However, when drilling 6.5 mm or smaller holes, use a

metalworking drill bit.

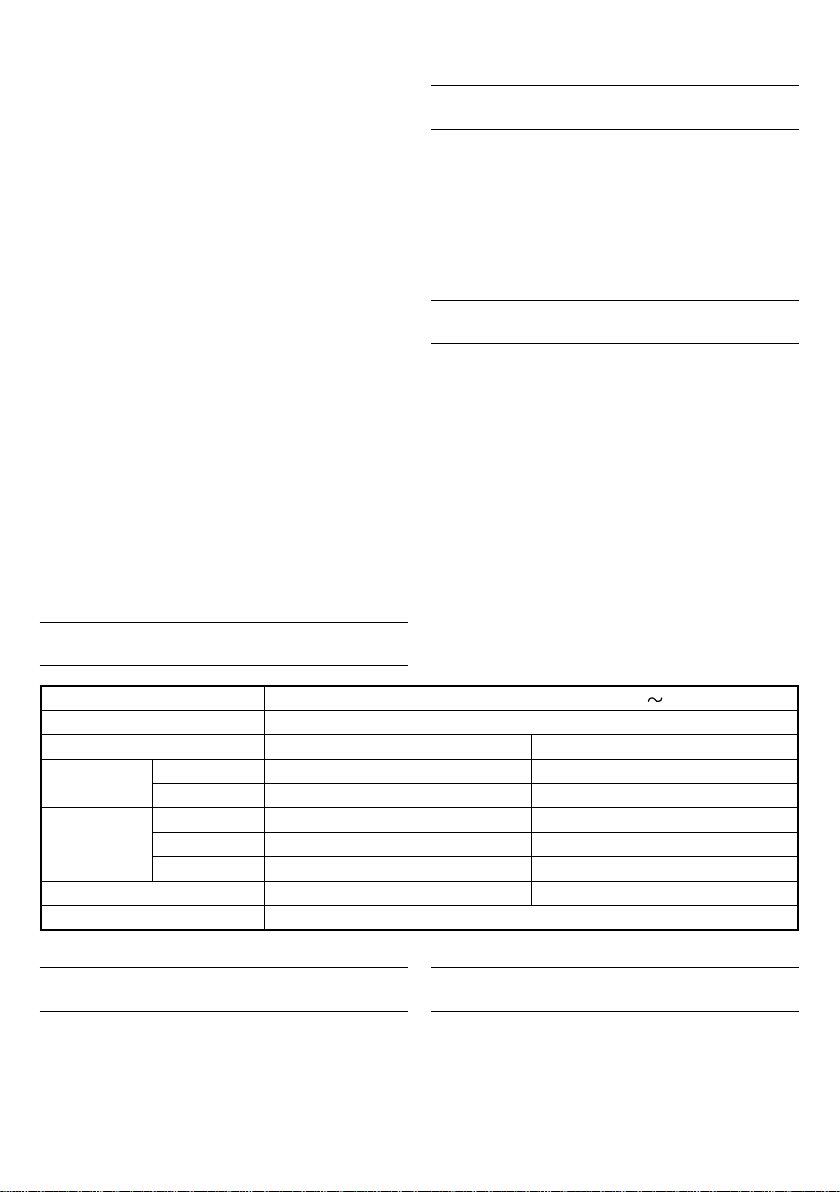

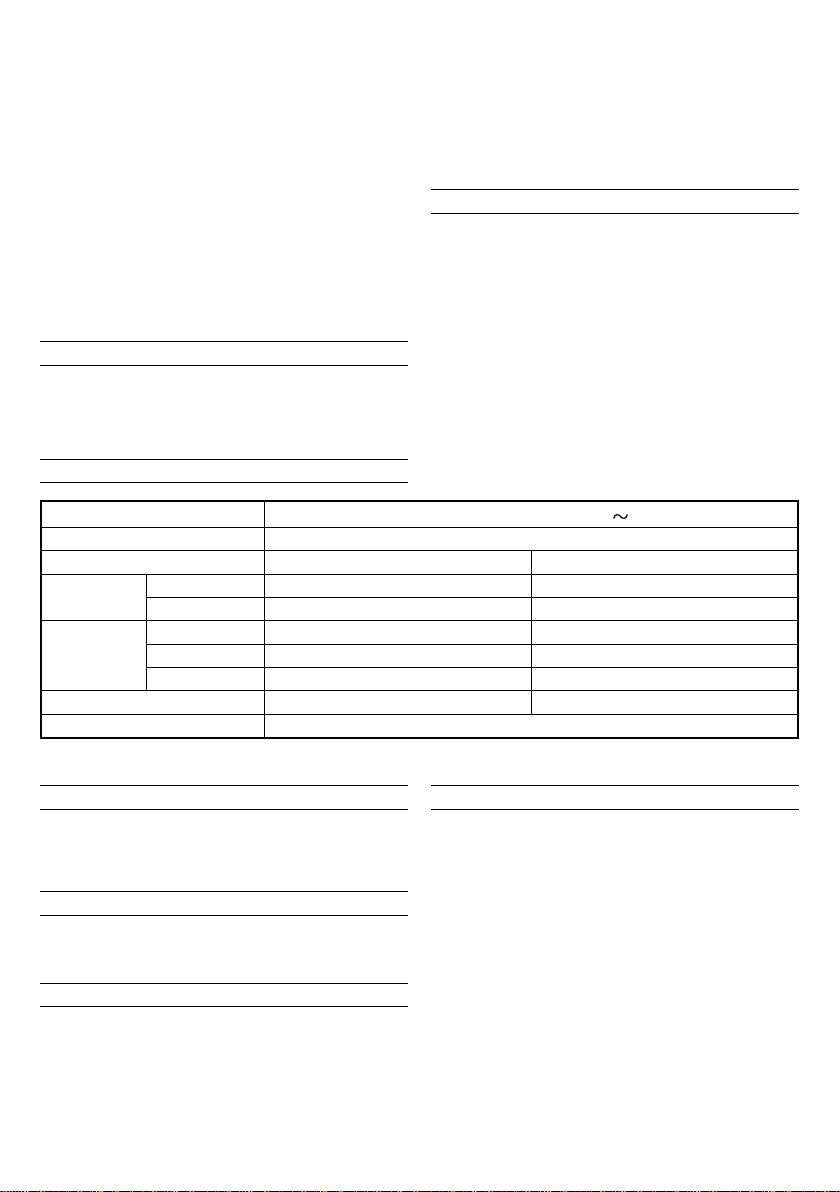

