Hillrom Primo P02033 User manual

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Primo™Service Manual - 171636(1)

Hill-Rom Industries S.A.

188, Rue du Caducée

Parc Euromédecine

34195 MONTPELLIER Cedex 5 - FRANCE

Tel: +33 (0)4 67 04 64 04

Fax: + 33 (0)4 67 04 64 00

www.hill-rom.com

First edition

First printing, 2012

Printed in Europe

171636, Rev.001 / September 2012

The information contained in this manual is confidential and may not

be reproduced or divulged in any form or by any means without the

prior written permission of Hill-Rom.

Hill-Rom®

is a registered trademark

of Hill-Rom Services, Inc.

I-mmersion™is a trademark of

Hill-RomServices, Inc.

Primo™

is a trademark of Hill-Rom Services, Inc.

Torx® is a registered trademark of Textron, Inc.

Hill-Rom reserves the right to make changes to the design,

characteristics and models without prior notice. The only warranty

Hill-Rom makes is the express written warranty extended on the sale or

rental of its products.

To order copies of this manual, refer to the last page, identify your

national Hill-Rom representative and order the article with the part

number 171636.

© 2012 by Hill-Rom Services, Inc. ALL RIGHTS RESERVED

Revision N° Affected pages Date

001 Original September 2012

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Primo™Service Manual - 171636(1) Page i

Table of Contents

Chapter 1:

Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Typographical conventions used in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Precautions for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Glossary of abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Warning labels:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Model identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Identification label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

General description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Operating principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Mechanical subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Electric subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Pneumatic subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Regulatory requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

End-of-life equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Chapter 2:

Troubleshooting Procedures

Safety recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Diagnostic tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Initial Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Problem/Solution Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Final actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Preventive maintenance instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Operational checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

RAP 2.1 Electric power supply fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

RAP 2.2 Mains power supply alarm fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

RAP 2.3 Compressor fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

RAP 2.4 Leak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

RAP 2.5 Malfunction alarm fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Chapter 3:

Procedures for

the removal, replacement and adjustment of parts

Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Prerequisites for all operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Replacing the mains socket fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Opening the control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Replacing the front unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Replacing the control PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Replacing the power PCB fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Replacing the power supply PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Replacing the hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Replacing the compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Replacing the mains socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Replacing the unit at the back of the control unit . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Replacing the CPR valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Replacing the CPR valve on the pressure relief valve . . . . . . . . . . . . . . . . . . . . 3 - 10

Replacing the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Replacing the mattress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page ii Primo™Service Manual - 171636(1)

Introduction

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 1 - 1

3

4

2

1

Chapter 1

Introduction

Introduction

This manual contains the information required for the normal operation and

maintenance of the Hill-Rom Primo™. The part numbers of the spares can be

found in the catalog P/N 171353.

This manual is intended for use by facility-authorized personnel. Use by

unauthorized personnel may result in damage to the equipment and/or serious

injury to staff or users.

Typographical conventions used in this manual

This manual contains different typefaces and icons designed to improve

readability and increase understanding of its content. Note the following

examples:

• Standard text: used for regular information.

•Bold text: emphasizes a word or phrase.

•NOTE: sets apart special information or important instruction

clarification.

The symbols below represent different risks or hazards:

Precautions for use

Before using, it is essential to read the User Manual of the Primo™and this

Service Manual and to strictly follow all the safety instructions in these

manuals.

Caregivers must be informed of the risks that may be encountered in the use

of electric devices.

Glossary of abbreviations

Table 1-1. Glossary of abbreviations

Symbol Description

WARNING

• This symbol indicates that the failure to follow the associated

recommendation can put the patient or the user in danger, or

damage the equipment.

CAUTION

• This symbol indicates that the failure to follow the associated

recommendation can result in damage to the equipment.

Electric Shock Hazard

Abbreviations Definition

CPR Return the head section to the flat position for cardio-

pulmonary

reanimation

I-mmersion™Trade mark: pressure control system

EV Electro valve

RAP Repair Analysis Procedure

P/N Part number

Warning labels:

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 1 - 2 Primo™Service Manual - 171636(1)

Warning labels:

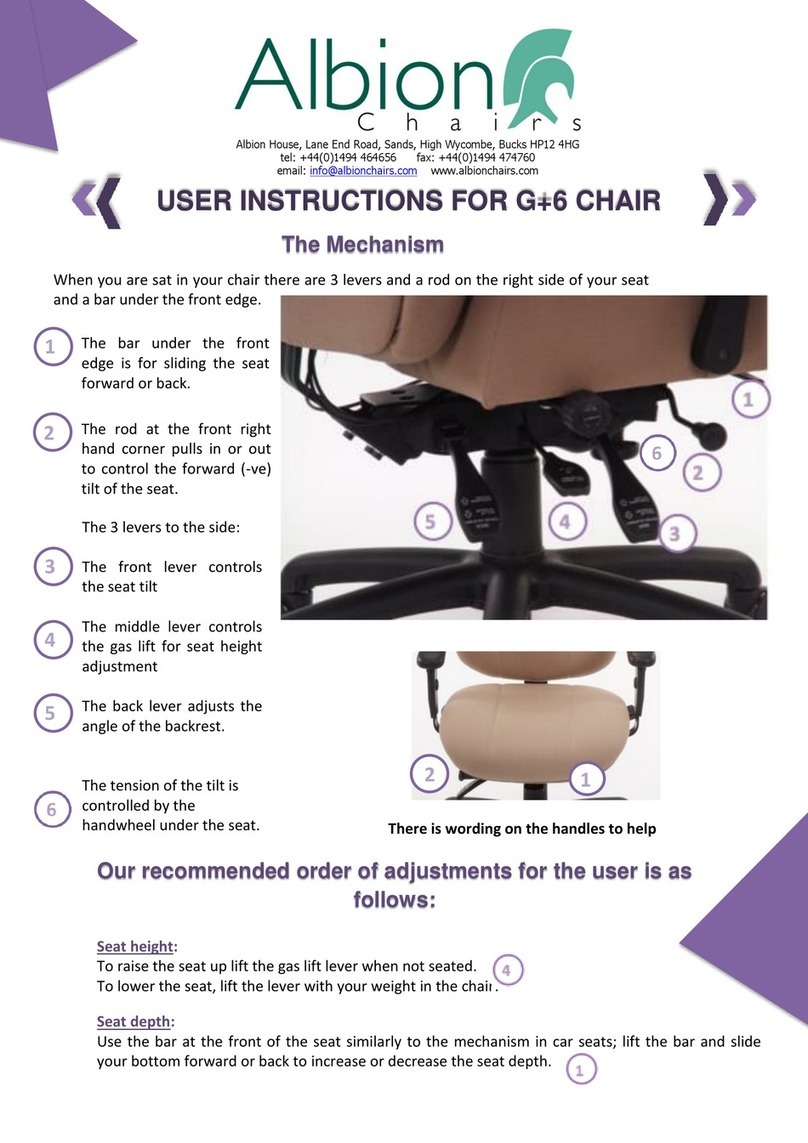

Figure 1-1. Control unit

Figure 1-2. Power PCB

A Identification labels

B Seat cushion inflation port

C

Fuses for 220-240 VAC

Fuses for 120 VAC

AB

C

D

Refer to the user manual.

