17

O G

C B O:A Convecon

Blower is standard equipment with the Model 2500. The

Convecon Blower increases the delivery of heated air into

the home. The Convecon Blower is equipped with a Ther-

mal Switch (snap disk) which turns the blower on as the

heater warms up and offas it cools, and a 3-speed Switch to

adjust the blower speed in relaon to the current burn rate.

Addional instrucons are on Page 23.

• Set the Toggle Switch to "Therm" to allow the blower to

turn on and offautomacally. Set the Toggle Switch to

"Manual" to bypass the thermal switch.

• Use the 3-speed Switch to turn the blower On/Offand to

increase/reduce the blower speed.

• Match the Convecon Blower speed to the burn rate. Re-

duce the blower speed if cool air is coming from the vent.

C G:The Model 2500 is equipped with a clear

window which allows monitoring the condion of the fire

without the need to open the Loading Door. The transparent

ceramic material has been safety tested for impact and ther-

mal resistance, however it can be damaged if it is abused.

Inspect the ceramic glass frequently for signs of damage.

Never operate the wood heater with damaged, cracked, or

broken ceramic glass. See Page 22.

Creosote deposits will build up on the window, especially

when burning low fires. The deposits may burn offwith a

hot fire. Never use oven cleaners, harsh cleaners contain-

ing ammonia, or abrasive cleaners that may cause scratches

that can develop into cracks. Harsh chemicals can also per-

manently damage the catalyst. A simple and cost effecve

soluon is to use damp (not wet) black & white newspaper

to remove light staining. To remove heavier deposits, dip the

newsprint (or a damp cloth) in a small amount of cold wood

ash. Special glass cleaners for woodstoves, formulated to

dissolve creosote, are also available. Check that they are la-

beled as safe for use with catalyc equipped wood heaters.

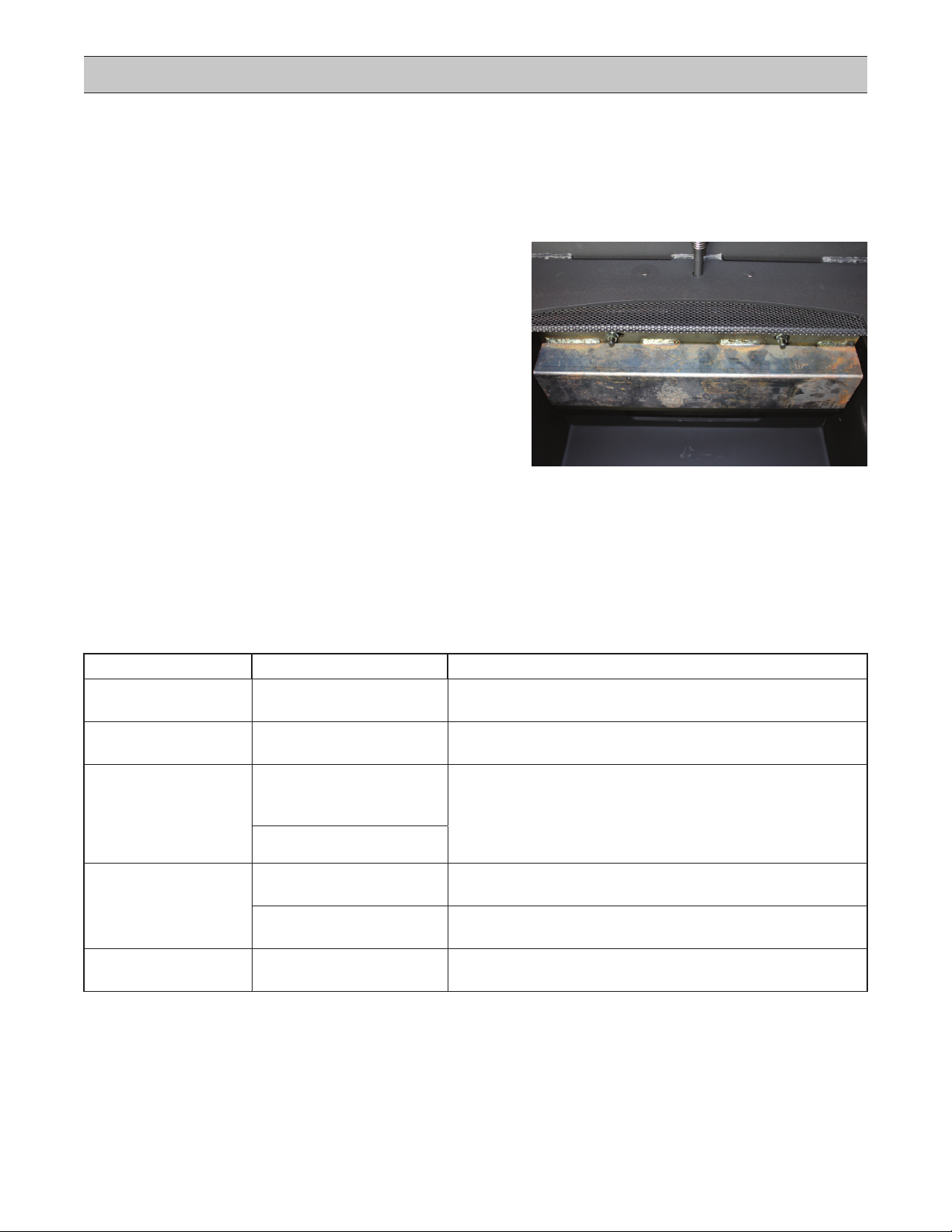

A D:Remove ashes once they get 2" to 3"

