual

Thank you very much for choosing this product. For future reference, please complete the owner’s

record below:

Model: Purchase Date: _______________

Save the receipt, the warranty and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This product is designed for certain applications only. The manufacturer and/or distributor cannot be

responsible for issues arising from modification. We strongly recommend that this product not be

modified and/or used for any application other than that for which it was designed. If you have any

questions relative to a particular application, DO NOT use the product until you have first contacted

the distributor to determine if it can, or should, be performed on the product.

For technical questions, please call 1-218-943-6290.

TECHNICAL SPECIFICATIONS

For use on a variety of applications including log splitters.

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions

listed below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this Hydraulic Reservoir

until they have read this manual and have developed a thorough understanding of how

this product works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors that cannot be built into this

product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep work area clean, free of clutter, and well-lit. Cluttered and dark work areas can cause accidents.

• Keep children and bystanders away while using the Hydraulic Reservoir. Visitors should remain at a

safe distance from the work area.

• Be alert of your surroundings. Using the Hydraulic Reservoir in confined work areas may put you in

a dangerous situation.

PERSONAL SAFETY

• Stay alert, watch what you are doing, and use common sense when using the Hydraulic Reservoir. Do

not use the Hydraulic Reservoir while you are tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while using the Hydraulic Reservoir may result in serious personal

injury.

• Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing, and

gloves away from moving parts.

• Safety Equipment. Wear heavy-duty work gloves, approved safety goggles, and proper head and

footwear.

5-GALLON HYDRAULIC

RESERVOIR

OWNER’S MANUAL

5-GALLON HYDRAULIC RESERVOIR OWNER’S MANUAL

Item# FTF-05GOR

1 of 3

WARNING:

Carefully read and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and

other basic safety precautions may result in serious personal injury.

Construction

Product Dimensions L x W x H

Steel welded construction with a black powder-coat finish

19-29/32’’ × 8-3/4’’ × 8-1/4’’

01012017

5-GALLON HYDRAULIC RESERVOIR OWNER’S MANUAL 5-GALLON HYDRAULIC RESERVOIR OWNER’S MANUAL

HYDRAULIC RESERVOIR USE AND CARE

• Do not modify the Hydraulic Reservoir in any way. Unauthorized modification may impair the

function and/or safety and could affect the life of the equipment.

• Always check for damaged or worn out parts before using the Hydraulic Reservoir.Broken parts

will affect its operation. Replace or repair damaged or worn parts immediately.

• NEVER USE YOUR HAND TO DETECT LEAKS!

CAUTION:

READ and UNDERSTAND this information completely before using Hydraulic Reservoir. All

operators of this equipment must read and completely understand all safety information and

usage instructions. Failure to comply with this information could result in serious injury to the

operator and bystanders or damage to equipment.

Do Not attempt to add more hydraulic fluid during operation to extend the hydraulic capacity. Ensure all

components in the hydraulic system are appropriately sized and rated for the application.

Do Not touch the exterior of the reservoir. It can become hot during operation.

Check the hydraulic system (hoses, tubing, clamps/fittings, pump, and cylinders) carefully

before each use. Do not operate the hydraulic system with frayed, kinked, cracked, or damaged

hydraulic hoses, fittings, or tubing, or if oily residue is observed on any of the components. High fluid

pressures and temperatures are developed in hydraulic equipment. Hydraulic fluid escaping through a

pinhole sized opening can burn or puncture skin, resulting in wounds that could cause blood poisoning,

infection, disability, gangrene, amputation, or death. Therefore, the following instructions should be

heeded at all times when inspecting or servicing hydraulic equipment.

Always make sure the engine/motor is off before servicing the hydraulic system. In addition,

disconnect spark plug/power supply and relieve system pressure before changing or adjusting hydraulic

system components such as hoses, tubing, fittings, or other components.

Never remove the hydraulic fill cap while in operation. Hot oil can escape, causing severe burns.

Allow hydraulic system to cool completely before removing hydraulic oil fill cap.

NEVER check for leaks with your hand. Leaks can be located by holding a piece of cardboard or

wood (at least two feet long) with your hand at one end and passing the other end over the suspected

area (wear eye protection). Look for discoloration of the cardboard or wood.

