HIOTS ioTest User manual

HIOTS Emission Monitoring Systems

Towards a sTrong and reliable emission moniToring sysTem!

ioTest

Cloud Data Logger

ioTest Instruction Manual

Version 2.2

HIOTS AG,

Hertensteinstr. 51, CH-6004 Lucerne

Phone: +41 (0) 41 5625777

Email: info@hiots.ch, Web: http://hiots.ch/

Contact our support team if you have any questions:

support@hiots.net

1

Table of Contents

Safety Considerations...................................................................................................................................................... 2

1. Summary ..................................................................................................................................................................... 3

2. System Overview ......................................................................................................................................................... 4

3. Installation of the HIOTS ioTest................................................................................................................................... 5

3.1. Hardware Components........................................................................................................................................ 5

3.2. Cable harness specification ................................................................................................................................. 9

3.3. Installation ......................................................................................................................................................... 11

3.3.1. Main data logger ........................................................................................................................................ 11

3.3.2. Cable harness ............................................................................................................................................. 11

3.3.3. Differential pressure sensor....................................................................................................................... 12

3.3.4. Temperature sensor................................................................................................................................... 14

3.3.5. CAN-Wideband Lambda Meter (option) .................................................................................................... 15

3.3.6. Smart NOx Sensor (option) ........................................................................................................................ 16

3.3.7. RPM signal input ........................................................................................................................................ 17

3.3.8. Engine RPM correction factor .................................................................................................................... 18

3.4. Technical specifications ..................................................................................................................................... 19

3.4.1. Data Logger and Modem............................................................................................................................ 19

3.4.2. Exhaust Pressure Sensor ............................................................................................................................ 19

3.4.3. Exhaust Temperature Sensor ..................................................................................................................... 19

3.4.4. CAN-Wideband Lambda Meter (option) .................................................................................................... 20

3.4.5. Smart NOx Sensor (option) ........................................................................................................................ 21

3.4.6. Particulate Matter Sensor (option) ............................................................................................................ 22

3.4.7. Wi-Fi Display (option)................................................................................................................................. 23

4. Initial steps to start operation................................................................................................................................... 24

5. Error Codes Guide ..................................................................................................................................................... 25

6. Data download and cloud server............................................................................................................................... 26

6.1. Real-time live data ............................................................................................................................................. 28

6.2. Data Management............................................................................................................................................. 29

6.2.1 Index Files.................................................................................................................................................... 29

6.2.2 Generate Data ............................................................................................................................................. 30

6.2.3 GPS Tracking................................................................................................................................................ 30

6.2.4. Device Configuration.................................................................................................................................. 31

6.2.5 Set Date/Time Manually ............................................................................................................................. 32

6.3. Device additional information ........................................................................................................................... 32

7. Progressive Web Application (PWA) ......................................................................................................................... 33

7.1. Desktop.............................................................................................................................................................. 33

7.2. Android .............................................................................................................................................................. 34

7.3 IOS....................................................................................................................................................................... 35

HIOTS AG 2Installation Guide for ioTest Data logger

Safety Considerations

About this document

•The instruction manual is an integral part of the instrument.

•Keep this documentation to hand so that you can refer to it when necessary.

•Always use the complete last version of instruction manual.

•Please read this instruction manual through carefully and familiarize yourself with

the product before putting it to use.

•Hand this instruction manual on to any subsequent users of the product.

•Pay particular attention to the safety instructions and warning advice in order to

prevent injury and damage to the product.

Security

General safety instructions

•Only operate the product properly, for its intended purpose, and within the

parameters specified in the technical data.

•Do not operate the instrument if there are signs of damage to the housing or

connected cables.

•Always comply with the locally valid safety regulations when carrying out

measurements.

•Only perform maintenance and repair work on this instrument that is described in

this documentation. Follow the prescribed steps exactly when doing the work.

•Use only original spare parts from HIOTS.

Warning notices

Always pay attention to any information denoted by the following warnings. Implement the

precautionary measures specified!

---------------------------------------------------- DANGER------------------------------------------------------

Indicates possible injury.