deep, or deep enough to impede the air inlet located be-

neath the Loading Door opening. Remove ashes when the

fire is exnguished or burned down to embers at the end of

the charcoal stage of combuson. Use a steel rake to gather

unburned charcoal or embers to one side and leave them

in the firebox to be consumed as fuel. Remove spent ash

only, leaving @ ½" to 1" of ash and hot coals in the firebox

to insulate the ember bed and ignite fresh fuel. Again, try

to avoid shoveling up hot coals or embers with the spent

ash. Embers can stay hot for days insulated in ashes. Use a

steel shovel to carefully remove the spent ashes into a steel

container with a ght-fing lid and move the container out-

doors immediately. The closed container of ashes should

be placed on a non-combusble surface or on bare ground,

well away from any building and all combusble materials,

pending final disposal. If the ashes are to be disposed of by

burial in soil or otherwise locally dispersed, they should be

retained in the closed container unl all embers have thor-

oughly cooled. No other waste of any kind shall be placed

in this container.

Some ashes may spill while removing them from the fire-

box. Ashes can be vacuumed up once they are completely

cool but ash may pass through the filter. Special vacuums,

equipped with heat resistant filters and designed for ash

clean-up and removal, are available through your dealer.

S O:The amount and density of smoke com-

ing from the chimney is a visual indicator of how cleanly the

wood heater is burning. Develop a habit of checking the

smoke opacity regularly, and at various stages of combus-

on. With experience a quick glance can confirm proper op-

eraon or signal that something needs aenon. Modern

catalyc equipped wood heaters can burn wood very cleanly

and efficiently but, ulmately, they rely on the operator to

engage the Catalyc Combustor at the proper mes and to

adjust the combuson air properly. Timing and air sengs

are dependent on the draof the chimney, the fuel being

burned, and the stage of combuson. Ideally you will ob-

serve lile or no smoke (0% opacity). Dense smoke indicates

poor combuson. Be aware that in cold weather what looks

like smoke could be moisture vapor condensing in cold air.

C F R:When wood

is burned slowly, it produces tar and other organic vapors

which combine with moisture to form creosote. At one

me it was popular to install a very large "air-ght" wood-

stove, load it full of wood, and reduce the combuson air;

perfect condions for producing creosote. Modern catalyc

equipped wood heaters, properly operated and maintained,

burn offthe smoke and creosote that older stoves produced,

but the same elements are present. Tars and vapors, com-

bined with moisture, can condense in the chimney at tem-

peratures below @ 250°F. The resulng creosote can accu-

mulate, clinging ghtly to the flue liner and, if ignited, can

create a very hot and dangerous chimney fire.

Creosote producing tars and vapors are burned at tempera-

tures over 1100°F in the presence of the Catalyc Combustor.

The Combustor will consume the smoke and creosote pro-

ducing tars if it is properly acvated and supplied with suf-

ficient combuson air. Even sll, in a relavely cool chimney,

especially an exterior masonry chimney, the exhaust gasses

can cool before they exit the flue and some creosote will be

produced. The chimney connector and chimney should be

inspected at least once every two months during the heang

season, or more frequently as needed, to determine if creo-

sote build-up has occurred. Contact your High Valley dealer

or local chimney sweep if you are uncertain how to inspect

the venng system. Always have the chimney cleaned at the

end of the burning season or before resuming operaon.

IC C F:If your wood heater is

operated properly to maintain clean, efficient combuson,

connected to a good chimney, burning good, dry wood, and

inspected regularly, a chimney fire should be an unlikely oc-

currence. If a chimney fire does occur it can be dangerous

and frightening. Chimney fires are oen accompanied by a

loud rushing sound and, at mes, banging noises within the

chimney. Should a chimney fire occur, alert everyone in the

home and leave the building immediately. Contact the fire

department. If it appears safe to reenter the home close

the Air Control and manual damper (if so equipped) wear-

ing a heat resistant glove, to cut offair to the fire. Do not

throw water on the wood heater. Thermal shock could break

the ceramic glass causing smoke and/or ember spillage, or

otherwise damage the wood heater. Have the chimney in-

spected and cleaned or repaired as necessary before resum-

ing operaon of the wood heater.