Hirschmann iFLEX TRS 10 User manual

iFLEX TRS 10

CAN Transceiver

for wireless sensors Contents

Safety instructions 1

Product description 2

Installation 3

Commissioning 4

Service and maintenance 5

Technical data 6

Appendix 7

User manual

Issue B - 08/2011

This document has the order no.

21-810-19-0001_421826_en

TABLE OF CONTENTS

1Safety instructions ...........................................................................................6

1.1 EU conformity declaration ............................................................................7

2Product description..........................................................................................9

2.1 General .........................................................................................................9

2.2 Product features .........................................................................................10

2.3 Use for the intended purpose .....................................................................10

2.4 Scope of supply ..........................................................................................10

2.5 View of device.............................................................................................11

2.6 Dimensions .................................................................................................12

3Installation.......................................................................................................13

3.1 Mounting the components ..........................................................................13

3.1.1 iFLEX TRS 10 ....................................................................................13

3.1.2 Short Antenna ....................................................................................13

3.1.3 Magnetic base antenna......................................................................13

3.2 Electrical connection...................................................................................14

3.2.1 Wiring of the central connector ..........................................................15

3.2.2 Wiring of the connecting cable...........................................................15

4Commissioning...............................................................................................16

4.1 Adding a Wireless Sensor ..........................................................................16

4.2 Status LEDs................................................................................................19

4.3 Troubleshooting ..........................................................................................20

5Service and maintenance ..............................................................................21

6Technical data.................................................................................................22

7Appendix .........................................................................................................23

7.1 Object listing table ......................................................................................23

7.2 Wiring of the adaptor cable for PCAN-USB................................................25

7.3 List of tables and illustrations .....................................................................25

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 2/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 3/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

VERSION OVERVIEW

Issue Date Description Editor

A 2010-06-29 Translation of German original issue A (2010-06-29) Konopka

B 2011-08-08 Made changes requested by HAC – Chambersburg

ECN 11-169

Gase

HIRSCHMANN Automation and Control GmbH

Hertzstr. 32-34, 76275 Ettlingen, phone +49 (0)7243-709-0

Introduction

INTRODUCTION

This manual is a component of the equipment or system supplied by Hirschmann Automation and

Control GmbH. Keep this manual in a safe place and ensure that it is available to all users.

About this manual

The contents of this manual are subject to change. Hirschmann Automation and Control GmbH

does not provide any guarantee for this material, including the associated guarantee regarding

marketability and suitability for certain intended purposes. Hirschmann Automation and Control

GmbH accepts no liability for errors in the contents of the manual or for direct or indirect damage in

connection with the provision and use of the manual.

Liability disclaimer

This manual is protected by copyright. All rights reserved. The manual or any of its parts may not

be duplicated, reproduced or translated into another language, either partially or completely, without

the prior written permission of Hirschmann Automation and Control GmbH.

Copyright

notice

The rendition of common names, trade names, trademarks etc. in this documentation should not be

construed to mean that such names, even without special identification, are free in the sense of

trademark and trademark protection legislation and hence usable by anyone.

Trademarks

This device / system is intended exclusively for the tasks described in this manual. Any other use

shall be construed as being inappropriate. The manufacturer accepts no liability for damage caused

by inappropriate or impermissible use. This device / system may only be used if it is in perfect tech-

nical condition.

Use for the intended

purpose

Only appropriately qualified personnel may work with this device / system, i.e. persons:

Qualification of the

operating personnel who are familiar with the operation or installation and commissioning

who know the current regulations used to prevent accidents

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 4/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Introduction

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 5/29

Notification Symbols

Dangers and other important notices are marked as follows in this user manual:

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

WARNING

Warning of direct threat of personal injury and damage to property.

Provides instructions on precautions to avoid danger.

CAUTION

Warning of dangerous situations. Also warns of damage to property.

Provides instructions on precautions to avoid danger.

IMPORTANT

Warning of a possibly damaging situation for the product.