---------------------------------------------------- WARNING-------------------------------------------------

Indicates possible damage to equipment.

HIOTS AG 3Installation Guide for ioTest Data logger

1. Summary

The ioTest is a continuous emission monitoring system which can be used as a tool to monitor

engine parameters such as exhaust temperature, backpressure, λ (lambda), O2, NOx, PM,

RPM, OBD-II and other parameters according to requirements.

The ioTest collects real-time data from onboard sensors and gives this opportunity to check

the measurements from anywhere through the web application. Along with online data

visualization and alarm notifications, the ioTest stores sensor data, alarm codes and audit logs

for compliance reporting up to 10 years. The ioTest can be used for R&D, regulatory

preparation, benchmarking or monitoring components involved in the after-treatment of

exhaust gases such as DPF and SCR.

Key Features:

Sensors customization according to requirements

Online access to data measurement and viewing LiveData

Anytime/Anywhere access via mobile apps

Powerful and flexible post-processing software

Alarm notifications

Robust design for use in harsh industrial environment

Stores data up to 10 years

Scope:

Passenger cars

Commercial vehicles

Non-road mobile machinery

Mining Industry

Generators

Marine vessels

Trains

How It Works:

HIOTS AG 4Installation Guide for ioTest Data logger

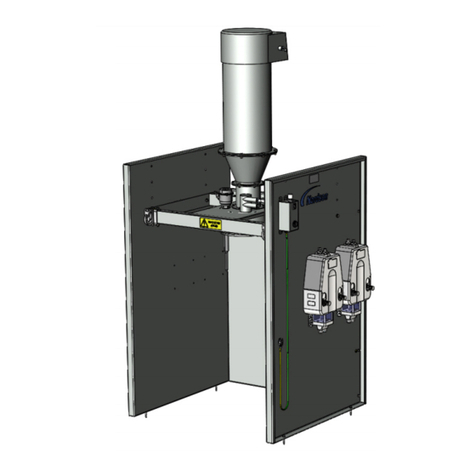

2. System Overview

HIOTS AG 5Installation Guide for ioTest Data logger

3. Installation of the HIOTS ioTest

3.1. Hardware Components

HIOTS Emission Monitoring Systems consist of the below components as described and

shown in the following:

1. ioTest Main data logger (Part No. : 30130 – Fig. 1)

Connects to the main connector (24 pin) of cable harness

2. Cable Harness (Part No. : 30210 – Fig. 2)

3. Cellular Modem (Part No. : 30550/30560 – Fig. 3)

Option A (Standard): 4G Dongle Cellular Modem - Part No. : 30550

Option B: 4G Industrial Cellular Modem - Part No. : 30560

4. Pressure Sensor (Part No. : 30250 – Fig. 4)

Connects to the Bosch 3 pin connector of the cable harness

5. Exhaust Temperature Sensor (Part No. : 30260 – Fig. 5)

Connects to the Deutsch connector of the cable harness

6. CAN- Wideband Lambda Meter (Part No. : 30630 - Fig. 6)

Connects to the 2 pin CAN connector of the cable harness

7. Smart NOx Sensor (Part No. : 30640 – Fig. 7)

Connects to the 2 pin CAN connector of the cable harness

8. GPS Antenna (Part No. : 30220 – Fig. 8)

Connects to the 7 pin round connector of the cable harness

9. Sensors Installation Pack (Part No. : 30230 – Fig. 9)

Stainless steel pipe and fittings for pressure and temperature sensors installation

10. Fuse Kit (Part No. : 30240 – Fig. 10)

1 Ampere Fuse, fuse holder and cable clamp – integrated in the power-supply

11. LED Indicator (Part No. : 30150 – Fig. 11)

LED lamp and fittings for installation

12. Buzzer Alert (Part No. : 30160 - Fig. 11)

Alerting buzzer

13. Wi-Fi-Display (Option) (Part No. : 30140 - Fig. 12)

A touch screen, designed to be connected with the data logger through wireless connection

