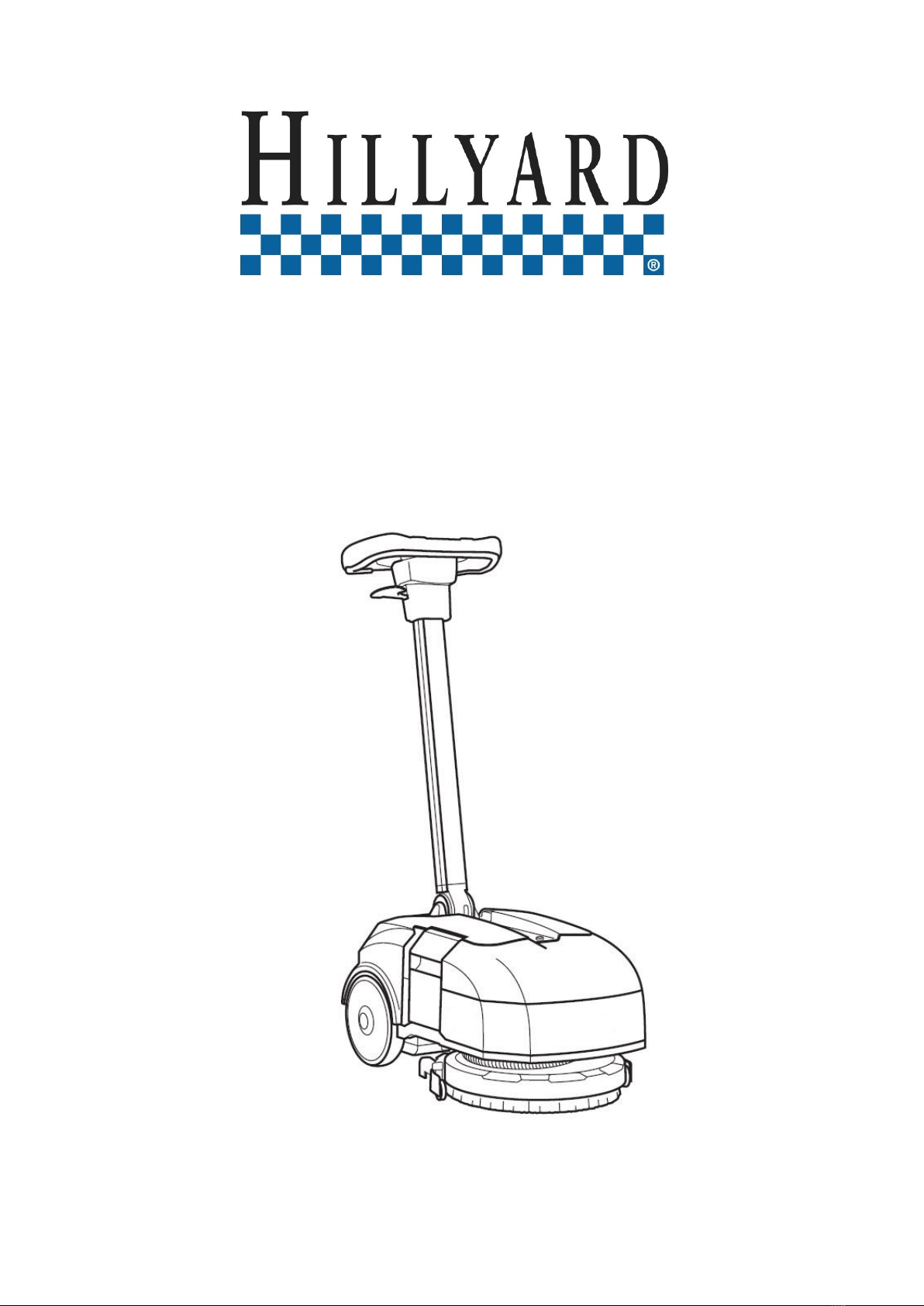

Hillyard TRIDENT XM13SC User manual

SERVICE MANUAL

TRIDENT XM13SC

Version: AB

Date: October 4, 2017

Document Number:10055555

Contents

I Product Introduction 4

1 Serial Number and Technical Support 5

1.1 The Serial Tag ................................. 5

1.2 Serial Tag location ............................... 5

2 Main Technical Features 6

II Anomalies Resolution Guide 7

3 Troubleshooting Guide 8

3.1 Basic Guide ................................... 8

3.2 Advanced Guide ................................ 13

4 Disassembling Procedures 19

4.1 Electrical Installation ............................. 20

4.2 Mechanical Friction System ......................... 22

4.3 Drying System ................................. 23

4.4 Frame and Traction System ......................... 24

4.5 Solution Delivery System ........................... 25

III Machine Description 26

5 Electrical System 27

5.1 Structure .................................... 27

5.2 Description ................................... 27

5.3 Location of Electrical components ...................... 28

5.4 Maintenance and Checks ........................... 32

5.5 Programming .................................. 33

5.6 Alarm Table ................................... 36

5.7 Menu tables ................................... 37

6 Mechanical Rubbing System 40

6.1 Structure .................................... 40

6.2 Description: ................................... 40

6.3 Maintenance and checks ........................... 41

2

7 Drying System 43

7.1 Structure .................................... 43

7.2 Description ................................... 43

7.3 Adjustments .................................. 44

7.4 Maintenance and Checks ........................... 44

8 Machine Frame and Traction System 47

8.1 Structure .................................... 47

8.2 Description ................................... 47

8.3 Maintenance and Checks ........................... 47

9 Cleaning Solution Supply System 48

9.1 Structure .................................... 48

