HGM SZI User manual

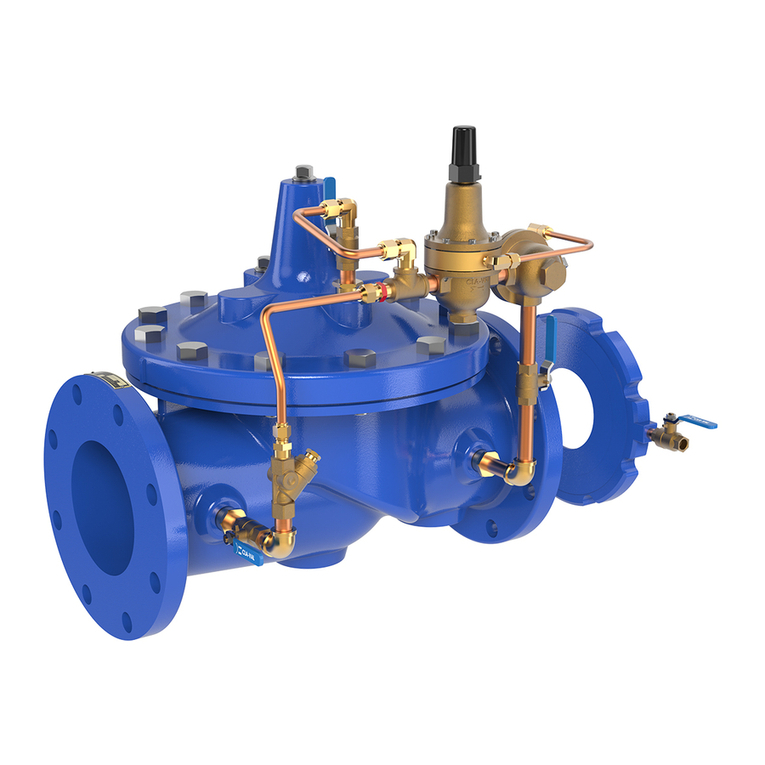

Valve box “SZI”

for compressed medical gases and the vacuum

complying to EN ISO 7396-1

INSTRUCTION MANUAL

2

Table of contents

1. Technical data ................................................................................................................................. 3

1.1 Information about the device ...................................................................................................... 3

2. Application ...................................................................................................................................... 3

3. Construction ................................................................................................................................... 4

4. Installation ...................................................................................................................................... 4

5. Operation ........................................................................................................................................ 4

5.1 First start-up ............................................................................................................................... 4

6. Maintenance / repair ...................................................................................................................... 5

6.1 List of spare parts ....................................................................................................................... 5

6.2 List of the authorized service points .......................................................................................... 5

8. Alarm system .................................................................................................................................. 7

8.1 Alarm unit mounted in valve box ............................................................................................... 7

8.2 Description of connections in alarm unit ................................................................................... 8

9. Remote alarm unit .......................................................................................................................... 8

9.1 Under plaster version ................................................................................................................. 8

9.1.1 Assembly drawing of under plaster alarm unit ................................................................... 9

9.2 Remote alarm unit – on wall version ......................................................................................... 9

9.2.1 Display .............................................................................................................................. 10

9.2.2 Mounting of on plaster alarm unit ..................................................................................... 10

9.3 Connecting cables .................................................................................................................... 11