HIOTS AG 6Installation Guide for ioTest Data logger

Fig. 1: ioTest main data logger

Fig. 2: Cable harness

HIOTS AG 7Installation Guide for ioTest Data logger

Fig. 3 (A). 4G Dongle Cellular Modem

Fig. 3(B): 4G Industrial Cellular Modem

Fig. 4: Pressure sensor

Fig. 6: CAN-Wideband Lambda Meter

Fig. 5: Exhaust Temperature sensor and fitting

Fig 7: Smart NOx Sensor

HIOTS AG 8Installation Guide for ioTest Data logger

Fig. 8: GPS antenna

Fig. 9: Sensors installation pack

Fig. 10: Fuse kit (1 Ampere Fuse)

Fig. 11: LED indicator/ Buzzer Alert

Fig. 12: Wi-Fi-Display

HIOTS AG 9Installation Guide for ioTest Data logger

3.2. Cable harness specification

A

Power supply

*Red Wire →

Supply(+) 10 ~ 38 Vdc

Black Wire →

Ground -

Yellow Wire →

Engine rpm

Red.White Wire →

LED indicator

Blue.White

Wire →

Buzzer

Red/Blue Wire →Digital Input /

Analog input

WARNING

*Note:

Integrate FUSE KIT in the power-supply (permanent positive

polarity) to provides

protection against overvoltage

*Note:

Connect Supply (+) to the ACC/ignition (Accessory power) instead of constant battery (+)

to Keeping the ioTest system powered off when Engine ignition is off.

HIOTS AG 10 Installation Guide for ioTest Data logger

B

Sensors connection

B2 Temperature sensor

connection

B1 Pressure sensor

connection

C

GPS connection

GPS antenna

connection

D

Modem

section

4G Dongle

Cellular

Modem with

SIM card slot

(Note: This section

is not available in

Industrial Modem

version)

Note: Please insert a Local SIM card with sufficient internet access into the modem slot.

Generally, to make sure the internet is available on the Modem, you can connect devices such as

smart phones and tablets to the modem Wi-Fi with SSID and Password printed on the sticker on the

bottom of the modem and check availability of internet!

E

Data connection

E1 CAN bus

connection

E2 Modbus

connection

HIOTS AG 11 Installation Guide for ioTest Data logger

3.3. Installation

The below picture illustrates the overview of the system installation.

3.3.1. Main data logger

At first, choose the appropriate position of the main device according to the permissible cable

length starting from the main data logger to each component position. We recommend that

the main data logger be placed in the vehicle with vibration-absorbing materials.

WARNING

The Main data logger must not be positioned too close to components that may get so

hot like engine exhaust and manifold. Insulate cables when running them close to hot

parts.

Try to isolate the main logger and modem module with a protective box in order to protect

them from any unauthorized accessibility. In addition, using vibration-absorbing material

beyond the main device is highly recommended.

3.3.2. Cable harness

The cable harness must be disconnected from the power supply when installing and

connecting the systems.

Insulate cables when running them close to hot parts.

To avoid short circuits, insulate the free ends of unused wires.

The plug connectors must face downwards.

IMPORTANT: DISCONNECT THE BATTERY BEFORE INSTALLATION!

HIOTS AG 12 Installation Guide for ioTest Data logger

3.3.3. Differential pressure sensor

1- Differential pressure sensor includes an installation package. This package contains

exhaust pressure sensor (with two inputs), steel pressure pipe, clamp-ring, fitting and hose.

2- Pay attention to the correct installation of upstream and downstream measuring inputs

on the sensor (Ø 8 mm connection: upstream of DPF, Ø 6 mm connection: Downstream of

DPF or may be left unused in case of ambient pressure reference usage).

3- The differential pressure sensor must be installed in a higher place than the measuring

point (figure below). For this, use the provided stainless steel pipe and hose to keep

pressure sensor away from exhaust pipe heat.

4- To install the sensor, you need to drill a hole in exhaust pipe in upstream of DPF. You can

either bolt or weld the provided fitting to the exhaust pipe. Insert the provided steel pipe into

the fitting (approx. 3 cm into the exhaust sampling line) and tighten the nut. Connect the

other end of the steel pipe to the “Before DPF” input (Pay attention to the attached labels)

through the provided hose and clamp-ring.

