HIOS HDP-50 User manual

17A

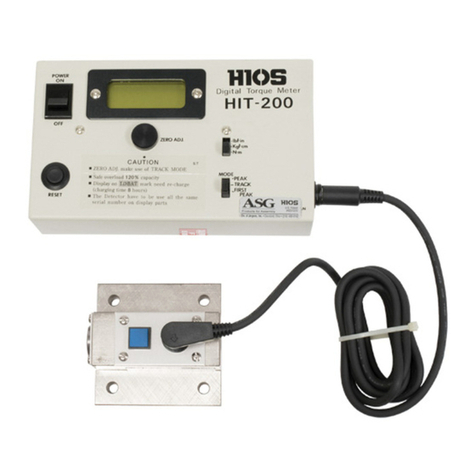

HIOS Digital Torque Meters

HDP-50

HDP-5

HDP-100

Option

Operation manual

(May 2017)

Operation manual No. ET−C007

Utilizing 100%post-consumer

recycled paper pulp

( )

Contents

•Applications and features of

HIOS Digital Torque Meters ............................1

•Safety Precautions............................................ 2

•HIOS Digital Torque Meter controls and

List of items.................................................... 3

•Functions............................................................4

•Operating procedure .........................................5

•Explanations of functions .............................. 6−8

DIP switch.......................................................6

Torque settings ...............................................6

Memory ..........................................................7

Average torque measurement ........................8

•Battery charger...................................................8

•Types of data output...........................................9

• Customer service ...............................................9

•Inspection and calibration ..................................9

•Troubleshooting ...............................................10

• Specications...................................................10

•External features diagram................................11

•Analog and serial data

output specications .....................................11

• China RoHS2 Table..........................................12

However high the quality of your screwdriver, you cannot make full use of its potential unless you know

the right amount of torque for each job and make sure that is the torque being delivered. This instrument

monitors tightening and loosening torque of screws. With an optional attachment, it is also possible to

transfer measurement data to a computer for use in integrated production management systems.

Easy to use, accurate and low in cost, HIOS digital torque meters are used by manufacturers of electronic

goods, cameras, watches and other kinds of precision instruments, as well as by makers of automobiles

and aircraft.

■Applications

•Measurement of tightening and loosening torque

(torque increase and slack torque).

•Torque measurement of other kinds of rotation

tools (may require adapter)

Examples of uses of torque measurement data

•Reference for preparation of tap screw coun-

terbore diameters

•Sorting screws by required torque values

•Classifying jars by screw cap tightness

•Destructive testing of small parts

•Quality control of plastic screw threads and

plastic parts

■Features

•Up to 100 data measurements can be stored in

memory at a time.

•Checks maximum, minimum and average torque

measurements.

•Torque value display can be automatically reset

to zero.

•Torque value display are automatically recali-

brated.

•First peak mode (F.PEAK*) measurement

makes it possible to determine slip torque.

*This function may not be available due to fas-

tening condition.

Please inquire to HIOS for the condition.

•Values are displayed digitally for ease and ac-

curacy in reading out data.

•The display captures torque peak measurements

until the reset button is pressed to assure accu-

racy of records.

•Can be set for rotation in either direction, for easy

measurement of both tightening and loosening

torque.

•Counterclockwise torque measurement is indi-

cated by a minus sign in front of displayed values.

•The strain meter is directly attached to the

torque sensor, as part of the instrument's simple,

rugged design.

•Can be integrated into a statistical process con-

trol system.

•Small, light and operated by rechargeable bat-

tery, this instrument is highly portable.

•Data can be output analogically, as waveforms

or numerical printouts, for a wide range of uses.

(Requires optional analog cord.)

•An input tool is available to make possible trans-

fer of measurement data to a computer. (See page

9 for details.)

•Comes with an AC adapter that can be used with

100 − 240 volt power sources. Runs on an envi-

ronment-friendly nickel-hydrogen battery.