Provides instructions for avoiding the possibly damaging situation.

NOTE

Usage instructions and information

HINT

Supplementary comments and recommendations for the user

Safety instructions

1 Safety instructions

In order to avoid possible personal injuries and damage to property when using this device, it is

essential to observe the following safety instructions:

CAUTION

Danger of electrical short-circuits.

Switch off all systems before commencing with the installation work!

IMPORTANT

Damage to the device can occur due to the penetration of water and dirt.

Never clean the device with a high pressure cleaner!

Have damage to the decorative foil repaired professionally without delay!

IMPORTANT

Damage to the device can occur if it is connected to an unsuitable power supply.

The device may only be connected to a DC voltage source of 10 V to 30 V!

IMPORTANT

Impairment of the system function or breaching of radio transmission regulations by the use

of components or extensions is not approved by the manufacturer.

Only use components or extensions that are approved by the manufacturer.

IMPORTANT

There is a possible impairment of the radio link/range when they are in direct proximity to

antenna systems with a high HF transmission power.

The device must not be used in the direct proximity of radar systems or transmitters (e.g.

radio, TV, mobile telephone etc.) or close to power supply systems.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 6/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Safety instructions

1.1 EU conformity declaration

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 7/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Safety instructions

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 8/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Product description

2 Product description

2.1 General

The iFLEX TRS 10 is a transceiver for the use of wireless sensors from the Hirschmann xSENS-

xxx-W1 family to a CAN bus.

Up to 4 wireless sensors can be connected wirelessly to a single iFLEX TRS 10. The number of

wireless sensors can be extended, as required, by using several transceivers.

How many sensors

can be connected?

All sensors from the xSENS-xxx-W1 family from Hirschmann’s extensive range of wireless sensors

can be used.

(the article numbers given on the right refer to the sensors including accessories)

Which wireless sen-

sors can be used?

Application Product designation Article no.

(set)

Load meas-

urement

fSENS KMD-006-W1 (up to 6 ton)

Art. no. 605792

alternatively also

fSENS KMD-020-W1 (up to 20 ton)

Art. no. 606345

Angle meas-

urement

gSENS WGF-W1 (0 to 90°)

Art. no. 608016

e.g. for boom angle measurement

alternatively also

gSENS WGS-W1 (-15 to +15°)

Art. no. 608185

for inclination measurement

Wind meas-

urement

iSENS WSS-W1

608179

Stroke end

monitoring

iSENS HES-W1

Art. no. 608015

608180

Table 1 Overview of xSENS-W1 wireless sensors

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 9/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Product description

2.2 Product features

The iFLEX TRS 10 has the following features:

Connects up to four wireless radio sensors with the CAN bus (expandable)

Simple setup of the wireless sensors via CAN bus

Automatic diagnostic function

CANopen slave in accordance with CiA DS-301/401

Transmission rate adjustable from 125 kbps to 1 Mbps

Battery monitoring for the connected wireless sensors

Protection class IP65, suitable for outdoor use

Operating temperature -40 to +85 °C

Voltage supply 10 to 30 V DC

2.3 Use for the intended purpose

The iFLEX TRS 10 is a transceiver used for the transmission of wireless sensor data to a CAN bus

using the CANopen protocol. Since impairment of the radio communication/range can occur, the

device must not be used in close proximity to antenna systems with a high HF transmission power

(e.g. radar / radio / TV / mobile telephone) or in close proximity to power supply systems.