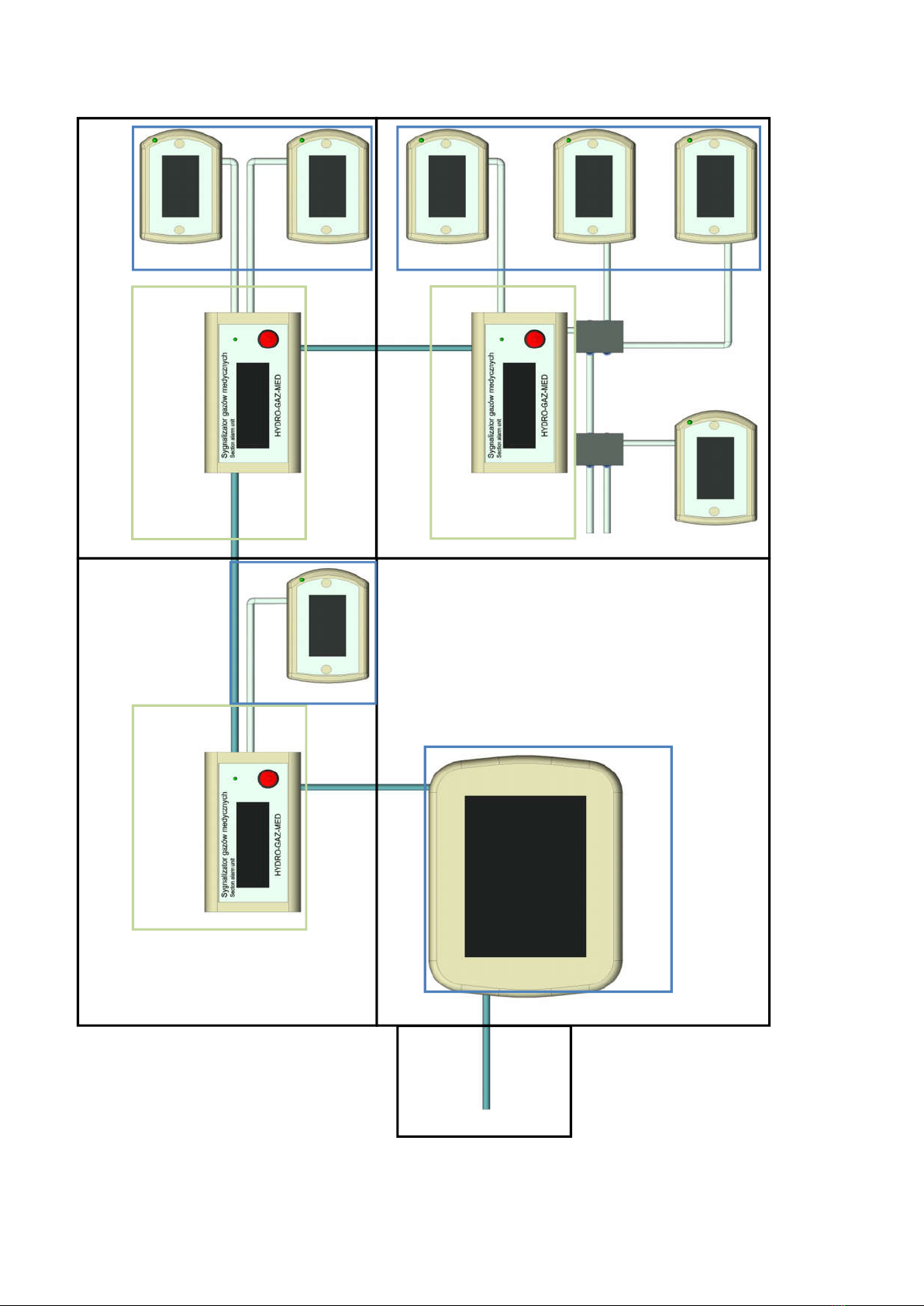

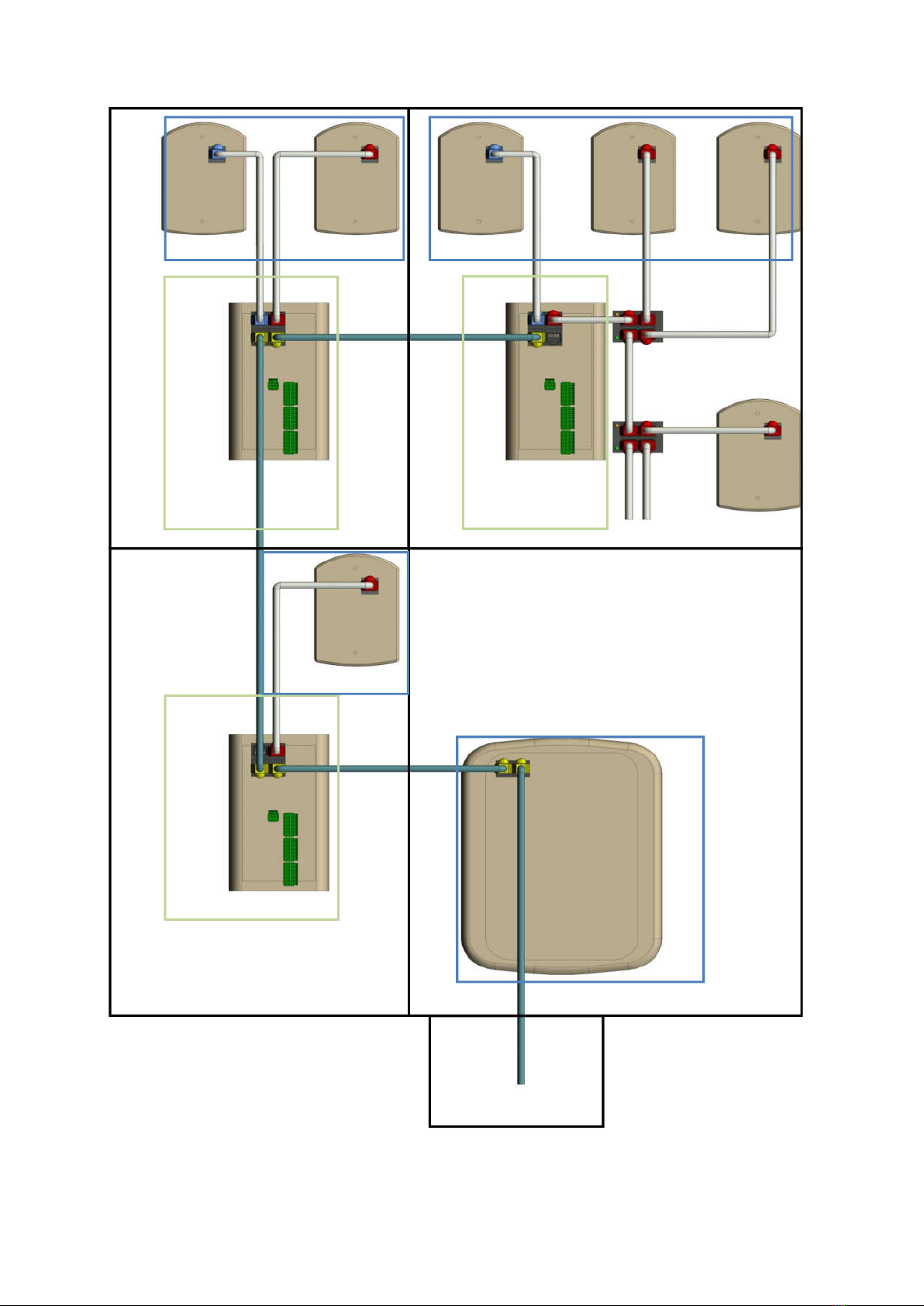

9.4 Exemplary diagram of the central monitoring system ............................................................. 12

3

1. Technical data

Construction: flush-mounted part is made of plastics or steel sheet, wall-mounted part (doors)

white, powder coated, equipped with the lock with the emergency

unlocking, inlet and outlet of gas from the top.

Pressure: compressed gases 0 – 10 bar

vacuum 0 - -0.9 bar

Weight Outer dimensions (WxHxD)

SZI-1 4.5 kg 380x450x90

SZI-2 6.1 kg 380x450x90

SZI-3 7.3 kg 380x450x90

SZI-4 10.5 kg 560x480x90

SZI-5 14.2 kg 560x480x90

SZI-6 15.4 kg 560x480x90

Power supply: 12V DC, 0.1A

Assembly: Flush-mounted or wall-mounted in a housing

Pressured inlets/outlets from the top: copper pipe 15x1.

Vacuum inlets/outlets from the top: copper pipe 15,18,22x1 or according to the design.

Optionally only informative inlets.

The box is equipped with a system of analog pressure converters 0-5V and built-in gas monitor. Too

high or too low level or excessive gas consumption is signaled optically and acoustically (break-down

consisting in damage of the distribution conduits or the medical equipment).

1.1 Information about the device

Device should be stored in a dry place in temperature between +10 C - +45 C.

The valve box is a part of a central gas supply system according to EN ISO 7396-1. The pipes

in the pipeline must by hard soldered.

The valve-informative box, according to 93/42/EWG directive and the decree of the Minis-

try of Health, Journal of Laws No 16 item 74 dated January 12, 2011 is a medical manufac-