- 1 -

Safety Precautions

■Before using

•Before you begin using the instrument, read the

operating instructions and also the precautions

given on the seal afxed to the instrument.

•The torque meter's display unit and sensor unit

come with the same serial number. These two

parts of the instrument are calibrated together;

do not use any different combination.

•HIOS cannot assume responsibility for ac-

cidents or difculties when the instrument has

been remodeled or disassembled, or when it has

been used in a way other than that explained in

the operating instructions.

■During operation

•Be sure to attach the bit securely into the sensor

unit chuck.

•For safety, make sure the bit never points at

anything other than the tool to be measured.

•When using the support arm that comes with

Model HDP-50, be sure to attach it securely to

prevent it from coming loose under high torque

loads.

•To avoid damaging the sensor unit, do not sub-

ject it to rough handling.

•If the torque meter shows any functioning ab-

normality, cease operation immediately and

contact HIOS Corporation or your HIOS dealer.

•Operators of power tools should always button

cuffs and shirt fronts and fasten zippers on ap-

parel when conducting operations.

•Operators of power tools should not wear gloves,

as this interferes dangerously with having a

proper grip on the tools.

■Precautions in operating a digital

torque meter

•Never exceed the maximum torque levels indi-

cated in the specications on page 10. Exceed-

ing capacity load levels by 120% will result in

internal damage to the meter.

•The battery charger is for NiMH batteries only. Nev-

er use any other kind of battery, even from HIOS.

•Do not disassemble the instrument or loosen the

screws on its body, as this could cause inaccu-

racy in measurement.

•Protect the display and sensor units from shocks

or impacts.

•Always detach the bit from the sensor unit after

use.

•Use of the battery charger

See page 8 for instructions on battery charging.

• Use only the products specied in these operat-

ing instructions for connection to the data out-

put ports.

•When disconnecting cables, grasp the cable plug

and take care not to damage connector pins.

•Always turn the power switch off after complet-

ing measurement operations.

•Do not strike the acrylic display panel or place

heavy objects on it.

•Avoid excessive internal adjustments for calibrat-

ing or other purposes.

•Handle the instrument with care and take care

not to drop it.

•This instrument is sensitive to ambient condi-

tions. Avoid using it in the following kinds of

places:

•Places where water, oil or other liquids could

fall onto or get inside the instrument.

•Places subject to vibration, dust or hot air.

•Outdoors, or places where electrical discharges

may occur.

•Places of high temperature or humidity. (Operat-

ing humidity and temperature ranges for digital

torque meters are 25% − 65% and 15℃ − 35℃).

•Any other place where there is a danger of the

instrument being damaged or its functioning

impaired.

•Please do not store the instrument in places of

high temperature or high humidity. This could

result in condensation forming inside, which

could endanger functioning.

Please read the following safety precautions

to ensure safe and correct operation.

- 2 -

■Items included with torque meter

Bit Support

Arm

HDP-50

HIOS shank ∅4

+Bit #0 ×40 mm

#1

×40 mm

#2

×40 mm 1 piece each

HDP-5

1 pc.

Model Sensor

Unit Cord

1.7 m

1 pc.

Part No.

DPC-0506

•The main unit and accessories come all together in a dedicated aluminum attache case.

■HIOS Digital Torque Meter controls

Exclusive Battery Charger 1 pc. (See p4)

Calibration Sheet

(quantity: 3)

●Please ask your distributor if you

want to know the plug type for the coun-

try not described in the list(page.4).

●The conversion plugs (attached with

TCH-MULTI-CE area) will be no longer

available as soon as the current stock

has run out.

We would like to ask those, who use BF

and S plug, to get them locally.

220 Volt Adaptor Plug

Market

Areas

China

Japan

Korea

Taiwan

Hong Kong

Singapore

Europe

U.S.A.

Canada

U.K.

