Hilintec D60 Series User manual

Copyright © Chengdu Hilin Technology Co., Ltd.

1

D60 Vacuum Pump and Compressors Series

User Guide

Issue

07

Date

2020-06

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

Copyright © Chengdu Hilin Technology Co., Ltd. 2020. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means

without prior written consent of Chengdu Hilin Technology Co., Ltd.

Trademarks and Permissions

is a trademark of Chengdu Hilin Technology Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of

their respective holders.

Notice

The purchased products, services and features are stipulated by the contract made

between Chengdu Hilin Technology Co., Ltd. and the customer. All or part of the products,

services and features described in this document may not be within the purchase scope or

the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties,

guarantees or representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has

been made in the preparation of this document to ensure accuracy of the contents, but all

statements, information, and recommendations in this document do not constitute a

warranty of any kind, express or implied.

Chengdu Hilin Technology Co., Ltd.

Address:

No.3663 Section 2 Muhua Road

Shuangliu District

Chengdu Sichuan China 610000

Website:

http://www.hilintec.com

Tel:

+86-28-62567958

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

I

About This Document

Purpose

This document is related to the D60 vacuum pump and compressor

series products,which is used to guide relevant technical personnel

to initially understand the characteristics of the product.

Intended Audience

This document is intended for technical personnel. You should have

a good understanding of your product and have a clear concept of

the relevant parameters, specifications, and other information of the

applications of the micro pump.