(if the battery fails, replace the power supply

PCB - follow procedure 3.6 page 3-5).

EWarning:

High voltage!

D

E

General description

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 1 - 3

3

4

2

1

Model identification

Refer to the table below to identify the models of the Primo™Therapeutic

Mattress.

Table 1-2. Model Identification

Identification label

Figure 1-3. Identification label

NOTE:

This procedure applies to class II*models which are identified by a P,

followed by five numbers, from version A onwards (see figure 1-3 page 1-3).

For all earlier versions, refer to the Service Manual P/N W10006.

Class II devices are identified by the symbol on the label.

General description

The Primo™

helps to prevent and treat pressure ulcers in all adult patients,

exposed to low to moderate risks

.

The pressure in the air bladders is automatically regulated by the innovative

I-mmersion™pressure control system.

This patented technology permanently detects the weight and position of the

patient's body and dynamically adjusts the pressure in the mattress.

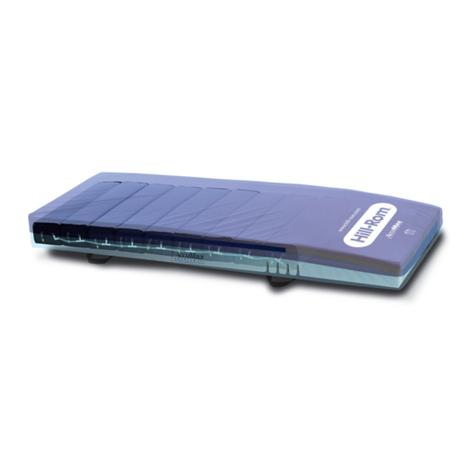

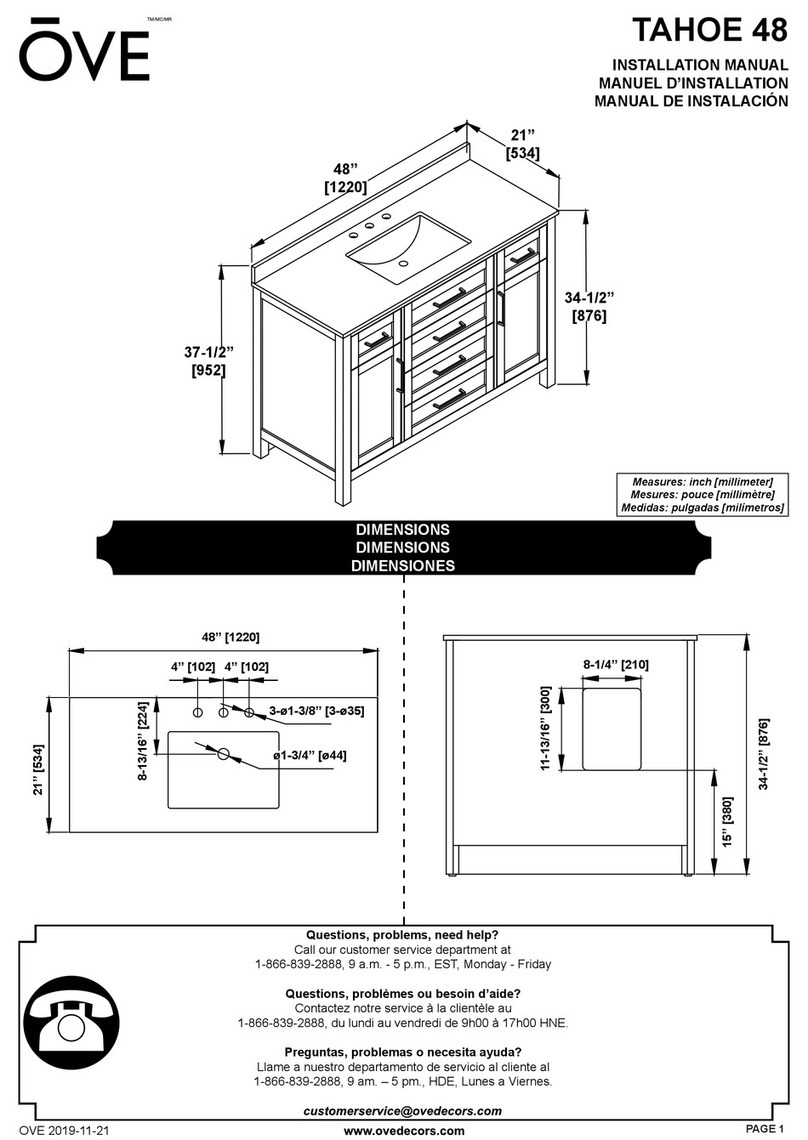

Figure 1-4. Exploded view of the Primo™

Name Part

number Technical characteristics

Primo 85x200 P02033 220 - 240V ~, 50/60Hz

Primo 85x200 P02034 120V ~, 60Hz

Primo 77x200 P02044 220 - 240V ~, 50/60Hz

Primo 85x200 FIRE P02047 220 - 240V ~, 50/60Hz

P02033 A

P+5 figures = model B = product version letter

1

2

3

5

4

6

7

8

8

9

Technical specifications

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 1 - 4 Primo™Service Manual - 171636(1)

Table 1-3. Description Technical specifications

Table 1-4. Control unit

Item Name

1 Upper cover

2 Air mattress

3 Control unit

4Sensor

5 Foam sub-mattress

6 Bottom cover

7CPRvalve

8Straps

9Sensorunit

Characteristics Description

Model P02033 P02047 P02034 P02044

Dimensions 15x29x12 cm / 6x11.5x5"

