PPI ScanLog 96 User manual

User Manual

ScanLog 96 Pen Drive Version

Single / Dual Channels

Universal Process Data Logger

with USB Port for Data Transfer to PC

via Pen Drive

User Manual

ScanLog 96

Pen Drive Version

User Manual

ScanLog 96 Pen Drive Version

CONTENTS

1. FRONT PANEL : LAYOUT AND OPERATION 1

2. BASIC OPERATION 3

3. PEN DRIVE OPERATION 6

4. OPERATOR PARAMETERS 12

5. ALARMS PARAMETERS 14

6. SUPERVISORY PARAMETERS 16

7. DEVICE CONFIGURATION 17

8. CHANNEL CONFIGURATION 18

9. ALARMS CONFIGURATION 23

10. RECORDER CONFIGURATION 24

11. RTC SETTINGS 25

12. UTILITIES 26

13. ELECTRICAL CONNECTIONS 27

APPENDIX-A : DC LINEAR SIGNAL INTERFACE 30

APPENDIX-B : LOW / HIGH CLIPPING 32

User Manual

ScanLog 96 Pen Drive Version

1

FRONT PANEL : LAYOUT AND OPERATION

Section 1

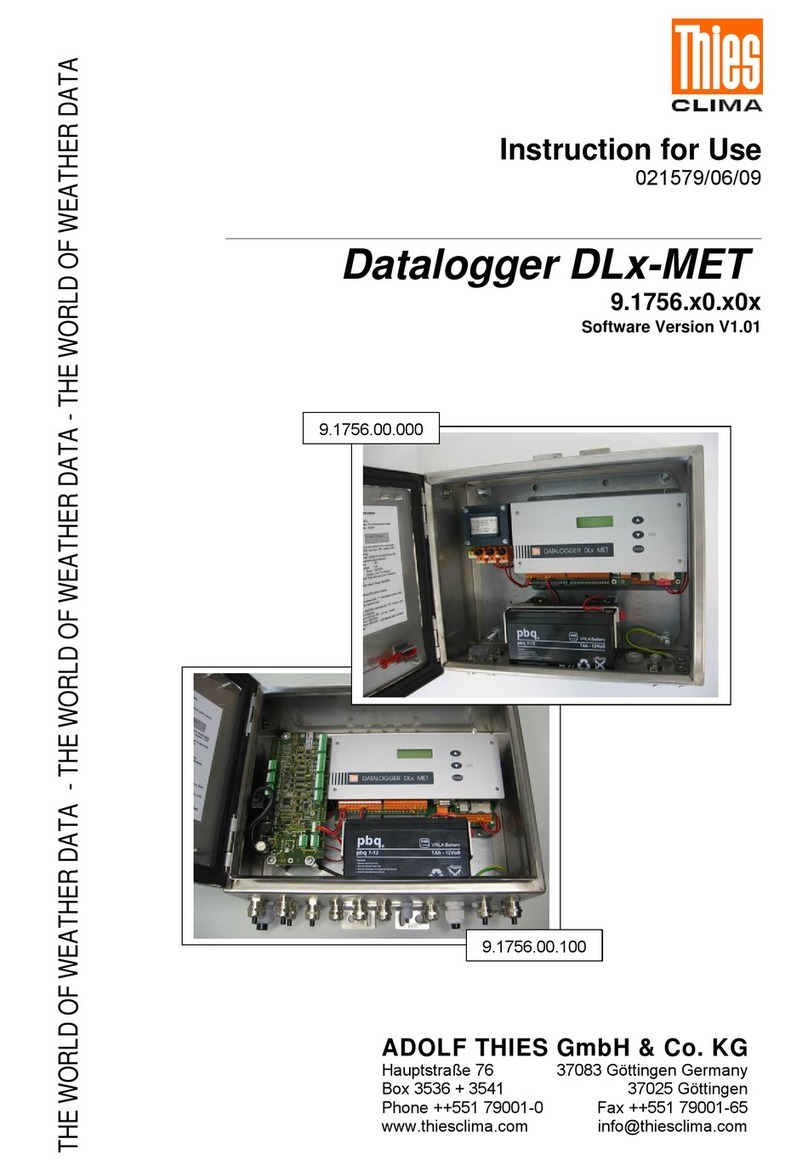

Figure 1.1

2 X 16 LCD Display

Keys USB Connector

ScanLog 96

AL4AL3AL2AL1AUTO

Boiler Pressure

2.1 PSI

Upper Row Lower Row

Alarm Status LEDs

Auto / Manual

Scan Mode Status

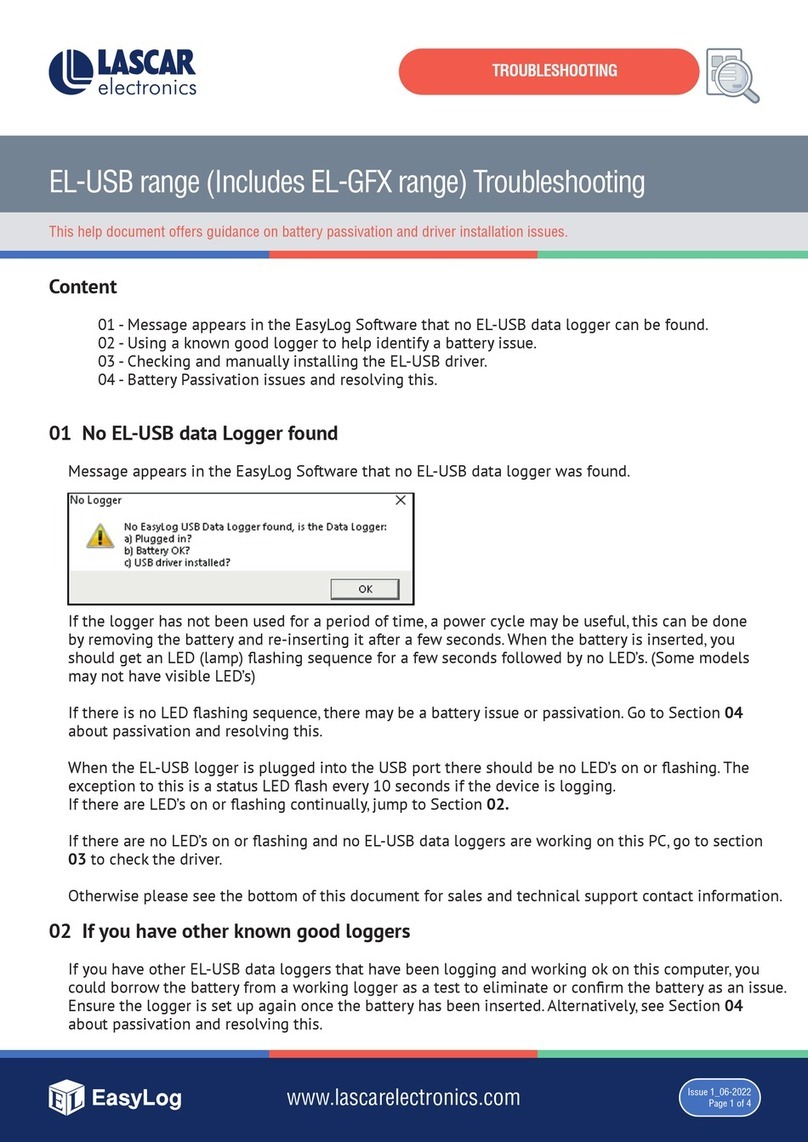

The front panel comprises of 2 X 16 (2 rows of 16 characters each) LCD Display, LED indicators & membrane keys. Refer

Figure 1.1 below.

LCD DISPLAY

The LCD Display has 2 rows, the Upper Row & the Lower Row; each having 16 Characters.

In normal mode of operation (Run Mode), the Upper Row displays the Channel Names and the Lower Row displays the

corresponding Process Values followed by Units. Refer Figure 1.2 (a) below.

Boiler Pressure

2.1 PSI

INPUT TYPE>>

Type K (Cr-Al)

Figure 1.2(a) Figure 1.2(b)

