!

!

!

!

<

IA669: A

>

!

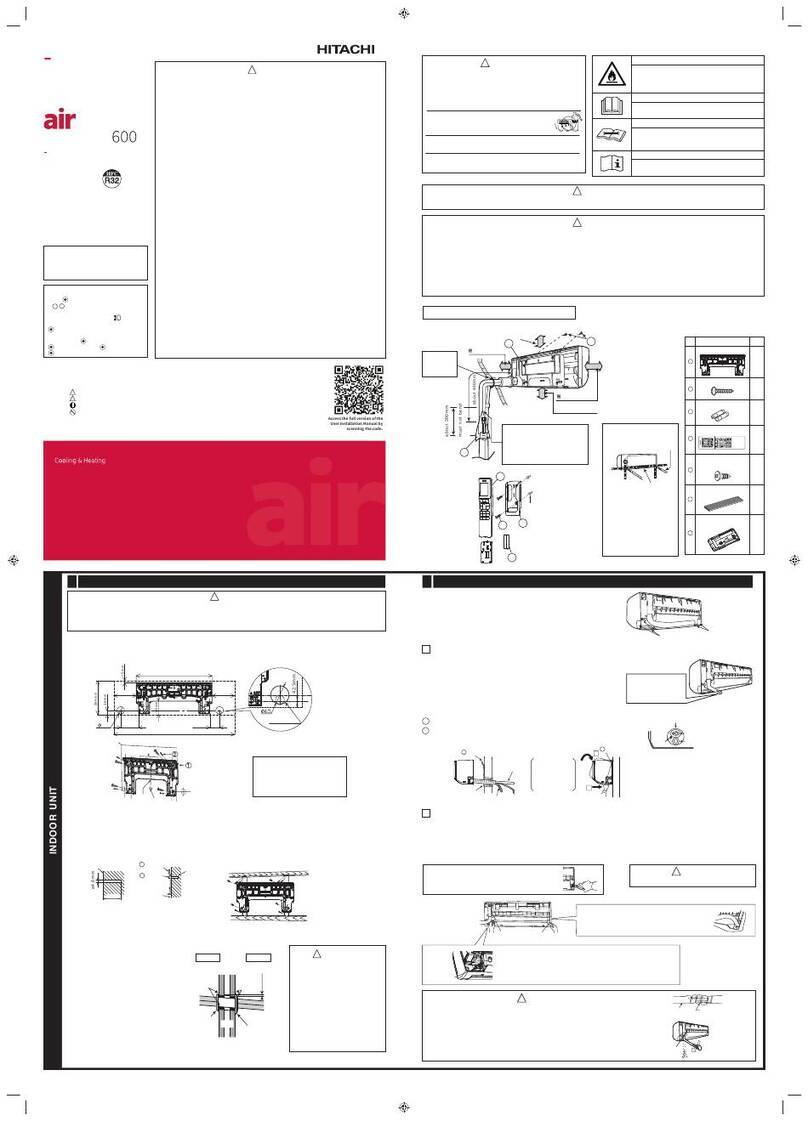

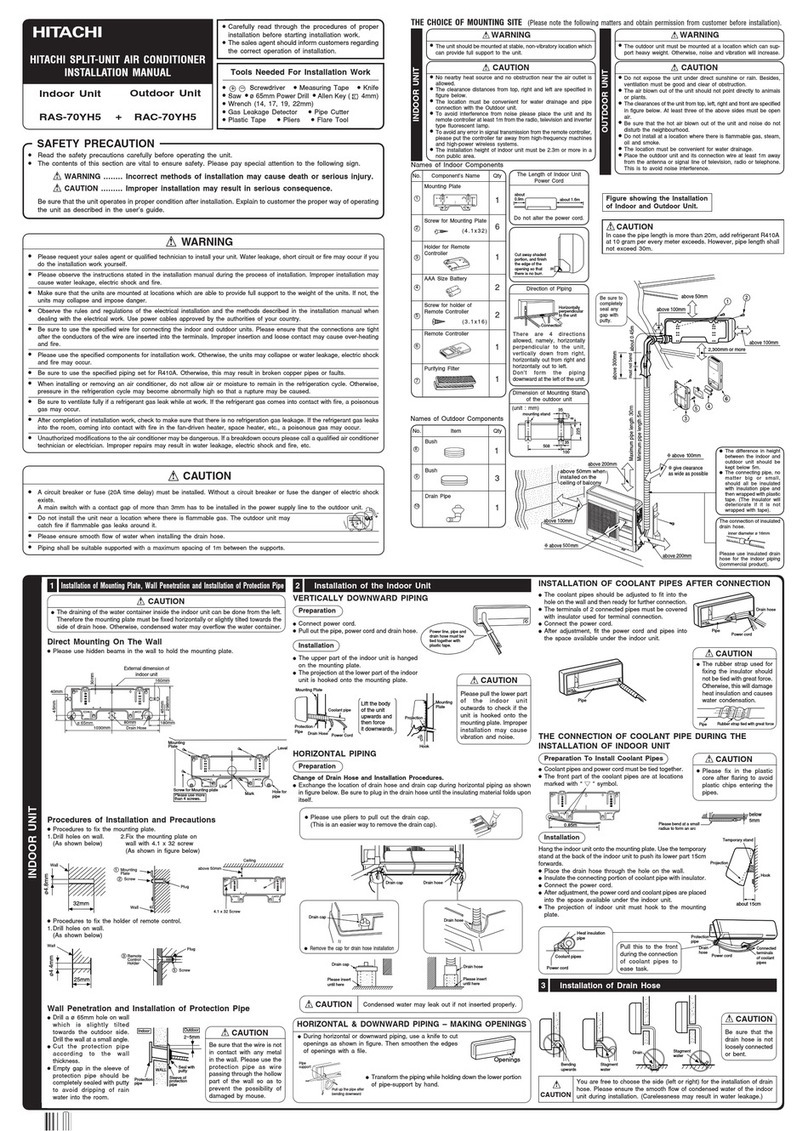

THE CHOICE OF MOUNTING SITE (Please note the following matters and obtain permission from customer before installation).

WARNING

!

OThe unit should be mounted at stable, non-vibratory location which can

provide full support to the unit.

WARNING

!

O

The Outdoor unit must be mounted at a location which can support heavy weight.

Otherwise, noise and vibration will increase.

!

O

No nearby heat source and no obstruction near the air outlet is allowed.

O

The clearance distances from top, right and left are specied in gure below.

O

The location must be convenient for water drainage and pipe connection with

the Outdoor unit.

O

To avoid interference from noise please place the unit and its remote controller

at least 1m from the radio, television and inverter type uorescent lamp.

O

To avoid any error in signal transmission from the remote controller, please put

the controller far away from high-frequency machines and high-power wireless

systems.

O

The installation height of indoor unit must be 2.3m or more.

CAUTION

!

O

Do not expose the unit under direct sunshine or rain. Besides, ventilation must be

good and clear of obstruction.

O

The air blown out of the unit should not point directly to animals or plants.

O

The clearances of the unit from top, left, right and front are specied in gure

below. At least 3 of the above sides must be open air.

O

Be sure that the hot air blown out of the unit and noise do not disturb the

neighbourhood.

O

Do not install at a location where there is ammable gas, steam, oil and smoke.

O

The location must be convenient for water drainage.

O

Place the Outdoor unit and its connecting cord at least 1m away from the antenna

or signal line of television, radio or telephone. This is to avoid noise interference.

O

Do not install outdoor unit facing strong wind direction. It may damage the fan

motor.

INDOOR UNIT

OUTDOOR UNIT

CAUTION

!

!

Other optional parts for display panel

& wireless remote control SPX-RCK4

Display panel

Panel installation plate

Panel cover

Remote controller

(wireless)

Holder for remote control

3.1 x 16 scr

ew

Item

Quantity

No.