Weight 3,5 kg / 8 lb

Power supply 220-240V

50/60 Hz

220-240V

50/60 Hz 120V 60Hz 220-240V

50/60 Hz

Apparent power 20 VA 20 VA 32 VA 20 VA

Maximum energy

consumption 16.4 Wh 16.4 Wh 16.4 Wh 16.4 Wh

Operation of the device Continuous

Sleeve material ABS PC V0

Device: Acoustic

pressure / power

(ISO 3744)

41 dB(A) / 52 dB(A)

Alarm: Acoustic

pressure / power

(IEC60601-1-8)

56 dB(A) / 67 dB(A)

Fuse T160 mA T160 mA T200 mA T160 mA

Compression 0-180 mBar 0-180 mBar 0-215 mBar 0-180 mBar

Maximum compressor

flow rate 10 l/min 10 l/min 12 l/min 10 l/min

IEC 60601-1

classification Class II

Degree of protection

provided by the unit

(IEC 60529)

IP21: protected against access to dangerous parts with

fingers and vertically dripping water

Protection against

inflammable anesthetic

mixtures

Not for use with flammable anesthetics

Battery life 1 hour

Operating principle

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 1 - 5

3

4

2

1

Table 1-5. Therapeutic Mattress Table 1-6. Conditions for transport, storage and use

Operating principle

The operation of the Primo™can be split into three categories or subsystems:

• Mechanical subsystem

• Electric subsystem

• Pneumatic subsystem

The device operates thanks to the combined functions of these three

subassemblies.

These three subassemblies must operate correctly with one another for the

device to function correctly.

Each of these subassemblies is described separately in the following sections.

Characteristics Val ues

Model P02033/P02047/P02034 P02044

Length (inflated) 200 cm / 79"

Width (inflated) 85 cm / 33.5" 77 cm / 30.5"

Height (inflated) 16 cm / 6"

Weight 8,4 kg / 18.5 lb

Operation in transport mode 2 hours

Upper cover

Polyurethane coating on polyester material

Low-friction, stretchable in both directions, breathing,

bacteriostatic, fungistatic and antimicrobial. Can be

wiped and washed.

Bladders Polyurethane

Safe working load,

including the total weight of the patient, accessories (if

they are supported by the support system of the medical

bed) and the load supported by these accessories

(excluding the weight of the patient).

Maximum pressure of the

safety valve 1 psi / 69 mBar

Degree of protection against

electric shock

Type BF applied parts protected against defibrillation

shocks (items 1 and 6 page 1-3)

Degree of protection

provided by the cover

(IEC 60529)

IP24: protected against access to dangerous parts with

fingers and splashes of water

250 250

Symbol

Features

Use Transport/storage15a

a. Applicable only if the device is stored in its original packaging.

Temperature

+5°C - +40°C -25°C - +70°C

Humidity

15%-93% 0%-93%

Atmospheric

pressure

700 mbar - 1,060 mbar 700 mbar - 1,060 mbar

Operating principle

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 1 - 6 Primo™Service Manual - 171636(1)

