High Tech IVC-45L User manual

Pantheon Sales & Rentals

Colorado Branch:

Address: 1820 W Baker Avenue Englewood, Colorado 80110

Customer Support & Sales: +1-720-504-5800

Email: sales@pantheonsurfaceprep.com

California Branch:

Address: 5556 Corporate Avenue Cypress, California 90630

Customer Support & Sales: +1-714-527-6700

Email: info@pantheonsurfaceprep.com

Contents

1.1 Summary ________________________________________________________01

4.2.3 Notes ______________________________________________________ 09

4.4 Start and stop the vacuum cleaner ___________________________________ 09

4.5 Sliding Valve_____________________________________________________ 10

1.2 Liability__________________________________________________________01

1.3 Manual__________________________________________________________01

4.6 Manual cleaning device 11

4.7

Dust Collecting System

13

1.4 Transportation 01

1.5 Accessories ______________________________________________________01

5.1

Overview________________________________________________________ 15

1.6 Package Acceptance _______________________________________________02

1.7 Machine nameplate________________________________________________02

5.2

Daily Inspection 15

5.3

Cleaning ________________________________________________________ 16

1.8 Handling and storage ______________________________________________02

2.1

Overview ________________________________________________________03

2.2

Operational safety guidance

03

2.3

Electrical Safety guidance

__________________________________________

04

5.3.1

Clean cyclone separator 16

5.3.2

Clean the filters 16

5.4

Overloading Protection 17

5.5

Maintenance items 17

18

3.1

Overview 05 19

3.2

Machine description________________________________________________05

3.2.1

Machine parts 05 20

3.2.2 Control Panel Information

_______________________________________

06

3.2.3 Cycloneseparator bucket

06

3.2.4 Filter barrel

07

3.3

Wheel brake 07

4.1

Overview 08

4.2

Machine position Description

08

4.2.1 Machine working position

08

4.3

Connection of hose andvacuum cleaner

09

4.2.2 Machine transportation position

09

1. Introduction

2.Safety Instruction

5.Maintenance

3.Machine Description

4.The Operation of Machine

6. Frequently Asked Questions and Solutions

7.Technical Data

8.Warranty

01

1.1

Summary

IVC-45L is an industrial vacuum cleaner specially designed for grinding machines.

It mainly uses cyclone separator and HEPA13 as the filtering device. The cyclone

separator is responsible for filtering most of eeeeee dust particles. A small part of the

light weight dust is filtered by HEPA13.The dust is filtered, so the vacuuming effect is

particularly good.

1.2

Liability

We make every effort to make this manual as complete and accurate as possible,

and we are not responsible for any errors or loss of information. Pantheon reserves

the right to change the instructions in this manual without prior notice.

This manual is protected by copyright law and cannot be reproduced or used in any

part without the express written consent of Pantheon.

1.3

Manual

In addition to general functions, this manual also provides information on the use,

repair and maintenance of vacuum cleaners.

1.6

Package

Acceptance

Check carefully to see if the package or the vacuum cleaner has been damaged

during delivery. If there is any sign of damage, contact your supplier and report it.

Check that whether the delivery matches the order. If there are any discrepancies,

contact your supplier.

When lifting the machine, be sure to follow the prescribed steps.

1.7

Machine nameplate

1.4

Transportation

Always ensure that the vacuum cleaner has emptied dust and other particles

before transporting, lifting or before lifting.Make sure the vacuum cleaner is securely

fastened and remember to press the brake pads of wheels to prevent the device from

moving during transportation. Ensure that the safety belt or other device used for

anchoring during transportation are tightened on non-moving parts such as dust trays

or handles on both ends of the dust tray.When lifting the machine, be sure to follow the

prescribed step.

1.5

Accessories

l.Model

2.Manufacturer date

3.Power

1.8

Handling and storage

4. Voltage

5.

Weight

6. Frequency

The product mainly includes the following accessories, please contact the retailer

if anything is lost.