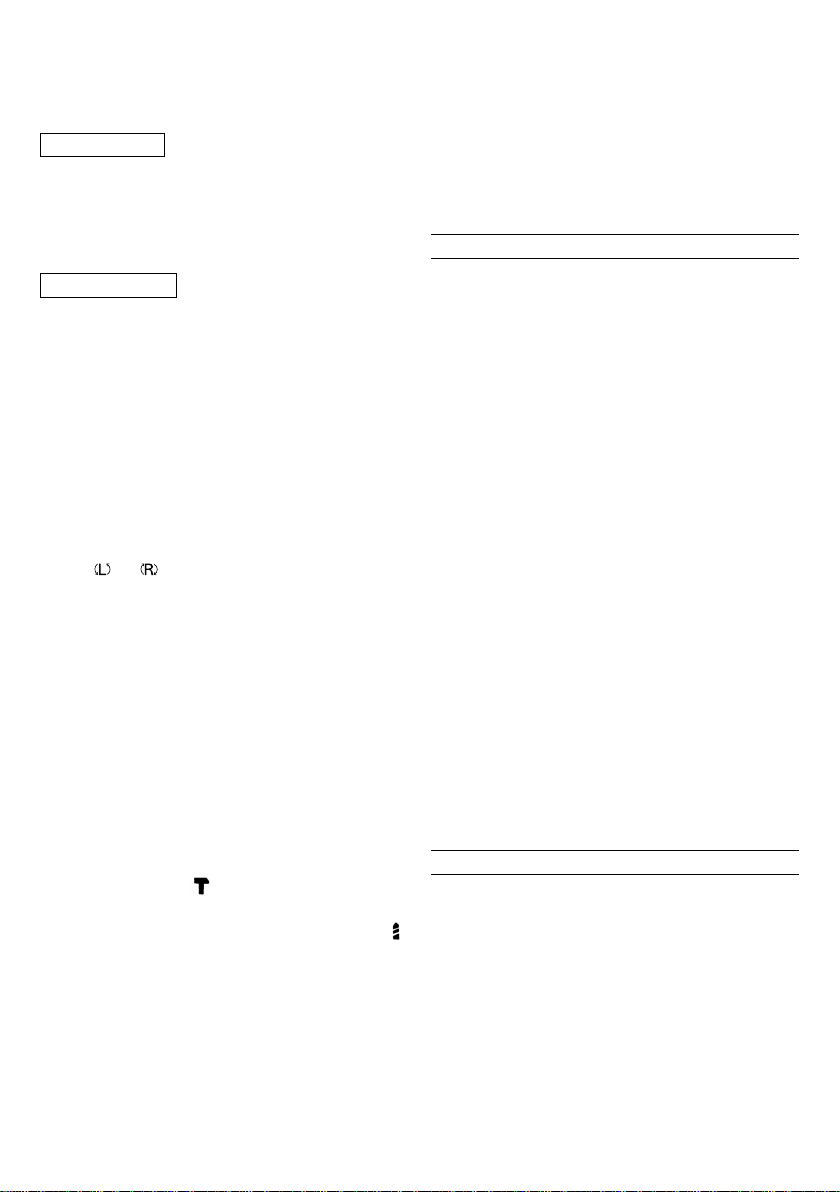

5. Mounting and dismounting of the bit

For keyed chuck (Fig. 1)

(1) Open the chuck jaws, and insert the bit into the chuck.