9.2 Description: ................................... 48

9.3 Maintenance and Checks ........................... 49

10 Consumable & Recommended Spare Parts 50

10.1Consumable Spare Parts ........................... 50

10.2Recommended Spare Parts .......................... 51

3

Part I

Product Introduction

4

Chapter 1

Serial Number and Technical Support

1.1 The Serial Tag

1.2 Serial Tag location

To have access to the Serial Tag it is sufficient to remove both tanks.

The Serial Number is an extremely important information which has to be provided

each time a Technical Support is required or is necessary to buy spare parts or

accessories. The serial number is the only way to identify the machine by model,

production date type equipments in general.

5

Chapter 2

Main Technical Features

Technical Data

TECHNICAL DESCRIPTION U/M XM13SC

Working Width in 11

Working Capacity, up to ft2

h9687

Brush Diameter/Revolutions φin-rpm 11-150

Brush Motor Voltage/Power V-W 36-90

Max Weight on brush lb 22

Total Power W 255

Squeegee Width in 12,8

Solution Tank gal 0,8

Recovery Tank gal 1

Vacuum Motor Voltage/Power V-W 36-150

Machine Length (Handlebar Up - Down) in 21,8-35,2

Machine Height (Handlebar Up - Down) in 41,3-13,8

Machine Width in 14,8

Sound pressure level (ISO 11201) LpA dB (A) ≤76

Hand vibration level (ISO 5349) m

s2≤2.5

Weights and Pressures1

TECHNICAL DESCRIPTION U/M XM13SC

Machine Weight (Machine + Brush + Squeegee) lb 40

Gross Weight of the machine in work conditions

(Machine + Battery+ Water + Brush + Squeegee)

lb 50

1Weight and Pressures depends on how much water there is in the tanks.

6

Part II

Anomalies Resolution Guide

7

Chapter 3

Troubleshooting Guide

3.1 Basic Guide

3.1.1 Electrical system: what to do if. . .

The machine doesn’t switch on

1. The main switch is not pushed ⇒Push the main switch.

2. The battery doesn’t work properly ⇒Refer to the proper section (see section

3.1.1 at page 8).

3. The problem is not solved ⇒Refer to the Advanced Guide (see section

3.2.2 at page 14).