Keyword

Remote control, related parameters, wiring instructions

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

II

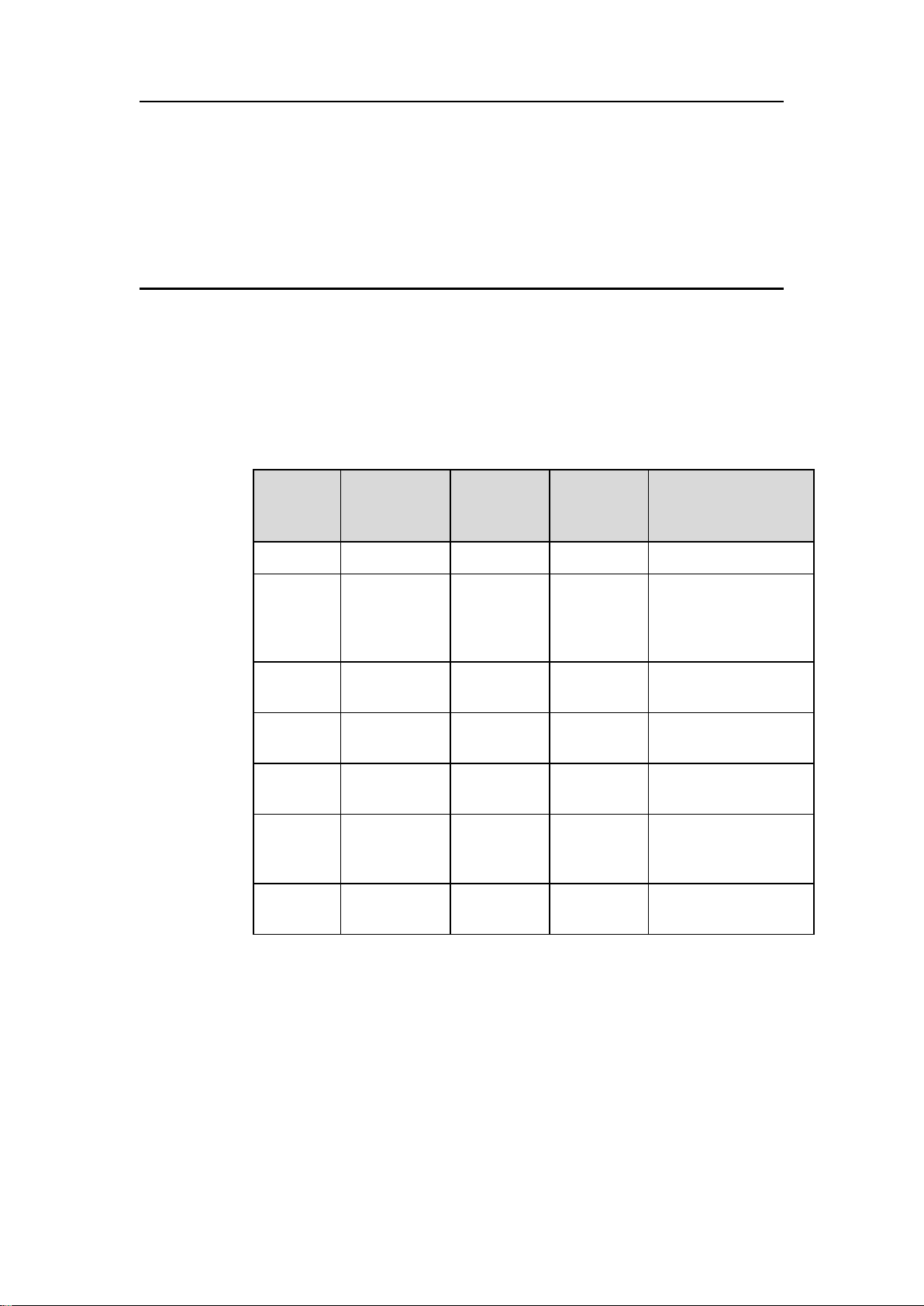

Change History

The change history accumulates each update of this document. The

latest version of the document contains all the previous updates.

Issue

Date

Product

Version

Issuer

Modification

01

2019-07

1.0

GZM

First official release

02

2019-09

1.0

GZM

Modify ‘ indicator light

flashes red’ to

‘indicator light remains

red’

03

2019-09

1.0

LYZ

Modify document

format

04

2019-12

1.0

FB

Update notes in section

3.1

05

2020-02

1.0

FB

Update drawings of

dimensions

06

2020-04

1.0

FB

Update reference curve

and correct part of the

descriptive information

07

2020-06

1.0

FB

Update medium

description

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

III

Contents

About This Document............................................................................................... I

Change History..........................................................................................................II

Contents.................................................................................................................... III

1Characteristics........................................................................................................1

1.1 Working Status Indicator......................................................................................................................1

1.2 Brush-less DC Motors..........................................................................................................................1

1.3 Protections............................................................................................................................................1

2Special Features.....................................................................................................2

2.1 Working Status Indication and Warning.............................................................................................. 2

3Technical Specifications...................................................................................... 3

3.1 Key Specifications............................................................................................................................... 3

3.2 Versions Description............................................................................................................................ 3

3.3 Description of Types............................................................................................................................ 4

3.4 List of Models Combination for Sale...................................................................................................4

3.5 Life-time Test Conditions.................................................................................................................... 5

3.6 Working Conditions............................................................................................................................. 5

3.7 Pump Materials.................................................................................................................................... 6

3.8 Parameter Curve...................................................................................................................................6

3.9 Starting Current Curve......................................................................................................................... 7

4Product Model Description................................................................................. 8

4.1 Brief Description of Model Naming.................................................................................................... 8

5Electrical Connection............................................................................................9

5.1 Basic Type............................................................................................................................................9

5.2 Remote Control Type........................................................................................................................... 9

6Cautions..................................................................................................................11

8Appearance............................................................................................................15

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

1

1Characteristics

1.1 Working Status Indicator

The remote control type and basic type are equipped with working

status indicator lights, which can visually feed back the working

status of the pump.

1.2 Brush-less DC Motors

This model is driven by brush-less motors which have the

advantages of long service life, low interference and high reliability.

1.3 Protections

Equipped with overheating protection, overload protection, power

supply under-voltage and over-voltage protection and reverse

connection protection function, which to the greatest extent prevents

accidental damage to the pump.

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

2

2Special Features

2.1 Working Status Indication and Warning

1.The basic type and remote control type are equipped with working

status indicator lights. Users can understand the working status of

the equipment through the color change of the indicator lights:

a. When the indicator light remains green, it means that the power

supply is normal and the pump is not working;

b. When the indicator light flashes green, it means the pump is

working normally;

c. When the indicator light remains red, it means the pump is

working abnormally;

d. When the positive and negative poles are reversed, the indicator

light is off, the pump does not work, but it will not damage the

pump.

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

3

3Technical Specifications

3.1 Key Specifications

Mode

l

Voltage

(V DC)

Load

Current

(A)

Flow(L/min)

Relative

Vacuum

(-kPa)

Maximu

m

Output

Pressure

(kPa)

Weight

(g)

Peak Flow

Average

Flow

D60L

24

≤1.3

≥26

≥18

≥50

≥100

≈850

Note: 1. The input voltage requires 24V±10%.

2. The parameters in the table are measured at the maximum speed of the

motor. When the motor speed changes, the pressure/vacuum level is basically

unchanged.

3. Unless otherwise specified, the technical parameters are measured under

the conditions of temperature 25℃ and standard atmospheric pressure of

101kPa. For products with other parameters and specifications, you can

contact us to customize.

4. The above parameters are measured under the configuration of standard

connectors. If other types of connectors are configured, the parameters may

change slightly.

