Hilintec D08 Series User manual

D08 Flo w Con t ro l Vacu u m Pum p and

Com p r ess o r Ser ies

Use r Gui de

Issue

1.0

Date

2021-10

D08 Flow Cont rol Va c u u m Pump an d Comp r essor Ser ies User Guide

Copyright © Chengdu Hilin Technology Co. Ltd.

Copyright © Chengdu Hilin Technology Co., Ltd. 2020. All rights reserved.

No part of this d o cu m ent m a y be repr o d u c e d or tran s m itte d in any fo r m or by an y m eans

wit hout prior writ ten consen t of Chen g du Hil i n Tech n o l o g y Co . , Ltd .

Trademarks and Permissions

is a tra d e mark of Che n g d u Hili n T echno l o g y Co., L t d .

All ot her tr a d e m a r ks an d tr ade na m e s m enti o n e d in this docu m e n t a r e the pr o p e r t y of

the i r r e s p e c t i v e holde r s .

Notice

The pur ch a s e d pro d u ct s, serv i ce s and featu r es are stipul a t e d by the cont r a c t made

bet w een Che n gdu H i l i n Tec h n o l o g y C o . , Lt d . an d t he cu s t ome r . Al l o r pa r t o f the pr o d u c t s ,

ser v i c e s and fea t ures des cr ibed in th i s docu m ent ma y not b e wit h in t h e pu r c h a s e scop e

or the us a g e sco p e . U n le s s oth e r w ise sp e ci f i e d in th e c on t r a c t , al l s t a t e m e nt s ,

inf o r m atio n , and r e co m men d a t i o n s i n th i s do c u m e nt a r e prov i d e d " A S I S " w i thou t

war rant i e s , gu a r ante e s or rep r esen t a t ions o f a n y k ind, e it her e x pre s s or im p lied .

The infor m atio n in this docum ent is subj e c t to cha n g e wit hout n otice . Eve r y eff o r t has

been m a d e i n t h e p r e p a r atio n o f t h i s docume n t t o e n s u r e accur acy of th e c o n t e n t s, but

all s t a t e m e n t s , i n f o r m a t i o n , a n d reco m m e n d a t i o n s in thi s d o cu m e n t do no t c o n s t it ute a

war rant y of any k ind, ex pre s s o r i m p l i e d .

Chengdu Hilin Technology Co., Ltd.

Address:

No.3663 Section 2 Muhua Road

Shuangliu District

Chengdu Sichuan China 610000

Website:

http://www.mini-pump.com

Tel:

+86-28-62567958

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

1

About This Document

Purpose

This document is a description of the D08 flow control vacuum

pump and compressor products in testing period, which is used to

guide relevant technical personnel to initially understand the

characteristics of the product.

Intended Audience

This document is intended for technical personnel. You should have

a good understanding of your product and have a clear concept of

the relevant parameters, specifications, and other information of the

applications of the micro pump.

Keyword

Compact size,wide voltage power supply, stable flow rate,related

parameters, wiring instructions

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

2

Change History

The change history accumulates each update of this document. The

latest version of the document contains all the previous updates.

Issue

Date

Product

Version

Issuer

Modification

01

2021-8

1.0

GZM

First official release.

01

2021-10

1.0

GZM

Added BDC parameters

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

3

Contents

Ab ou t T hi s Do c u m e n t

..............................................................................................1

Ch an ge H is to r y

......................................................................................................... 2

Co n t e n t s

......................................................................................................................3

1Ch a r ac t e r i s t i c s

....................................................................................................... 1

1.1 Compact Size..................................................................................................................................... 1

1.2 Multiple motor options.......................................................................................................................1

1.3 High vacuum, Big pressure................................................................................................................1

1.4 Industrial-grade reliability..................................................................................................................2

2Fu n c t i o n s

.................................................................................................................2

2.1 Speed Control Function..................................................................................................................... 2

2.2 Modular hose connector options........................................................................................................ 2

3Te ch n ic a l Sp ec i f i ca t i o ns

.................................................................................... 3

3.1 Performance Specifications................................................................................................................3

3.2 Configuration Options........................................................................................................................4

3.3 Reliability Parameters........................................................................................................................ 5

3.4 Versions Description..........................................................................................................................6

3.5 List of Models Combination for Sale.................................................................................................7

