2.6 Quickscan detection with accurate depth measurement

Before scanning, the operator is required to enter values for the diameter of the reinforcing bars and the spacing

between the bars. The scan is then carried out as described for Quickscan detection.

2.7 Quickscan recording

Data is recorded automatically as the scanner is moved over the surface of the concrete. This data is subsequently

transferred to the monitor where it can be evaluated and the average depth of cover determined. If the data is

downloaded to a PC, the information can be evaluated, archived and a report printed. Further evaluation options

allow Quickscan recordings to be imported and evaluated automatically, statistical evaluations prepared and scans

displayed in the form of large-area evaluations.

2.8 Imagescan

A reference grid is attached at the area of interest using the adhesive tape supplied. After selecting the Imagescan

mode with the scanner, the rows and columns of the grid are scanned following the instructions on the screen. The

data is transferred to the monitor where the image can be viewed and evaluated. The position of the reinforcing bars

relative to the concrete surface is indicated. Bar diameter can be estimated and bar depth determined. If the data is

downloaded to the PC application, this information can be evaluated as on the monitor, with the additional advantage

of allowing a series of points to be recorded along with associated depth and diameter, and the data saved for

future use. Reports can also be printed. Further evaluation options allow Imagescans to be imported and evaluated

automatically, statistical evaluations prepared and scans displayed in the form of large-area evaluations.

2.9 Blockscan

A reference grid is attached at the area of interest using the adhesive tape supplied. After selecting Blockscan mode,

the user is prompted to select the first area to scan. An Imagescan is then made. After completing the Imagescan, the

user is prompted to select the next area to scan. This should be adjacent to the previous area. Attach the grid and then

scan as before. This procedure can be repeated for up to 3 x 3 Imagescans. The data is transferred to the monitor. The

Imagescans are automatically stitched together to form a larger image. The reinforcement layout can then be viewed

over the whole area. Individual Imagescans can be selected for evaluation by “zooming in”. If the data is downloaded

to the PC application, this information can be evaluated as on the monitor, with the additional advantage of allowing a

series of points to be recorded along with associated depth and diameter, andthedatasavedforfutureuse.Reports

can also be printed.

3 Items supplied, accessories, spare parts

3.1 Items supplied

3.1.1 PS 250 Ferroscan system

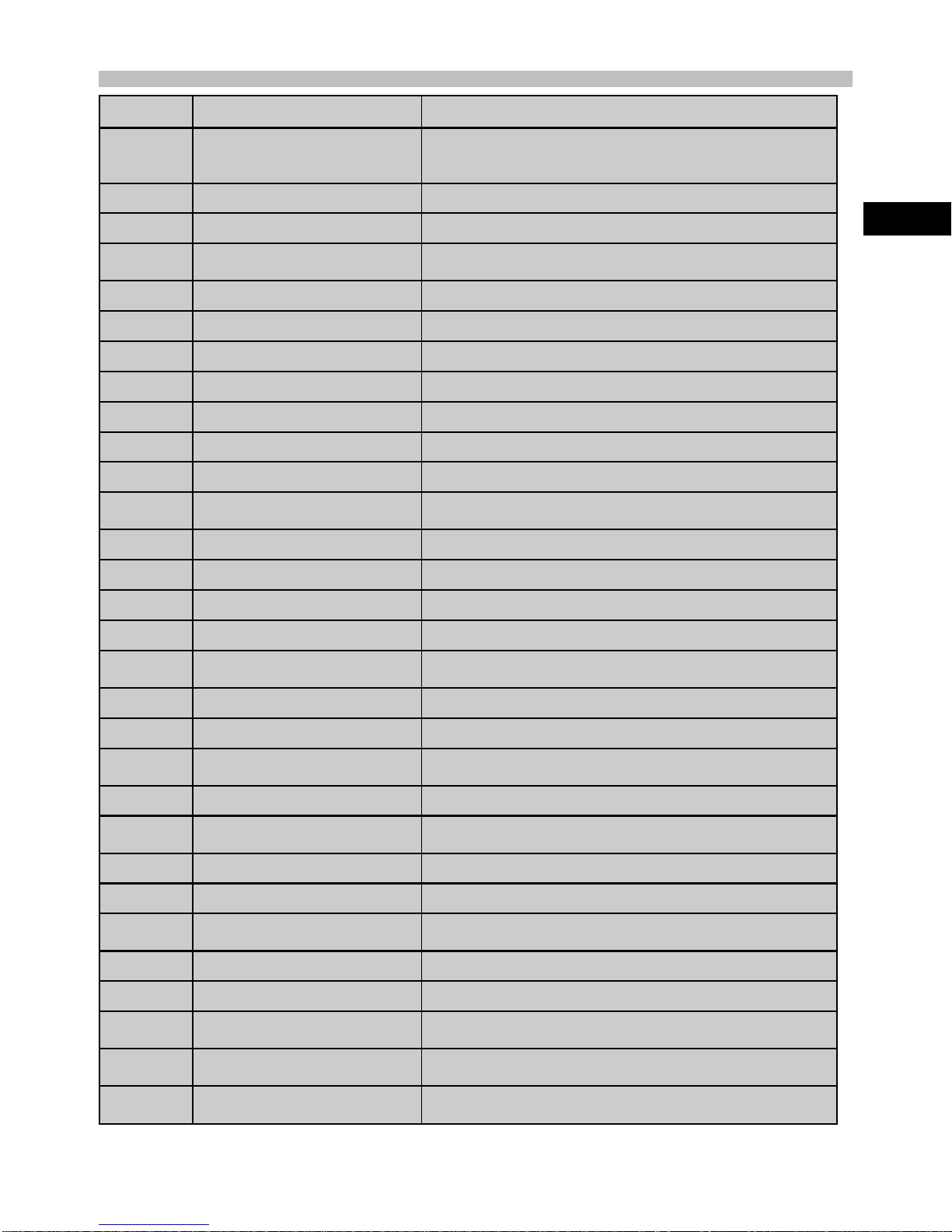

Num-

ber

Designation Comments

1PS 200 S scanner 1

1 PSA 60 soft pouch Soft pouch for the PS 200 S scanner

1PSA 100 monitor1

1 PSA 64 soft pouch Soft pouch for the PSA 100 monitor

1 PSA 63 hand strap For the PS 200 S scanner

1 PSA 55 infrared adapter For temporary storage of data from the PS 200 S scanner

1 PUA 95 Micro USB data cable Data cable for connecting the PSA 55 infrared adapter to a PC

1 PSA 97 data module Contains the operating instructions in electronic form and is used to

update the PSA 100 monitor

1Version depends on the country-specific version of the system ordered.

2May or may not be included in the items supplied, depending on the country-specific version of the system ordered.

en

44

Printed: 07.07.2013 | Doc-Nr: PUB / 5135462 / 000 / 00