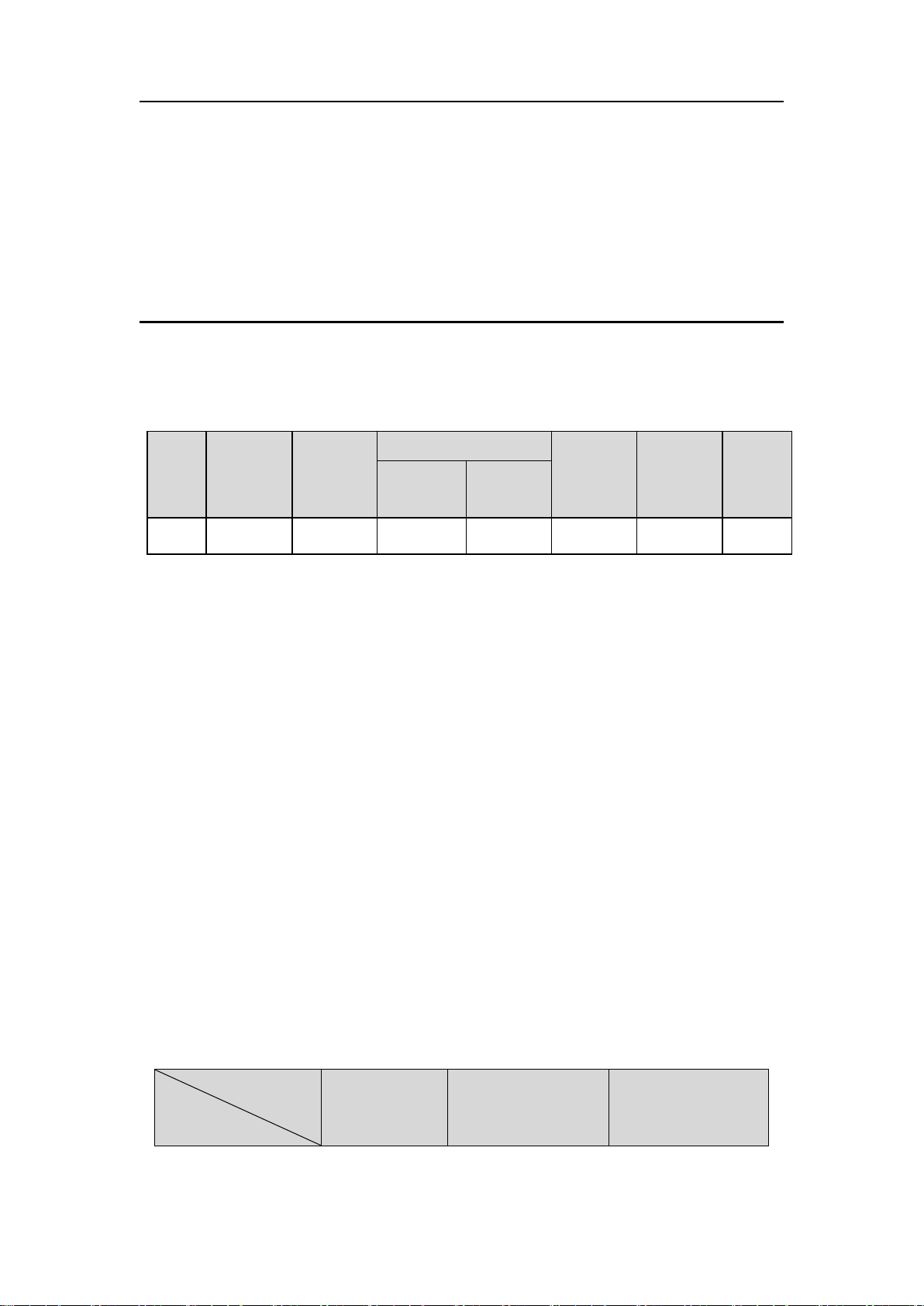

3.2 Versions Description

Performance

Version

Simplified

Version

Standard Version

Premium Version

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

4

Lifetime

≥2500h

≥6000h

≥8000h

Noise

★

★★

★★★

Reliability

★

★★

★★★

Parameter consistency

★

★★

★★★

EMC

★

★★

★★★

Ambient temperature

0~40℃

0~50℃

0~50℃

Note: 1. The more ★, the better performance of this item.

2. The noise data of the simplified version and the standard version are not

specified. For the noise data of the premium version, please refer to the latest

information.

3.3 Description of Types

Types

Function and Configurations

Basic

Type

Only equipped with indicator lights and start-stop switch.

Remote

Control

Type

Besides the indicator light and start-stop switch of the basic type,

it is also equipped with a remote control connector, from which

the user can control the start and stop of the pump from a remote

location. Note: If you want to use the remote control function,

the start-stop switch on the panel should be set to the "on"

position.