3.6 Pump material..................................................................................................................................... 7

3.7 Flow Rate Curve................................................................................................................................ 7

3.8 Starting Current..................................................................................................................................8

4Pr o d u ct Mo d el D e s c r i p t i o n

................................................................................9

4.1 Brief Description of Model Naming.................................................................................................. 9

5El ec t r ic a l Co n ne ct i o n

.........................................................................................10

5.1 Definition of Signals(Equipped with BDC motor).......................................................................... 10

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

4

5.2 Logic Wiring Diagram(Equipped with BDC motor)......................................................................... 9

5.3 Definition of Signals(Equipped with BLDC motor)..........................................................................9

5.4 Logic Wiring Diagram(Equipped with BLDC motor).......................................................................9

6Ca ut i on s

.................................................................................................................13

7Di m e n s i o n s

............................................................................................................15

8Ap p e ar a n c e

...........................................................................................................16

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

1

1Characteristics

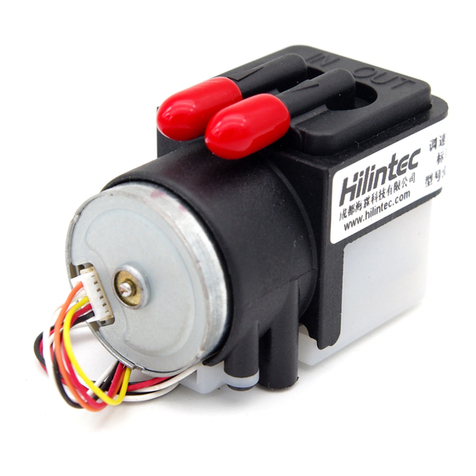

1.1 Compact Size

The overall size of the product(equipped with a brushless motor) is

about 34.5×21×32.5mm; the overall size of the product(equipped

with a brushed motor) is 40 ×17 ×23.5mm; it is suitable for

applications that require a very small space of air pumps.

1.2 Multiple Motor Options

Two choices of brushed and brushless motors are provided to meet

the different needs of costs and service lifetime;

The brushless motor uses 12V DC power supply; the brushed motor

uses 3-5V DC power supply.

1.3 High Vacuum, Big Pressure

Under the premise of extremely compact size, it can achieve

vacuum degree -49kPa and maximum positive pressure 88kPa;

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

2

1.4 Industrial-grade Reliability

Whether pumps equipped with brushed motors or brushless

motors,which have passed rigorous life tests and promise to meet

industrial-grade reliability requirements under test conditions.

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

3

2Functions

2.1 Speed Control Function

For brushed motor version, The flow rate of the pump can be

changed by adjusting the motor speed and changing the input

voltage , For brushless motor version,The flow rate of the pump can

be changed by adjusting the motor speed through PWM signal.

2.2 Modular Hose Connector Options

Under the premise of a small volume, a replaceable connector is

available, which can be equipped with copper or stainless steel hose

connector and M3 internal thread connectors.

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

1

3Technical Specifications

3.1 Performance Specifications

(Standard atmospheric pressure 101kpa)

M o de l

V ol t a g e

(V D C )

M a x .

L oa d

Cu r r e nt

(m A )

M a x F l o w r a t e

(L /m i n)

M a x .

V a c u u m

( - k P a )

M a x . P r e s s u r e

( k P a )

P e ak

F l ow

A v e r a g e

F l ow

Material Option A

Pump Head:Aluminum Alloy,Diaphragm/Valves:EPDM, Motor: BDC

D08L-53-0610

5

≤210

≥110

≥95

≥49

≥88

Material Option B

Pump Head:Aluminum Alloy,Diaphragm/Valves:EPDM, Motor: BLDC

D08L-23-0600

12

≤65

≥210

≥175

≥46

≥75

N ot e :

1.O p e r a t i n g volt a g e 、 i n put vo l t a g e ch a n g e s w ill af f ect th e l o a d cu r r ent

2.U n l e s s oth e r wis e s p e c i f i e d , t he tec h n i c a l pa r amet e r s are me a s u r ed und e r

the con d it i o n s o f te m p e r a t u r e 20℃ a n d st a n d a r d a t m o s ph e r i c p r es s u r e o f

101 k P a .

