Telect 600CB10 Operating and maintenance instructions

Dual-Feed 600A Load

Center Frame

600CB10 & 600CB12 Installation Guide

600CB10 – Front View

600CB10-C – Rear View

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

I

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

Installation Guide Part Number, 136429-2

Applies to: 600CB10 :: 600CB10-C :: 600CB10-VL :: 600CB10-CL :: 600CB12 :: 600CB12-C ::

600CB12-VL :: 600CB12-CL

Copyright 2017, Telect, Inc., All Rights Reserved

Telect and Connecting the Future are registered trademarks of Telect, Inc.

22425 #11 East Appleway Ave.

Liberty Lake, WA 99019

Telect assumes no liability from the application or use of these products. Neither does Telect convey any license under its

patent rights nor the patent rights of others. This document and the products described herein are subject to change

without notice.

Connecting the future for over 30 years

Telect challenges the status quo and looks beyond what is possible in network connectivity and power management.

Founded in 1982, Telect is driven by the principles of innovation and customer service. Headquartered in Liberty

Lake, WA, the privately held company supports a global network of customers with a comprehensive product

portfolio and a values-driven corporate culture.

Our products and solutions are found across communications service-provider networks, data centers and utility

networks around the globe.

At Telect, we pride ourselves on our ability to respond to customer challenges, building a reputation among

communications service providers for delivering solutions uniquely tailored to their needs.

We simplify networks.™

• Custom configured solutions

• Products integrate seamlessly into existing infrastructure

• Exceptional customer service

• Hassle-free warranty

Technical Support

Email: support@telect.com

Phone: 509-926-6000

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

II

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

Table of Contents

1.1 Overview ...........................................................................................................................................................................1

1.2 Installation Guidelines.......................................................................................................................................................2

1.3 Specifications....................................................................................................................................................................2

1.4 Installation Instructions......................................................................................................................................................4

1.5 Parts & Accessories........................................................................................................................................................13

1.6 Interconnections..............................................................................................................................................................15

1.7 Drawings .........................................................................................................................................................................16

List of Figures

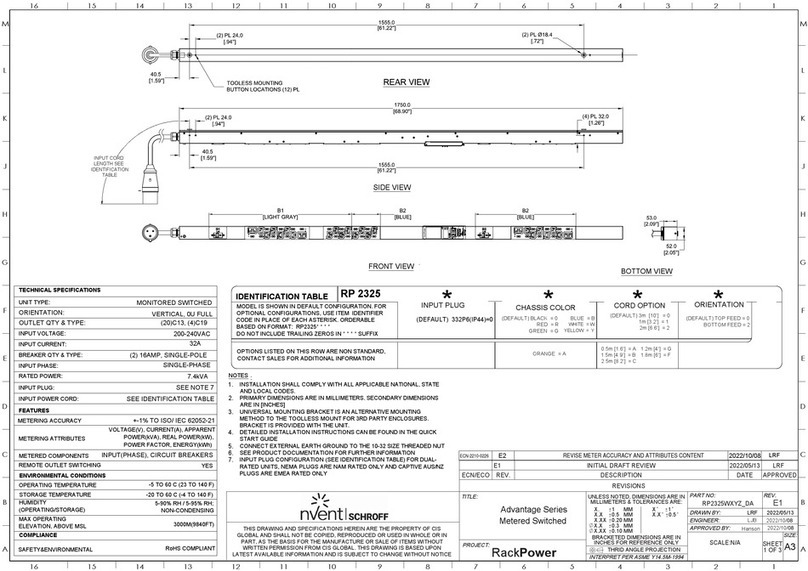

Figure 1 – 600CB10, 19" 10/10 Position Load Center Frame ................................................................................................1

Figure 2 – Installing Load Straps ............................................................................................................................................5

Figure 3 – Alarm Board Location (Bottom View of Side A).....................................................................................................5

Figure 4 – Alarm Board Jumper Settings................................................................................................................................6

Figure 5 – Alarm Wiring ..........................................................................................................................................................6

Figure 6 – Rack Mounting.......................................................................................................................................................7