3.4 List of Models Combination for Sale

Version

Type

Simplified

Version

Standard

Version

Premium

Version

Basic Type

√

Customizable

Customizable

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

5

Remote Control Type

√

√

Customizable

Touch Control Type

Top Configuration Type

Note: √ in the above table means that there is a corresponding product for sale,

unchecked means that there is no corresponding product. (The above table

does not include customized products.)

3.5 Life-time Test Conditions

In a clean, non-corrosive laboratory, the pump carries a full load(the

outlet is blocked and the inlet directly connected to the atmosphere),

and operates continuously around the clock. The ambient

temperature is 5℃ ~33℃, fluctuates with the climate; the relative

humidity is 30%~90%, which fluctuates with the climate.

3.6 Working Conditions

1.Environment: Permissible ambient temperature range of the

simplified version products is 0 ℃ ~ 40 ℃, and the permissible

ambient temperature of the standard and premium versions is 0℃~

50℃. The permissible relative humidity of all pumps in this series is

≤90%, no condensation.The pump should not be exposed to the

sun, and should work in a clean and ventilated environment.

2.Medium: Permissible gaseous media temperature range is 0 ℃ ~

50℃. The medium is allowed to be rich in water vapor, but cannot

contain particles or oil mist.

3. Load:

1) When used as a compressor: the outlet can run at full load (i.e

completely blocked the outlet), but the applied load cannot exceed

the maximum discharge pressure of the pump; the inlet must be

unobstructed.

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

6

2) When used as a vacuum pump: the inlet can operate at full load

(i.e completely blocked the inlet), but the applied load cannot

exceed the maximum vacuum degree of the pump; the outlet must

keep unobstructed.

3.7 Pump Materials

1. The materials of the wetted parts: reinforced nylon, EPDM

rubber,nitrile rubber and silicone rubber. Please check the tolerance

of the medium according to the wetted material.

2. The material of the plastic parts of the pump body is fiber

reinforced nylon, and the material of the shock absorb foot is PVC.

3.8 Parameter Curve

Pressure-flow rate curve, there are individual differences between

different micro pumps, so this curve is a statistical value, only as a

technical reference for users to confirm the working point. The

"flow" mentioned in this section refers to the "average flow".

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

7

Note: 1. The maximum average flow rate of the curve will be slightly lower than the

nominal value, which is due to the resistance of the test pipeline components,

which leads to the attenuation of the flow;

2.The value of this curve is for reference only, not as a basis for product

acceptance.