Australia

HDP-50

HDP-5

HIOS shank ∅5

+Bit #0 ×60 mm

#1

×60 mm

#2

×60 mm 1 piece each

6.35 mm hex shank

+Bit #1 ×50 mm

#2

×50 mm 1 piece each

6.35 mm hex shank

+Bit #1 ×50 mm

#2

×50 mm 1 piece each

1 pc.

6.35 mm hex shank

+Bit #1 ×50 mm

#2

×50 mm 1 piece each

HDP-100

(option)

HDP-100

(option)

Type BF

Type S

- 3 -

■Functions

Control Function

Power switch

【POWER】

Button switch. The LED lights when the power is on. *1

The power is automatically turned off when the instrument is not operated (or torque

load is less than 10) for a period of 10 minutes.

Reset switch

【RESET】

Used to return the display to zero or print out data.

Display Measuring unit display

Unit selector【UNIT】

Switches between one of the following combinations of torque measurement units,

depending on which combination the purchaser ordered: N•m↔lbf•in, N•m↔N•cm,

N•m↔kgf•cm

Measuring mode selector PEAK: Freezes display at peak torque value. (Press reset to cancel)

【MODE】

TRACK: Displays current torque value.

F.PEAK: Freezes display at rst peak torque value.

AC connector For battery charger.

Analog data output Port for analog voltage data output.

【ANALOG OUT】

Digital data output Press reset to output measurement data. This functions makes it possible to use the

【DATA OUT】

instrument in statistical process control systems.*2

DIP switch For setting auto reset timer and turning data output on ("P.ON" LED indicates "on"

setting).

Torque set switch A

【SET】

Sets maximum torque load at which warning tone will sound.

Memory function toggle switch The LED lights when the memory function is on.

【M_SET】

Torque set switch B

【▲】

Sets the torque level at which the warning tone sounds.

Max load warning tone The LED lights when this function is on.

on/off switch

【BZ】

Memory clear switch【M_CR】

Deletes data in memory.

Average measurement When average measurement mode is on, the LED lights and the torque measure-

mode switch

【AVE】

ment average values are displayed.

Support arm (comes with Model HDP-50/HDP-100)

Use the support arm when measured torque is too high for the operator to control

without assistance. It makes stable measurement possible with merely a light touch.

*1Please push the power switch and detach it immediately until a buzzersounds.

*2

Statistical Process Control (SPC) uses statistical techniques to monitor variations in manufacturing processes for use in quality control.

Support arm

Model N•m N•cm

HDP-5 0.000 0.0

HDP-50 0.00 0

HDP-100 0.00 0

Part No.

TCH-MULTI 1 pc

(for AC100-240V, A plug)

PSE, cUL, UL

JAPAN, U.S.A, Canada,

Mexico, Taiwan, Thailand,

Philippines

Part No.

TCH-MULTI-CN 1 pc

(for AC100-240V, A plug)

CCC

China

Part No.

TCH-MULTI-CE 1 pc

(for AC100-240V, A plug)

CE

Vietnam, Indonesia, India,

Singapore, Malaysia, Korea,

Hong Kong, U.K., Ireland,

South America, The Middle

East, New Zealand

Part No. TCH-EU 1 pc

(for AC100-240V, C plug)

CE

Europe (except U.K.,

Ireland)

• Battery Charger

- 4 -

8. To output data using a Mitutoyo Input Tool, set

the No. 3 connector of the DIP switch (page 6)

to the on position (so the "P.ON" LED lights),

set the【MODE】switch to "PEAK" and press

the【RESET】switch (which functions the same

as the Enter key on a computer) . The Input Tool

will convert the measurement data for direct

input to a spreadsheet application. In order to

output data, please conduct measurement within

the instrument's peak measurement range, as in-

dicated in the specications.

•Minus signs denoting counterclockwise torque

are transferred with the measurement data.

9. Fit the bit into a fastened screw to be tested.

Clockwise rotation measures tightening torque

and counterclockwise rotation measures loosen-

ing torque. All torque measurements are dis-

played digitally and the data is stored.