2.4 Scope of supply

The scope of supply of the iFLEX TRS 10 with accessories (art. no. 608178)

consists of the following parts:

iFLEX TRS 10

Magnetic base antenna with 4 m connecting cable or short antenna

CAN T-piece M12

CAN connection cable, 0.6 m, with prefabricated plug connectors at both ends

User manual

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 10/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Product description

2.5 View of device

Operating

status

Indicators for

registered wire-

less sensors

channels 1 to 4

Indicator fo

r

hoist limit

signal

Indicator for low

sensor battery

channels 1 to 4

Coaxial socket

for antenna

Central plug

Figure 1: View of the iFLEX TRS 10

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 11/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Product description

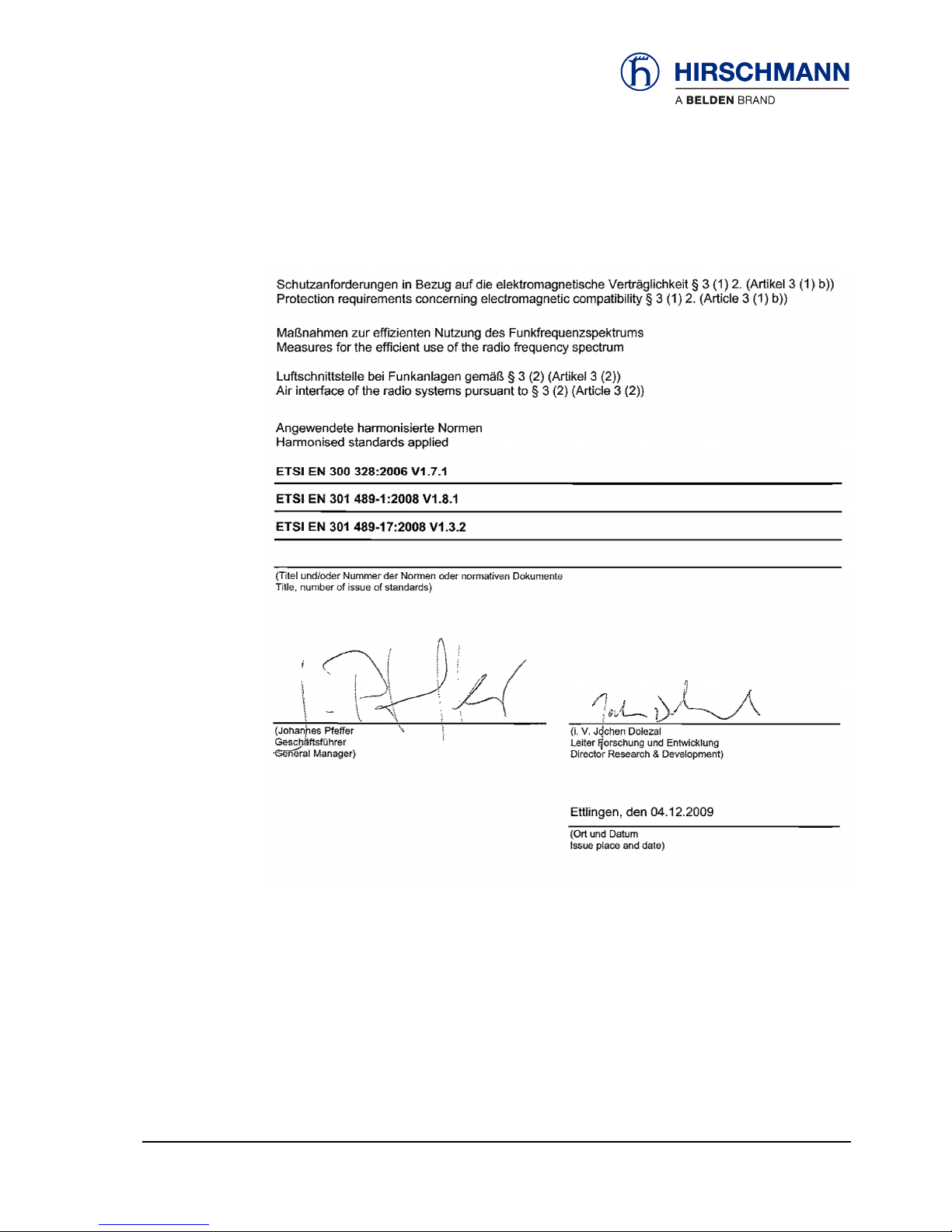

2.6 Dimensions

Figure 2: Dimensions of the iFLEX TRS 10 (with magnetic base antenna)

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 12/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Installation

3 Installation

3.1 Mounting the components

The iFLEX TRS 10 is supplied complete with all necessary mounting parts. Mounting can therefore

be performed simply and quickly. For mounting the wireless sensors, please refer to the instructions

provided with the respective sensor.