The battery don’t work properly

1. The battery is not properly con-

nected

⇒Insert the battery until the end posi-

tion clicks.

2. The battery is discharged ⇒Perform a complete charge cycle.

3. The battery is faulty ⇒Refer to the Advanced Guide (see section

3.2.3 at page 15).

4. The battery charger doesn’t work ⇒Check the proper section (see section 3.1.1

at page 8).

8

The battery charger doesn’t work

1. The battery charger is not con-

nected to the power supply

⇒Connect the charger to a supplied

electric socket.

2. The charger has the power switch

in position 0

⇒Move the power switch in position 1.

3. The battery charger has the Red

LED blinking

⇒The battery charger is in error con-

ditions, verify the alarm tables and

solve the issue by following the re-

lated instructions (see section 5.3.5 at page

32).

4. The battery charger plugged in and

turned on does not activate the

Green LED (electrical continuity)

⇒Replace the battery charger.

5. The battery charger plugged in and

turned on with battery inserted

does not activate the Red LED

(charging)

⇒Make sure the battery is properly

positioned inside the slot and the

terminals have a good contact.

The battery may be already

charged.

The display shows an alarm message

1. The display shows an alarm mes-

sage

⇒Check what alarm message is

shown and solve the related issue

by following the proper instructions

(see section 5.6.1 at page 36).

The machine has a very limited working autonomy

1. The battery is discharged ⇒Perform a complete charge cycle.

2. The battery have been working for

several cycles

⇒Replace the battery.

9

3.1.2 Mechanical scrubbing system: what to do if. . .

The machine doesn’t clean well

1. The machine is switched off ⇒Switch on the machine.

2. The machine doesn’t switch on ⇒Refer to the proper section (see section

3.1.1 at page 8).

3. The display shows an alarm mes-

sage

⇒Check what alarm message is

shown and solve the related issue

by following the proper instructions

(see section 5.6.1 at page 36).

4. The switch ”Auto” is not pressed ⇒Press the ”Auto” switch.

5. The brush motor is not working ⇒Refer to the Advanced Guide (see section

3.2.5 at page 16).

6. The brush is not properly engaged ⇒Release and engage properly the

brush.

7. The solution flow rate is not correct

or not enough

⇒Refer to the proper section (see section

3.1.4 at page 12).

8. The detergent doesn’t fit the type of

dirt

⇒Replace the detergent with a proper

one.

10

3.1.3 Drying system: what to do if. . .

The machine doesn’t dry well

1. The machine is switched off ⇒Switch on the machine.

2. The machine doesn’t switch on ⇒Refer to the proper section (see section

3.1.1 at page 8).

3. The vacuum motor doesn’t work ⇒Refer to the Advanced Guide (see section

3.2.6 at page 18).

4. The machine is in ”ECO” mode ⇒Set up the machine as per standard

configuration.

5. The display shows an alarm mes-

sage

⇒Check what alarm message is

shown and solve the related issue

by following the proper instructions

(see section 5.6.1 at page 36).

6. The recovery tank is full ⇒Empty the recovery tank following

the proper procedure.

7. The squeegee is lifted up from the

floor

⇒Lower down the squeegee.

8. The squeegee rubber blades are

worn out or broken

⇒Rotate or replace the squeegee rub-

ber blades (see section 7.4.1 at page 44).

9. The squeegee is not properly ad-

justed

⇒Adjust the squeegee properly follow-

ing the proper procedure (see section 7.3.1

at page 44).

10. The squeegee vacuum chamber or

the adapter is stuck or dirty

⇒Clean the squeegee.

11. The vacuum hose is stuck or bro-

ken

⇒Clean or replace the vacuum hose.

12. The vacuum hose is not properly

fitted in

⇒Connect the vacuum hose properly.

13. The intake manifold is stuck or bro-

ken

⇒Clean or replace the intake manifold.

14. The vacuum cover is not well posi-

tioned or is missing

⇒Position properly the vacuum cover.

15. The vacuum cover gasket doesn’t

adhere properly

⇒Replace the vacuum cover.