10. Be sure to turn off the power when you are nished

measuring.

■Operating instructions

First check the state of the battery charge. When

the power is on and the battery has an insufcient

charge, the display reads "LOBAT." When this hap-

pens, use the battery charger to recharge the battery

for at least 3 hours and no more than 6 hours.

1. Connect the sensor and display units using the

sensor unit cord. The plugs on either end of this

cord have the same pin arrangement, so it doesn’t

matter which unit gets which plug, but one is L-

shaped and the other is straight, so choose the

combination most convenient for operation.

When making the connection, look at the pins in

the plug and take care to t them smoothly into

the connector to avoid bending them.

2. Attach the bit provided with the torque meter to

the sensor unit.

Fit the joint shaft collar over

the driver and insert the bit

into the collar.

3. Select the unit of measurement desired

【UNIT】

switch. (N•m↔N•cm) (N•m↔lbf•in)

(N•m↔kgf•cm)

4. Conduct zero adjustment. Set【MODE】

switch

to "TRACK," then press both the

【SET】and

【▲】switches at the same time for less than 2

seconds. This adjusts the meter to zero. (Note:

If you press the switches for than 2 seconds, the

meter will go into another mode. If this happens,

press【RESET】, then repeat the zero adjust-

ment process.)

5. Set【MODE】switch to "PEAK" or "F.PEAK."

• In peak mode the peak torque value reached dur-

ing measurement is displayed. Thus, the display

does not change. Model HDP-50 measures up to

10 N•m of torque, which corresponds to a dis-

play value of 15. Please conduct measurements

within this range.

• In "F.PEAK" mode the first peak value is dis-

played and does not change even if higher torque

is applied.

6. Press the

【RESET】switch to cancel the display.

7. Minus signs appear in front of measurements of

counterclockwise torque.

- 5 -

■Explanations of functions

DIP switch

Always turn off the power before

changing DIP switch settings.

•Auto-reset

DIP switch settings

Notes

1The reset switch does not function when auto-reset is on.

2The error display (see below) appears when a printer

or the Mitutoyo Input Tool is connected for data out-

put and the LED lights.

A.RESET TIME

P.ON/OFF

1 2 3 4

1 sec ON ON − −

2 sec ON OFF − −

5 sec OFF ON − −

OFF OFF OFF − −

Printer ON 2 − − ON−

Printer OFF −−OFF−

Time to auto-

reset 1

Data output

Switch number

Error display

•Data output

1. Set the【MODE】switch to "PEAK" or "F.PEAK."

2. Set data output DIP switch number 3 to the on

position.

3. Connect a printer or the Mitutoyo Input Tool

to the Digital data output port. (Pressing the

【RESET】

switch in this state will result in the

error display. An error will also result if you try

to print out data with a printer that cannot print

out numerical data containing decimal points.

4. Conduct measurement, then press the

【RESET】

switch to output the data. Average ("AVE") val-

ues cannot be output.

Output of data from the memory (memory func-

tion on)

Note: Please cancel auto-reset.

1. Press the reset button for 2 seconds.

2. When the display shows the let-

ters "Prn," press reset.

3. All the torque data, from memory number

0001, will be output. The display flickers

during data transfer.

Setting torque

The digital torque meter is shipped with the warn-

ing tone set to sound when maximum torque load is

reached. This tone also sounds when the torque set-

ON ON

Reset

Setting

Warning

tone

Track Peak

Switch functions for setting torque

Switches used

① ② ③

①

【SET】switch

1. Press for 2 seconds to enter torque setting mode.

Press for 2 seconds once again to exit torque set-

ting mode.

2. When the meter is in

torque setting mode,

the 4-digit display

can be adjusted, one

digit at a time. Use the SET switch to select the

digit for adjustment. The selected digit blinks

on and off. Each time the SET switch is pressed,

the next digit to the left is selected (or, if pressed

while the leftmost digit is selected, the rightmost

digit will be selected.)