Figure 7 – Ground Lug Connection.........................................................................................................................................8

Figure 8 – Input Lugs ..............................................................................................................................................................9

Figure 10 – Output Lug Connections....................................................................................................................................10

Figure 11 – Installing Circuit Breakers..................................................................................................................................11

Figure 12 – Installing Fuse Holders and Fuses ....................................................................................................................11

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

1

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

1.1 Overview

The Telect dual-feed 600A per feed load center frames

provide high-capacity, -48V and ±24V power protection

for secondary power distribution and data, and

communications equipment. Telect load center frames

are also ideal for primary distribution in small central

offices and at remote sites.

Models 600CB10 and 600CB12 are open-frame

chassis providing excellent heat dissipation and

overhead access to the load center’s BATT and RTN

terminals, vertical inputs.

Models 600CB10 and 600CB12 are white, 2RU, and fit

racks with either EIA or WECO spacing.

•Model 600CB10 contains 10 interrupter positions

on each side and fits a 19-in. rack (an adapter

kit can be purchased separately to mount the

600CB10 in a 23" rack).

•Model 600CB12 has 12 interrupter positions on

each side and fits a 23-in. rack.

Both accommodate AIRPAX®-style LEL or Carling CA1 circuit breakers or fuses (TPC/TPW and TPS/TLS) in single-

through quad-pole configurations. Each circuit breaker or fuse pole position accommodates a bullet-style, plug-in circuit

breaker or fuse holder up to 100A. With double-pole circuit breakers or TPW fuses, the maximum output load can be up to

200A. The triple-pole circuit breakers have a maximum load of 250A and the quad-pole circuit breakers have a maximum

load of 400A.

Sides A and B are electrically isolated except for the alarm card, which contains power, fuse and bay status relays with

dry, Form-C contacts. The contacts are connected to wire-wrap pins to switch on external power to visual/audio external

alarms. The alarm card also controls the three dual-color LEDs on the front panel.

All input, output and alarm terminals are within the open-frame chassis. All BATT and RTN inputs, outputs and ground

accommodate dual-hole lugs. Input and output terminals are studs and the ground terminals are bolt connections at the

sides of the load center near the rear corners. Only one ground connection is required.

Fuses, fuse holders and circuit breakers are sold separately. Also sold separately are single-, double-, triple- and quad-

pole straps for the output of the breakers or fuses. These copper straps bridge the output of the fuse holders or circuit

breakers to the output studs. See telect.com to order breakers, fuses, fuse holders and load straps.

The 600CB10-C and 600CB12-C provide horizontal inputs and a cover. The 600CB10-CL and 600CB12-CL also provide

horizontal inputs, a cover and single-pole load straps pre-installed into the panel.

The 600CB10-VL and 600CB12-VL provide vertical inputs as well as single-pole load straps pre-installed into the panel.

Figure 1 – 600CB10, 19" 10/10 Position

Load Center Frame

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

2

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

1.2 Installation Guidelines

Elevated Operating Ambient – If installed in a closed or multi-unit rack assembly, the operating ambient temperature of

the rack environment may be greater than the room ambient. Therefore, consideration should be given to installing the

equipment in an environment compatible with the maximum ambient temperature (TMA) specified by the manufacturer.

Reduced Air Flow – Installation of the equipment in a rack should be such that the amount of air flow required for safe

operation of the equipment is not compromised.

Mechanical Loading – Mounting of the equipment in the rack should be such that a hazardous condition is not achieved

due to uneven mechanical loading.

Circuit Overloading – Consideration should be given to the connection of the equipment to the supply circuit and the

effect that overloading of the circuits might have on overcurrent protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Reliable Earthing – Reliable earthing of rack-mounted equipment should be maintained. Attention should be given to

supply connections other than direct connections to the branch circuit (e.g. use of power strips).

Disconnect Device – A readily available disconnect device shall be incorporated in the building installation wiring.