11

3.1.4 Solution delivery system: what to do if. . .

The delivered solution is not correct or not enough

1. The machine is switched off ⇒Switch on the machine.

2. The machine doesn’t switch on ⇒Refer to the proper section (see section

3.1.1 at page 8).

3. The solution tank is empty ⇒Fill up the solution tank.

4. The solution filter is missing ⇒Restore the solution filter in the cor-

rect position (see section 4.5 at page 25).

5. The solution filter is stuck ⇒Clean the solution filter (see section 4.5 at

page 25).

6. The water flow is adjusted at mini-

mum

⇒Increase the water flow adjustment.

7. The water pump doesn’t work ⇒Refer to the Advanced Guide (see section

3.2.7 at page 18).

8. The display shows an alarm mes-

sage

⇒Check what alarm message is

shown and solve the related issue

by following the proper instructions

(see section 5.6.1 at page 36).

12

3.2 Advanced Guide

3.2.1 Electric Cards Overview

Main Card

Handle Control Card

Motor Control Card

13

3.2.2 The Display doesn’t switch ON

1. Check the battery

voltage V≥33

YES ⇒Point 2

NO ⇒Replace the

battery

2. Check the voltage on

the connector J2 V≥33

YES ⇒Point 3

NO ⇒Replace the

cables

3. Check the voltage

J6-Pink / J2-Black V≥33

YES ⇒Point 4

NO ⇒Replace the

main card

4. Check the voltage

J6-Pink / J2-Black V≥33

YES ⇒Point 5

NO ⇒Replace the

cables

5.

Push the main switch

and check the voltage

J6-White / J2-Black

V≥33

YES ⇒Point 6

NO ⇒Replace the

switch

6. Check the voltage

J6-White / J2-Black V≥33

YES ⇒Point 7

NO ⇒Replace the

cables

7.

On the Handle card,

check the voltage on

the connector J4

Yellow & Green

V≥33 YES ⇒Point 8

NO ⇒Point 10

14

8.

On the Handle card,

check the voltage on

the connector J4

Yellow & Brown

V≥1YES ⇒Point 9

NO ⇒Point 11

9.

On the Handle card,

check the voltage on

the connector J4

Yellow & White

V≥1

YES ⇒Replace the

handle card

NO ⇒Point 12

10.

On the Main card,

check the voltage on

the connector J4

Yellow & Green

V≥33

YES ⇒Replace the

cables

NO ⇒Replace the

main card

11.

On the Main card,

check the voltage on

the connector J4

Yellow & Brown

V≥1

YES ⇒Replace the

cables

NO ⇒Replace the

main card

12.

On the Main card,

check the voltage on

the connector J4

Yellow & White

V≥1

YES ⇒Replace the

cables

NO ⇒Replace the

main card

3.2.3 The battery doesn’t work

1. Check the battery

voltage V≥33

YES ⇒Perform a

complete

charge cy-

cle.

NO ⇒Replace the

battery

15

3.2.4 The Display doesn’t show the battery level

All the other devices of the machine are functioning properly

1. Check the voltage

J5-Gray / J2-Black V≥1YES ⇒Point 2

NO ⇒Point 3

2. Check the voltage

J5-Violet / J2-Black V≥1

YES ⇒Replace the

main card

NO ⇒Point 4

3. Check the battery

voltage V≥1

YES ⇒Replace the

cables

NO ⇒Replace the

battery

4. Check the battery

voltage V≥1

YES ⇒Replace the

cables

NO ⇒Replace the

battery

3.2.5 The brush Motor doesn’t work

All the other devices of the machine are functioning properly

1.

Check the voltage in

AC on the connector Y

Blue & Yellow (with

running machine)

V≥25 YES ⇒Point 2

NO ⇒Point 4

2.

Check the voltage in

AC on the connector Y

Blue & Red (with

running machine)

V≥25 YES ⇒Point 3

NO ⇒Point 4

16

3.