1

2

3

4

5

6

1

1

1

1

1

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

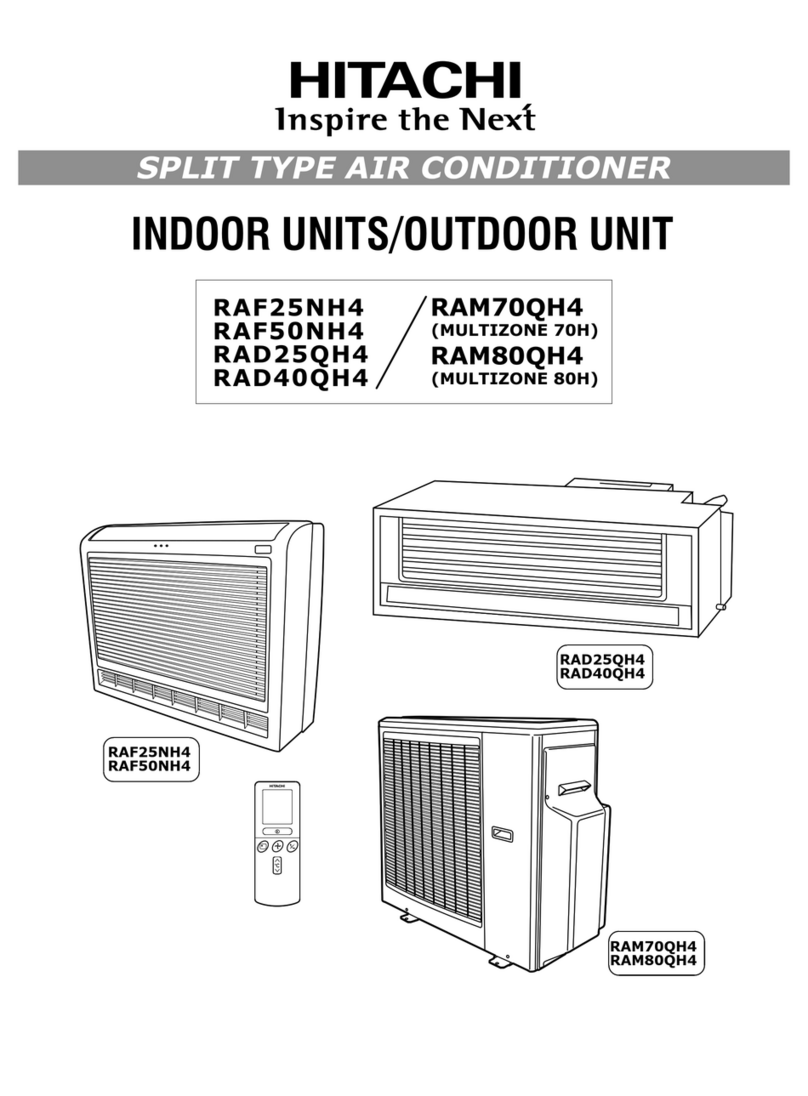

HITACHI CEILING CASSETTE-UNIT AIR

CONDITIONER INSTALLATION MANUAL

Maximum pipe length 50m

Minimum pipe length 5m

Above 100mm

give clearance

as wide as

possible

Above 200mm

Above 50mm when

installed on the

ceiling of balcony

Above 200mm

Above 100mm

Above 500mm

Air

outlet

Air

outlet 1000 mm

or more

1000 mm

or more

Air inlet

300 mm

or more

Air

outlet

Air

outlet

1000 mm

or more

1000 mm

or more

Air inlet

2500 mm

or more

O Carefully read through the procedures of proper installation

before starting installation work.

O The sales agent should inform customers regarding the correct

operation of installation.