(1)

Vacuumcleanerx1set

(2) Manual x 1

(3)

Tube x1 (80 vacuum hose* 15 meters)

(4)

Quick connector x 1(set)

(5)

Hose clamps x 2pcs

(6)

Dust bagx 2(roll)

(7)

Power plug x 1

(8)

Nylon cable ties x 2 (bag)

(9)

Squeegee x 1(set)

The vacuum cleaner should be stored in a dry place at room temperature when not

in use. Otherwise it may be condensed and cold damaged. The size and weight of the

cleaner are given in the technical data of the Manual. Note! Improper operation may

lead to the vacuum cleaner overturned and damaged, even endanger personal safety.

When lifting the machine, be sure to follow the prescribed steps.

1.Introduction

03

2.1

Overview

This manual records the key information for machine safety operation. Read the

manual carefully before your first operation. Any non-standard operation,

modification or maintenance without training may cause an unknown impact on the

machine even cause losses, machine problems or injury. All maintenance must be

done by qualified professional technician. Any machine parts that need to be changed

mustbeprovided by Pantheon.

Notes:

1

.

Read and understand the safety guide totally. Different models have different

accessories and operation instructions;

2.

Operation of this machine only needs one person. Keep children and irrelevant

person away. Keep in mind that "one machine one person";

3.

This machine is only suitable for vacuuming during dry grinding;

4.

Do not startthe machine without dust baginstalled.

5.

There are two working positions for the filter barrel of this machine. The

functions of different positions are described in the relevant picture content in this

manual.

6.

Do not

lend or rent the machine without instruction manual;

7.

Dust masks, protective gloves, work clothes, helmet and insulated shoes are

necessary when operating the machine.

8.

Keep body, jewelry or any loose clothing away from machine moving parts.

Otherwise, it may endanger personaI safety.

9.

Random modification of the machine is not allowed. Only Pantheon accessories

can be used for maintenance and adjustment;

10.

Do not operate the machine in rainy or foggy days;

11.

Ensure no explosive flammable materials and steam nearby when operate

machine. Do not operate machine nearby the place with fuel, grain dust, solvents,

dilution agent or other flammable items.

2.2

Operational

safety guidance

1.

Operators should wear protective equipment when using the machine, such as

dust masks, protective gloves,overalls, helmets,insulated shoes and so on.

2.

Make sure there is no oil leakage, electric leakage, water leakage on the machine

before using. The machine can be used normally.

3.

Before the operation, please check the integrity of the machine to ensure that the

machine operation control and the electrical parts are free ofmoisture. The operation

control switch knob should be intact.

4.

Make sure no obstacle or human being at working area.and make sure there is

enough lighting device.

5.

Double check before connecting to power, make sure the working voltage, HZ is

same with input Voltage and HZ, no lack of phase of input power.(lf the machine do not

work normally, and it results in the input power and working power is not the same,

then manufacturers warranty is unavailable.)

6.

The machine should be connected to appropriate electrical outlet. Only use

power cables that can withstand high current.

7.

Connecting with a grinder to achieveddust free working condition.

8.

Keep the machine away from drains and furnace mouths or other dangerous

goods, otherwise it may cause personal injury or loss of machinery and property.

9.

After confirming the working position, brake the brake wheels.

10.

Lift the filter bucket to working position.

11.

Do not adjust the liftingsupport duringoperation.

12.

Observe the value on the pressure sensor after the device has been running for a

period of time. If the value (not considering the sign) is too large (about lSkpa), it

indicates that the suction hose isblocked. Please shake the hose in time toclear it.

13.

After the equipment has been running for a period of time, observe the

amount of dust in the dust bagand make corresponding treatment.

2.3

Electrical Safetyguidance

1.

All circuit repairs can only be operated by professionals;

2.

Note: After the machine is stopped, the line is still powered. Turn off all power

before servicing the machine.

3.

The machine is equipped with an overload protection device and it will

automatically jump off when the machine is overloaded, to prohibit the machine from

running; (re-adjust this overload in case of safety) Continue to use the machine in the

overloaded situation may cause some other losses even machine can't work

normally,then manufacturers warranty is unavailable.

4.

If the machine current is overloaded, please pay special attention;

5.

When the cables is energized or loaded, do not connect or disconnect the wires;

6.

Using a damaged power cord may result in electric shock. Do not use a damaged

power cord.

7.

Wires should be kept away from hot surfaces.

8.