In Set-up Mode, the Upper Row displays the parameter Name and the Lower Row displays the corresponding parameter

Value. Refer Figure 1.2(b) above.

LED INDICATORS

There are 5 front panel 3mm round RED LED indicators described below in table 1.1.

Table 1.1

Remains off for Single Channel Version

In Dual Channel Version the ON status indicates that the

process value indication for channels is updated

automatically with user set Scan Time.

A UTO

AL 1 Flashes while Alarm-1 of any one or more channels is active.

LED Status

AL 2

AL 3

AL 4

Flashes while Alarm-2 of any one or more channels is active.

Flashes while Alarm-3 of any one or more channels is active.

Flashes while Alarm-4 of any one or more channels is active.

User Manual

ScanLog 96 Pen Drive Version

2

KEYS

There are four tactile keys provided on the front panel for setting-up the parameter values and for other functions &

commands. The Table 1.2 below lists each key and the associated function.

Table 1.2

PEN-DRIVE SLOT

A rectangular slot with USB connector type A is provided for Pen-Drive operation.

ENTER /

Alarm ACK

Symbol Key Function

DOWN

UP

SET-UP Press to enter / exit Set-up Mode.

Press to decrease the parameter value. Pressing once

decreases the value by one count; holding the key pressed

speeds up the change.

Press to increase the parameter value. Pressing once

increases the value by one count; holding the key pressed

speeds up the change.

Press to store the set parameter value and to scroll to the next

parameter in Set-up Mode.

Press to acknowledge / mute alarm output (if active).