1.3 Specifications

Inputs:

Specifications:

Voltage range (nominal voltage)

±21.6V to ±30V (nominal ±24 VDC)

-40V to -60V (nominal -48 VDC)

Max. input load rating

600A per side at max. operating ambient of 49°C (120°F)

Short circuit withstand rating

5000A

Nominal power loss at full load

Less than 75W per side @ 28,800W full load per side (600A x 48V)

Percentage of full power dissipation at nominal voltage

Less than 1%

Max. input interrupt device

750A

Input terminal studs (with nuts, flat washers and spring

washers) for dual-hole compression lugs

Two pairs of 3/

8

-16 studs on 1-in. centers per terminal [max. lug

width of 1.94-in. (49.2 mm)] per pair. Torque nut (using 9/16-in. or 15

mm wrench) to 150-in./lb. (~17 N•m), max.

Input wire size

#1 AWG to 750 MCM

Grounding:

Specifications:

Earth GND terminal bolts (with washers) for dual-hole

compression lug

Two pair of 1/

4

-20 threaded holes on 5/

8

-in. centers. Torque bolts

(using 7/16-in. or 12 mm wrench) to 50-in./lb. (5.5 N•m), max.

Ground wire size

#2 AWG (min.) for any input interrupt device 400A or more

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

3

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

Outputs:

Specifications:

Max. output circuit breaker or fuse holder

Single-pole: 100A; Double-pole: 175A

Max. output load – continuous

Single-pole: 80A; Double-pole: 140A

Minimum short circuit interrupt rating

5000A

Max. total output load

550A per side

Output terminal studs (with KEPS nuts and washers) for

dual-hole compression lugs

1/

4-20 studs on

5/

8-in. centers [max. lug width of 0.625-in.

(15.8 mm) for a BATT terminal and 0.70 (17.7 mm) for a RTN

terminal]. Torque bolts (using 7/16-in. or 12 wrench) to a 50-in./lb.

(5.5 N•m), max.

Output wire size

•#10 AWG (min.) for a 25A single-pole interrupter to #2 AWG (min.)

for a 100A single-pole interrupter

•#2 AWG (min.) for double-pole interrupters from 100 to 175A

•2/0 AWG (min.) for triple-pole interrupters

•

4/0 AWG (min.) for quad-pole interrupters

Circuit breakers*

•AIRPAX®-style LEL or Carling-style CA1**

Fuses and fuse holders

•TFD fuse holders for single-pole TLS or TPS fuses

•TPC DC-BBE-3 fuse holders for single-pole TPC fuses

•

TPW fuse holders for double-pole TPC fuses

Alarms:

Specifications:

Alarm relay contacts

2A @ 30 VDC; 0.6A @ 60 VDC

Max. alarm card power rating

@24V: 103 mA (2.47W); @48V: 128 mA (6.14W)

Alarm wire size

#24 AWG, typical (#26 to #20 AWG)

Alarm terminals

Wire wrap

Dimensions:

Specifications:

600CB10 width (all models)

600CB12 width (all models)

Height

Depth

19-in. (483 mm)

23-in. (584 mm)

3.5-in. (88 mm)

12-in. (305 mm)

Dimensions:

Specifications:

Weight, without packaging and accessories

600CB10: 18 lbs. (8.2 kg); 600CB12: 22 lbs. (10 kg)

600CB10-xL: 21 lbs. (9.5 kg); 600CB12-xL: 25 lbs. (11.3 kg)

Weight, shipping

600CB12: 25 lbs. (11 kg); 600CB12: 30 lbs. (14 kg)

600CB12-xL: 28 lbs. (12.7 kg); 600CB12-xL: 33 lbs. (15 kg)

Environment:

Specifications:

Operating temperature

-10°C (14°F) to 55°C (131°F)

Humidity

90%, non-condensing

Compliance:

Specifications:

UL Recognized, NEBS Level 3

*Telect suggests you avoid using different types of circuit breakers or fuses in the same load center. Alarm contacts may

vary among interrupter manufacturers and may incapacitate the alarm system.

** Circuit breakers for this load center are designed and manufactured by Airpax Corporation and Carling Industries to

meet Telect’s specifications. Order circuit breakers only from Telect.