②

【▲】switch

When the meter is in torque setting mode, this

switch increases

the selected

number by one

each time it is

pressed. Note

that the leftmost

digit can only be

0 or 1.

③

【RESET】switch

Pressing this

switch readies

the meter to

begin measure-

ment. Pressing it

while in torque

setting mode

cancels the pro-

cess and takes

the meter out of

torque setting

mode.

SET RESET

0 - 90 or 10- 90- 9

Setting torque

Setting torque

(Example: Changing a torque

setting from "0000" to "0100")

Ready for

measurement

①【SET】switch

①【SET】switch

①【SET】switch

The last 0 flickers

②【▲】switch

Press for 2 seconds

to enter torque

setting mode.

Press twice to

select the third 0.

Press for 2 seconds

to exit torque

setting mode.

The last 0 is now

selected.

Press once to

increase the selected

digit from to 1.

ting has been changed. The torque setting can be

changed as desired. The warning tone signals that

the set torque value has been measured.

Example (torque set at 100)

Data is output only for measurements up 100.

- 6 -

Fig. 1 Recording readout

Ready for

measurement

Example of memory readout

Memory mode on (LED on)

Setting screw torque

③【RESET】switch

Sensor unit bit exerts torque on screw.

When the memory function is on, pressing this

switch returns the instrument to a state of

readiness to begin recording data again. Press

to end recording, to display or to delete data.

Fig. 2 Displaying recorded data

Example of data display

(Memory function on, LED on, measurement data in memory)

Ready for

measurement

①②【SET】and【▲】

switches

①【SET】switch

②【▲】switch

③【RESET】switch

"SET" advances the display to the next measure-

ment result.

【▲】

goes back to the previous meas-

urement result.

Press once to advance the display to the next data result.

The data number (e.g. 0002) is displayed below. The

measurement data and data number flicker alternately.

Press once to advance the display to the previous

data result.

Data readout mode terminated when this switch is

pressed, when there is no action for 30 seconds or

a new torque signal is received.

Fig. 3 Partial deletion of measurement data

E

xa

m

pl

e

o

f

p

a

r

t

i

a

l

d

e

l

e

t

ion

o

f

t

o

r

qu

e

va

lu

e

d

a

t

a

(Memory function on, LED on, measurement data in memory)

Ready for measurement

Memory readout mode

on

⑤【

M

_CR

】switch

⑤【

M

_CR

】switch

Data deleted

Display measurement result for deletion

Partial data deletion mode display

Press

once Display flickers

Exit partial deletion mode 【

R

ESET

】pressed or no action for 30 seconds

Each time a measurement result is delet-

ed, each of the measurement results shift

one place backwards to occupy the va-

cated places in the memory.*

DATA1 DATA2 DATA3 DATA4

DATA1 DATA3 DATA4

Data shifts to previous position

0001 0002 0003 0004

0001 0002 0003 0004

Fig. 4 Full deletion of measurement data

* Partial deletion of measurement results

Example of full deletion of measurement data

(Memory function on, LED on, measurement data in memory)

Ready for measurement

⑤【M_CR】switch

⑤【M_CR】switch

Full data deletion mode display

Press for

2 seconds

Display flickers

Exit full deletion mode 【RESET】pressed or no action for 30 seconds

Press once; data deletion takes 5 seconds

Data deleted

Memory

Objective

Measurement data can be stored in the memory for

management of everyday operations.

Storing and reading out measurement data

1. The memory can store 100 measurements. The

measurements are numbered automatically, from

0001 to 0100. If data from previous measurements

remains in the memory, the new measurements

begin from the next available number. (Fig. 1)

2. Fig. 2 shows how to display data stored in the

memory.

3. When the 100th result has been stored in the

memory, delete some of the data (Fig. 3) or all

of the data (Fig. 4) to make room for the next

series of measurements.

Memory full display

The flickering display "FUL" ap-

pears when the memory is full. To

clear this display, press【RESET】

.