Check the voltage in

AC on the connector Y

Yellow & Red (with

running machine)

V≥25

YES ⇒Replace the

motor

NO ⇒Point 4

4.

Check the voltage

on the connector X

Red & Black (with

running machine)

V≥33

YES ⇒Replace the

motor card

NO ⇒Point 5

5.

Check the voltage

on the connector W

Black & Yellow (with

running machine)

V≥0

YES ⇒Point 6

NO ⇒Replace the

motor

6.

Check the voltage

on the connector W

Black & White (with

running machine)

V≥0

YES ⇒Point 7

NO ⇒Replace the

motor

7.

Check the voltage

on the connector W

Black & Green (with

running machine)

V≥0

YES ⇒Replace the

motor card

NO ⇒Replace the

motor

8.

Check the voltage

on the connector J1

Red & Black (with

running machine)

V≥33

YES ⇒Replace the

cables

NO ⇒Replace the

main card

17

3.2.6 The suction Motor doesn’t work

All the other devices of the machine are functioning properly

1.

Check the voltage on

the faston (with

running machine)

V≥33

YES ⇒Replace the

motor

NO ⇒Point 2

2.

Check the voltage on

the connector J1

Gray & Pink (with

running machine)

V≥33

YES ⇒Replace the

cables

NO ⇒Replace the

main card

3.2.7 The Pump doesn’t work

All the other devices of the machine are functioning properly

1.

Check the voltage in

AC on the Pump’s

connectors, Don’t

disconnect the

connectors from the

pump (with running

machine)

V≥8

YES ⇒Replace the

pump

NO ⇒Point 2

2.

Check the voltage in

AC on the connector

J1 Green & Yellow

(with running

machine)

V≥36

YES ⇒Replace the

cables

NO ⇒Replace the

main card

18

Chapter 4

Disassembling Procedures

WARNING:BEFORE TO PERFORM ANY OPERATION DESCRIBED BELOW VERIFY THAT

THE MACHINE TANKS ARE COMPLETELY EMPTY,THE MACHINE HAS TO BE TURNED OFF.

REMOVE THE BATTERY FROM THE MACHINE. AT LAST,VERIFY THAT THE MACHINE IS

IN A TOTALLY SAFE CONDITION.