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

4

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

ALERT! Only qualified technicians may install and maintain this product. Verify all connections meet

requirements specified in local electric codes or operating company guidelines before supplying power.

Protect this equipment with a fuse or breaker sufficient to interrupt power levels specified.

Install this product in locations accessible only to qualified personnel. The panel weighs more than 35 lbs.

(~ 16 kg); two persons may be required for handling and installing the Load Center Frame.

1.4 Installation Instructions

Please read these instructions carefully before beginning installation. If assistance is required, call Technical Support at

509.926.6000 or email at support@telect.com.

•Telect is not liable for shipping damage. If damaged, notify the carrier and call Telect at 509.926.6000 for

further recourse.

•Telect recommends that you install load straps before installing the load center on the rack. Also, install load

straps now for future add-on loads.

•Inspect equipment after unpacking and compare it to the packing list. Immediately report any shipping damage,

defects or missing parts to Telect at 509.926.6000. Keep all documentation that comes with your shipment.

1. Assign interrupter positions and install load straps for those positions before installing the load center in a rack

as follows:

a. Choose interrupter positions for breakers or fuses.

You may mix interrupter ratings and single- and multi-pole interrupters in the same load center. Telect

recommends not mixing fuses with circuit breakers.

•Avoid mixing non-mid-trip and mid-trip breakers.

•Avoid mixing TLS/TPS with TPC fuses. (TLS and TPS fuses are compatible but made by

different manufacturers.)

•Do not use multiple, single-pole breakers or fuses with multi-pole load straps.

b. Record interrupter position(s) and amperage of each intended interrupter.

•To mitigate heat buildup caused by heavy loads ≥100A, plan a space on one side of the interrupters.

c. Remove bottom screw holding circuit breaker cover to selected interrupter positions. Refer to Figure 2.

•Retain screw and cover if you intend to use circuit breaker

•Retain screw but discard cover if you intend to use fuses

•Remove corresponding screw in plastic load-strap support

•Slip receptacle(s) of load strap into plastic load strap receptacle holder and fasten with screw removed in the

previous step

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

5

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

2. Turn over the load center and check the jumper settings on the alarm board located on the underside of the chassis.

Refer to Figures 3 and 4. The jumpers are set up for REC-4 (non-mid-trip) circuit breakers and fuses. If you plan on

using RLS-4 mid-trip circuit breakers, change the jumper setting as indicated.

Figure 2 – Installing Load Straps

Figure 3 – Alarm Board Location

(Bottom View of Side A)

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

6

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

3. If you intend to install alarm wiring for load center

and/or bay alarms, consider doing so now before

installing the load center in the rack. The alarm

terminal is located near the top center of the load

center. Refer to Figure 5.

a. If you intend the alarm wires to exit at the back

of the rack, don’t forget to feed alarm wiring

from the back to the front of the rack before wire

wrapping the alarm pins.

b. It is possible to use a short, manual wire-wrap

tool to install alarm wiring after securing the load

center to the rack. If you intend to use a power

or larger manual wire-wrap tool, you must install

alarm wiring now.

Figure 4 – Alarm Board Jumper Settings

Figure 5 – Alarm Wiring

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

7

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

4. Locate an unused rack position and mount the load center using at least two sets of fasteners per side, as shown in

Figure 6.

Mount the panel as high as possible on the rack, leaving at least 1RU of access space above the load center. Tighten

screws to 35-in./lb. (4.29 N•m).

Telect recommends using a seismic rack for best rigidity.

WARNING! Failure to properly ground this equipment can create hazardous conditions to installation personnel

and to the equipment.

Figure 6 – Rack Mounting

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

8

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

ALERT! Only use components and crimping tools approved by agencies or certifying bodies recognized in your

country or region such as Underwriter’s Laboratories (UL), TUV, etc.

5. Use an approved crimping tool to attach approved, dual-hole compression lug onto suitable grounding wire.

(Size of ground depends on input interruption device.)