Switch functions in memory mode

Switches used

① ② ③ ④ ⑤

①

【SET】

switch

When the memory function is on, pressing this

switch displays the last measurement in the

memory.

②

【▲】

switch

When the memory function is on, pressing this

switch displays the first measurement in the

memory.

③

【RESET】

switch

When the memory function is on, pressing this

switch returns the instrument to a state of readi-

ness to begin recording data again. Press to end

recording, to display or to delete data.

④

【M_SET】

switch

Press for 2 seconds to enter or exit measuring

mode. The LED lights when measuring mode is

on.

⑤

【M_CR】

switch

Pressing this switch deletes memory contents.

SET RESET M_SET M_CR

- 7 -

Measurement of average torque

Objective

Use for routine checks of loosening and tightening

torque.

Measurement procedure

Makes possible measurement of the minimum,

average and maximum values among sets of mea-

surements, each set consisting of up to ten measure-

ments.

1. The measurement results are automatically num-

bered, from 0001 to 0010. Negative displays are

not recorded. Measurements in average mode are

automatically deleted when the meter exits aver-

age mode.

2. If less than 10 measurements are made, the dis-

play shows only those measurements.

Switch functions in average measurement mode

Switches used

③ ⑥

③

【RESET】

switch

Puts the instrument into a state of readiness to

begin measurement when in average measure-

ment mode. Press to end measurement or dis-

play of measurement sets.

⑥

【AV E 】

switch

Press for 2 seconds to enter or exit average mea-

surement mode. The LED lights when in aver-

age measurement mode. The figure show the

average measurement and display cycles.

AVE

RESET

Max

Example of average measurement

(Average measurement mode, LED on.)

Ready for measurement

Setting screw torque

③【RESET】switch

Sensor unit bit exerts torque on screw.

Press once. "0001" flickers.

(Same for auto-reset.)

Repeat measurements until sufficient data is

obtained.

Display of average measurement data

(Data is displayed while in average measurement mode and is deleted

when the mode is terminated.)

⑥ Each time the【AVE】switch is pressed minimum, average and maxi-

mum values are displayed flickering.

Fig. 1

Min Ave

1st measurement deleted

11th measurement recorded

0001 0002 0003 0010

0001 0002 0003 0009 0010

0001 0002 0003 0009 0010

Notes

1.Be sure to set

【MODE】switch to "PEAK" or

"F.PEAK" before entering average measurement mode.

2. The【UNIT】switch does not function in average

measurement mode.

■Battery charger

To charge batteries for the HIOS torque meter use

only the battery charger provided with the meter.

Always turn the power off when charging. The rst

time will require 6 hours for a full charge.

Caution

• Do not recharge the battery for longer than 6

hours.

•Use only NiMH batteries, never any other kind,

even if obtained from HIOS Corporation.

•Do not use the meter while charging the battery.

•When the letters "LOBAT" appear in the display,

stop measurement and recharge the battery.

•Do not use the battery charger for any purpose

other than charging batteries for this instrument.

•Do not place objects on top of the battery char-

ger's cord. Do not subject the cord to extreme

bending or tie it in knots.

•Be sure the power to the instrument is off when

attaching or detaching the battery charger.

•Do not attempt to remove the battery from the

instrument.

Danger!

•Leaving the battery charger on for the maximum

recharge time of 6 hours could lead to overheat-

ing, damage to the instrument or res.

■How to recharge

1. Turn off the power to the torque meter and insert

the battery charger cord into a power source.

2. When recharging is complete, unplug the cord,

turn the torque meter power switch on and check

that the display goes on.

3. Wait for the battery charger to cool, and store it

in an appropriate location.

- 8 -

■Types of data output

Use the Mitutoyo Input Tool (available for pur-

chase from many dealers) to transfer measurement

data to a computer.

• Model: IT-005D 264-005 (For any standard Win-

dows computer)

Connection cable NO.937244 2 m (sold sepa-

rately)

(Please contact Mitutoyo Corporation or a Mitutoyo

dealer about purchasing these items.)