User Manual

ScanLog 96 Pen Drive Version

3

BASIC OPERATION

Section 2

POWER-UP

Upon switching on the power to the unit, the display shows the following information for approximately 4 seconds.

After the power-up display information, the instrument starts showing the process value(s) for Single / Dual Channels. This is

the MAIN Display Mode that shall be used most often.

MAIN DISPLAY MODE

This is the default display mode. This mode actually comprises of 4 different screens providing different information. The 4

screens are described below. Use Enter key (press and release) to switch from one screen to the next. The last screen rolls

back to the first screen. The multiple information within a selected screen can be viewed using UP / DOWN keys.

Process Value Screen

This is the default screen upon entering the Main Display Mode. The Upper Row shows the Channel Name and the Lower Row

shows the corresponding Process Value along with user set Units as shown below.

Boiler Pressure

2.1 PSI

Channel Name

Process Value

Units

In case of process value error, the Lower Row indicates the type of error in place of process value and units. The various errors

and the respective causes are listed in Table 2.1.

Table 2.1

Process Value above Max. Range

Process Value below Min. Range

Error Message Cause

Thermocouple / RTD broken

Sensor Open

Under Range

Over Range

In case of Dual Channel, the channel-wise process value indication update depends upon the selected Auto / Manual scan

mode. The scan mode can be toggled between Auto and Manual by holding the ENTER key pressed for approximately 5

Seconds. The front panel LED indicator glows ON in Auto mode and remains OFF in manual mode. The channel update rate in

Auto mode depends upon the set value (1 to 99 Sec.) for the parameter ‘Scan Rate’. In Manual mode, the channels can only

be scrolled using UP and DOWN keys. However, in Auto Mode though the channels are automatically scrolled with set

interval, the UP/DOWN Keys can still be used for quick manual scrolling through channels.

Alarm Status Information Screen

There are up to 4 soft Alarms (AL1, AL2, AL3 and AL4) provided for each channel. If any one or more set Alarms for a channel

is active, the channel is said to be under Alarm condition. The channel names under Alarm condition keep flashing on the

Upper Row in Process Value screen.

The complete Alarm status information for the channels under Alarm condition is available on this Screen. For example; If

Alarm1 (AL1) and Alarm3 (AL3) of a channel named ‘Boiler Pressure’ is active then the screen displays the following

information.

ScanLog 96

Single

PD

1.0.1.0

Model Name

Channels

Pen-Drive Interface

Firmware Version

User Manual

ScanLog 96 Pen Drive Version

4

Boiler Pressure

AL1 AL3

For Dual Channel Version, if both channels are under Alarm condition; use UP / DOWN keys to scroll through the channels for

viewing the individual Alarm status information.

Note :

The front panel ENTER key can be used as Alarm - Acknowledge key. Use Alarm Acknowledgment feature to de-activate the Alarm relays.

Note that acknowledging the Alarm(s) does not remove the Alarm condition(s).

Recording Information Screen

This screen facilitates viewing information related to the recording feature. Use UP / DOWN keys to scroll through the various

information described below in Table 2.2.

Table 2.2

REMAINING BATCH TIME

This information is available if ‘Batch Recording’ mode is selected

and shows the remaining batch time in Hours:Minutes:Seconds

(HH:MM:SS) format if the batch is in progress. Upon completion or

prior to start of the batch, the remaining time is shown as 0:00:00.

Balance Time>>

1:12:36

Information Sample Screen

NEW RECORDS IN MEMORY

Shows the numbers of new records available in the recorder

memory for copying (downloading) to Pen-Drive using ‘Copy

(New)’ command.

New Records>>

12523

OLD RECORDS IN MEMORY

Shows the numbers of old records available in the recorder

memory that were copied (downloaded) in the previous session.

These records can be re-copied using ‘Re-copy (Old)’ command.

Old Records>>

10067

FREE SPACE AVAILABLE FOR NEW RECORDS

Shows the recorder memory space available for new records.

That is, this information shows how many more new records can

be stored in the memory before it gets full.

Free Space>>

3833410

DATE STAMP FOR THE FIRST NEW RECORD IN THE

MEMORY

This information shows the calendar date of recording of the first

available new record in the memory. This information does not

appear if there are no new records in the memory.

First Record>>

Date: 01:01:20

TIME STAMP FOR THE FIRST NEW RECORD IN THE

MEMORY

This information shows the clock time of recording of the first

available new record in the memory. This information does not

appear if there are no new records in the memory.

First Record>>

Time: 23:05:40

User Manual

ScanLog 96 Pen Drive Version

5

Information Sample Screen

DATE STAMP FOR THE LAST NEW RECORD IN THE

MEMORY

This information shows the calendar date of recording of the latest

available new record in the memory. This information does not

appear if there are no new records in the memory.

Last Record>>

Date: 02:01:20

TIME STAMP FOR THE LAST NEW RECORD IN THE MEMORY

This information shows the clock time of recording of the latest

available new record in the memory. This information does not

appear if there are no new records in the memory.