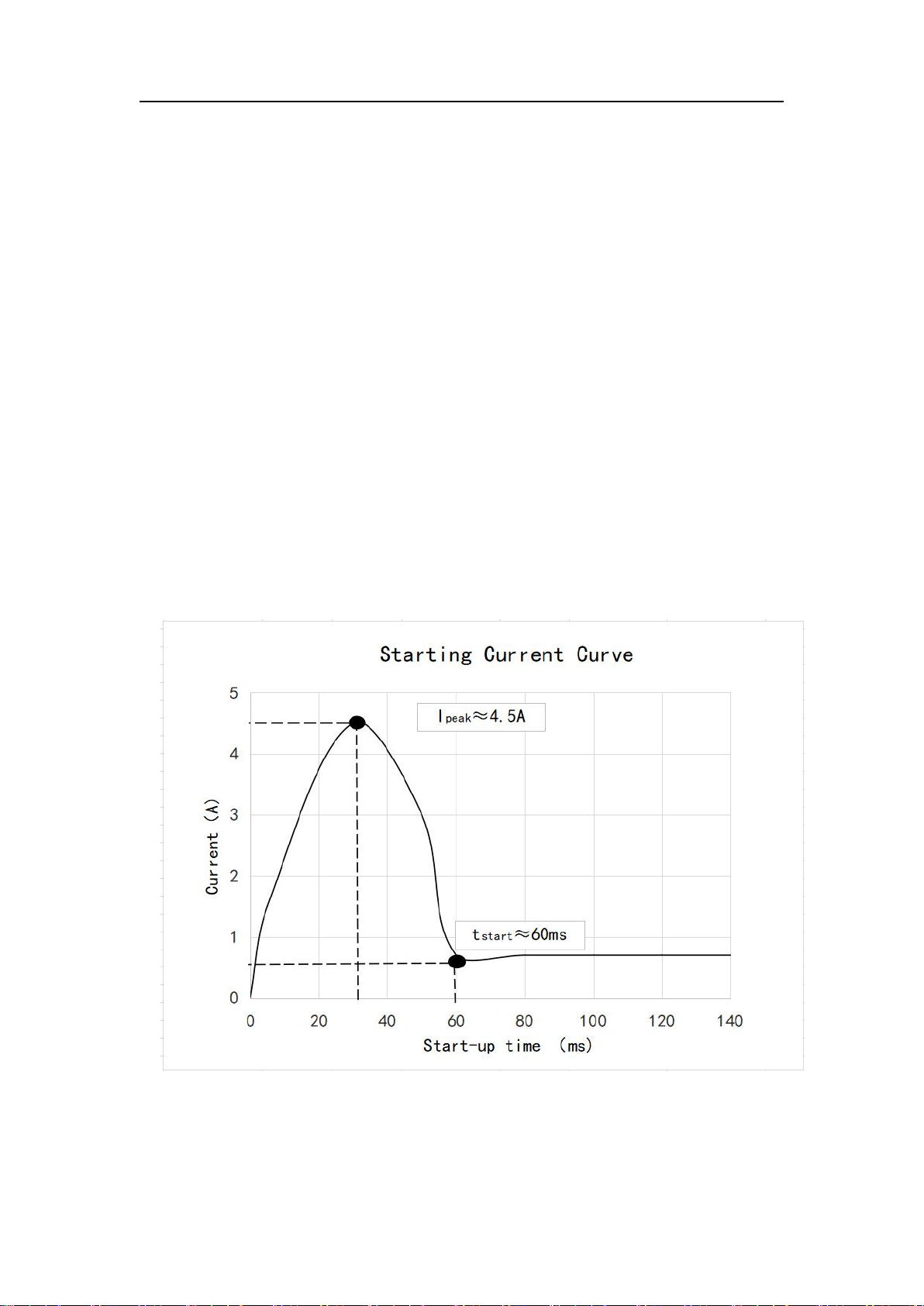

3.9 Starting Current Curve

The starting current curve is measured under the working condition

that the inlet and outlet are directly connected to the atmosphere,

and there are certain individual differences between different micro

pumps. This curve is a statistical value, which is only used as a

technical reference when users determine the power supply system,

and is not for acceptance data.

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

8

4Product Model Description

4.1 Brief Description of Model Naming

There are two types of this series of pumps: basic type and remote

control type,

Note: If the remarks starts with a letter, it means a special custom function. For

example, letter "GJ" means customized high-temperature medium function,

and "GH", means customized high-temperature environment function. If it

starts with a number, it means other information.

Example 1: D60L-41J( D60L pump, 24V voltage basic type simplified version)