19

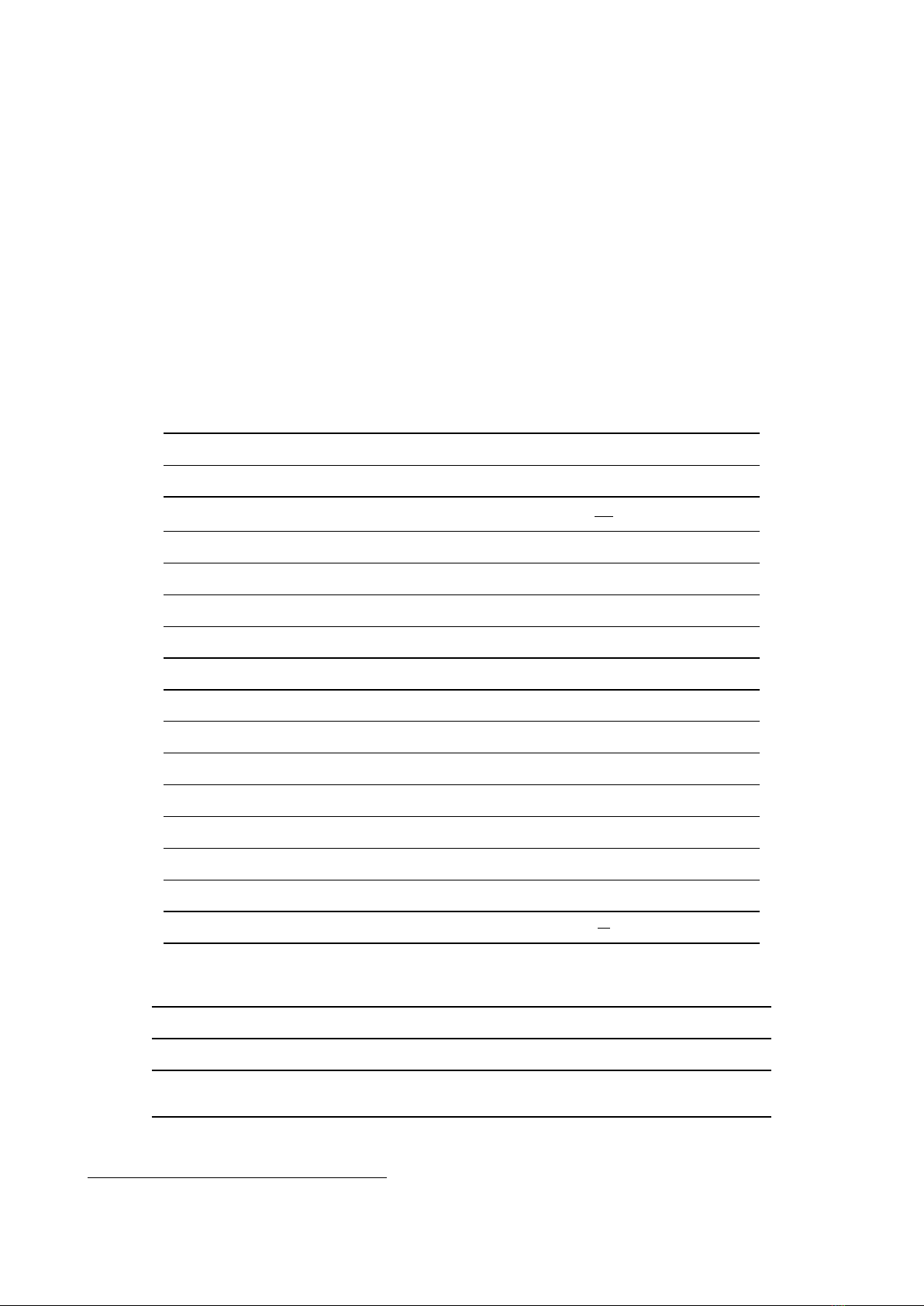

4.1 Electrical Installation

•Put the machine in safe conditions.

•Turn the handlebar forward in hori-

zontal position.

•Separate the lower casing of the

handlebar from the upper casing by

unscrewing the lower screws.

•Disconnect the connecting cable

from the control card and release the

cable from the fastening clamp.

•Remove the screws that secure the

Handlebar Control Card to the up-

per casing and remove the card.

•Remove the lifting handle from the

handlebar stem by unscrewing the

screws (see fig. 4.1.0-1).