6. If required, lightly coat antioxidant on lug and grounding surface on side of panel. Connect the lug using 1/4-20 bolts,

flat washers and split washers provided, as shown in Figure 7. Tighten the bolt to 50-in./lb. (5.5 N•m).

WARNING! Before connecting input power cables, make sure input power to the panel is turned off.

7. Make sure input power is off before connecting the panel’s input cables to PDU or battery.

8. For input wiring, crimp dual-hole compression lugs onto #1 AWG to 750 MCM copper wires. The choice of input

wiring depends on the following criteria:

•Input interrupt device rating affects size of input wiring.

•Ambient operating temperature affects the type of input wire insulation. Use the table on the following page

to choose the correct temperature-rated input wires. For further information, consult the National Electrical

Code (NEC).

Figure 7 – Ground Lug Connection

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

9

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

Ambient Operating Temperature Range

Max. Current Rating Per Side

Min. Cable Insulation Temperature Rating

-5°to 49°C (23°to 120°F)

600A

75°C (167°F)

49°to 55°C (120°to 131°F)

550A

75°C (167°F)

49°to 55°C (120°to 131°F)

600A

90°C (194°F)

9. Insulate the lug barrels with UL94 V-0 rated heat shrink tubing.

10. Clean terminals and lugs with a non-abrasive, non-metallic pad.

11. If required, lightly coat antioxidant on lugs and input BATT and RTN terminals and then connect lugs to input

terminals, as shown in Figure 8. Tighten lugs to 150-in./lb. (~17 N•m), max.

12. Make sure the breaker or fuse holder positions are either empty, off or

contain dummy fuses (phony, inoperative, all-plastic slugs).

13. Enable the fuse or breaker at primary distribution unit or battery

(750A max.) to turn on Feed A to Side A of load center and then

check voltage and polarity at input connectors of the panel.

Verify the following:

•A PWR LED on front of panel turns green

•B PWR LED turns red

14. With A PWR LED green (normal operation) – but with B PWR LED red

(off or failure operation) – test A PWR relay and contact alarm terminal:

•Expect continuity (0Ω) between Terminals C and NC

•Expect an open circuit (∞Ω) between Terminals C and NO

Figure 8 – Input Lugs

Figure 9 – LED Panel

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

10

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

15. Also, test fuse alarm relay contacts at CB-F alarm terminals.

•Expect continuity (0Ω) between Terminals C and NC

•Expect an open circuit (∞Ω) between Terminals C and NO

16. Repeat Steps 13 and 14 to power up Side B. A PWR and B PWR LEDs must both be green.

17. Make sure input power is off again before installing output wiring to this device.

18. For output wiring, crimp dual-hole lugs onto one end of #10 to #2/0 AWG copper output wires, as required by NEC.

(Work with one output wire at a time.)

19. Insulate lug barrels with UL94 V-0 rated heat shrink tubing.

20. Clean the panel terminal and lugs with non-abrasive, non-metallic pad.

21. If required, lightly coat antioxidant on lugs and output BATT and RTN terminals and then connect lugs to terminals, as

shown in Figure 10. (NEC specifics only one lug and load at each output terminal.) Tighten nuts to no more than 50-

in./lb. (5.6 N•m), max. Then connect other end of output wire to load.

22. Install circuit breakers or fuses, as shown in Figures 11 and 12.

a. Use screws provided with circuit breaker or fuse

holder to attach cover to breaker or holder. (Use

the cover removed previously for circuit breakers.

The fuse holder requires a cover.)

b. Insert a breaker in the load center frame. (“Line”

is on top. Breaker is “upside down” so ON toggle

is up.) Or, insert holder in load center frame

(“Load” is on top.)

c. Fasten the cover to the load center using the

screw previously removed with the cover in Step 1.

d. If applicable, install fuse.

Figure 10 – Output Lug Connections

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

11

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

23. With the output loads (devices fed by this load center) disabled, re-enable fuses or breakers at primary distribution

unit or battery.