Last Record>>

Time: 14:12:10

RTC Screen

This screen provides the Real Time Clock (RTC) information as shown below. The upper row shows the current calendar date

in dd/mm/yy format and the lower row shows the running clock time in hh:mm:ss (24 Hours) format.

Date: 05/01/20

Time: 08:56:00

File Name

This screen shows the File Name that the device uses to download the internal stored records onto the Pen-Drive (Refer

Section 3 : PEN-DRIVE OPERATION. This is a Read Only screen.

File Name>>

REC30006

User Manual

ScanLog 96 Pen Drive Version

6

PEN-DRIVE OPERATIONS

Section 3

The Instrument can perform both, File Read and File Write, operations on the Pen Drive. The File Read Operation facilitates

assigning user defined names to each input channels while the File Write operation allows copying the Process Value records

(stored inside the internal memory of the instrument) onto the Pen Drive for subsequent reading in Excel Sheet. The two file

operations are described in detail in the following pages.

File System for Read Operation

The Instrument continuously monitors and updates the Process Values (PVs) for each channel. The Process Values are

displayed on the front panel Dual Row LCD display. The Upper Row displays the channel name whereas the corresponding

PV and measurement Units are shown on the Lower Row.

Channel Names

The Instrument is shipped from the factory with each channel assigned a factory set default name in accordance to the

numbers assigned to the channels. That is, Channel-1 & Channel-2. The user can, however, assign a more meaningful name

(such as Boiler Pressure, Oil Temperature, etc.), to each channel for easy identification of the process parameters that are

being measured and displayed.

Instrument Name

The Instrument Name is useful in identifying the equipment (like Ageing Oven, Muffle Furnace, Test Chamber, etc.) or the

location (like Paint Room, Test Lab, etc.) where recording is performed. The Instrument Name is mentioned in the File Header

(described later) section of the file where the stored records are copied. The instrument is shipped from the factory with a

default Instrument Name; ScanLog 96. This default instrument name can be changed by the user using the file read facility.

File Name

The instrument (ScanLog) downloads the records by creating a unique default File Name (explained later). The user can

however define a different file name by using file read facility.

For File read operation the user should create and save a text document file with the name Set.txt using Microsoft Notepad

Application tool. The Set.txt file must be saved on the Pen Drive in the main directory (outside of any folders).

Refer Figure 3.1 for example file. Follow the guidelines below for creating and/or editing the file Set.txt.

1. The lines with text within square brackets before user defined names are required.

2. The text within square brackets are case insensitive.

3. No blank lines are permitted. Do not press enter after typing last line.

4. The Channel Names must not exceed 16 characters.

5. The Instrument Name must not exceed 16 characters.

6. The File Name must not exceed 8 characters. Regardless of the letter case (lower or upper) used for the file name set by

the user, the file is always created with upper case letters. For example; for the user set file name NewName, the

instrument creates file NEWNAME.csv.

User Manual

ScanLog 96 Pen Drive Version

7

Figure 3.1

File System for Write Operation

ScanLog continuously monitors and measures the process values for all channels and compares these values with the user

set Alarm limits to generate Alarm Status.

A set of Process Values along with the corresponding Alarm Status for all channels, stamped with the current Date and Time, is

called a Record. ScanLog stores such records in its internal memory at user set time interval, called Recording Interval. These

stored records are then available for downloading to a Pen Drive via the front panel USB connector.

Each of the installed ScanLog creates and maintains its own Record-Data file on Pen Drive using either user defined File

Name or a file naming scheme that involves a unique 5 Digit Code which is factory set. This 5 Digit Code can be viewed using

the Read-only parameter “UNIQUE ID NUMBER” on the page “RTC Settings”. This Read parameter value is actually an 8 digit

number of which last 5 digits are used for file naming. Under this file naming scheme the file is named RECnnnnn.csv; where

nnnnn is the unique 5 Digit Code just described above. For example; if the “UNIQUE ID NUMBER” is 15030006 then the file is

named REC30006.csv. The records are downloaded to the file on Pen Drive in Comma Separated Values (CSV) format and

thus the file is assigned the extension “.csv ”. Note that once the user supplies his own File Name the ScanLog does not use

the file naming scheme stated above. That is either the user defined File Name or the file name created using unique 5 Digit

Code is stored inside ScanLog’s memory. The stored File Name can be viewed using Enter Key (Refer Section 2 : Basic

Operation).

Upon selecting the ‘Copy (New)’ or ‘Re-copy (Old)’ operation (explained later) after insertion of the Pen Drive; the ScanLog

first searches for any existing file that matches with the file name stored in its memory.