The dryness of all electrical equipment of the machine should be maintained

andthe machine should be kept in a dry place.

9.

The machine motor and electric control box are prohibited from entering water;

(the other damage caused by the water inflow then the machine is not working

properly, the manufacturer does not afford the warranty);

10.

The machine must be connected to the qualified wire and voltage,

specifications is noted by the manufacturer. (The machine label indicates the power

supply specifications)

2.Safety Instructions

05

06

3.1

Overview

IVC-45L is a vacuum cleaner mainly used for industrial and construction purposes.

It is mainly used to absorb dry dust particles, such as dust generated in the process of

grinding concrete, stone, and wood. The vacuum cleaner has two filtering systems, the

cyclone is the main filter, and the HEPA13 filter barrel is the secondary filtering device.

The vacuum cleaner is equipped with a quick connector, which can be used to safely

and quickly connect with various grinding machines for dust removal.The primary

filtration system in the vacuum cleaner is a cyclone separator, which main function is

to filter larger particles of dust, so most of the dust will be filtered here. The remaining

small dust particles will be filtered by the secondary filter system HEPA13 filter barrel

device. Therefore, the vacuum cleaner has high dust filtering effect, super high

performance and long service life.

3.2

Machine description

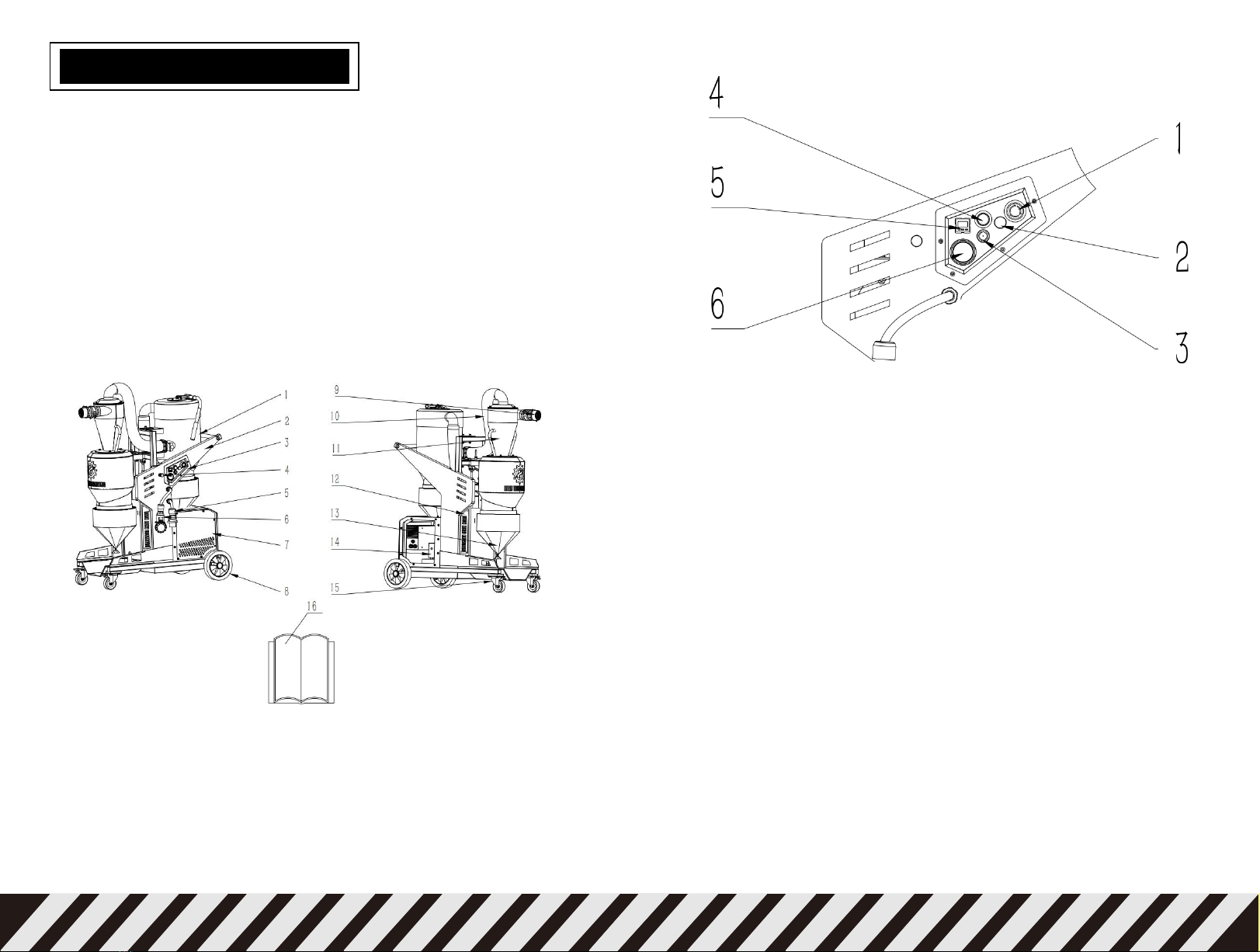

3.2.1

Machine parts

3.2.2

Control Panel Information

1.

Emergency stop switch: When the machine is in a dangerous state or to

stop,cut off the power supply through the emergency stop switch to stop the

operation of the equipment to protect thesafety of people and equipment.

2,Green indicator light: when working, the light will be on.

3,Buzzer: Negative pressure 30kpa,sound an alarm.

4,Start button:tostart thedevice.

5, Pressure sensor: Displays the current vacuum pressure in filter bucket. When the

value of pressure gauge (not considering the symbol) becomes larger and larger, it

means that there is dust clogging in the suction hose or excessive dust accumulation

on the filter. Then, shake the vacuum hose to clear it.

6, Timer: shows the cumulative running time of the device.

1,Filter barrelassembly

2,Rack components

3,Control panel

4,Index reset pin

5,4-core male connector

6,4-core female connector

7,Fan cover assembly

8,Wheel

9,Quick adapter

10,Hose

11,Centrifugal bucket assembly

12,Decorative sheet metal