tured product – class IIb.

2. Application

For monitoring pressure of medical gases and vacuum for hospital units, operating theatres, ICU

rooms in central gas supply systems. Possibility of transmitting information to the central alarm unit

or central computer.

4

3. Construction

The housing of the valve box contains up to 6 shut-off valves, analog pressure converters 0-5V,

emergency supply point type NIST and gas alarm unit with LCD display mounted on the doors.

4. Installation

Wall mounting of the housing – the doors should be disassembled prior to the assembly.

Connection of copper pipes to the main system.

Before start-up of the installation the doors should be assembled again.

Supply the 12V DC voltage to a box.

Connect „+” and „-” poles to marked pins.

!!! Attention !!!

Mounting must be performed ONLY by qualified technicians experienced in servicing

medical equipment.

Read manual before mounting valve box.

!!! Attention !!!

Polarity of the connection is very important, any mistake causes a damage of the electronic

system

!!! Attention !!!

Before performing a leak test vacoumeter should be removed.

Perform leak test of pipeline system in accordance with the EN ISO 7396-1;

5. Operation

5.1 First start-up

1. Before start-up make sure all tests in accordance with EN ISO 7396-1 finished successfully.

2. Slowly open each valves in box;

3. Make sure that pressures in manometers are as determined by project;

4. Connect power supply;

5. Make sure that alarm unit shows correct informations (gas type and pressure);

6. Device is ready to use.

In order to use shut-off valves, the doors must be opened.