Case 1 : File exists

If the File with the name stored in ScanLog’s memory exists on the pen drive, the ScanLog first reads the File Header that

comprises the Instrument Name & the 8 digit UNIQUE ID NUMBER (Refer Figure 3.2). If the 8 digit UNIQUE ID NUMBER

matches then the ScanLog appends the available stored records to the file, else the message shown in the figure is displayed :

User Defined

Instrument Name

User Defined

File Name

User Defined

Channel Names

{

Could not Append

Device Differs

User Manual

ScanLog 96 Pen Drive Version

8

Back-up File System

It is possible that a file-write operation may be interrupted due to reasons like sudden power-failure or removal (or, loose-

contact) of the Pen Drive, resulting in a partial transfer of records. An interrupted file-write operation makes the file unusable

for appending any further records. Also, the partially transferred records in the interrupted file are lost (but are still retained

inside the ScanLog’s internal memory). That is, the file on Pen Drive exists with the previous records intact (if any) and

becomes a read-only file.

An interrupted file-write operation event is registered by the ScanLog in its internal memory as well as on the Pen Drive that

was being written. Upon resumption of operation, the ScanLog prompts for Recovery of the interrupted operation. Upon

selecting the “Recover” operation, the following sequence of steps is executed.

1. A back-up file of the interrupted file is created to retain the previous records

The back-up file is named BN_S.csv; where, ‘N’ is the last 3 digits of the 5 Digit Code and ‘S’ is the sequential number (1 to

250) assigned to the back-up file. For example; if the 5 Digit Code is 30006 and there does not exist any previous back-up

file, then the new back-up file is named B006_1.csv. If, however, there exists previous back-up file(s), then ‘S’ is assigned

the lowest numeric value (in sequential order). For example; if a Pen Drive already contains back-up files - [B006_1.csv,

B006_4.csv and B006_14.csv] - then the new back-up file is named B006_2.csv.

2. The interrupted file is deleted.

3. A New File with the same name as the deleted interrupted file is created.

4. All the records (including those that were partially transferred during the interrupted operation) are downloaded to the New

File.

The above message implies that there exists multiple ScanLog with the same user defined file names. Assign a different file

name and then download the records.

Case 2 : File does not exist

If the file does not exist, the ScanLog automatically creates a new file with the name stored in its memory and then creates a

File Header using the Instrument Name & the 8 digit UNIQUE ID NUMBER. This is followed by downloading the records. Refer

Figure 3.2.

Figure 3.2

8 digit

UNIQUE ID NUMBER

Instrument Name

Records

{

File Header

{

01-01-20

01-01-20

01-01-20

User Manual

ScanLog 96 Pen Drive Version

9

Select Operation

If the “Pen Drive Checking” operation is successful; the ScanLog presents one or more of the following options for the next

operation:

None

Copy (New)

Re-copy (Old)

Read Set.txt File

Recover

The above option list is presented one option at a time. Use UP / DOWN keys to view the options & then press ENTER key to

select the option. Select option ‘None’ to revert to normal RUN mode screen.

The ‘Copy (New)’ option is presented only if there are new records available in the internal memory and the ‘Recover’ option is

not presented.

The ‘Re-copy (Old)’ option is presented only if there are old records available in the internal memory and the ‘Recover’ option

is not presented.

The ‘Read Set.txt File’ option is presented only if the inserted Pen Drive contains a file with the name Set.txt.

The option ‘Recover’ is presented only if the previous write file operation was interrupted. In this case, the ‘Copy (New)’ and

‘Re-copy (Old)’ options are not presented.

Use UP/DOWN keys to select the desired option and then press ENTER key to execute the selected operation.

Pen Drive Checking

Upon inserting the Pen Drive into the USB port, the ScanLog responds by displaying the

message shown in the figure 3.3(a). During this time, the ScanLog checks the file format on the

Pen Drive and also searches for existence of Set.txt file (file containing Instrument Name, File

Name & Channel Names) and any interrupted file-write operation in the previous operation. The

message may last for 5 to 60 seconds depending upon the disc size and occupancy percentage.

In case of any error in reading the Pen Drive or if the Pen Drive dose not respond for more then

60 seconds, the message shown in the figure 3.3(b) is displayed.

Ensure proper insertion of the Pen Drive into the USB port and acknowledge the message by

pressing front panel ENTER key. The ScanLog repeats the device checking operation. If the

error persists; remove the Pen Drive from the port and acknowledge the message (using

ENTER key). The ScanLog responds with the message shown in the figure 3.3(c). Acknowledge

the message to revert to normal RUN mode screen or insert a new Pen Drive to continue with file

read/write operations.

PEN DRIVE (MEMORY-STICK) OPERATION

The ScanLog is provided with a front panel USB port for file read and write operations using Pen Drive.

Figure 3.3(a)

Please Wait.....

Figure 3.3(b)

Device Failure

Figure 3.3(c)

Insert Drive

User Manual

ScanLog 96 Pen Drive Version

10

In case of any of the above Error Messages, make sure that the Pen Drive is firmly inserted in the USB port and retry the

operation by acknowledging the error message through front panel ENTER key. If the error persists, replace the Pen Drive.