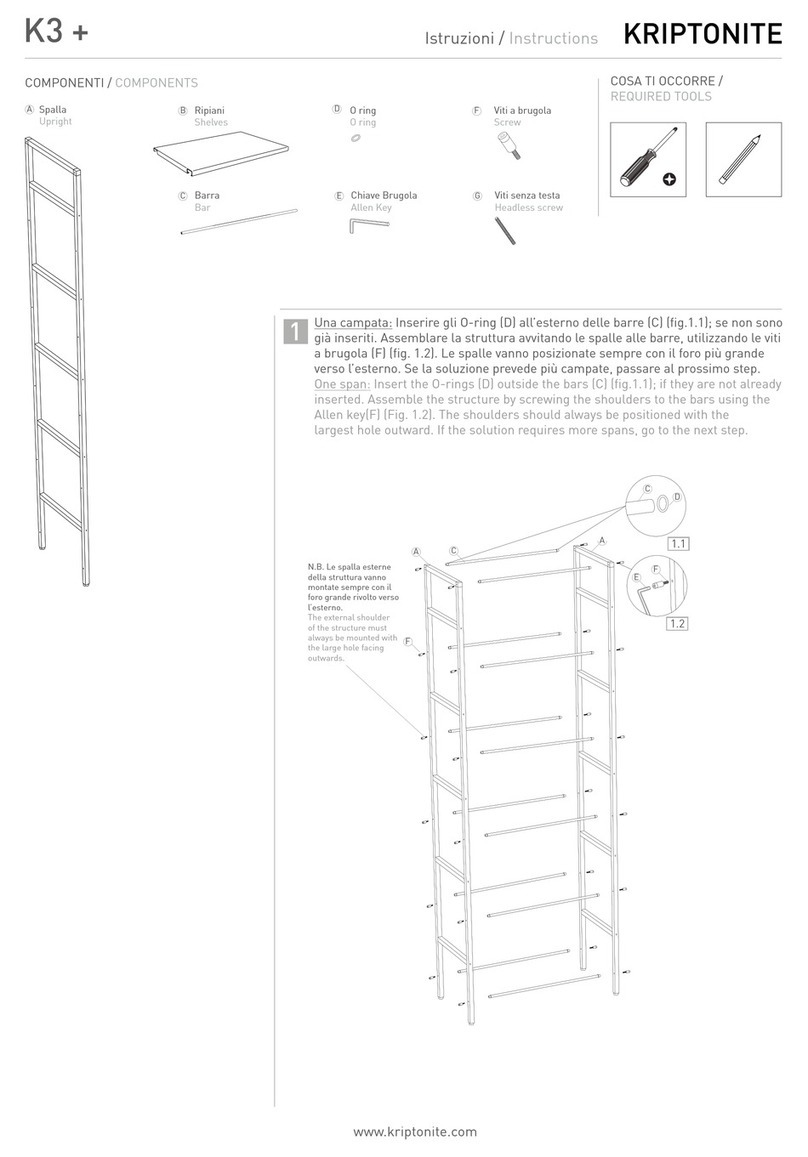

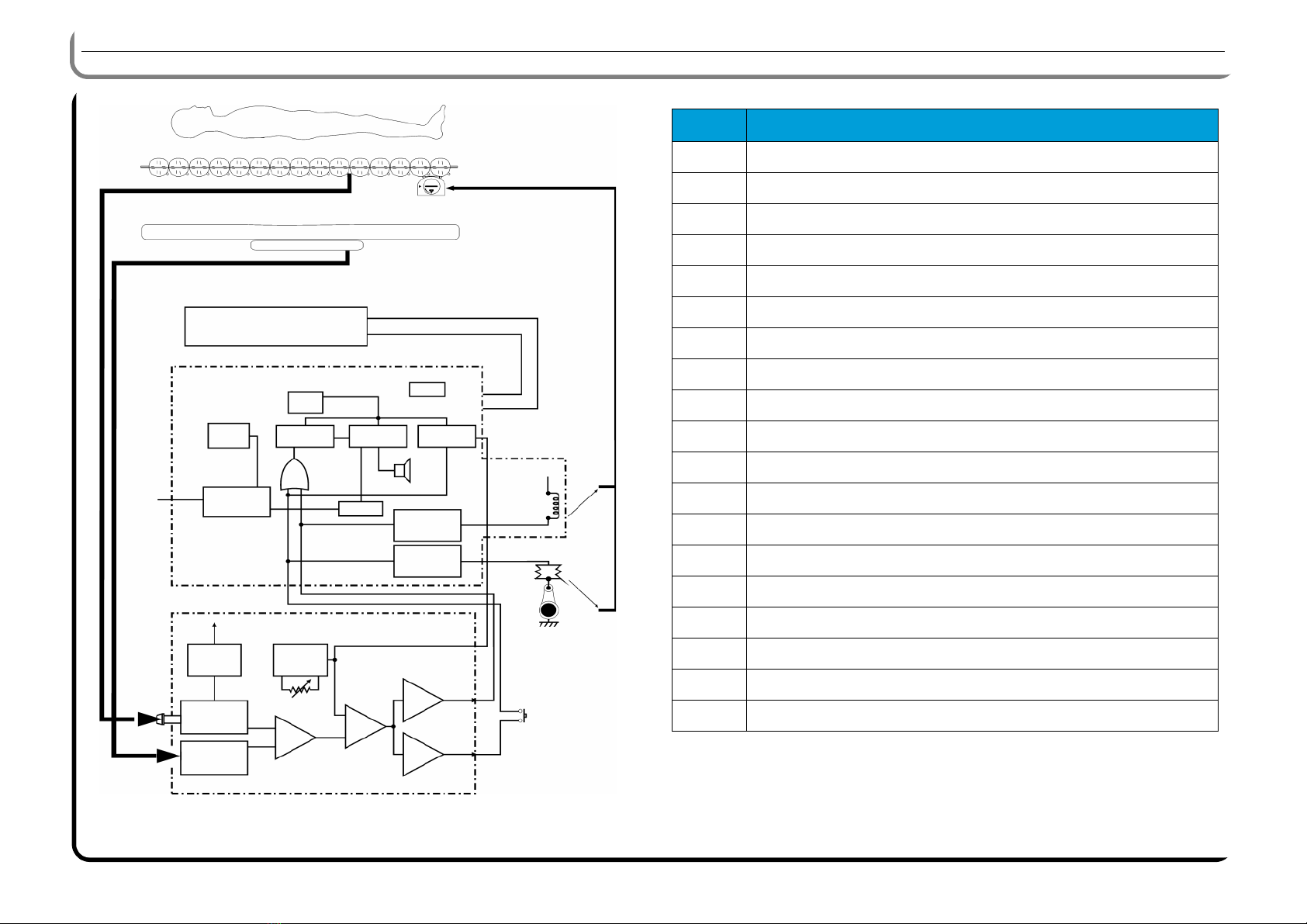

Figure 1-5. Overview Table 1-7. General description

PATIENT

Sensor

Valve control board

Power supply PCB

Regulation PCB

AIR

1

8

6

7

10

11

Mains supply

9Solenoid

Compressor

12

13

15

17

14

AIR

3

2

45

16

18

19

Item Name

1Clock

2Battery

3 Malfunction alarm time delay

4 Alarm silence time delay

5 Compressor override time delay

6Alarm

7 Mains power alarm

8 On/Off switch

9 +12V power

10 Leak control

11 Compressor control

12 Power supply

13 Air pressure transducer

14 Sensor signal conditioning

15 Set point adjustment

16 Amplifier

17 Integrator

18 High comparator

19 Low comparator

Operating principle

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 1 - 7

3

4

2

1

Mechanical subsystem

CPR valve

The CPR valve is at the foot of the mattress. Turn the yellow valve clockwise

(A) to activate the CPR. Activating the CPR deflates the mattress in less than

20 seconds.

Turn the yellow valve (B) anti-clockwise to its original position to deactivate

the CPR.

Seat cushion connector

The seat cushion connector used to inflate the cushion is on the left-hand side

of the control unit. It is available as an option.