If injured by escaping fluid, no matter how small the wound is, see a doctor at once. A typical injection

injury may be a small wound that does not look serious. However, severe infection or reaction can result

if proper medical treatment is not administered immediately by a doctor who is familiar with injection

injuries.

PARTS DIAGRAM:

PARTS LIST:

For replacement parts and technical questions, please call 1-218-943-6290.

WARRANTY

One-year limited parts warranty

BAC Industries

PO BOX 155

Miltona, MN 56354

Made in CHINA

2 of 3 3 of 3

Part#

1

2

3

4

Description

Filler/Breather Cap

Inlet Screen

Tank

3/4’’NPT Drain plug

Qty.

1

1

1

1

Part#

5

6

7

8

Description

Suction Screen

3/4’’NPT Return port

1-1/2’’ NPT Suction port

Plug

Qty.

1

1

1

2

Size:145x210mm 157G铜版纸 REV 01/01/17 2.09.05.30.688

Popular Portable Generator manuals by other brands

Tesla

Tesla TI206 MPU-24 user manual

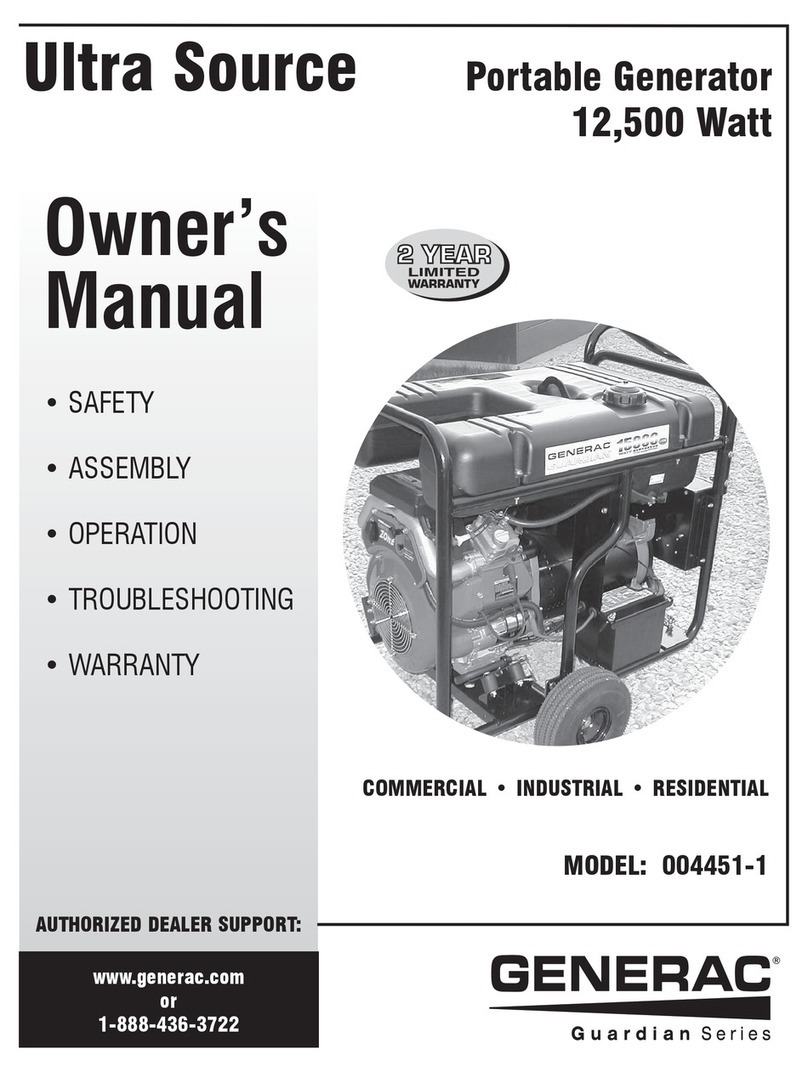

Generac Power Systems

Generac Power Systems Guardian Ultra Source 004451-1 owner's manual

Schmalz

Schmalz ECBPMi UR operating instructions

Pylon Technologies

Pylon Technologies BP Series product manual

Generac Power Systems

Generac Power Systems PP5000T owner's manual

PDWERTECH

PDWERTECH MG-4502 operating instructions