■Types of analog data output

An analog cord is available for separate purchase

(1.5 m, item HP-8060). This cable can be used to

connect a pen recorder, oscilloscope or voltmeter

to the HIOS torque meter. When using these instru-

ments, read their operation manuals to insure cor-

rect operation.

■Customer service

•Repair

1. Service charges will be made for repairs under

the following circumstances:

(1) Malfunctioning or damage caused by incor-

rect use of the instrument, the instrument has

been disassembled or it malfunctions due to

attempted repair.

(2) Oil has been added to the sensor unit,

switches or inside the instrument.

(3) The instrument has been damaged during

shipping, by dropping, etc.

(4) Damage due to re, exposure to gas, earth-

quake, water, irregular power supply or

other type of disaster.

(5) Service charges will also be made for cali-

bration, inspection or parts replacement.

2. No charge will be made for service in the case

of inspection and/or calibration of the same part

that becomes necessary within three months after

inspection or calibration has been performed.

(This does not apply under circumstances (1) − (4)

above.)

•Shipping and handling charges incurred for re-

pair service must be paid by the customer. Please

direct questions about customer services to HIOS

Corporation or your HIOS dealer.

■Attention

The product that you have purchased contains a

rechargeable battery. The battery is recyclable. At

the end of it's useful life, under various state and

local laws, it may be illegal to dispose of this bat-

tery into the municipal waste stream. Check with

your local solid waste ofcials for details in your

area for recycling options or proper disposal.

■Inspections and calibration

HIOS torque meters employ a unique sensor mech-

anism that maintains accuracy for long periods. We

recommend that the torque meter be sent in to HIOS

Corporation for inspection at least once a year. (Note

that a fee is charged for this service.)

HIOS torque meters are shipped calibrated to meet

our accuracy standards. Depending on the condi-

tions under which the meter is used, accuracy may

be affected over the course of months or years.

Therefore, HIOS offers calibration and, when nec-

essary, overhaul services. We also recommend use

of the periodic calibration documentation included

with the torque meter. This documentation shows

the relation of the HIOS standards to Japan's stan-

dards.

■Cautions to be observed when

sending the torque meter in for

calibration or repair

1. Pack the meter in the attache case in which it

was originally shipped to protect it from violent

impacts during shipping.

2. Do not put anything into the attache case other

than the items originally shipped inside. Never

include items such as homemade mounting

plates, tools or extra bits. HIOS cannot assume

responsibility for these.

3. Please explain the nature of the difculty with

the instrument in sufcient detail.

- 9 -

The display says "LOBAT"

There is no display

The displayed value does

not return to zero

The displayed values do

not stop changing

Unable to recharge the

battery

The "LOBAT" display reap-

pears after battery recharg-

ing is complete

The display shows a

numerical value when it

shouldn't

Problem Causes Resolving the problem

• Recharge the battery as explained on page 8. If this

does not resolve the problem, contact HIOS or your

HIOS dealer.

• Turn the power switch off, conduct a full battery

recharge (6 hours, no more), then turn the power

switch on and see if there is a display. If there is not,

contact HIOS or your HIOS dealer.

• Conduct zero adjustment.

• Set to "PEAK."

• Check that the plug is connected properly.

• Connect to the battery charger socket.

• If the above does not remedy the problem, contact

HIOS or your HIOS dealer.

• Send to HIOS for repair.

• Recharge the battery for no more than 6 hours.

• Press【RESET】switch to clear the display.

• Insufcient battery charge

• This may be due to long-term use of the

meter or natural battery discharge over

time.

• Unable to conduct zero adjustment.

• The【MODE】switch is set to "TRACK"

• The battery charger plug may not be en-

gaged all the way into its socket.

• The connection may be to the wrong termi-

nal.

• The battery may have reached the end of

its operational life.

• The battery charge may be insufcient.

• This may be due to noise occurring from

the power source, etc.