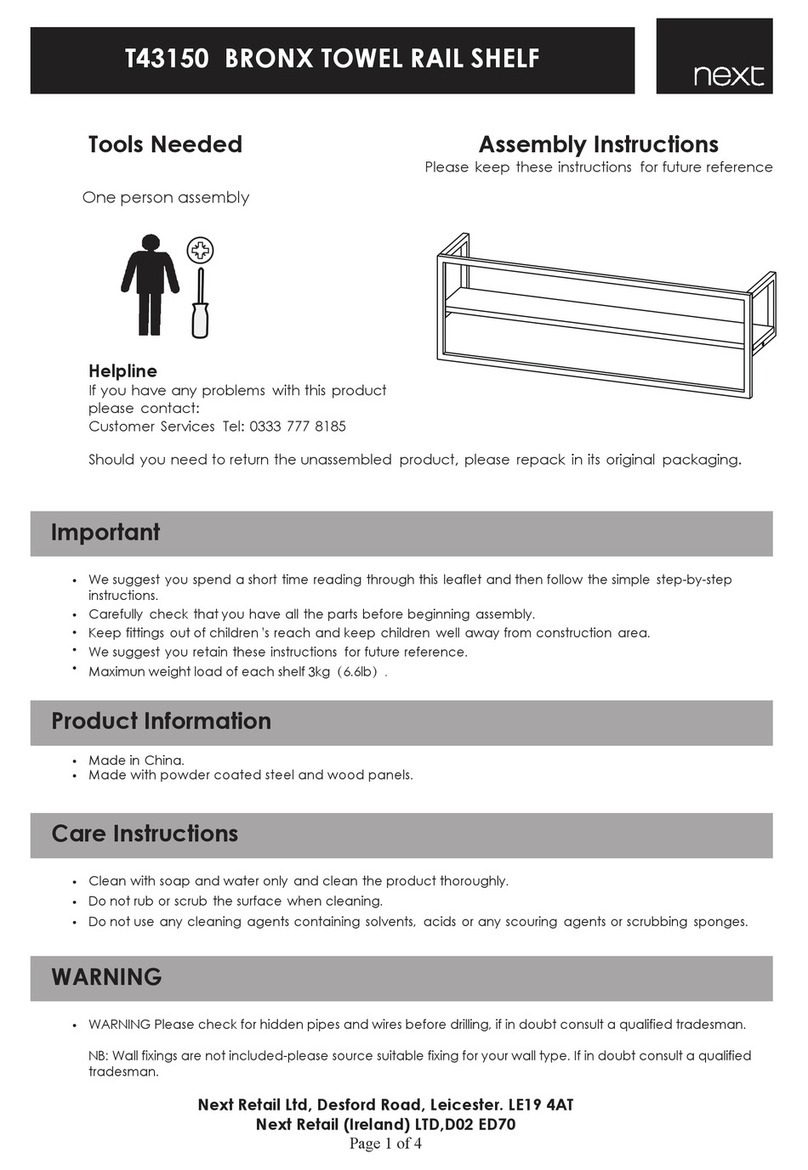

Figure 1-6. Wiring and electrical distribution

AB

Sensor

Control PCB

Power supply PCB

1 Phase - 230VAC

2 Spare

3 Spare

4 Spare

5 Neutral - 230VAC

J1 - Mains power

Compressor

1 Neutral - Compressor

2 Spare

3 Spare

4 Spare

5 Phase - Compressor

J2 - Compressor

1 On/Off switch LED

2 On/Off switch

3 Inflate cushion

4 Inflate cushion LED

5 Silence alarms

6

7 Mains fault alarm LED

8 Malfunction alarm LED

9 +5VDC

10 +12VDC

J3 - Control panel

Operating principle

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 1 - 8 Primo™Service Manual - 171636(1)

Electric subsystem

All the major systems are protected by fuses.

The fuses are located:

• on the mains power socket (See “Replacing the mains socket fuse” page

3-2);

• at input of mains transformer, marked F1 on the power PCB (See

“Replacing the power PCB fuses” page 3 - 5);

• at output of solid-state relay of the compressor, marked F2 on the power

PCB (See “Replacing the power PCB fuses” page 3 - 5).

The I-mmersion™control circuit constitutes the heart of the system:

• It automatically compensates for patient/bed position changes and

supports the patient at the optimal pressure.

• It automatically corrects the pressure in the bladders.

• It automatically compensates most variations due to external parameters.

Control unit

The control unit contains a rechargeable battery on the power PCB. It powers

the mains supply alarm in the event of a power cut.

The control unit panel is the main means of controlling the Primo™. It

contains the minimal functions and provides the user with feedback on the

status of the device and any malfunctions that may occur.

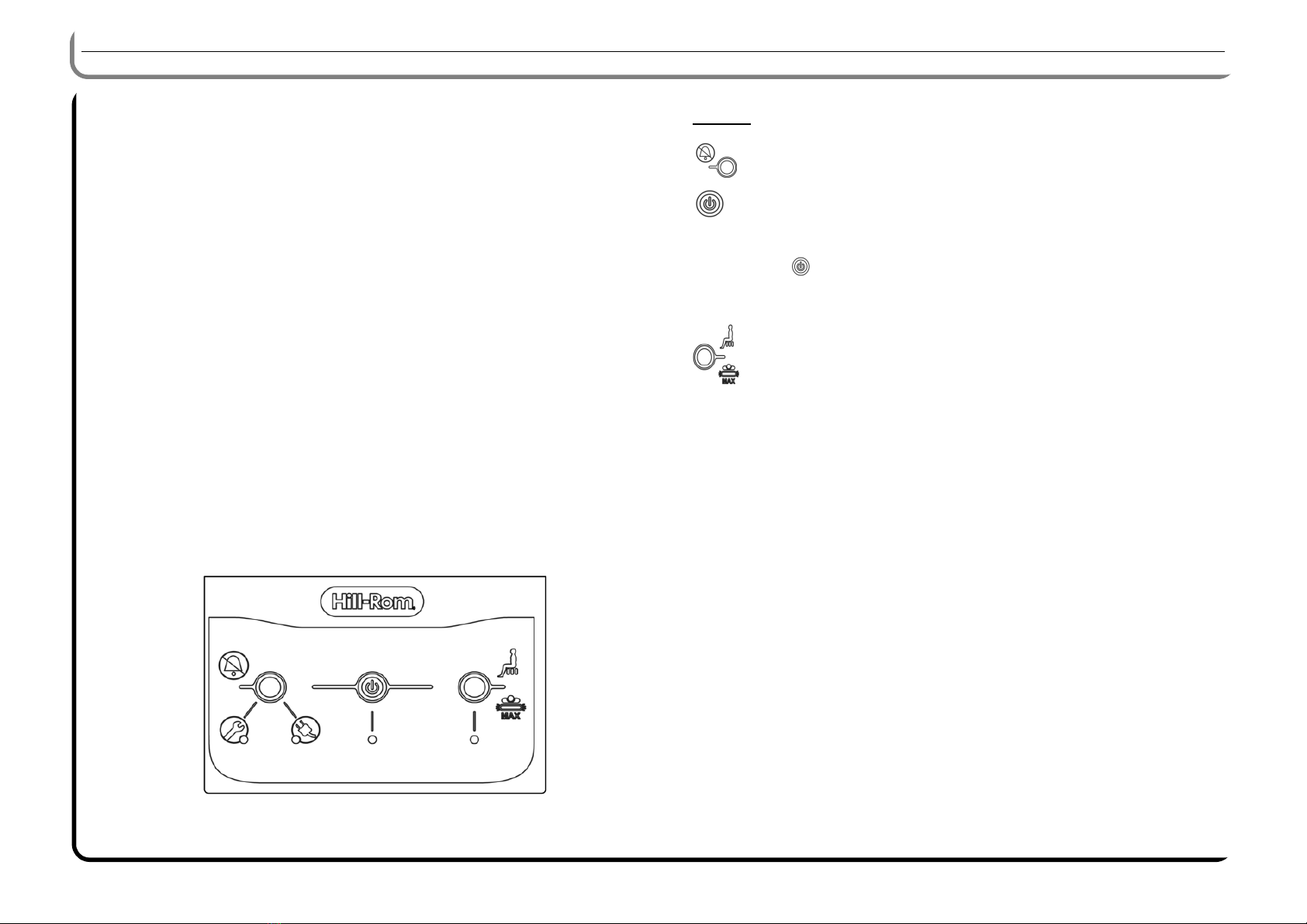

Figure 1-7. Control unit panel

Buttons and indicator lights

Buttons

1 - Audio alarm silence:

deactivates the Mains fault and Malfunction audio alarms.