Inputs

Before DPF

After DPF

HIOTS AG 13 Installation Guide for ioTest Data logger

5- Please note that the current sensor includes two inputs. First input (Before DPF) must be

connected upstream in order to measure the backpressure. Second input (After DPF) can

either be connected downstream of DPF or remain unused.

6- In order to prevent the condensed water droplets blocking the hosing line or reaching to

the pressure sensor, try to avoid making U-shapes in both steel pipe and pressure hose and

always install the hosing in a rising line up to the pressure sensor.

7- If you need to lower the size of steel pipe for a proper installation, try to make round coils

instead of cutting pipe to the suitable size.

HIOTS AG 14 Installation Guide for ioTest Data logger

3.3.4. Temperature sensor

1- When using the sensor, remove the plastic cap.

2- Exhaust temperature sensor should be placed close to engine and in the upstream of the

DPF/SCR.

3- Drill a hole in the exhaust pipe/manifold and thread the tap. Attach the provided fitting to

the exhaust pipe/manifold and tighten it. Insert the sensor tip (probe) in the sampling line as

long as it gets to the direct stream of exhaust gas (approx. 3 to 5 cm) and tighten the nut.

You can also weld the provided fitting than wrenching it (in this case you do not need to

thread the tap).

4- Be careful not to over tighten the screw connection, as this could damage the probe. Before

fully tightening the nut, make sure the cable starts 90 Degrees from the final resting position.

In addition, try to avoid temperature wire contact with components that heat up.

5- Connect the probe wire to the harness wire and be careful not to damage the lock.

HIOTS AG 15 Installation Guide for ioTest Data logger

3.3.5. CAN-Wideband Lambda Meter (option)

DANGER

The Lambda Sensor used in this device gets very hot in operation. Do not touch the hot

sensor. Do not let a hot sensor touch a combustible surface. Do not use the sensor with

or near flammable liquids or gases. Failure to heed these warnings may result in severe

burns, explosions or fires.

1. When using the sensor, remove the plastic cap.

2. The sensor body should be perpendicular to the exhaust gas flow, and it should also

be tilted in the range of 10˚to 75˚from the horizontal line (see the figure). The typical

tilt-angle is 30˚. The sensor probe should be close to the center of the exhaust pipe.

3. Find a location in upstream of the exhaust pipe (down the merge collector), drill a hole

of 18 mm in diameter and weld the provided threaded bung onto it. Small pin-hole

leak in a poorly welded sensor bung will affect the accuracy and performance of your

sensor. Remember, any deviation from the instructions provided for proper sensor

installation will lead to inaccurate readings.

4. The sensor is not to be fitted near to the exhaust pipe outlet, so that the influence of

the outside air can be ruled out.

5. The sensor connects through the 2-pin CAN bus connection of the HIOTS cable

harness.

6. Make sure the connection is fused with a minimum fuse size of 5A.

7. Lambda Meter Operating Voltage is 10 ~ 15 Vdc. In case that only 24 voltage source is

available, a voltage converter 24 to 12 volt must be placed.

8. Supply Lambda Meter to the ACC/ignition (Accessory power) instead of constant

battery (+) to Keeping the Lambda Meter powered off when engine ignition is off.

WARNING

When the Lambda Sensor installed in the exhaust, the sensor MUST be connected and

operated whenever the engine is running. An un-powered sensor will be damaged when

exposed to hot exhaust gases.

HIOTS AG 16 Installation Guide for ioTest Data logger

3.3.6. Smart NOx Sensor (option)

DANGER

The Smart NOx Sensor used in this device gets very hot in operation. Do not touch the

hot sensor. Do not let a hot sensor touch a combustible surface. Do not use the sensor

with or near flammable liquids or gases. Failure to heed these warnings may result in

severe burns, explosions or fires.

1. When using the sensor, remove the plastic cap.

2. The sensor body should be perpendicular to the exhaust gas flow, and it should also

be tilted in the range of 10˚ from the Vertical line (see the figure).

3. The sensor is not to be fitted near to the exhaust pipe outlet, so that the influence of

the outside air can be ruled out.