Table : 3.1

Error Message Operation What it Means

Copy (New)

Re-copy (Old)

Recover

Copy (New)

Re-copy (Old)

Recover

Copy (New)

Re-copy (Old)

Recover

Copy (New)

Re-copy (Old)

Recover

Unable to open an existing file or

create a new file.

Unable to write records in an Open

file.

No space on Pen Drive to continue

writing records in an Open file.

Unable to close the file after

successful downloading

Recover

Recover

Unable to rename an interrupted

file for back-up

Unable to delete an interrupted file.

Cant Open File

Cant Write File

Bal 1234

Disc Full

Bal 1234

Cant Close File

Cant Rename File

Cant Delete File

Recover, Copy(New), & Re-copy(Old) Operations

The ‘Recover’, ‘Copy (New), & ‘Re-copy(Old)’ options are similar in operations as they all download (copy) records available in

the internal memory onto the inserted Pen Drive. The difference lies in the set of records that is downloaded.

The ‘Copy (New)’ operation downloads the records that are not yet downloaded even once, that is, “new” records. After

successfully downloading the “new” records, the ScanLog retains this set of records as “old” records until next successful

‘Copy (New)’ operation is executed.

The ‘Re-copy (Old)’ operation downloads the set of records that were successfully copied during last ‘Copy (New)’ operation

and were, thus, retained as “old” records. This feature allows re-gaining the copied records in case the Pen Drive fails or

malfunctions after copying records or after inadvertent deletion of the record file from the Pen Drive.

The ‘Recover’ operation copies the records that were being downloaded in the previous ‘Copy (New)’ or ‘Re-copy (Old)’

operation that was interrupted.

Upon selecting one of the above 3 operations, the ScanLog opens an existing file or creates a new file for downloading the

records (refer section “File System for Write Operation”)

If there is an error in opening/creating a file or deleting/re-naming a file (while creating back-up file for ‘Recover’ operation) or

any other errors encountered while downloading the records; the ScanLog displays an appropriate error message. The Upper

Row shows the message while the Lower Row shows the numbers of records pending for downloading.

For various error messages, the operation types for their occurrence and the meaning of the errors, refer Table 3.1 below.

User Manual

ScanLog 96 Pen Drive Version

11

USB Port Failure

In case of any failure of the USB port itself; one of the following two messages may be displayed on the front panel LCD

depending upon the type of error. The ScanLog needs servicing for any further Pen Drive operations.

If no error is encountered while opening/creating a file for copying the records, the ScanLog

begins downloading the records with the message shown in the figure 3.4(a). The upper row

shows the operation type; Copying for ‘Copy’ operation or Re-copying for ‘Re-copy’ or ‘Recover’

operation. The Lower Row displays countdown of the numbers of balance records.

Upon successful completion of the operation, the ScanLog displays the total numbers of records

copied (or, re-copied) through the message shown in figure 3.4(b). Remove the Pen Drive and

acknowledge the message using ENTER key. The ScanLog reverts to normal RUN mode.

‘Read Set.txt File’ Operation

Upon selecting ‘Read Set.txt File’ operation, the ScanLog opens the file named Set.txt for reading the user defined Instrument

Name, File Name & Channel Names (refer section “File System for Read Operation”).

If there is an error in opening the file or any other errors encountered while reading the file; the ScanLog displays an

appropriate error message on the Upper Row.

For various error messages and their meaning, refer Table 3.2 below.

Table : 3.2

In case of any of the above Error Messages, make sure that the Pen Drive is firmly inserted in the

USB port and retry the operation by acknowledging the error message through front panel

ENTER key. If the error persists, replace the Pen Drive.

If no error is encountered while opening, reading or closing the file, the ScanLog displays the

message shown in figure 3.5 after successfully reading file contents. Remove the Pen Drive and

acknowledge the message using ENTER key. The ScanLog reverts to normal RUN mode.

Error Message What it Means

Unable to open the Set.txt file or read the file size.

Unable to read the file contents.

Unable to close the file after successful reading file contents.

Cant Sync USB Cant Change Baud

Cant Open File

Cant Close File

Cant Read File

Figure : 3.5

Names Assigned

Figure : 3.4(a)

Copying.....

Bal 1234

Figure : 3.4(b)

Records Copied

1234

User Manual

ScanLog 96 Pen Drive Version

12

OPERATOR PARAMETERS

Section 4

The Figure 4.1 shows how to access Operator Parameters. The Example illustrates how to start batch recording.

The Table 4.1 below described the Operator Parameters in detail.

Figure 4.1

Table 4.1

Parameter Description Settings

No

Yes

This command is presented only while the ScanLog is

downloading (copying) the records to pen drive. Set this

parameter to ‘Yes’ to abort the copying operation.