The box may also be opened without a key in case of an emergency. This is done by pushing the lock

with the plastic mounting into the box. Upon completion of the necessary steps, the plastic mounting

fixing the lock should be replaced and put back in the door. Close the door with a key.

5

According to EN ISO 7396-1, the valve box is equipped with the physical unsealing. For this purpose

the relevant shut-off valve must be closed, the pipeline behind the valve should be emptied. Then,

physical cut-off may be unscrewed and screwed in again after the works.

For the emergency supply, NIST connectors should be used. They are encoded for the given

gas. NIST connectors together with the pressure reducer should be mounted on the emergency bottle

with compressed gas, placed in proper socket, pushing it in and screwing down the pin cap. Before

opening of the valve of the bottle, it is required to loosen reducer’s hand wheel. After slow opening

of the valve of the bottle the pressure on the reducer may be set as per working pressure in the instal-

lation.

6. Maintenance / repair

Each valve box must be subjected to maintenance at least once a year. In particular, it is re-

quired to check the shut-off valves and points of emergency supply and check the tightness of the

pressure connections inside the box. Any repairs may only be performed by a qualified personnel.

Use only genuine parts of HYDRO-GAZ-MED Sp.j.

6.1 List of spare parts

Analog pressure transducer 0-16 bar –

Cat. No.: 3100R0016G05B000

Analog pressure transducer -1-0 bar –

- Cat. No.: 3300R00B0V05B00001

ball valve ½” degreased – cat. No.: ZKUL-DN15