13,Dust bag

14,Vortex fan

15,Universal wheel

16,Usermanual

3.2.3

Cyclone separator bucket

The cyclone separator is a cyclone type structure. Its working principle is that the

tangential introduction of the air flow causes a rotary motion, so that the solid

particles or droplets with large inertial centrifugal force are thrown to the outer wall

surface and separated, which has a high separation efficiency. The cyclone barrel is

also equipped with a quick connector, which can be connected safely and quickly to

the grinder to achieve the effect of vacuuming.

Most of the dust is separated in the cyclone separator, and the separated dust

mainly falls on the inside of the bottom of the cyclone barrel. There is a locked rotating

mechanism and a dust bag hanging barrel under the cyclone separation barrel. When

the dust in the barrel accumulates to a certain amount, due to gravity, the locked

rotating mechanism will be unlocked and the dust will fall into the dust bag inside.

3.Machine Description

07

08

3.2.4

Filter barrel

The filter element barrel is mainly composed of a filter element device. Due to the

adsorption

effect of the filter element, the dust in the air will beadsorbed on the surface ofthe

filter element when passing through the filter element device or fall on the lock

mechanism of filter barrel due to gravity.

Due to the adsorption effect of the filter element, it will absorb too much dust

and affect the efficiency of filtration. Therefore, a cleaning device is installed on the

filter barrel. The dust cleaning device can clean the dust adsorbed on the filter element

and improve the filtering efficiency.Operation mode of cleaning device: manual

blowing.

3.3

Wheel brake

To lock the rear wheel, press the brake pad "ON" with foot to achieve the brake

function.

If you want to unlock the locking rear wheel, press the brake pad "OFF" with foot

to unlock it.

4.1

Overview

The following sections describe the vacuum cleaner at different locations during

operation, the main operation, and how to install the longopac dust bag.

Note:

1.

Vacuum cleaners can only be used or repaired by personnel who have received

the necessary theoretical and practical training and have carefully read the user

manual.

2.Wear protective equipment such as protective gloves, protective masks, overalls,

helmets,insulatedshoes,etc. when operating thevacuum cleaner.

3.The vacuum cleaner can only be used and moved on a horizontal surface.There is

a risk of squeezing and crushing when the wheels roll, so pay more attention.