2 - On/Off.

NOTE:

To switch off the mains power supply:

press to cut out the battery. In this case, no mains power supply

fault alarms will be raised;

Unplug the device from the wall socket.

3 - Maximum inflate:

increases the pressure in the mattress to the maximum value for

5 minutes and automatically returns to therapeutic mode.

Is also used to inflate the seat cushion.

ABCD

123

Operating principle

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 1 - 9

3

4

2

1

Indicators / alarms

(see figure 1-7 page 1-8)

A - Malfunction alarm:

the audio alarm sounds and the yellow visual alarm lights up after

about 10 minutes, when:

• the sensor is faulty;

• the sensor is disconnected;

• CPR mode is active;

• the mattress is damaged (tears, leaks, damaged couplings, etc).

The audio alarm sounds and the yellow visual alarm lights up after

about 20 minutes, when:

• the pressure in the mattress drops below 4″H2O +/- 0.8"H2O

(10 mbar +/- 2 mbar);

B - Mains power fault alarm:

The audio alarm sounds and the yellow visual alarm lights up

immediately, in the event of:

• electric power cut;

• damaged power supply cable;

• accidental disconnection of the power supply cable;

• fuse on the mains power supply socket, or fuse F1 on the power

supply PCB damaged;

• transport.

C - On/Off indicator light:

the green light comes on when the control unit is on.

D - Inflation indicator:

the green light flashes for 5 minutes as the mattress is inflated.

I-mmersion™sensor

The I-mmersion™sensor, which has its own PCB, uses resistive variation due

to the applied force. When the patient's sacrum presses against the mattress,

this pressure is transmitted to the sensor as a force. The variation in the

resistivity of the sensor is measured. A signal is then sent to the control unit to

deflate or inflate the mattress, until the pressure in the mattress is equal to the

pressure of the sensor.

By calibrating the balance of the I-mmersion™sensor, the servo-control

always optimizes the support of the patient, irrespective of their weight or

position (within the limits specified in page 1-5).

CPR valve

In CPR mode, the regulation functions normally, the compressor remains

under control, but not the leak solenoid.

The yellow visual alarm lights up

to indicate that that the pressure is low

.

A low-priority alarm sounds

immediately, intermittently and at a moderate volume.

Pneumatic subsystem

The air is drawn into the control unit through the air filter. The air filter limits

the ingress of dust, which could clog the pneumatic circuit. The air then flows

into the compressor inlet.

When the air leaves the compressor, it is distributed between the bladders in

the mattress, the mattress/seat cushion coupling and the pressure relief valve

on the electric power supply PCB.

Two-tier mattress

The mattress is made up of two levels:

• a therapeutic mattress;

• a foam sub-mattress, which includes the sensor unit, and a lower cover

that includes the sensor.

The therapeutic mattress is a single piece made up of a series of 15 airtight

bladders. The air pressure in these bladders is the same as the pressure in the

sensor in the lower cover.

The I-mmersion™detector is located beneath the sacrum zone of the

therapeutic mattress.

Regulatory requirements

Chapter 1: Introduction

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 1 - 10 Primo™Service Manual - 171636(1)