Signaling device with measuring module – cat. No.: IBPL H0122N

Remote signaling device – cat. No.: IBPL-H01

6.2 List of the authorized service points

Hydro-Gaz-Med. Sp.j.,

Willowa 40 St.,

05-205 Dobczyn,

Poland

tel. +48 22 787 65 60,

6

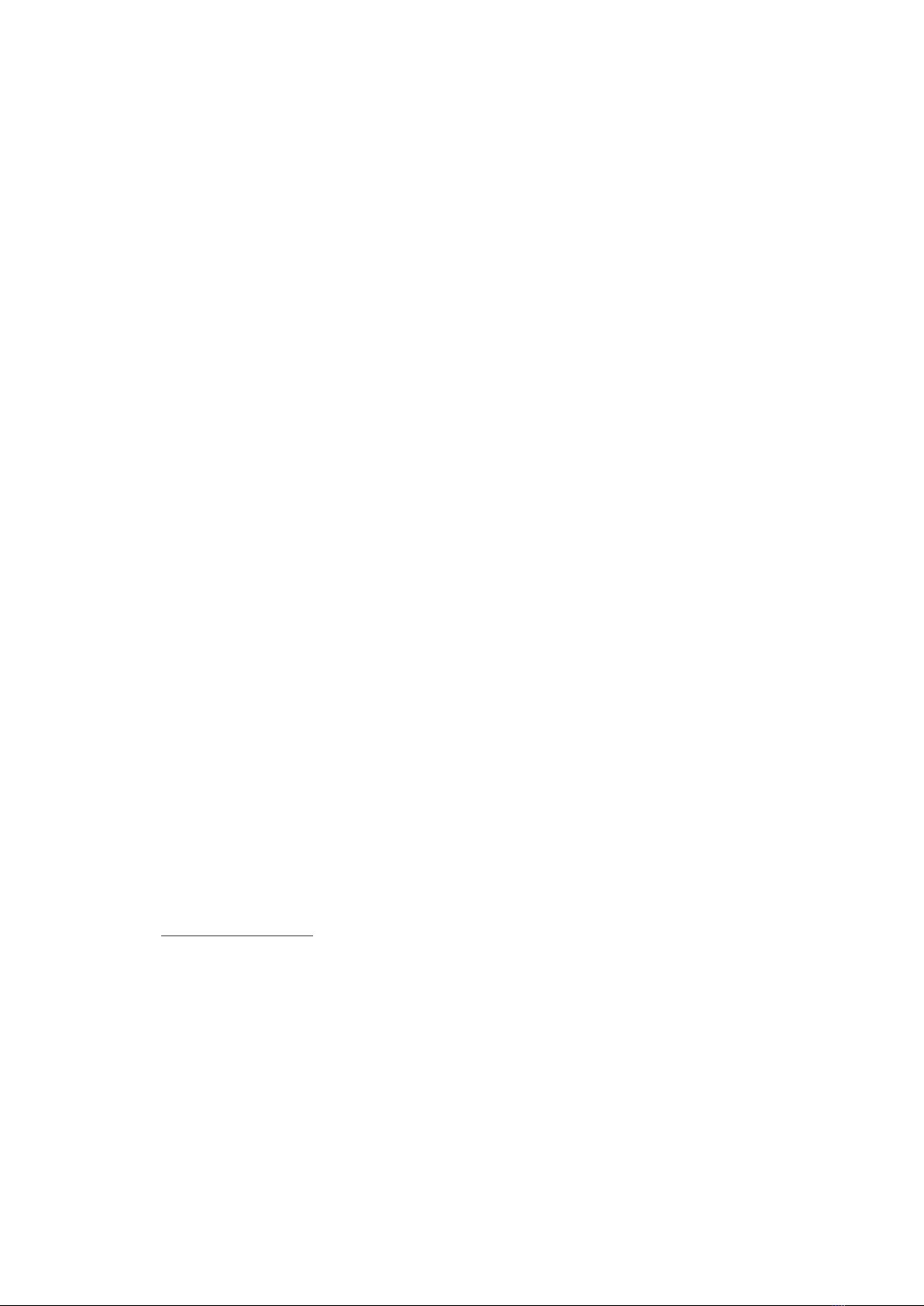

7. Cosntruction diagram

emergency supply

point NIST

Phisical opening

of pipeline

system

Pressure

transducer Manometer

Shut off valves

7

8. Alarm system

8.1 Alarm unit mounted in valve box

Functions: transmission of data to the remote alarm unit and display of information on the status of

the monitored gases together with visual and audio alarm status.

Power input: < 750mW

Length: 148 mm

Width: 80 mm

Height: 41 mm

Weight: ca 165 g

Screen overview

For each gas its pressure is displayed with the accuracy of a tenth of a bar. In case the pressure of any

of the gases is lower than this user-defined in the program, the name of the gas and red diode start to

blink, and the sonic alarm activates. The sonic alarm may be switched off for a period of 15 minutes

by pressing a button. If the pressure of a gas is higher than the user-defined in the system, the name

of the gas and green diode start to blink, and the sonic alarm activates. The sonic alarm may be

switched off for a period of 15 minutes by pressing a button.

8

8.2 Description of connections in alarm unit

9. Remote alarm unit

9.1 Under plaster version

Functions: displays informations on a status of monitored gasses together with visual and audio

signalling the alarm status. The remote alarm unit operates identically as the alarm unit

mounted in the valve box.