STOP COPY

(Available only when a Pen Drive is attached to the USB socket.

This list is also presented automatically in the Run Mode upon

detection of the Pen Drive insertion)

Refer Section 3 : PEN DRIVE OPERATION for details on each

operation.

SELECT OPTION 1. None

2. Copy (New)

3. Re-copy (Old)

4. Read Chan Names

5. Recover

(Default : None)

Main Screen First (desired)

Page

First Parameter

Press SET-UP Key Press ENTER Key

To open Operator

Parameter List

Boiler Pressure

2.1 PSI

SELECT PAGE>>

Operator Paras

BATCH START>>

No

or

Desired Value

Press UP/DOWN Keys

to adjust Parameter Value

Press ENTER Key

to store the New Value

& to move to Next Parameter or

return to Main screen

BATCH START>>

Yes

Main Screen

Boiler Pressure

2.1 PSI

User Manual

ScanLog 96 Pen Drive Version

13

Parameter Description Settings

No

Yes

BATCH START

(Available if Batch Recording is selected)

This parameter is presented only if the batch is not already

started.

Set BATCH START command to ‘Yes’ to start recording the data.

This is usually issued at the begin of a batch process.

(Available if Batch Recording is selected)

This parameter is presented only if the batch is already started.

Through the Batch Recording automatically stops at the end of the

set time interval; there may be a need to abort recording any time

during the batch. Set BATCH STOP command to ‘Yes’ to stop

recording the data and terminate the batch.

BATCH STOP

No

Yes

User Manual

ScanLog 96 Pen Drive Version

14

Parameter Description

SELECT CHANNEL

(Available only for Dual Channel Version)

Select the desired Channel Name whose Alarms parameters are

to be set.

1 or 2

Settings

(Default Value)

ALARM SETTINGS

Section 5

The Figure 5.1 shows how to access Alarm Setting Parameters. The Example illustrates how to change the Alarm 2 setpoint

value for channel 2.

Figure 5.1

Main Screen First Page Next (desired)

Page

Press SET-UP Key

or

First Alarm (AL1)

*Desired Channel

Press UP/DOWN Keys

to select Channel Value

Press ENTER Key

to select Alarm

number

or

Press UP/DOWN Keys

to select next Page

Press ENTER Key

To open Alarm

Settings List

or

Press UP/DOWN Keys

to select Alarm Number

Desired Alarm

Number

Press ENTER Key

to open AL2

Parameter List

Press ENTER Key

to select desired

parameter

or

Press UP/DOWN Keys

to adjust Parameter Value

Press ENTER Key

to store the New Value

& to move to Next Parameter

*First Parameter

in Alarm Settings

List

First Parameter

for Alarm 2

Desired Parameter

for Alarm 2

Desired Value Next Parameter

Boiler Pressure

2.1 PSI

SELECT PAGE>>

Operator Paras

SELECT PAGE>>

Alarm Settings

SELECT CHANNEL>>

1

SELECT CHANNEL>>

2

SELECT ALARM>>

AL1

SELECT ALARM>>

AL2

AL2 TYPE>>

Process Low

AL2 SETPOINT>>

1.6

AL2 SETPOINT>>

1.4

AL2 HYSTERESIS>>

0.2

* Parameters not present in Single Channel Version

User Manual

ScanLog 96 Pen Drive Version

15

Table : 5.1

Parameter Description

SELECT ALARM

Select the desired Alarm Number whose parameters are to be set.

AL1, AL2, AL3, AL4

(The actual available

options depends on the

numbers of Alarms

set per channel on

Alarm configuration page)

x = 1, 2, 3 or 4 depending upon the Alarm selected : AL1, AL2, AL3

or AL4

None :

Disable Alarm.

Process Low :

The Alarm activates when the PV equals or falls below the ‘Alarm

Setpoint’ value.

Process High :

The Alarm activates when the PV equals or exceeds the ‘Alarm

Setpoint’ value.

ALx TYPE

x = 1, 2, 3 or 4 depending upon the Alarm selected : AL1, AL2, AL3

or AL4

Setpoint Value for ‘Process High’ or ‘Process Low’ Alarm.

ALx SETPOINT

x = 1, 2, 3 or 4 depending upon the Alarm selected : AL1, AL2, AL3

or AL4

This parameter Value sets a differential (dead) band between the

ON and OFF Alarm states.

ALx HYSTERESIS

Settings

(Default Value)

None

Process Low

Process High

(Default : None)

Min. to Max. of selected

input type range

(Default : 0)

1 to 30000

(Default : 20)

x = 1, 2, 3 or 4 depending upon the Alarm selected : AL1, AL2, AL3

or AL4

No :

The Alarm is not suppressed during the start-up Alarm conditions.

Yes :

The Alarm activation is suppressed until the PV is within Alarm

limits from the time the Recorder is switched ON.