(2) Place the chuck wrench in each of the three holes in the

chuck, and turn it in the clockwise direction (viewed from

the front side). Tighten securely.

(3) To remove the bit, place the chuck wrench into one of

the holes in the chuck and turn it in the counter-clockwise

direction.

For keyless chuck (Fig. 2)

(1) Mounting the bit

Turn the sleeve counterclockwise and open the chuck.

After inserting the drill bit into the chuck as far it will go,

grip the ring and close the chuck by turning the sleeve

clockwise as viewed from the front.

(2) Dismounting the bit

Grip the ring and open the chuck by turning the sleeve

counterclockwise.

NOTE

When the sleeve does not become loose any further, fix

the side handle to ring, hold side handle firmly, then turn

the sleeve to loosen by hand. (Fig. 3)

6. Check the rotational direction (Fig. 4)

The bit rotates clockwise (viewed from the rear side) by

pushing the R-side of the push button.

The L-side of the push button is pushed to turn the bit

counterclockwise.

(The

and marks are provided on the body.)

CAUTION:

Always use the impact drill with clockwise rotation, when

using it as an impact drill.

7. Fixing the side handle (Fig. 5)

Attach the side handle to the mounting part.

Rotate the side handle grip in a clockwise direction to

secure it.

Set the side handle to a position that is suited to the

operation and then securely tighten the side handle grip.

To attach a depth gauge on the side handle, insert the

gauge into the U-shaped groove on the side handle,

adjust the position of the depth gauge in accordance with

the desired depth of the hole, and firmly tighten the side

handle grip. (Fig. 6)

8. IMPACT to ROTATION changeover (Fig. 7)

Shift the change lever between the right and left positions

to switch easily between IMPACT (rotation and impact)

and ROTATION (rotation only), respectively.

To bore holes in hard materials such as concrete, stone

and tiles, shift the change lever to the right-hand position

(as indicated by the mark). The drill bit operates by

the combined actions of impact and rotation.

To bore holes in metal, wood and plastic, shift the change

lever to the left-hand position (as indicated by the " "

mark). The drill bit operates by rotational action only, as

in the case of a conventional electric drill.

CAUTION:

○Do not use the impact drill in the IMPACT function if the

material can be bored by rotation only. Such action will

not only reduce drill efficiency, but may also damage the

drill tip.

○Operating the impact drill with the change lever in mid-

position may result in damage. When switching, make

sure that you shift the change lever to the correct position.

9. High-speed/Low-speed changeover:

Prior to changing speed, ensure that the switch is in the

OFF position, and the drill has come to a complete stop.

To change speed, rotate the gear shift dial as indicated

by the arrow in Fig. 8. The numeral "1" engraved on the

drill body denotes low speed, the numeral "2" denotes

high speed.

If it is hard to turn the gear shift dial, turn the chuck slightly

in either direction and then turn the gear shift dial again.

HOW TO USE

1. Switch operation

○When the trigger is depressed, the tool rotates. When the

trigger is released, the tool stops.

○The rotational speed of the drill can be controlled by

varying the amount that the trigger switch is pulled.

Speed is low when the trigger switch is pulled slightly and

increases as the trigger switch is pulled more.

○The desired rotation speed can be pre-selected with the

speed control dial.

Turn the speed control dial clockwise for higher speed

and counterclockwise for lower speed. (Fig. 9)

○Pulling the trigger and pushing the stopper, it keeps

the switched-on condition which is convenient for

continuous running. When switching off, the stopper can

be disconnected by pulling the trigger again.

CAUTION:

If the L-side of push button is pressed for reverse bit

rotation, the stopper cannot be used.

2. Drilling

○When drilling, start the drill slowly, and gradually

increasing speed as you drill.

○Always apply pressure in a straight line with the bit. Use

enough pressure to keep drilling, but do not push hard

enough to stall the motor or deflect the bit.

○To minimize stalling or breaking through the material,

reduce pressure on drill and ease the bit through the last

part of the hole.

○If the drill stalls, release the trigger immediately, remove

the bit from the work and start again. Do not click the

trigger on and offin an attempt to start a stalled drill. This

can damage the drill.

○The larger the drill bit diameter, the larger the reactive

force on your arm.

Be careful not to lose control of the drill because of this

reactive force.

To maintain firm control, establish a good foothold, use

side handle, hold the drill tightly with both hands, and

ensure that the drill is vertical to the material being drilled.

MAINTENANCE AND INSPECTION

1. Inspecting the drill bits

Since use of an abraded drill bits will cause motor

malfunctioning and degraded efficiency, replace the drill

bits with a new one or resharpening without delay when

abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very "heart" of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

9

000BookDV18VChS.indb9000BookDV18VChS.indb9 2018/09/1910:45:012018/09/1910:45:01