Power input: < 100 mA

Length: 180 mm

Width: 90 mm

Height: 42 mm

Weight: ~ 200 g

Blocks for connecting

analog converters

12V DC connection block

+12V

-

9

9.1.1 Assembly drawing of under plaster alarm unit

9.2 Remote alarm unit – on wall version

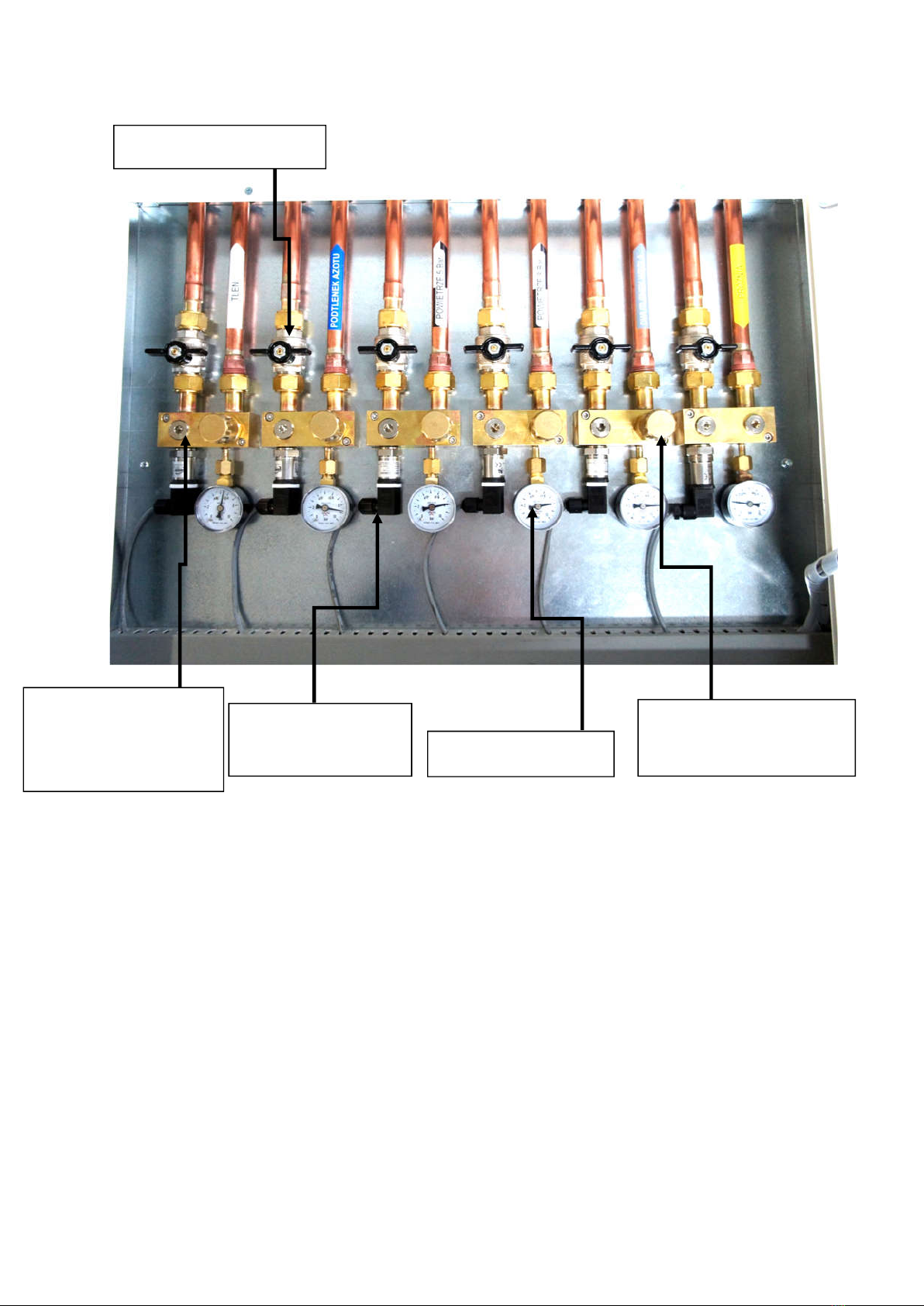

Alarm unit is equipped in touchscreen. On the screen there is TEST buton, which should be

weekly used to check functioning of alarm unit.

On the housing we have dual color LED from visual signal. In case of alarm the LED blinks;

green light when pressure is to high, and red light when pressure is to low.

With each visual signal there is also audio signal.

10

-OK- 1/001 bar

O2 5.1 VAC -0.6

N2O 4.9

AIR5 4.8

Sygnalizator gazów

medycznych

To mute the audio signal we need to touch the bell symbol on the screen. After 15 minutes, if

the cause of the alarm was not removed, audio signal returns. It will be returning till cause of the

alarm will not be gone.

During normal work green is LED is constantly ON.