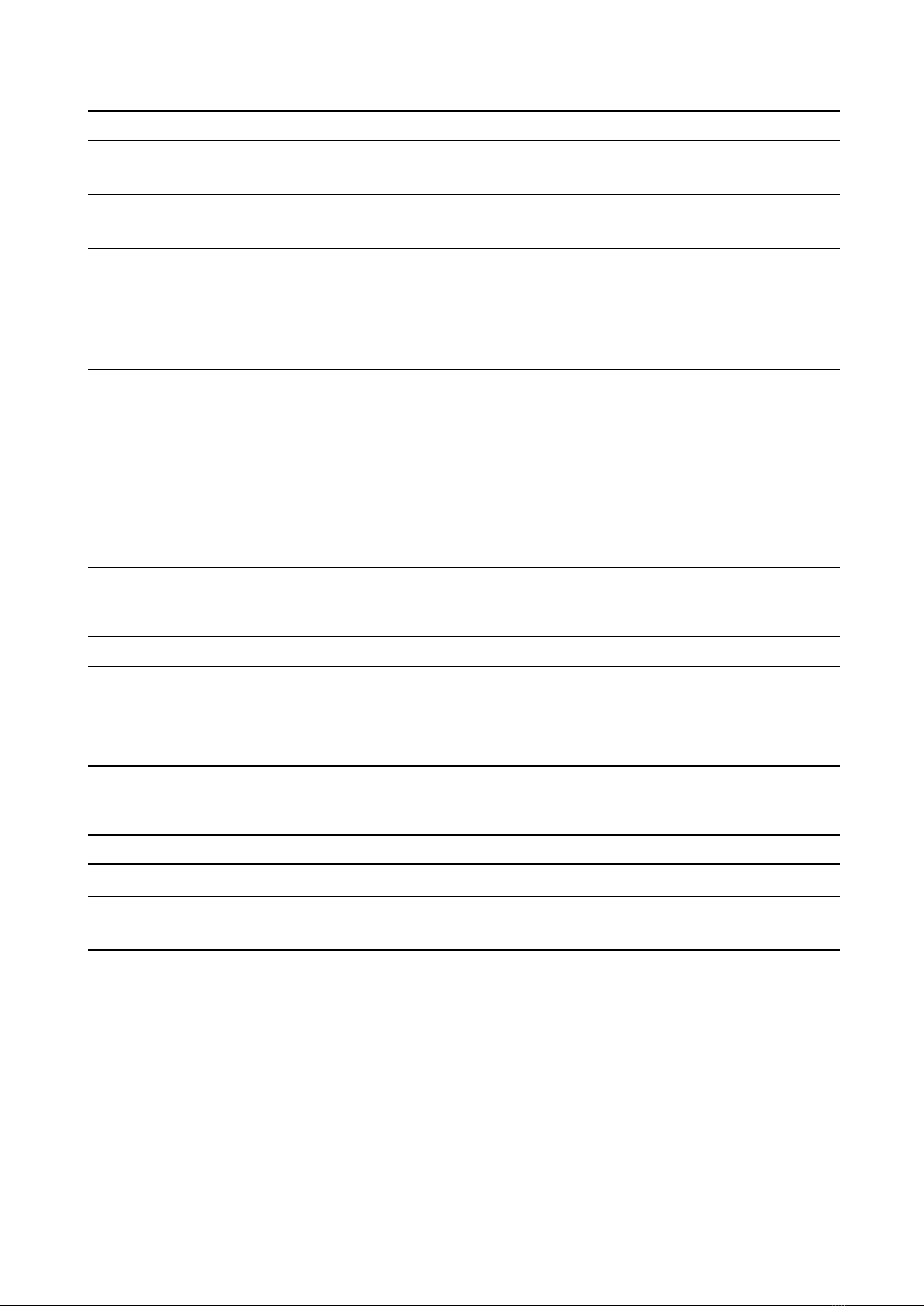

•Release the lock levers of the tanks,

and remove them (see fig. 4.1.0-2).

4.1.0-1 4.1.0-2

•Lay the machine on its side, and

loosen the lower screws of the Up-

per Carter, near the wheels and the

On/Off button.

•Reposition the machine and remove

the upper screws from the front part

of the Upper Carter.

20

Other manuals for TRIDENT XM13SC

1

Table of contents

Other Hillyard Floor Machine manuals

Hillyard

Hillyard Trident BU1500 User manual

Hillyard

Hillyard TRIDENT T26SC PLUS User manual

Hillyard

Hillyard Trident EX8 User manual

Hillyard

Hillyard TRIDENT EX7 User manual

Hillyard

Hillyard TRIDENT EX12 User manual

Hillyard

Hillyard TRIDENT EX20 User manual

Hillyard

Hillyard TRIDENT T26 SC PLUS User manual

Popular Floor Machine manuals by other brands

Nilfisk-Advance

Nilfisk-Advance Hydro-Retriever 2052 Instructions for use

Superabrasive

Superabrasive Lavina 32 Pro user manual

Tennant

Tennant 355E Operator's manual

Kärcher

Kärcher BDS 43/180 C manual

Powr-Flite

Powr-Flite PEB Operator's manual & parts list

Tornado

Tornado 97564 Operation & maintenance manual