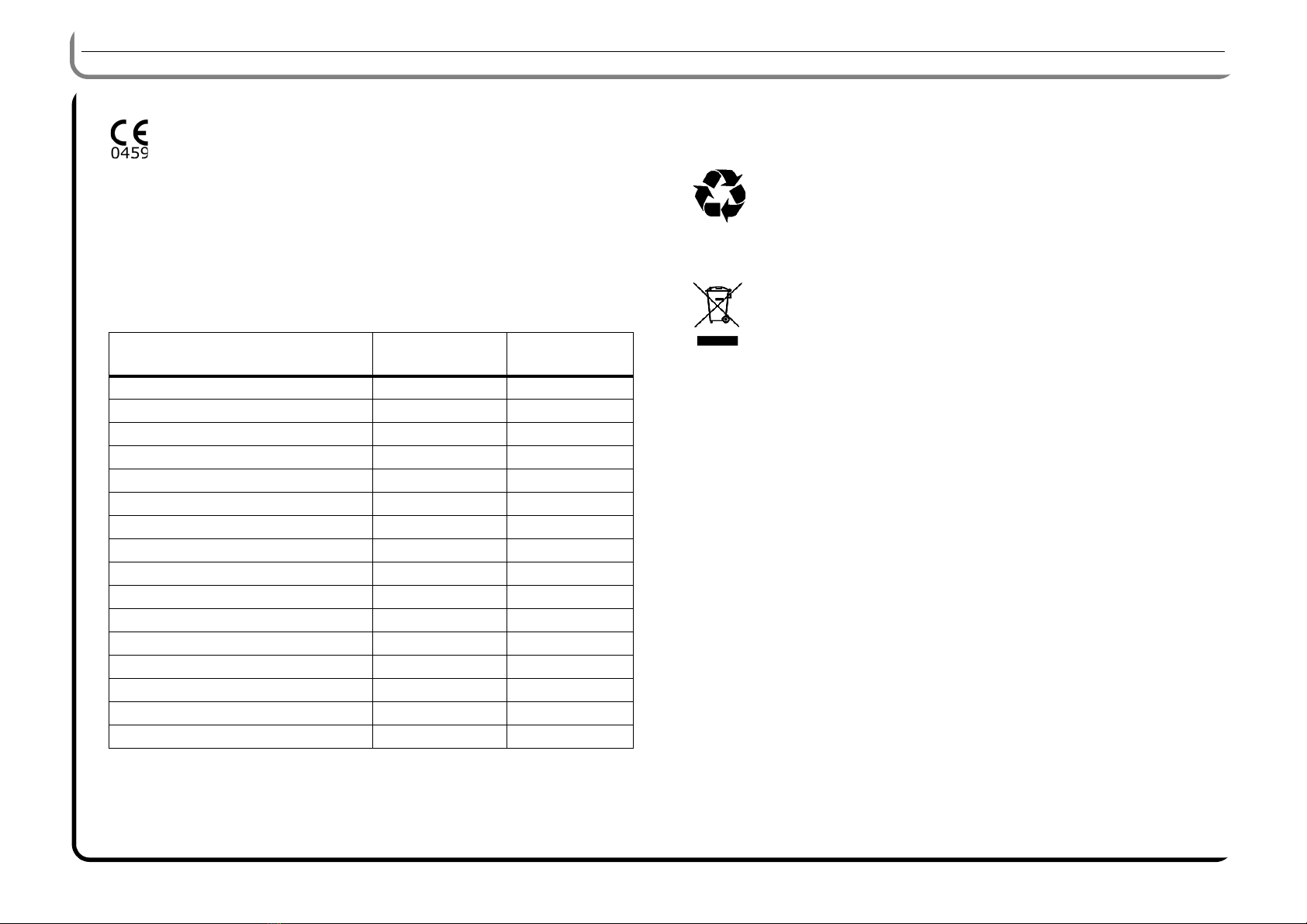

Regulatory requirements

The Primo™is a class IIa medical device that complies with the

requirements of Directive 93/42/EC and its amendments.

The CE mark was applied in 1998.

The Primo™is designed and manufactured in accordance with the following

standards and classifications:

Quality standards:

Technical standards:

End-of-life equipment

The Primo™and its accessories should be cleaned and disinfected before

de-commissioning.

Decommissioned equipment materials (plastics, electrical

components, etc.) must be recycled in accordance with local

recycling regulations. Always meet the applicable demands and local

rules relating to environmental protection, in particular for waste

from medical devices.

Do not dispose of electric and electronic equipment in the waste bin

(as per directive 2012/19/EC).

Never discard the batteries or accumulators of your device. They

may contain substances and metals that are hazardous for the

environment and health (as per Directive 2006/96/EC).

- ISO 9001: 2008 - ISO 13485: 2012 - ISO 14001: 2004

Name P02033/P02034/

P02044

P02047

EN IEC 60601-1: 2006 YES YES

EN IEC 60601-1-2: 2007 YES YES

EN IEC 60601-1-6: 2010 YES YES

EN IEC 60601-1-8: 2007 YES YES

EN IEC 60601-1-11: 2010 YES YES

EN ISO 14971: 2012 YES YES

EN ISO 10993-1: 2009 YES YES

EN ISO 10993-5: 2010 YES YES

EN ISO 10993-10: 2009 YES YES

EN ISO 980: 2009 YES YES

EN 597-1: 1995 YES YES

EN 597-2: 1995 YES YES

SS 876 00 01 (NT FIRE 037) YES YES

UNI 9175: 2008 (Class 1 IM) NO YES

BS 6807: 2006, Clause 9, Ignition/5 NO YES

BS 7177: 1996 (Medium hazard) NO YES

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 2 - 1

3

4

2

1

Chapter 2

Troubleshooting Procedures

Safety recommendations

Never modify this device without Hill-Rom's prior written consent.

Only facility-authorized personnel should perform maintenance.

Changes made by unauthorized personnel may result in damage to the

equipment and/or serious injury to staff or users.

Before maintenance or servicing works:

• Check that the brakes are applied on the bed on which the mattress is

installed.

• Lock out all electrical functions.

• Unplug the device.

• Secure the mattress support platform and take whatever steps are

necessary to prevent any movement.

Required tools

The following tools are required to troubleshoot the Primo™therapeutic

mattress:

• clamping pliers (P/N: G01008);

• digital pressure gauge kit (P/N G05003);

• diagnostic tester (P/N G05002);

• 25kg test load (P/N G02004).

For details of the list of tools, refer to the spare parts catalog (P/N: 169854).

NOTE:

Refer to the following at the start of each RAP if necessary:

• "Glossary of abbreviations" page 1-1 for the meaning of the

abbreviations used in this manual.

Diagnostic tester

The diagnostic tester is used to detect fault signals between the control unit

and the sensor. Connector on the normal connection of the CPR valve

(see figure below).

Figure 2-1. Connection of the diagnostic tester to the CPR valve

Getting Started

Chapter 2: Troubleshooting Procedures

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 2 - 2 Primo™Service Manual - 171636(1)

The diagnosis tester is used to:

• measure the 12 V DC supply voltage of the I-mmersion sensor;

• check the inflation signal sent by the I-mmersion sensor;

• check the deflation signal sent by the I-mmersion sensor;

• check the temporary inflation signal sent by the power PCB when the

seat cushion inflate function is activated.

Figure 2-2. Indicator lights (LED) on the diagnostic tester

Getting Started

Start all of the procedures in this Chapter at step 1. Follow the indicated order.

Each step assumes that the preceding steps have been correctly completed.

Each step corresponds to the normal operation of the product. Please answer

"Yes" or "No" to the question. If more than one component is listed, replace

them in the given order, and re-install the original component that was found

to be OK.

1. To begin gathering information about the problem, start with the initial

actions.

2. Perform functional checks to locate/identify a problem and check the

repair after every corrective action (e.g., replacing or adjusting a part,

installing a cable).

3. To verify the repair, perform the final actions after the function

checks.

If the troubleshooting procedures do not isolate the problem, call your

national Hill-Rom Technical Support (see back cover) for assistance.

NOTE:

The purpose of the proposed troubleshooting method is to limit as much as

possible the number of spare parts required and costs when analyzing the

failure.

Initial Actions

Chapter 2: Troubleshooting Procedures

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 2 - 3

3

4

2

1

Initial Actions

Use the initial actions to gather information from operators concerning

problems with the Primo™. Note the symptoms and all other information

concerning the problem that the operator describes. This information helps

identify the probable cause.

Problem/Solution Table

If the problem can be easily identified, use the following tables to determine

the appropriate troubleshooting procedure.

Table 2-1. Problem/Solution Table

Final actions

1. Perform the required preventive maintenance procedures. Refer to the

"Preventive maintenance form" in the PM-PDI manual (P/N: 172559).

2. Complete all required administrative tasks.

Someone who can explain the problem is

available.

Is the problem a result of improper

operator action?

Ask this person to demonstrate or explain

the problem.