ALx INHIBIT

No

Yes

(Default : No)

User Manual

ScanLog 96 Pen Drive Version

16

The Page Header ‘Spvr. Config’ encompasses a subset of Page Headers containing parameters that are set less frequently.

These parameters should only be accessible to Supervisory level and thus are protected by password. Upon entering the

appropriate password for the parameter ‘ENTER PASSCODE’ , the following list of Page Header is available.

1. Device Configuration (Device Config)

2. Channel Configuration (Channel Config)

3. Alarm Configuration (Alarm Config)

4. Recorder Configuration (Recorder Config)

5. RTC Settings (RTC Settings)

6. Utilites (Utilites)

7. Return to Main Mode (Exit)

The figure below illustrates how to access the parameters under the supervisory Page Header “Alarm Configuration”. The

parameters covered under each Page Header are described in detail in the following sections.

SUPERVISORY CONFIGURATION

Section 6

Figure 6.1

Main Screen First Page Desired Page

Press SET-UP Key

or

Press UP/DOWN Keys

to select next Page

Press ENTER Key

Press UP/DOWN Keys

to select desired Page

Header

or

Press ENTER Key

To access parameters

for selected Page

Header

First Parameter

under selected

Page Header

Desired

Page Header

First

Page Header

Press UP/DOWN Keys

to enter correct

passcode

or

Correct PasscodePasscode Screen

Press ENTER Key

To access Page

Header

Boiler Pressure

2.1 PSI

SELECT PAGE>>

Operator Paras

SELECT PAGE>>

Spvr. Config

ENTER PASSCODE>>

0

ENTER PASSCODE>>

22

SELECT PAGE>>

Device Config

SELECT PAGE>>

Alarm Config

ALARMS/CHAN>>

4

User Manual

ScanLog 96 Pen Drive Version

17

DEVICE CONFIGURATION

Table : 7.1

Parameter Description

DELETE RECORDS

Setting this command to ‘Yes’, erases all the records stored in the

internal Memory. (Default : No)

No

Yes

Settings

(Default Value)

Section 7

This parameter value sets the time interval for which each channel

is displayed. In other words, the rate at which the channels are

sequentially updated for indication.

SCAN RATE

1 Sec. to 99 Sec.

(Default : 3 Sec.)

User Manual

ScanLog 96 Pen Drive Version

18

The Channel configuration parameters are listed in Table below and are generally required to be set only at the time of

installation.

CHANNEL CONFIGURATION

Table : 8.1

Parameter Description

1 or 2

Set the type of Thermocouple / RTD / DC Linear signal input type

connected to the selected channel.

INPUT TYPE Refer Table 8.2

(Default : 0 to 10 V)

RESOLUTION

Set the process value indication resolution (decimal point). All the

resolution based parameters (Hysteresis, Alarm Setpoints etc.)

then follow this resolution setting.

(Applicable only for DC Linear Inputs)

The transmitter output signal value corresponding to RANGE

LOW process value.

Refer Appendix-A : DC Linear Signal Interface for details.

SIGNAL LOW

Settings

(Default Value)

Section 8

Input Type Settings Default

0 to 20 mA 0.00 to Signal High 0.00

4 to 20 mA

0 to 80 mV

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

4.00 to Signal High

0.00 to Signal High

0.000 to Signal High

0.000 to Signal High

0.00 to Signal High

1.000 to Signal High

4.00

0.00

0.000

0.000

0.00

1.000

SELECT CHANNEL

(This parameter is available for Dual Channel Version only)

Select the channel for which parameter settings are desired.

(Applicable only for DC Linear Inputs)

The transmitter output signal value corresponding to RANGE

HIGH process value.

Refer Appendix-A : DC Linear Signal Interface for details.

SIGNAL HIGH Input Type Settings Default

0 to 20 mA

4 to 20 mA

0 to 80 mV

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

Signal Low to 20.00 20.00

20.00

80.00

1.250

5.000

10.00

5.000

Signal Low to 20.00

Signal Low to 80.00

Signal Low to 1.250

Signal Low to 5.000

Signal Low to 10.00

Signal Low to 5.000

Refer Table 8.2

Select the Units that shall be displayed along with the measured

PV on the display. For temperature input (Thermocouple & RTD),

only °C and °F units are available and represent actual converted

values. All other units available for DC Linear signal input are for

indication purpose only and should be selected as per the units

specified by the transmitter.

UNITS

Refer Table .38

(Default : °C)

Table of contents

Other PPI Data Logger manuals

Popular Data Logger manuals by other brands

Phoenix Geophysics

Phoenix Geophysics RXU-8A quick start guide

Measurement Computing

Measurement Computing USB-TEMP user guide

ACR Electronics

ACR Electronics Nautilus reference guide

ThermoWorks

ThermoWorks RF ThermaData quick start guide

HWM

HWM Multilog 2 WW Installation and setup

Lascar Electronics

Lascar Electronics EL-USB Series Troubleshooting