4. Punch a hole in exhaust pipe and weld the provided threaded bung onto it.

5. After finding the right location on the exhaust pipe, drill a hole of 18 mm in

diameter. Use the tightening torque of 50 Nm.

6. The sensor connects through the 2-pin CAN bus connection of the cable harness.

7. Make sure the connection is fused with a minimum fuse size of 5A.

8. Smart NOx Sensor Operating Voltage is 24 Vdc.

9. Supply Smart NOx Sensor to the ACC/ignition (Accessory power) instead of constant

battery (+) to Keeping the Smart NOx Sensor powered off when engine ignition is off.

WARNING

When the Smart NOx Sensor installed in the exhaust, the sensor MUST be connected and

operated whenever the Engine is running. An un-powered sensor will be damaged when

exposed to hot exhaust gases.

HIOTS AG 17 Installation Guide for ioTest Data logger

3.3.7. RPM signal input

HIOTS Emission Monitoring Systems measure the rotation speed of a crankshaft and calculate

the revolutions per minute (RPM). Typically, alternator W terminal (AC Signal) use for this

purpose. You can connect the RPM wire (yellow wire) on cable harness to engine’s alternator

W terminal to obtain engine RPM. The W terminal generally outputs an unrectified AC

voltage, the frequency of which is proportional to the engine speed.

In cases where alternator’s signal is not available, you can connect any type of RPM Sensor

with pulse output to obtain engine RPM.

HIOTS AG 18 Installation Guide for ioTest Data logger

3.3.8. Engine RPM correction factor

To calculate the engine RPM correction factor, knowing the correct pulses per rotation cycle

(P) and the diameters of the V-belt pulley of the crankshaft (d1) and the diameters of the

alternator pulley (d2) is important. Alternator mostly gives 6 pulses in each single rotation

cycle (in some cases it could be 4 or 8 according to the alternator concept of design).

d1: crankshaft pulley diameter, d2alternator pulley diameter

Once you know the parameters, use this formula to determine RPM correction factor:

1

2

d

P

d

×

Example:

Crankshaft pulley diameter: d1= 385 mm, Alternator pulley diameter: d2= 82 mm

Number of pulses in each revolution: P = 6

RPM correction factor = 6 × 385

82

= 28.171

The RPM pulses can also be obtained from engine ECU output or RPM sensor with pulse

output. In these cases, mostly the number of pulses per minute represents the real engine

speed and RPM correction factor = 1.

HIOTS AG 19 Installation Guide for ioTest Data logger

3.4. Technical specifications

3.4.1. Data Logger and Modem

The ioTest data logger is a completely isolated device which collects, stores and transmits

data to a cloud database without being dependent on any external sources. The main data

logger section (Fig. 1) is responsible for collecting data coming from sensors and storing them

on an internal SD card. Benefiting from a Wi-Fi connection provided by external 4G cellular

modem (Fig. 3 / Fig. 4), data would be transmitted to the data server.

Data logger

Power supply

Pressure range

Temperature range

RPM range

Memory capacity

Wi-Fi protocols

Wi-Fi frequency range

Processor cores

Operating Temp

Dimensions

10 – 38 VDC

0 – 700 mbar

0 – 900 ˚C

0 – 10000 rpm

16 GB - Storage up to 10 years

802.11 b/g/n

2.4 ~ 2.5 GHz

2

-20 ~ 80 ˚C

120 × 108 × 32 mm

Modem

4G LTE/3G with up to 150 Mbps

Connect via Wi-Fi

Onboard SIM card slot

WPA2TM and Wi-Fi protected setupTM

(WPS)

3.4.2. Exhaust Pressure Sensor

Measuring range (max) 700.00 mbar

Measuring range (min) 0.00

Operating Temperature range (max) 130 ˚C

Operating Temperature range (min) - 40 ˚C

Response time 1 ms

3.4.3. Exhaust Temperature Sensor

Type PT200 resistance thermometer

Measuring range (max) 900.00 ˚C

Measuring range (min) 0.00 ˚C

Response time 1 ms

Table of contents