9.2.1 Display

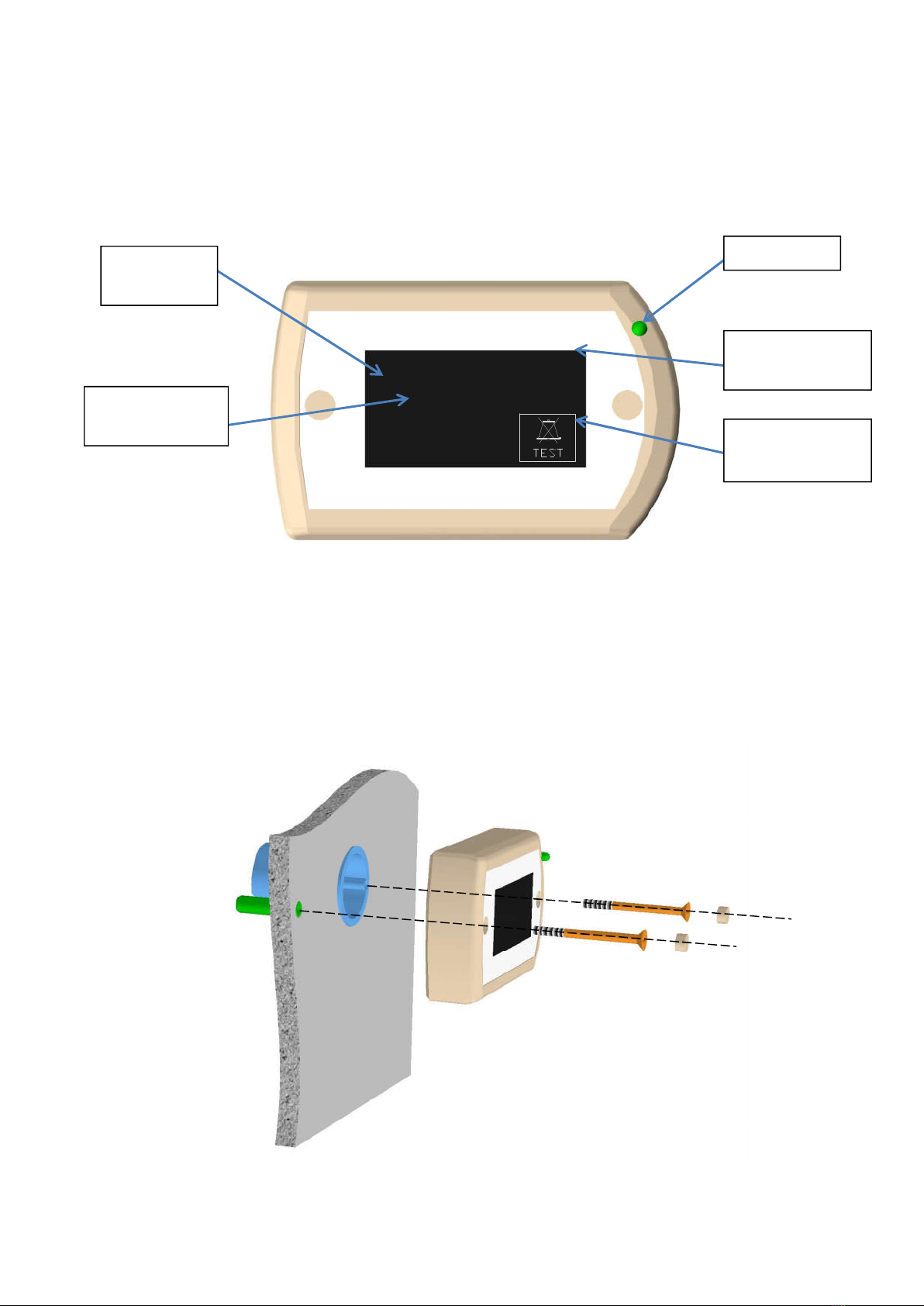

9.2.2 Mounting of on plaster alarm unit

Scope of delivery:

- 35 mm plastic under plaster casing

- 2 screws and 1 fisher

- plugs for installation holes

gas

symbol

pressure

value

LED

pressure

unit

TEST / mute

button

11

9.2.3 Mounting procedurę

1. Install plastic casing

2. Mount the alarm unit with one screw to plastic casing

3. Mark the other hole

4. Drill the second hole and mount the fisher in

5. Prepare cable (see clause 8.6)

6. Pull the cable out of the wall through the plastic casing, max length from the wall 5-8 cm

7. Put the plug in the alarm unit

8. Mount the alarm unit

9. Put the plugs in the holes after the screws

9.3 Connecting cables

In order to connect the external alarm unit (mounted in the Operating Theatre or ICU room

etc.) the standard UTP or FTP cable should be used (4-pair coil of fifth or higher category). All trans-

mission cables must be tipped with standard RJ-45 pins. The connection cables do not have interlace.

In the back side of the housing there are 4 RJ-45 sockets for the connection with the transmis-

sion cables. To sockets closer to the edge of the housing, the cable connected to the remote alarm unit

or BMS system should be connected. To sockets close to the middle part of the housing, the cable

connected to the computer with BMS/SCADA system and / or transmission cable to another valve

box should be connected. If the sockets have not been used for the connection of the transmission

cable, the IBPL-T1 terminator should be put in them.

Cable diagram and recommended colors of wires:

If transmission cables that are too short may be elongated by connecting them with the help of the

splitters, while each empty socket of the splitter should have terminator in it.

The pin should be placed in the back panel of the alarm unit.

PIN 1 ––––– PIN 1 - green

PIN 2 ––––– PIN 2 - blue

PIN 3 ––––– PIN 3 - brown

PIN 4 ––––– PIN 4 - orange

PIN 5 ––––– PIN 5 - orange-white

PIN 6 ––––– PIN 6 - brown-white

PIN 7 ––––– PIN 7 - blue-white

PIN 8

–––––

PIN 8

- green-white

12

9.4 Exemplary diagram of the central monitoring system

Front view

TECHNICAL DIRECTOR

Central alarm unit 7”

To computer with

MS Windows®

Hospital Ward #45

Valve box #45

Alarm unit

Hospital Ward#2

Valve box #2

Alarm units

Hospital Ward #1

Valve box #1

Alarm units

13

Back view

TECHNICAL DIRECTOR

Central alarm unit 7”