4.

Check the minimum recommended cable area before using the extension cable.

You can find the recommended cable area onthe technical data.

4.2

Machine position Description

4.2.1

Machine working position

To use the vacuum cleaner, press the machine, pull out the spring pin in limiting

device on frame, lift the machine to the highest position, and then insert the spring pin

inside the corresponding hole.

4.The Operation of Machine

09

10

4.2.2

Machine transportation position

When the machine is not in use, first gently lift the machine to pull out the spring

latch, then press the machine down to the lowest position,the spring latch will be

inserted into the control panel rack,keep the machine from floating.

The package size is as follows.

4.2.3

Notes

l.

lmproper operation may lead to the vacuum cleaner overturned and damaged,

even endanger personal safety.

2.

When the spring bolt is pulled out (inserted in), it may get stuck. At this time,you

only need to press the machine down (upward) and then you can pull out the spring

pin (insert it). When the spring pin is pulled out, it may get stuck. Just press the

machine down (up) and then you can pull out(insert) the springbolt.

3.

Be ca refuI when the vacuum cleaner is adjusted to the position of transportation

and there is a risk of crushing injury.

4.

Dust inhalation is harmful. Please bring a professional mask during operation to

ensure physical safety.

4.3

Connection of hose and vacuum cleaner

The IVC-45L is equipped with an 80mm connector, which can quickly and safely

connect the grinder and the vacuum cleaner.

4.4

Start and stop the vacuum cleaner

l.Connect the vacuum cleaner to power supply. Use cables suitable for vacuum

cleaners (see technical data for minimum cable area).

Start the vacuum cleaner:Rotate the emergency switch, press the start button.

2.Stop the vacuum cleaner:Press the emergency stop switch to stop the equipment.