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

9

5Electrical Connection

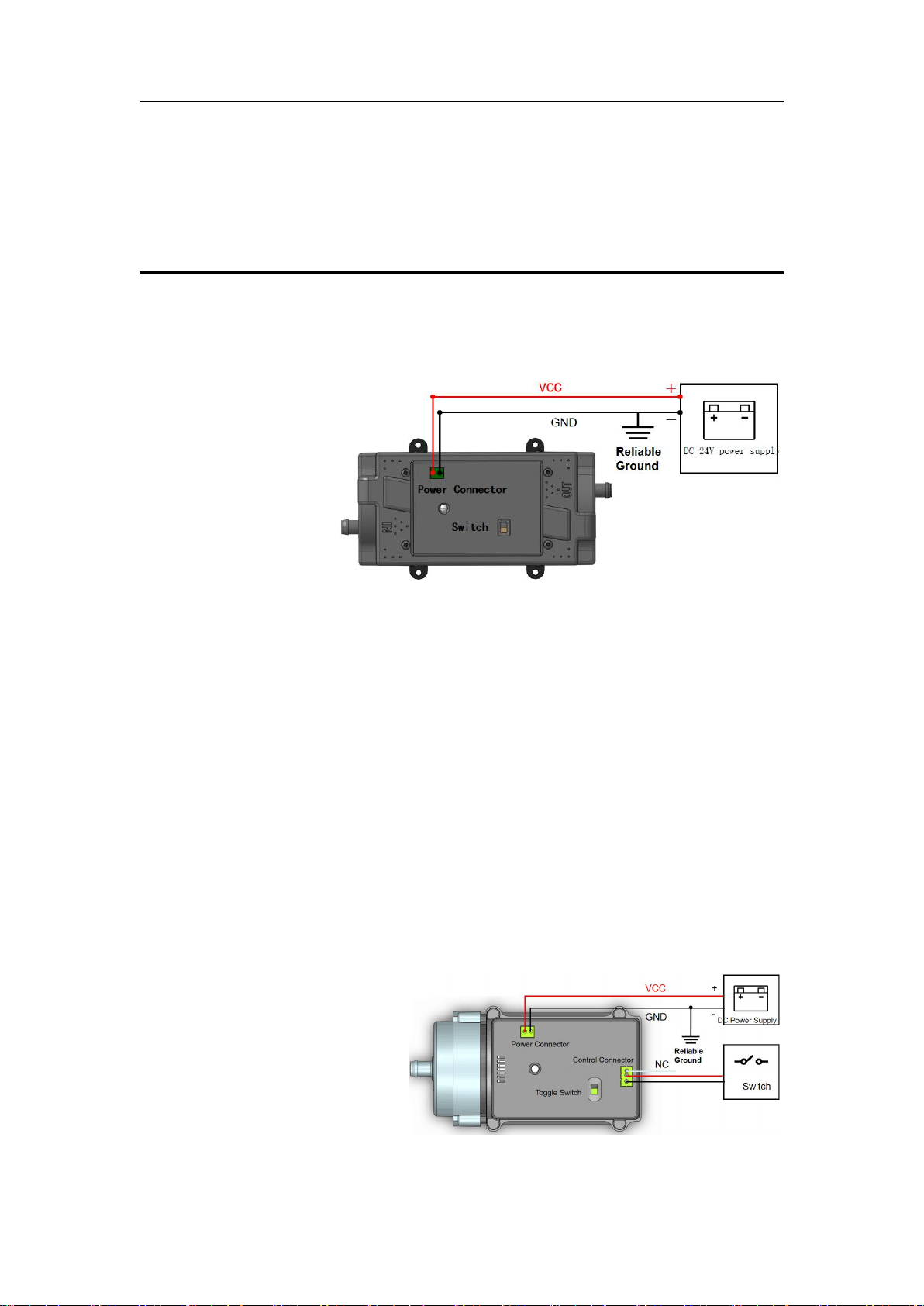

5.1 Basic Type

Figure 5-1 Wiring Instructions for Basic Type

Instruction: The red wire of the power connector is connected to the

positive pole of the DC 24V power supply, the black wire is

connected to the negative pole of the power supply. Control the start

and stop of the pump by the toggle switch.

Note: 1. The start and stop of the pump is not allowed by cutting off/connecting the

24V power supply, otherwise it may cause damage to the micro pump motor; if

you need to control the start and stop of the micro pump through a signal,

please choose a remote control product.