24. If applicable, switch circuit breakers ON and then check voltage and polarity at loads.

Figure 11 – Installing Circuit Breakers

Figure 12 – Installing Fuse Holders and Fuses

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

12

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

25. If possible, either replace one of the functioning fuses with a blown fuse or switch OFF breaker.

•For a load center with fuses or non-mid-trip circuit breakers, the applicable ALM LED will turn red

•For a load center with mid-trip breakers, the applicable ALM LED will remain green

26. Check the CB-F alarm terminals. For a load center with fuses or non-mid-trip circuit breakers, expect the following:

•An open circuit (∞Ω) between Terminals C and NC

•Continuity (0Ω) between Terminals C and NO

27. For a load center with mid-trip breakers, expect the following:

•Continuity (0Ω) between Terminals C and NC

•An open circuit (∞Ω) between Terminals C and NO

28. Re-install operable fuses or switch ON breakers before proceeding.

29. Record circuit assignments in accordance with operating company procedures and guidelines.

30. Lastly, enable equipment loads one at a time to verify proper operation of loads.

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

13

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

1.5 Parts & Accessories

The following tables list optional and replacement items for the load center. For wire sizing and labeling, please refer to

Wire Sizing & Label Convention (Telect part number 117995) included with your load center. Order parts and accessories

online at telect.com.

ALERT! Use only UL-listed or UL-recognized component secondary protection devices.

Steps for configuring a panel:

1. Choose vertical or horizontal input.

2. Determine the quantity of load connections

required (one load connection per populated

fuse or circuit breaker position).

3. Choose multi-pole connections if required.

4. Select circuit breakers or fuses:

•If fuses, choose TPC or TFD holders

•If circuit breakers (or fuse holders), select

quantity equal to number of load connections

•Select circuit breaker or fuse amperage values

1Two kits are required for dual feed inputs.

2Required when using the 600CB1X-3PK or 600CB1X-4PK.

3Holder kits contain fuse holder, cover and fasteners.

4Load connection kits contain receptacle, strap assembly and lug fasteners.

Single-pole

Breakers

Part Number

Multi-pole

Breakers

Part Number

30A

116671

125A (2-pole)

134634

40A

116672

150A (2-pole)

134635

50A

116673

175A (2-pole)

135921

60A

118160

200A (3-pole)

134636

70A

118161

225A (3-pole)

134637

80A

118162

250A (3-pole)

134638

90A

118163

400A (4-pole)

143962

100A

118159

Adapter2

(1" C-C)

600CB08-RPK

Panel

Part Number

600A Dual-feed 10/10 load center frame,

vertical inputs

600CB10

600A Dual-feed 10/10 load center frame,

horizontal inputs

600CB10-C

600A Dual-feed 10/10 load center frame,

vertical, loaded

600CB10-VL

600A Dual-feed 10/10 load center frame,

horizontal, loaded

600CB10-CL

600A Dual-feed 12/12 load center frame,

vertical inputs

600CB12

600A Dual-feed 12/12 load center frame,

horizontal inputs

600CB12-C

600A Dual-feed 12/12 load center frame,

vertical, loaded

600CB12-VL

600A Dual-feed 12/12 load center frame,

horizontal, loaded

600CB12-CL

Adapter kit to mount 600CB10 in a 23" rack

02117-02+746

Adapter kit for double-pole input1

600CB1X-2FA

Fuses

TPC

TPS

TLS

25A

125441

130476

N/A

30A

125442

130478

N/A

40A

125443

130482

N/A

50A

125444

130484

N/A

60A

125445

130486

N/A

70A

N/A

130488

N/A

75A

125446

N/A

N/A

80A

N/A

N/A

140640

90A

125447

N/A

140641

100A

125448

N/A

140642

125A

125449

N/A

140644

TPC fuse holder3

129347

TFD fuse holder

(for TPS/TLS fuses)

3

129816

Fuse holder cover4

600CBXX-CFK

Load Connections

Part Number

Single-pole

600CB1X-1PK

Double-pole

600CB1X-2PK

Triple-pole

600CB1X-3PK

Four-pole

600CB1X-4PK

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

14

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

ALERT! Only use components and crimping tools approved by agencies or certifying bodies recognized in your

country or region such as Underwriter’s Laboratories (UL), TUV, etc.