3.1.1 iFLEX TRS 10

The iFLEX TRS 10 must be mounted in a suitable place on a sufficiently firm surface with the con-

nections at the bottom.

The distance between the holes in the housing is 102 mm.

3.1.2 Short Antenna

Antenna, 2.4 GHz

TRS 10

Figure 3: Short, direct connection antenna

3.1.3 Magnetic base antenna

Antenna radiator 2.4 GHz

Antenna base

Magnetic baseplate

Figure 4: Magnetic base antenna (art. no.536023) with mounted radiator

Screw the antenna radiator hand tight onto the thread on the TRS 10 or on the top side of the an-

tenna base until you feel a stop. (Remove the protective cap from the thread if necessary).

Preparation of the

antenna

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 13/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Installation

If applicable, the antenna has a magnetic base plate and adheres securely to all ferromagnetic

surfaces.

How do I mount the

antenna?

NOTE

Optimal ranges are achieved if the antenna is aligned in accordance with the alignment of

the wireless sensor antennas and can radiate as freely as possible.

Niches or recesses are therefore less suitable as mounting locations!

Please follow the instructions below for laying the antenna cable (if applicable):

How should the

cable be laid?

IMPORTANT

The antenna cable can be damaged if it is squeezed or kinked.

Therefore, lay the antenna cable in such a way that it is neither squeezed nor laid around

sharp edges!

IMPORTANT

The function of the antenna and hence the whole system can be impaired if a mismatching

antenna radiator is used.

Always use the antenna radiator contained in the scope of supply!

After laying the cable, connect the coaxial connector of the antenna to the antenna socket on the

underside of the iFLEX TRS 10 or connect the antenna directly to the base of the TRS 10. Screw

the connector on hand tight.

Where is the

antenna

connected?

3.2 Electrical connection

Connection of the device to an existing CAN bus is simple thanks to the fully prefabricated connect-

ing cable (length 0.6 m) included in the scope of supply. The CAN T-piece included in the scope of

supply can also be used for this if necessary.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 14/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Installation

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 15/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

CAUTION

Danger of electrical short-circuits.

Switch off all systems before commencing with the installation work!

IMPORTANT

Damage to the device if connected to an unsuitable power supply.

The device may only be connected to a DC voltage source of 10 V to 30 V!

3.2.1 Wiring of the central connector

Please refer to the following illustration for the pin configuration of the connector on the underside

of the iFLEX TRS 10:

Pin 1 +VDC (10 …30 V)

Pin 2 GND

Pin 11 CAN L

Pin 12 CAN H

Figure 5: Pin configuration of the central connector

3.2.2 Wiring of the connecting cable

Please refer to the following illustration for the wiring of the connecting cable (article no. 536025):

Figure 6: Wiring of the CAN connecting cable

Length:

0,6 m

Commissioning

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 16/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

4 Commissioning

At least one functional wireless sensor must be available in order to commission and operate the

A guide to commissioning the iFLEX TRS 10 and connecting the wireless sensors is provided be-