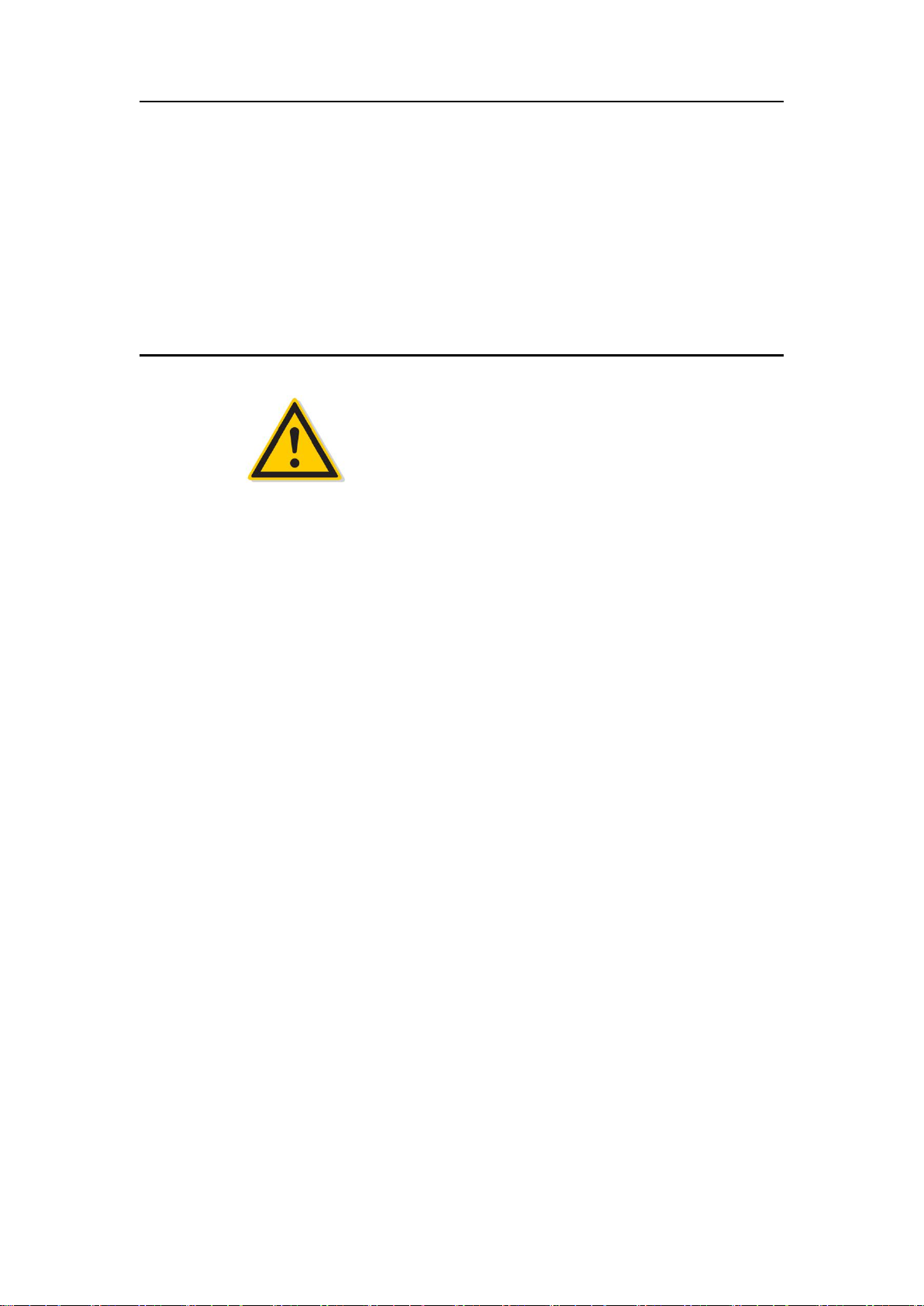

5.2 Remote Control Type

Figure 5-2 Wiring Instructions for Remote Control Type

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

10

Instruction: The red wire of the power connector is connected to the

positive pole of the 24V DC power supply, and the black wire is

connected to the negative pole of the power supply. When using the

remote control function, you need to set the toggle switch to the

"on" position. The red wire and black wire of the control connector

are connected to the hardware switch. If the red wire and the black

wire are connected , the pump will stop; if disconnected, the pump

will start.

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

11

6Cautions

Please read the instructions in this chapter carefully and follow

the instructions strictly before use.

1. This product has no waterproof, dust-proof, and explosion-proof

functions and cannot be used in flammable and explosive environment!

2. Foreign matter must not fall into the hydraulic connectors, and there

should be no solid particles in the medium, otherwise the micro pump will

be damaged!

3. When used as a compressor, the inlet of the pump must keep

unobstructed, otherwise it will damage the micro pump!

4. When used as a vacuum pump, the outlet of the pump must keep

unobstructed, otherwise it will damage the micro pump!

5. When this product is used to transfer harmful medium, it must be

double-sealed to ensure personal safety!

6. The matching piping components and containers must have

sufficient strength to ensure personal safety!

7. Built-in precision control circuit, need to use high-quality switching

power supply or DC stabilized power supply!

8. This series of products are not allowed to be shut down directly by

cutting off the 24V power supply. To stop the machine, the user shall

perform a soft shutdown through the panel toggle switch or remote

control switch before cutting off the power supply, otherwise it may affect

the motor life!

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

12

9. If this series of pumps are not used with our matching power supply,

it may cause interference to the operation of the pump. Leading the

ground wire at the power connector to reliably ground will help improve

the reliability of operation!

10. Please operate strictly in accordance with the requirements of this

user guide.