Input Power Lugs

400 MCM

500 MCM

750 MCM

777.7 MCM

T&B

54216

(Die code 76)

54218

(Die code 87)

--

--

Burndy

YA322TC38

(Die code 19)

YA342TC38

(Die code 20)

YA392NT38

(Die code 24)

YA44L-2NT38-FX

(Die code L115)

Panduit

LCD400-38D-6

(Die code 76)

LCD500-38D-6

(Die code 87)

LCDN750-38D-6

(Die code 106)

--

Ground and Circuit Breaker Output Lugs (1/4-in. dual-holes on 5/8-in. centers, uninsulated)

#8 AWG

#6 AWG

#4 AWG

#2 AWG

#2/0 AWG

T&B

542040410

(Die code 21)

54205

(Die code 24)

54206

(Die code 29)

54207

(Die code 33)

--

Burndy

YA8CL-2TC14

(Die code 49)

YA6CL-2L

(Die code 7)

YA4C-2L

(Die code 8)

YA2CL-2TC14

(Die code 10)

YA26L2NT14

(Die code 13)

Panduit

LCD8-14A-L

(Die code 21)

LCD6-14A-L

(Die code 24)

LCD4-14A-L

(Die code 29)

LCD2-14A-Q

(Die code 33)

LCDN2/0-14A-X

(Die code 45)

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

15

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

1.6 Interconnections

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

16

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

1.7 Drawings

Telect assumes no liability for the application or use of these products. Neither does Telect convey any license under its

patent rights or the patent rights of others. This document and the products described herein are subject to change

without notice.

A

INPUT

BUS

600A

48

24

-

+

-

B

V- - -

BAY

ALM

A PWR/

ALM

B PWR/

ALM

910 1211 910 1211

100A MAX PER POLE

23.00 [584.2]

22.31 [566.7]

21.00 [533.4]

1.25 [31.8] 1.75 [44.5]

3.00 [76.2]

0.50 [12.7] FRONT VIEW

TOP VIEW

12.61 [320.3]

0.73 [18.5]

0.625 [15.9]

¼-20 x ¾ in.

0.625 [15.9] ¼-20 x ¾ in. Stud, KEPS Nut, & Washer ¼-20 x 1 in. Stud, KEPS Nut, & Washer

1.00 [25.4]

1.00 [25.4]

38-16 x 114in. Stud, Nut,

Lock Washer, & Flat Washer 38-16 x 114in. Stud, Nut,

Lock Washer, & Flat Washer

REAR VIEW

(ROTATED)

12.00 [304.8]

RTN A BUS RTN B BUS

BATT A BUS BATT B BUS

RTN A Input Terminal RTN B Input Terminal

BATT A Input Terminal BATT B Input Terminal

NOTES 1. Dimensions are in in. [mm].

2. Breakers/Fuses sold separately.

3. Breaker/Fuse line straps sold separately.

4. Max lug width for input BATT and RTN is ~50 mm (~2 in.)

0.69 [17.5], Max. Lug Width

(See Note 4.)(See Note 4.)

3.47 [88.1]

Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

17

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

600CB12-CL – Top View

600CB12-VL – Top View

This manual suits for next models

1

Table of contents

Other Telect Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

Middle Atlantic Products

Middle Atlantic Products Premium+ RackLink RLNK-P420 user manual

Liebert

Liebert MP115HW user manual

Altinex

Altinex UT240-600 user guide

ABB

ABB Relion 670 series Technical reference manual

Compaq

Compaq NA295365-003 Information guide

Tripp Lite

Tripp Lite AG-05F3 Series owner's manual

Marway

Marway Optima 320 Series Operating Guide and Reference

Middle Atlantic Products

Middle Atlantic Products Protection Series instruction sheet

nvent

nvent Schroff RackPower RP 2325 Wiring diagram

ferroamp

ferroamp ESS Power Case installation manual

Konig

Konig CMP-POWG21 manual

Videx

Videx 316C installation instructions