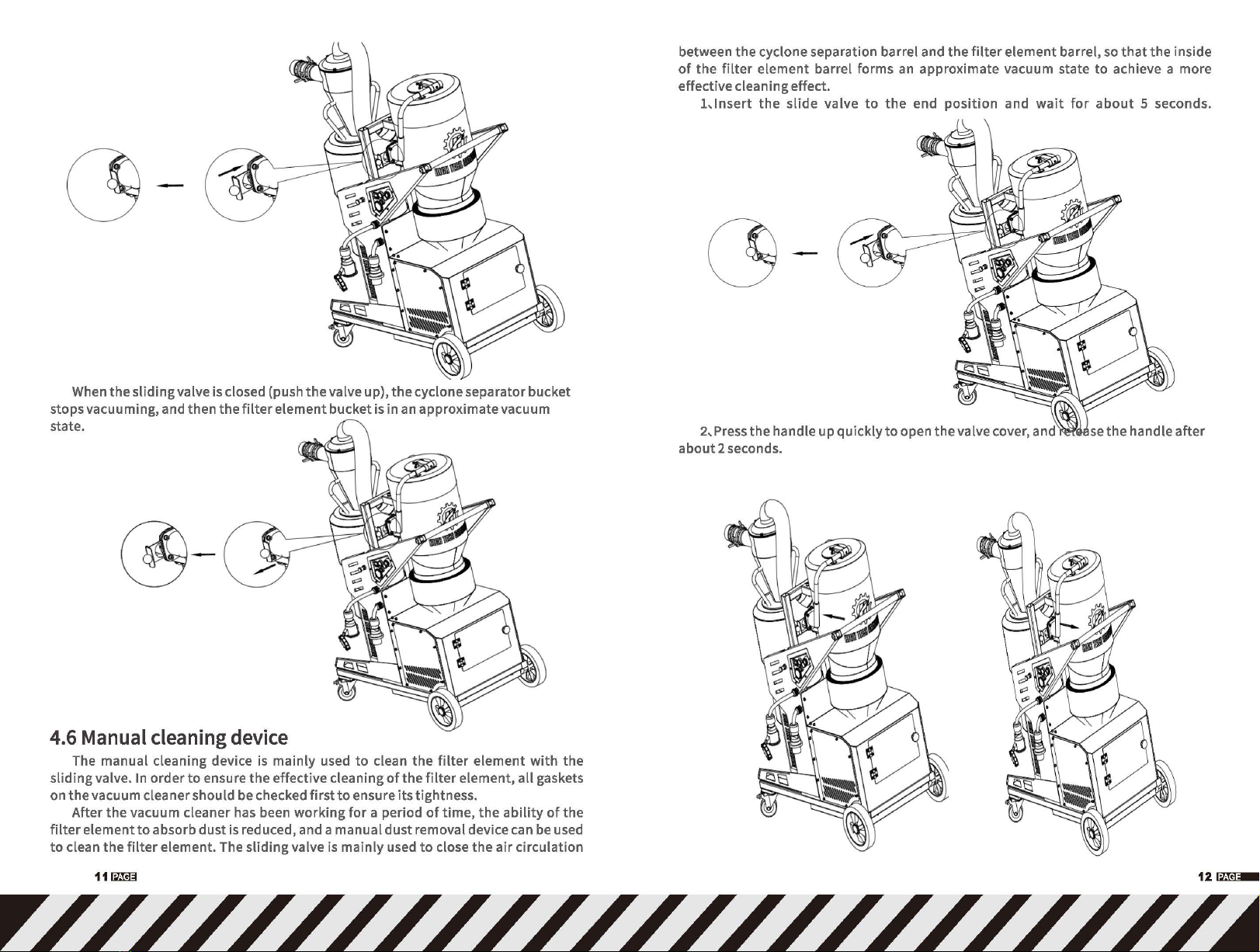

4.5

Sliding Valve

The sliding valve is installed between the cyclone separation barrel and the filter

element barrel. When the sliding valve is opened, the air filtered through the cyclone

separation barrel will be filtered through the filter element barrel for a second time.

14

3, Wait 3-5 seconds, and then repeat "Step 2" at least fourto five times.

4,After cleaning, puIIup the slidingvalve to normalworkingcondition.

Note: The interval of manual cleaning depends on the actuaI amount of dust.

4.7

Dust Collecting System

The vacuum cleaner is equipped with a set of collecting device. which is mainly

composed of a dust bag hanging barrel and dust bag. Install the dust bag on dust bag

hanging barrel, and then install the barrel under the cyclone separation barrel and the

filter barrel respectively. Before the vacuum cleaner is ready for work, pull the dust bag

from the dust bag hanging bucket and tie it with a cable tie to prepare for dust

collection.

After the vacuum cleaner has been running for a period of time, the dust in the dust

bag has reached a certain amount, please clean the dust bag and prepare for the next

dust collection.

16

5.1

Overview

It is recommend that the vacuum cleaner be checked regularly to extend the

service life.

Note:

During the maintenance and repair process, the power supply of the vacuum

cleaner must be disconnected. Wear protective equipment such as safety shoes,

protective gloves, protective masks, etc.

5.2

Daily Inspection

Check that the accessories connected to the vacuum cleaner are intact, without

any cracks, etc. In addition, make sure that the air can flow without obstruction. If

necessary,the hosecan bereplaced.

Check the dust cleaning device: check whether the suction pipes in the barrel are

damaged and whether some other impurities are also sucked in; check whether the

sealing ring and the sealing strip are intact and replace them if necessary. Check

whether the cartridge barrel cover is sealed on the sealing surface of the cartridge

barrel.

Check the cyclone separator: lower the vacuum cleaner to transport position,

disassemble locking

buckle and take off cyclone barrel cover. Use a flashlight to illuminate the cyclone

separator. The surface of separator should be dull. If there is a light spot on the surface,

the separator is blocked and need to be cleaned.

Check the filter barrel: lower the vacuum cleaner to the lowest transport position,

disassemble locking buckle and remove the filter barrel cover. Take out the filter to see

if it

is covered with dust,ifitis,putitinaplastic bag for vibration cleaning.

Check the internal hose: check whether the internal hose is intact, and replace the

hose if necessary.

Check draught fan: remove the fan cover, check whether the fan is blocked by dust,

and clean it if necessary. While the machine is running, listen carefully for any harsh

sound coming from inside the fan cover.

Check the tightness of the accessories: check all bolts and screws for tightness

every six months.