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

13

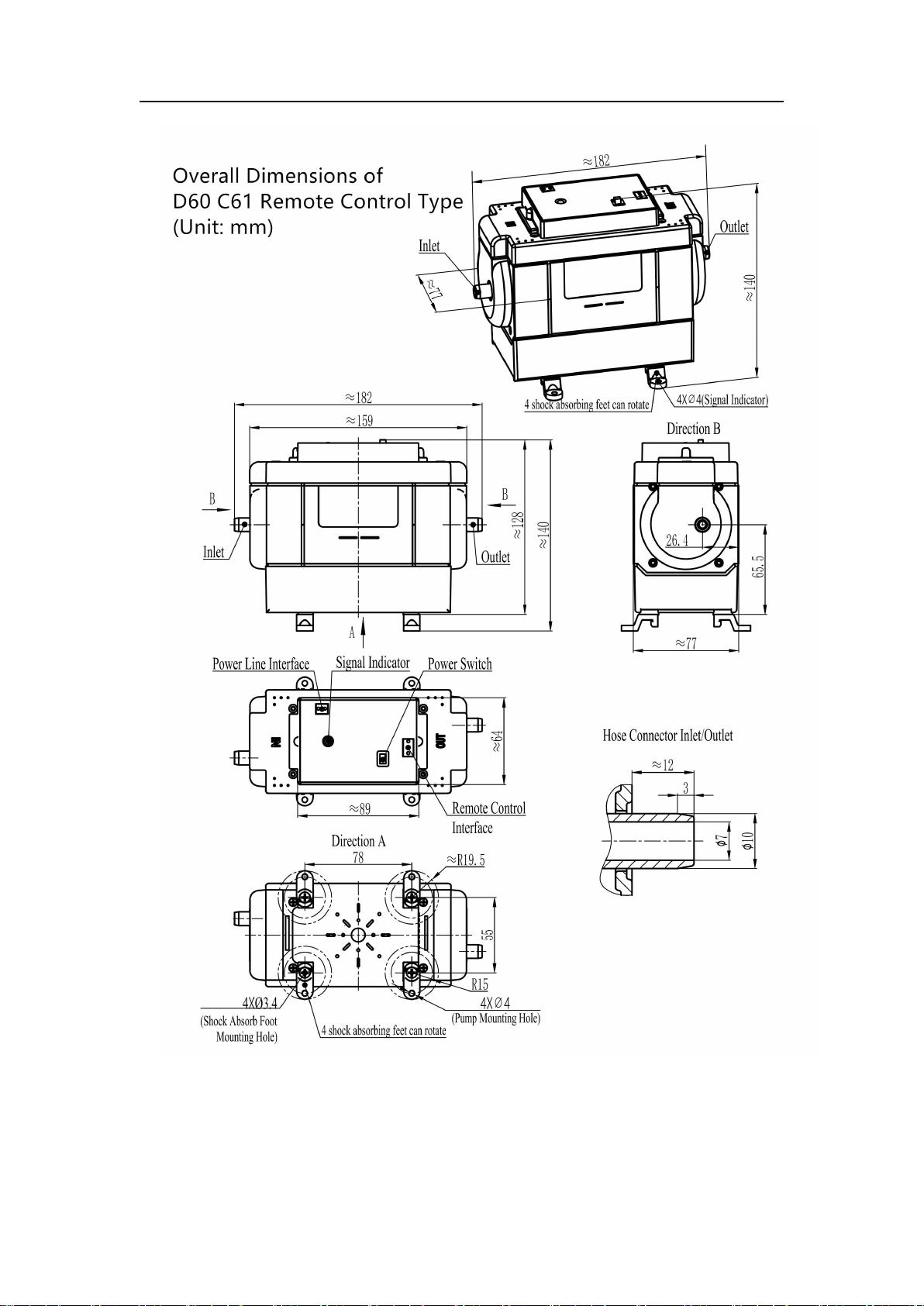

7Dimensions

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

14

Installation instructions:

1. The screws on the pump cannot be removed, otherwise it will damage the pump;

2. The mounting holes are self-tapping screw holes, not suitable for repeated tightening and

disassembly, otherwise the installation will be loose and unreliable.

D60 Vacuum Pump and Compressors Series User Guide

Copyright © Chengdu Hilin Technology Co., Ltd.

15

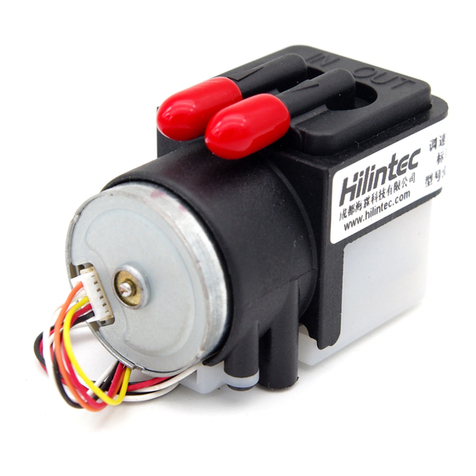

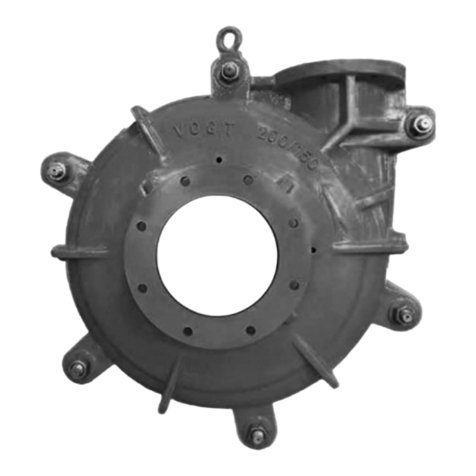

8Appearance

D60-Basic Type

This manual suits for next models

1

Table of contents

Other Hilintec Water Pump manuals

Popular Water Pump manuals by other brands

Pentair

Pentair SHURFLO BLASTER 4238 Series manual

YATO

YATO YT-85290 manual

Champion Power Equipment

Champion Power Equipment 66520 owner's manual

Vogt

Vogt HAD Series Service manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBA401-V operating instructions

Pacific hydrostar

Pacific hydrostar PacificHydrostar 2" Gasoline Powered Clear Water... manual