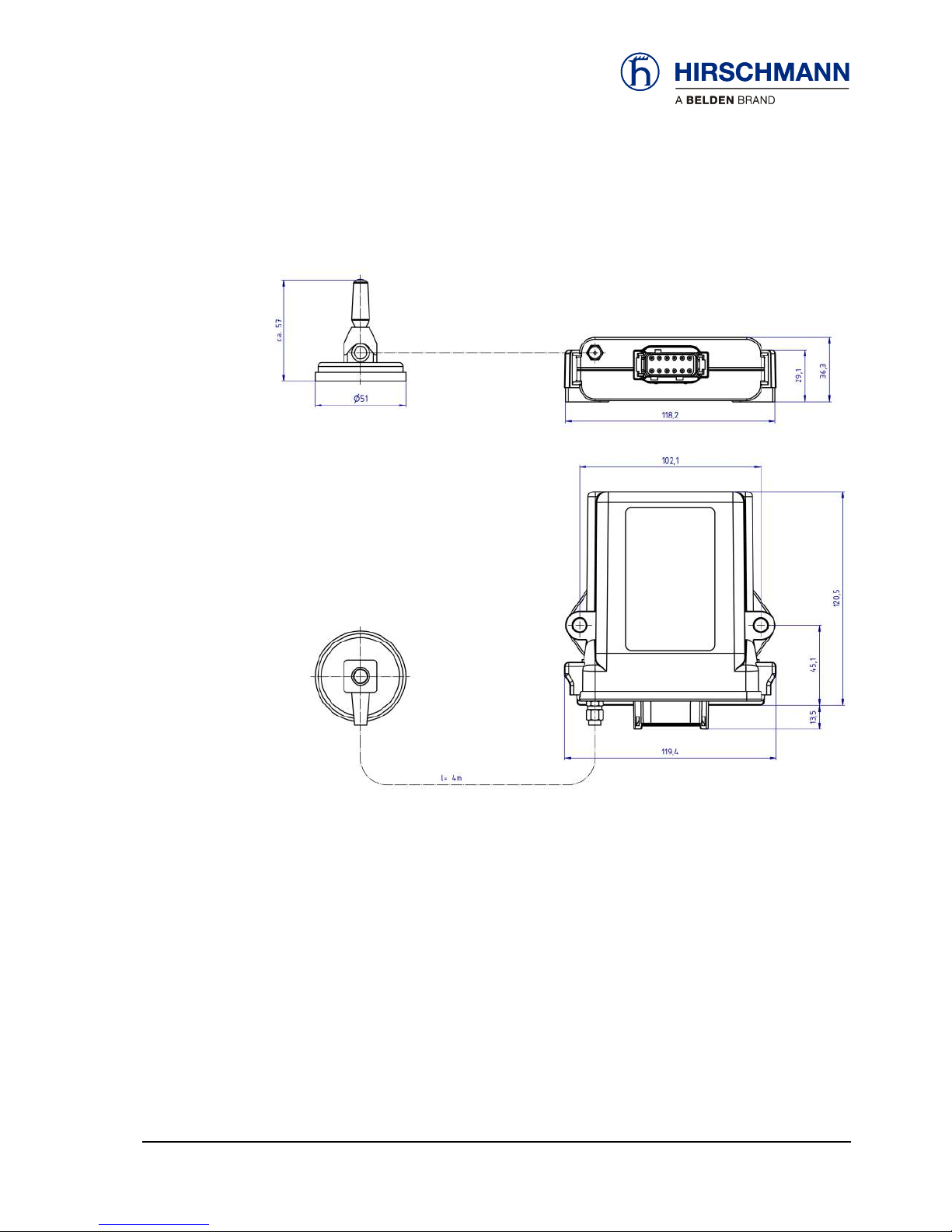

1. First, open the battery compartment of the wireless sensor after undoing the 4 screws and

Figure 7: Steps for Removing Batteries

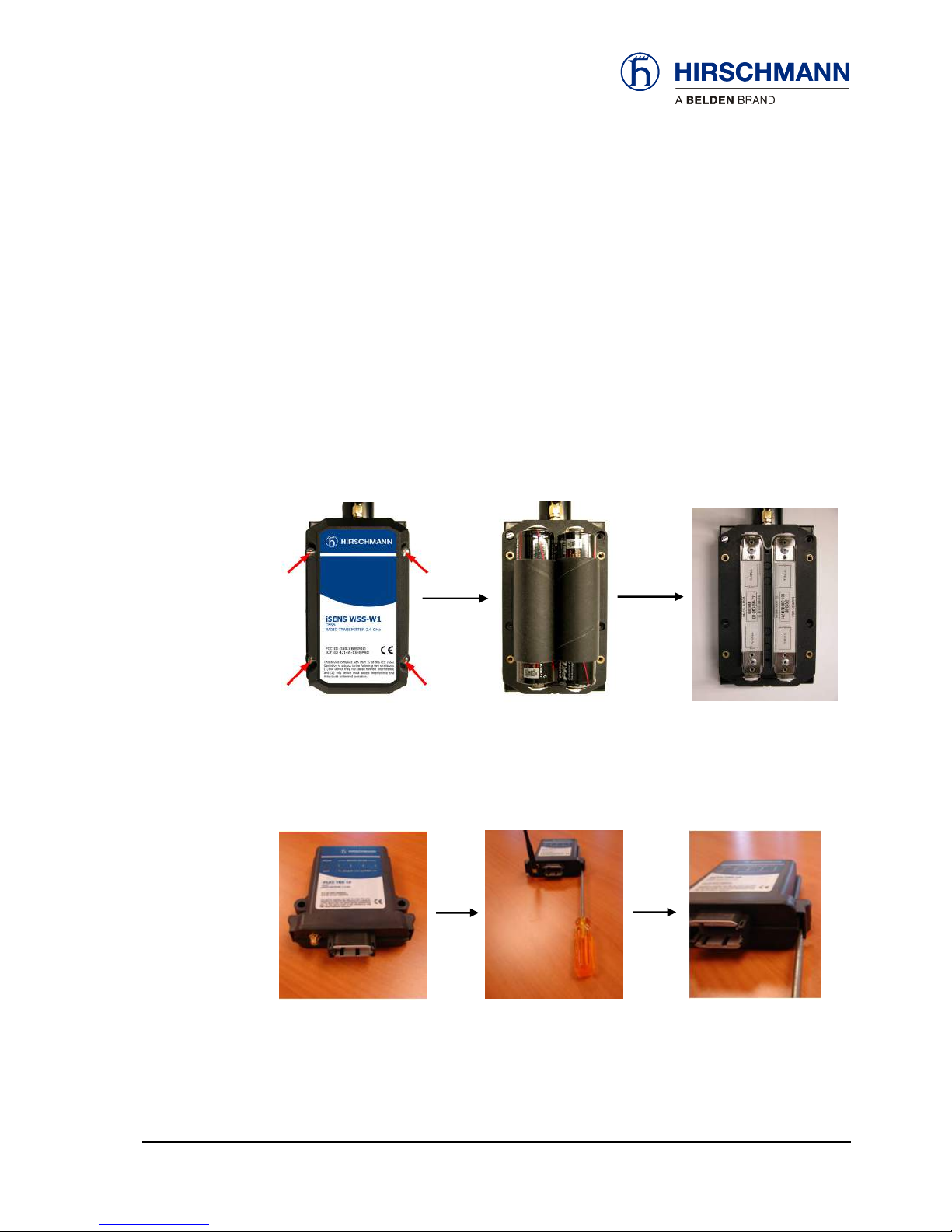

2. Next, remove the cover of the TRS 10 by pushing in the two tabs located on each side of the

Figure 8: Steps for Removing TRS 10 Cover

system.

low.

4.1 Adding a Wireless Sensor

remove the batteries as shown in Figure 7.

casing, as pictured below in Figure 8.

Commissioning

3. After Removing the outer cover, supply power to TRS 10 by either using your Deutsch con-

nector wired to your 10 to 30 volt power supply or use a DC power supply to provide 10 to 30

volts to pin 1 and ground to pin 2 of the connector. Refer to Figure 5 for the pin layout of the

connector.