To computer with

MS Windows®

Hospital Ward#45

Valve box #45

Alarm unit

Hospital ward #2

Valve box#2

Alarm units

Hospital Ward #1

Valve box #1

Alarm units

Table of contents

Popular Control Unit manuals by other brands

Toto

Toto TS970C1 installation manual

schmersal

schmersal CSS 34 operating instructions

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R AnyWireASLINK user manual

National Instruments

National Instruments NI 9760 user manual

National Instruments

National Instruments PXIe-4480 user manual

KLINGER

KLINGER ABM Standard Operation Manual

Bastl Instruments

Bastl Instruments Spa Assembly guide

Hunter

Hunter HYDRAWISE X2 quick start guide

Resol

Resol VA20 manual

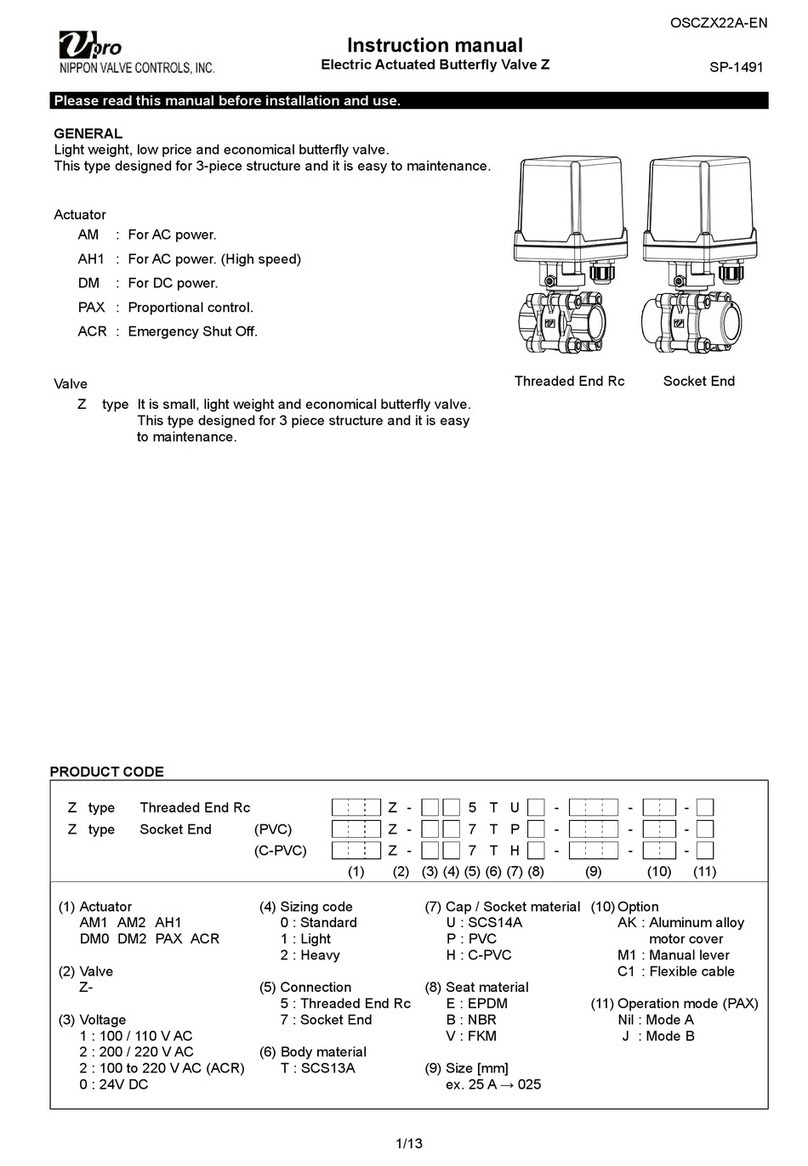

NIPPON VALVE CONTROLS

NIPPON VALVE CONTROLS SP-1491 instruction manual

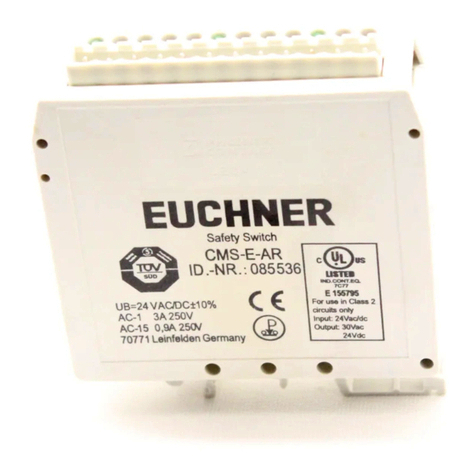

EUCHNER

EUCHNER CMS-E-AR operating instructions

Bosch

Bosch Rexroth IndraControl XFE 01.1 Series operating instructions