3. The p a r a m eter s i n t h e t a b l e are me a s u r ed at th e ma x imu m s p e e d of the

mot o r . Wh en the mot or s p e e d ch a n g e s , the pr essu r e /v acuu m l e v el is

basi c a l l y un chan g e d .

4. The p e ak f l ow rat e in the t ab l e re f e r s t o t h e f l o w v al u e m easu r e d w i t h a

rot a m e t er, an d t h e a v e r age flo w rat e i s m e a s u r e d w ith a so a p f i l m

flow -me t e r .

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

2

3.2 Configuration Options

Material

option

pump head

Reinforced nylon

diaphragm

EPDM

one-way valve

EPDM

motor

BLDC

BDC

Connector

Option

Connector type

default copper hose

connector

304 stainless steel hose

connector

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

3

3.3 Reliability Parameters

M o de l s

D 0 8 L e q u i p p e d w i t h B L D C m o t o r

V e r s i on s

S i m p l i f i e d

S t a n d a r d

P r e m i u m

Fully Loaded Lifetime

(hrs)

12000

(Estimated lifetime)

Unloaded Lifetime

(hrs)

18000

Motor Lifetime(hrs)

20000

Lifetime test

instructions:

Full-load life test conditions: block the exhaust port of the pump, and the

suction port is directly connected to the atmosphere, so that the pump

can operate continuously without stopping for 24 hours under the

maximum vacuum condition;

No-load life test conditions :The pump suction port and exhaust hole

are directly open to the atmosphere, so that the pump works under

normal pressure for 24 hours without stopping and continuous operation;

Motor life test conditions: under good ventilation and heat dissipation

conditions, the motor does not carry a load for 24 hours without stopping

Continuous operation;

Environmental conditions for life test: In a clean, non-corrosive

laboratory, the ambient temperature is 5~33℃fluctuates with the

climate, and the relative humidity of the environment is 50%~85%,

fluctuates with the climate;

The source of the experimental data is from Hailin Technology Aging

and life laboratory and supplier laboratory

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

4

Working

Conditions

Environment

Permissible ambient temperature range of the simplified version products is 0℃~

40℃, and the permissible ambient temperature of the standard and premium

versions is 0℃~50℃. The permissible relative humidity of all pumps in this series

is ≤90%, no condensation.The pump should not be exposed to the sun, and should

work in a clean and ventilated environment.

Medium

Permissible gaseous media temperature range is 0℃~50℃. The medium is allowed

to contain water vapor, but cannot contain particles or oil mist.

Load

The inlet/outlet can be operated at full load (i.e. completely block the inlet/outlet),

but the applied load cannot exceed the maximum vacuum of the pump; the outlet

must keep unobstructed.

Corrosion

The materials of the wetted parts:nozzle, pump head,diaphragm,one-way valve(See

Configuration Options for component materials),The above materials have a certain

degree of corrosion resistance. Please further judge the resistance to the medium

according to the wetted materials

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

5

3.4 Versions Description

Per f or m a n ce

Ver sion

Sim p l i f i e d

Ver sion

Sta n d a r d V e r s i o n

Pre m i u m Ver s i o n

Lif e t i m e

★★

★★★

★★★★

Nois e

★

★★

★★★

Rel i a b i l i t y

★

★★

★★★

Par a m e t er

Cons i s t ency

★

★★

★★★

N ot e : 1 . T h e m o r e ★, t h e b e t t er p er f o r m an ce o f t h i s i t e m .

2 . T h e q u a n t i t y ★ i s f o r r e f e r e n c e o n l y , s o t h a t r ea d e r s c a n u n d e r s t a n d

t h e d i f f e r e n ce s b e t w e e n v e r s i on s .

3.5 List of Models Combination for Sale

Version

Type

Sim p l i f i e d Ver s i o n

Sta n d a r d

Ver sion

Pre mium

Ver sion

D08L

equipped with

BLDC motor

/

/

√

D08L

equipped with

BDC motor

/

/

√

3.6 Pump Materials

The materials of the wetted parts: LY12 aluminum alloy,EPDM

rubber and copper. Please check the tolerance of the medium

according to the wetted material.(For special needs, you can

customize stainless steel head and stainless steel pneumatic

connectors.

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

6

3.7 Flow Rate Curve

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

7

3.8 Starting Current

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

8

4Product Model Description

4.1 Brief Description of Model Naming

This series of products are premium version.