The problem can be

duplicated.

Instruct the operators to refer to the

procedures in the User Manual of the

Primo™.

See ”Operational checks”

page 2-5

See "Problem/Solution Table"

page 2-3

Has the faulty function been identified?

Problem Solution

The system does not start “RAP 2.1 Electric power supply fault”,

page 6

The audible mains fault alarm does not

sound

“RAP 2.2 Mains power supply alarm

fault”, page 7

The compressor does not start “RAP 2.3 Compressor fault”, page 8

The compressor does not stop “RAP 2.4 Leak”, page 9

The audible malfunction alarm does

not sound

“RAP 2.5 Malfunction alarm fault”,

page 10

Preventive maintenance instructions

Chapter 2: Troubleshooting Procedures

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 2 - 4 Primo™Service Manual - 171636(1)

Preventive maintenance instructions

Refer to the “Preventive maintenance and Pre-Delivery Inspection Instructions” (P/N: 172559).

The frequency of inspections must be adapted to the general condition of the product and its use, for example, if the overlay is used by heavy patients. It is the

responsibility of the facility to implement a preventive maintenance program for the mattress functions under its conditions of use.

The mattress and accessories should be inspected at least once a year to keep them in good condition and working properly.

Every three years, it is preferable to ask Hill-Rom After-Sales Service or a Hill-Rom approved supplier to inspect the device in order to keep it in safe and good

working order over time. Depending on the maintenance operations and observations, the date of the next inspection must be recommended every time the bed is

serviced.

In order to benefit from optimal and rapid service when calling Hill-Rom about your Primo™, provide the serial number of the system about which you are calling.

Operational checks

Chapter 2: Troubleshooting Procedures

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

Primo™Service Manual - 171636(1) Page 2 - 5

3

4

2

1

Operational checks

Operational checks

Connect the system.

Does the compressor

stop after about 20

minutes?

Does the On/Off

indicator light come

on? "RAP 2.1 Electric power

supply fault" page 2-6

"RAP 2.2 Mains power

supply alarm fault" page

2-7

The compressor starts.

Activate the CPR valve.

Press .

Unplug the device.

The visual and

audible mains

fault alarms are

activated.

The visual and audible

mains fault alarms are

activated after 10 minutes.

Perform the Final actions on

page 2-3.

"RAP 2.3 Compressor

fault" page 2-8

Is the pressure

stable between

7

and 9" H

2

0

?

"RAP 2.4 Leak" page 2-9

"RAP 2.5 Malfunction alarm

fault" page 2-10

Connect the pressure gauge to

the seat cushion connector.

Activate the CPR valve for 10

seconds then deactivate it.

Replace the (see procedure

3.13 page 3-11) sensor.

The audible alarm

sounds.

Replace the power supply PCB

(see procedure 3.6 page 3-5).

Connect the system.

The problem is solved.

The problem is solved.

Contact your

Hill-Rom

representative (see last

page of the manual).

Operational checks

Chapter 2: Troubleshooting Procedures

PROPRIETARY AND CONFIDENTIAL DRAFT September 24, 2012

2

3

Page 2 - 6 Primo™Service Manual - 171636(1)

RAP 2.1 Electric power supply fault

RAP 2.1

Electric power supply fault

Disconnect the device

from the mains.

Connect the device again

The fuse is faulty.

Inform the customer that

the connector is faulty.

Check the fuse in the

control unit (see procedure

3.1 page 3-2).

Connect the device to

another functional power

source.

Perform the Operational

checks on page 2-5.

Replace the fuse (see

procedure 3.5 page 3-5).

The wall socket is live.

The On/Off indicator

light comes on.

The On/Off indicator

light comes on.

Disconnect the device from

the mains.

Open the control unit (see

procedure 3.5 page 3-5).

The mains socket is

disconnected (J1) or

damaged?

Replace the fuse.

Connect the device

Close the control unit.

Replace the power supply

PCB(see procedure 3.6

page 3-5).

Connect the mains socket to

J1 (see figure 1-6 page 1-7)

or replace it, where

appropriate (see procedure

3.9 page 3-7).

Fuse F1 is faulty.

Replace the power

cable.

The On/Off indicator

light comes on.

Replace the control PCB

(see procedure 3.4 page

3-4).

Other manuals for Primo P02033

1

This manual suits for next models

3

Table of contents

Other Hillrom Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

BIG FURNITURE WAREHOUSE

BIG FURNITURE WAREHOUSE NORDICA 2 DRAWER LOW COFFEE TABLE Assembly instructions

Vivo

Vivo MOUNT-KB05GP instruction manual

Teknik

Teknik Boulevard Cafe Series Assembly instructions

Home Decorators Collection

Home Decorators Collection Manhattan WSHCSSU Assembly instructions

Novogratz

Novogratz Bushwick 4044449N manual

Great Little Trading

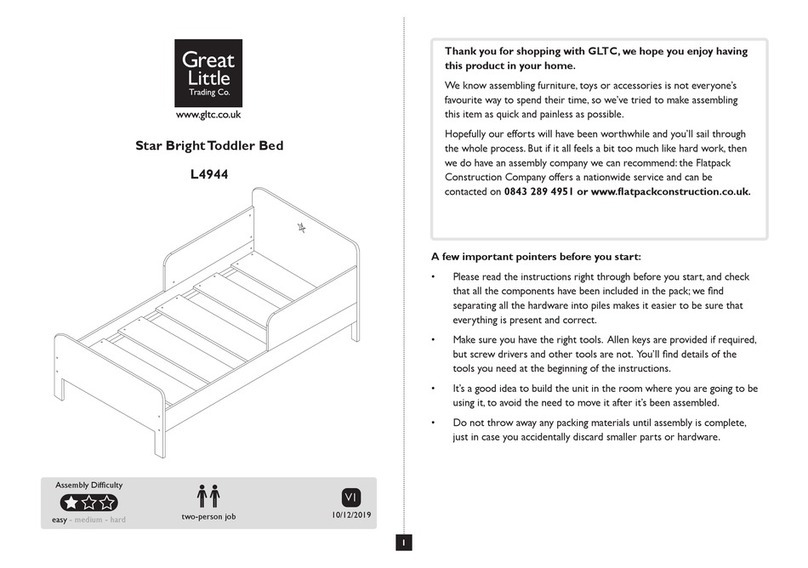

Great Little Trading Star Bright L4944 quick start guide