4. Verify power is being supplied to the TRS 10 by checking to see if the “Power” Led is lit as

seen in Figure 9.

Figure 9: “Power” LED as indicated by the red light

5. Next, push and hold the red button located in the upper, left-hand corner of the TRS 10

board (Figure 10). Continue holding the button down for approximately 5 seconds until the

green LED, which corresponds to position 1 of the “Sensor Online” row located on the cover,

begins to blink slowly.

Figure 10: Red push button on TRS 10 board

6. Replace the batteries in the wireless sensor that you are trying to connect, following

the correct polarity. First, you will see the yellow LED located on the bottom of the sensor

turn on and stay lit for approximately 3 to 5 seconds. After the yellow LED on the sensor

changes to a short blink every 5 seconds, verify that the green LED in the “Sensor Online”

row, position 1 is now consistently lit and no longer flashing. If this is true, then your wireless

sensor has successfully connected to the TRS 10.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 17/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Commissioning

7. To connect another wireless sensor, move to the next unoccupied position that corresponds

to the “Sensor Online” row located on the cover of the TRS 10, by holding down the same

red button previously used step 5. Follow steps 4 to 6 as a guide if needed.

8. When all of your sensors have been connected to the TRS 10, replace each cover of the

wireless sensors my tightening the four screws. As well, reattach the cover of the TRS 10

making sure the two clips that were pushed in during the removal process have now

snapped back into place. It is critical that all screws be properly tightened and the TRS 10

cover be fitted back to its original position in order to maintain weather resistant capabilities.

Note: If a sensor does not successfully connect, remove its batteries, wait 15 seconds and then

follow steps 4 through 6.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 18/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Commissioning

4.2 Status LEDs

There are 10 LEDs on the front panel of the device, which indicate the status of various operating

conditions.

The meaning of the signals can be taken from the table:

LED: off

lights

flashes slowly

flashes rapidly

No supply

voltage pre-

sent

Supply voltage is

present

Sensor reports an

alarm (e.g. hoist limit

switch) or link to the

indicated sensor is

lost

During the sys-

tem diagnosis

No sensor

registered to

this channel

Sensor registered to

this channel and

ready for operation

Radio link to the

sensor on this

channel inter-

rupted

Batteries of the wire-

less sensor on this

channel are almost

exhausted! (Capacity

less than 6.5%)

Replace the batter-

ies soon!

Table 2 Overview of status LED

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 19/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Commissioning

4.3 Troubleshooting

After wiring the iFLEX TRS 10, the device switches itself on as soon as a supply voltage is present

on the CAN bus. After switching on, the system begins with a self-diagnostic routine.

How is the device

switched on?

The self-diagnosis takes approx. 5 seconds. During these tests the LEDs light up successively with

a test pattern:

How long does the

self-diagnosis take?

LED key: off: lights: flashes slowly: flashes rapidly:

If no wireless sensors have been registered and saved yet, only the ‘Power’ LED should be lit after

completion of the self-diagnosis:

How can I tell

whether the device is

working correctly?

If wireless sensors have already been registered and saved, the ‘Sensor Online’ LED of the corre-

sponding channel lights up, indicating that the radio link has been established.

If a ‘Low Battery’ LED lights up, this means that the battery set in the respective wireless sensor is

exhausted (remaining capacity < 6.5%) and must be replaced as soon as possible.

What does it mean

when a ‘Low Battery’

LED lights up?

If a ‘Sensor Online’ LED flashes rapidly after conclusion of the self-diagnosis, this means that the

radio link to the sensor on the indicated channel has been interrupted.

What does it mean

when a ‘Sensor

Online’ LED flashes

rapidly?

NOTE

If the link to a wireless sensor is interrupted, rectify the fault first before putting the system

into operation.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: [email protected] 20/29

21-810-19-0001_421826_en_Rev_B.doc / 2011-08-09 / Issue B / rk, kg.

Table of contents

Other Hirschmann Transceiver manuals