Exa m p l e 1 : D 0 8 L -5 1 J - 0 6 1 0 (D08L pump , 5V vol t a g e , basic si m p l i f i ed ver s i o n ,

rub b e r m ater i a l : EP DM , pum p head mat e r ial: LY1 2 a l u m i n um al l o y , bru s h e d

mot o r , conn e c t o r t ype: h o s e connec t o r )

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

9

5Electrical Connection

The Electrical Connection section introduces how to connect this

product to an external power supply and the wiring instruction of

signal wires. This product is equipped with standard connection

wires at the factory, and the wire definitions are distinguished by

colors.

5.1 Definition of Signals(D08 Equipped with BDC Motor)

There are 5 motor wires for this product. The wiring and usage instructions are as

follows.

5.2 Logic Wiring Diagram(D08 Equipped with BDC

Motor)

S . N .

C o l o r

F u n c t i o n

E x p l a n a t i o n

R e m ar k s

1

Black

Negative pole of the

power supply

GND

2

Red

Positive pole of the

power supply

DC5V

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

10

5.3 Definition of Signals(D08 Equipped with BLDC Motor)

There are 5 motor wires for this product. The wiring and usage instructions are as

follows.

N o t e : If s p e e d cont r ol a n d s p e e d feed b a c k ar e n o t need e d , t h e r e d w ire sha l l b e

conn e ct e d to t h e posi t i v e pole of th e pow e r supp l y , and the black, whi t e and

ora n g e w ires co n n e c t e d to the nega t ive pole of t he power supp l y ; the yel l o w

wir e shal l b e in s u l a t e d a n d wr a p p e d .

S . N .

C o l o r

F u n c t i o n

E x p l a n a t i o n

R e m ar k s

1

Black

Negative pole of the

power supply

GND

2

Red

Positive pole of the

power supply

DC12V (±10%)

3

Yellow

FG feedback signal

(motor speed feedback

signal, pulse signal), the

motor outputs 6 pulses

per rotation

Output:

4V≤High Level

Low Level≤0.6V

The maximum rated

current of the FG

feedback signal is

3mA.

The internal of the motor is

open-drain, which requires a

pull-up externally. Voltage

DC 5V, resistance 4.7kΩ.

4

White

Pulse Width

Modulation(PWM)

Input:

0V≤VIL≤0.8V

2V≤VIH≤..5V

(15kHz~25kHz)

Use PWM to change the

motor speed and adjust the

flow. PWM input signal

frequency range: 15kHz ~

25kHz. This port cannot be

used to control the start and

stop of the pump.

5

Orange(

or

Gray)

Control the start and

stop of the motor.

Input:

Level Signal:

2V≤Stop≤5V

0V≤Start≤0.8V

This signal line can be used

to control the start and stop

of the pump, especially for

frequent start and stop. If the

pump does not work for a

long time, disconnect the red

power cord.

D08 Flow Cont rol Va c u u m P u mp and Co m pres s or Se r ies User Gui d e

Copyright © Chengdu Hilin Technology Co., Ltd.

11

5.4 Logic Wiring Diagram(D08 Equipped with BLDC

Motor)

If speed control and speed feedback are not needed, the red wire

shall be connected to the positive pole of the power supply, and the

black, white and orange wires connected to the negative pole of the

power supply; the yellow wire shall be insulated and wrapped and

the pump will work at the rated speed.

When you need to use the PWM speed control function, you need to

use a signal source that supports PWM signal output (function

signal generator, MCU, PLC, etc.), connect the signal source output

to the white PWM input cable, and connect the PWM signal source

ground to the ground of the DC power supply and wrap the yellow

wire with insulation.

This manual suits for next models

2

Table of contents

Other Hilintec Water Pump manuals

Popular Water Pump manuals by other brands

Danfoss

Danfoss PAH 25 instructions

ULTIMATE SPEED

ULTIMATE SPEED 12 V UOP 12 C1 Operation and safety notes

Gotec

Gotec eckerle SP32/02-80-M technical information

Atlas Copco

Atlas Copco LWP 2 Safety and operating instructions

PG Drives Technology

PG Drives Technology SK79647-02 Technical manual

JEC Pumps

JEC Pumps JRZL Series operating & maintenance manual