■Troubleshooting

Before you conclude the torque meter is broken, go through the following troubleshooting guide. If, by fol-

lowing the instructions, you are unable to resolve the difculty, please contact HIOS Corporation or your

HIOS dealer.

Peak range N•m 0.015 - 0.500 0.15 - 5.00 0.15 - 10.00

N•cm 1.5 - 50.0 15 - 500 15 - 1000

lbf•in 0.15 - 4.40 1.5 - 44.0 1.5 - 90.0

(kgf•cm) 0.15 - 5.00 1.5 - 50.0 1.5 - 100.0

Accuracy* within ±0.5% (at full scale)

Power ve 1.2 V NiMH cells 1,000 mA

Recharge time up to 6 hours

Running time on full charge 8 hours

(continuous operation)

Battery life About 300 chargings

Dimensions See gure

Weight Display 780 g

Sensor unit 68 g 250 g

Battery charger Runs on 100 - 240 V AC power (50 or 60 Hz)

Output 7.3 - 8 V DC (0.5 A)

Model HDP-5 HDP-50 HDP-100

■ Specications

• Never exceed the maximum

torque tolerance level for the in-

strument.

• Because battery life depends on

operating conditions, this cannot

be guaranteed.

- 10 -

Unit: mm

Max

BZ

AveMinP.ON

SET

Digital Torque Meter

AVEM_CRM_SET

PEAK

TRAK

POWER

ON

MODEUNITRESET

F.PEAK

125

95.6

42

5

21

15

Sensor Unit

HDP-50 (HIOS shank H5) HDP-100 (HEX shank)

HDP-5 (HIOS shank H4)

∅10

∅21

7029

104

∅12.5

∅34.5

120

35

160

MIN MAX UNIT

T02

—sec

T10.2 0.4 sec

T20.2 0.4 mS

T30.5 1 mS

T40.2 0.4 mS

3. Timing chart

■ Analog and data output specications

d1d2d3d4d5d6d7d8d9d10 d11 d12 d13

A display of 500 means approximately 0.5 volt.

■ Serial data output specications

1. Pin assignments

Mitutoyo MQ65-5P

①GND: Ground

②DATA:Outputs data in the for-

mat indicated below.

③CK: Clock

④RD: Demands data reception

2. Data output format

Following is an explanation of the meanings of the 13-digit data output from the torque meter.

Sign

Entry number

Data type

Decimal point position

Measured value

⑤REQ: Demands data output from exter-

nal source

①- ④: Open drain

-0.3 − +7 V (400 µA max.)

⑤: Pull up to VDD (1.55 V)

Each digit is output in four-bit binary notation from the least signicant bit in the sequence 20→21→22→23.

External features diagram

•Both Model HP-100 and HP-10 have the same dimensions.

Note that specications or the external appearance of HIOS torque meters are subject to change without no-

tice.

- 11 -

■China RoHS2 Table

If you are asked by China Customs, please show this table to them.

In addition, the China RoHS marks also is required at the product and product box.

At the product, you can nd it at the bottom and it is marked on the product box.

If you cannot nd the mark, please ask your distributor.

In case of emergency, please cut the mark below and stick at the bottom of product and on the product box.

China RoHS mark

Note: minimum size of China RoHS mark is 5mm at outer diameter

- 12 -

1-16-5 Akiyama, Matsudo City,

Chiba Pref., Japan

TEL: 81 (Japan) 47-392-2001

FAX: 81 (Japan) 47-392-7773

This manual suits for next models

2

Table of contents

Other HIOS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

AMO

AMO AMOSIN WMI-100 Installation and mounting instructions

Mirion Technologies

Mirion Technologies AVIOR-2 user manual

Brodie

Brodie BiRotor BA-89 Installation and operation manual

Hilti

Hilti PR 30-HVSG A12 manual

Azbil

Azbil MCF Series user manual

Lutron Electronics

Lutron Electronics CM-9942G Operation manual