Note:

Press emergency stop and disconnect the power before checking. When lowering

the vacuum cleaner to the transport position, wear protective gloves to avoid the risk

of crushing. When carrying out the inspection, wear a protective mask to avoid

inhalation of dust.

5.3

Cleaning

5.3.1

Clean cyclone separator

Press the emergency stop button and pull out the power.After stopping the

machine, lower the cyclone barrel to the transport position and loosen the three bolts

on the cyclone barrel.(Figure1)

Remove the cover from the integrated bucket, remove the suction hose from the

cyclone, illuminate it with a flashlight, check if the inside is blocked, and clean the

inside of thecyclone if necessary.

5.3.2

Clean the filters

Enter the manual cleaning mode, and after repeated many times, the filter element

can be cleaned.

5.Maintenance

18

To clean the filter element thoroughly, remove the filter element for cleaning.

Press emergency stop button and unplug power supply to stop the machine. Adjust

the device to transportation position.Loosen the three tower buttons on the filter

cover and turn the filter counterclockwise to remove it.

5.4

Overloading Protection

The electric control box is equipped with a thermal relay. When the current exceeds

the set value, it will enter the overload protection. In this case, just open the electric

control box and press the reset button to solve it.

5.5

Maintenance items

Any repairs must be performed by Pantheon Service Center training service

personnel and use original

Pantheon accessories. If your machine needs repair, please contact with your

retailer.

This chapter describes some of the possible failures and howto handle them.If you

still cannot resolve or have an error, please contact your nearest retailer.

Problem

Possible reason

Solution

Machine cannot start

The machine does not receive

or output power

Connect the power cable to

machine and start up

Motor protecting has tripped

For the operation steps,see 5.5

Overloading Protection

Cable damages

Contact a licensed electrician

Control circuit damage

Contact a licensed electrician

or Pantheon Service center

The vacuum cleaner stops

after starting

Some objects obstruct airflow

Clean hoses, filters etc.

Relay overload protection

For the operation steps,see 5.5

Overloading Protection

The machine uttered a low

buzz when turn on and turn

off

Phase lost input, currently only

two phase inputs.Turn off the

machine to avoid burningthe

motor.

Contact a licensed electrician

orcheck the input power has

three -phase input.

Dust in the motor impeller

Contact a licensed electrician

Motor burned down.

Contact a licensed electrician

or Pantheon Service center

The machine is blowing, not

sucking.

Phase relay failure

Contact a licensed electrician to

adjust the position of L1 and L3

wires on the power plug and

replace the phase relay if

necessary.

Poor suction performance

Maybe that thevacuum system

is not sealed.

Check and repair the seal.

Cyclone separator or filter

Use a compressed air or brush

to clean the cyclone and filter.

Hose blockageis not sealed.

Shake suction pipe wavily

The machine isblowing

dust

Incorrect installation of the filter

Installthe filter correctly

Filter has been dislocated

Reinstall the filter

The filter is broken

Replace with new filter

Cyclone separation bucket

does not work

The dust is too light and too

thin

Cyclone blockage

Clean the cyclone( see above).

6.Frequently Asked Questions & Solutions

20

Tables and pictures show the technical data and dimensions of the vacuum cleaner.

This warranty covers only manufacturing defects. Pantheon does not assume

damage in the transport, unpacking or operation. The manufacturer is not

responsible for any damage or defects caused by improper use, corrosion or use of

specifications beyond the noted specifications. The manufacturer shall not be

responsible for any indirect damage or expense under any circumstances. For

complete information on the manufacturer's warranty period, please refer to the

current warranty terms of Pantheon. Local retailer may has special warranty terms. If

you have any uncertainty about the warranty terms, please contact with your retailer.

IVC-45L

Power (KW)

5.5

Rated Voltage (V)

380V/220V {3P)

Rated

Current(A)

13.3/25

Max.Suction (Kpa)

30

Max. Airflow(m3/h)

600

Recommended minimum

cable size(m

2

/h)

3*4+1*2.5

Overall Filter Area(m2)

2.8

Filter Degree

HEPA13

Weight(kg)

223.5

Size, (LxWxH) (mm)

1250*711*1930

Lifting Size (mm)

1250*711*1630

7.Technical Data

8.Warranty

Table of contents