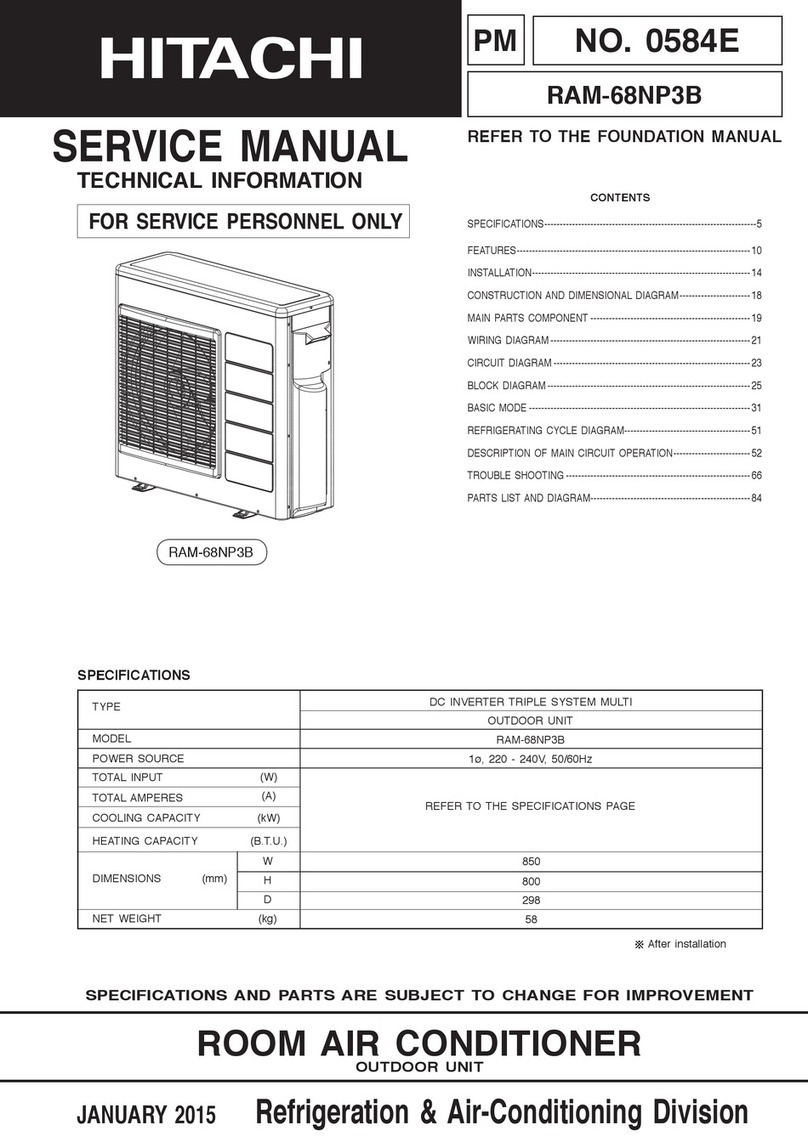

FOR SERVICE PERSONNEL ONLY

Tools Needed For Installation Work

O+ – Screwdriver OMeasuring Tape OKnife OSaw

Oø 65mm Power Drill OHexagonal Wrench Key ( 4mm)

OWrench (14,17,19,22,26,27mm) OGas Leakage Detector

OPipe Cutter OVinyl Tape O Pliers OFlare Tool

ORead the safety precautions carefully before operating the unit.

OThe contents of this section are vital to ensure safety. Please pay special attention to the following sign.

WARNING ........ Incorrect methods of installation may cause death or serious injury.

CAUTION ......... Improper installation may result in serious consequence.

Be sure that the unit operates in proper condition after installation. Explain to customer the proper way of operating the unit as

described in the user’s guide.

WARNING

OPlease request your sales agent or qualied technician ti install your unit. Water leakage, sort circuit or re may occur if you do the

installtion work yourself.

OPlease observe the instructions stated in the installation manual during the process of installation. Improper installation may cause

water leakage, electric shock and re.

OMake sure that the units are mounted at locations which are able to provide full support to the weight of the units. If not, the units

may collapse and impose danger.

OObserve the rules and regulations of the electrical installtion and the methods described in the installation manual when dealing

with the electrical work. Use power cables approved by the authorities of your country.

OBe sure to use specied wire for the connection indoor and outdoor units. Please ensure that the connections are tight after the

conductors of the wire are inserted into the terminals. Improper insertion and loose contact may cause over-heating and re.

OPlease use the specied components for installtion work. Otherwise, the units may collapse or water leakege, electric shock and

re may occur.

OBe sure to use the specied piping set for R-22. Otherwise, this may result in broken copper pipes or faults.

OWhen installing or removing an air conditioner, only specied refrigerant (R-22) shall be allowed, do not allow air or moisture to

remain in the refrigeration cycle. Otherwise, pressure in the refrigeration cycle may become abnormally high so that a rupture may

be caused.

OBe sure to ventilate fully if a refrigerant gas leak while at work. If the refrigerant gas comes into contact with re, a poisonous gas

may occur.

OAfter completion of installation work, check to make sure that there is no refrigeration gas leakage. If the refrigerant gas leaks into

the room, coming into contact with re in the fan-driven heater, space heater, etc., a poisonuos gas may occur.

OUnauthorized modications to the air conditioner may be dangerous. If a breakdown occurs please call a qualied air conditoner

technician or electrician. Improper repairs may result in water leakage, electric shock and re, etc.

OA circuit breaker or fuse (20A time delay) must be installed. Without a circuit breaker or fuse the danger of electric shock exists.

A main switch with a contact gap of more than 3.5mm has to be installed in the power supply line to the outdoor unit.

OPiping shall be suitable supported with a maximum spacing of 1m between the supports.

ODo not install the unit near a location where there is ammable gas. The outdoor unit may catch re if

ammable gas leaks around it.

OFor installation of front panel RAI-ZCPM, please follow exactly the instruction in the manual.

OPlease ensure smooth ow of water when installing the drain hose.

Paper Pattern

(Carton Board)

Names of Indoor Components

Level Scaler

(Cut and Take

Out it from the

Carton Board)

Cross Recessed

Head Screws (M6)

Washer with Insulation

Material (M10)

Washer (M10)

Drain Hose

Hose Clamp

Insulation (22iD)

Insulation (28ID)

Cord Clamp

Packing

(5Tx50x200)

Cord Clamp

Remote Controller

Packing

(5Tx270x270)

Screw for holder of

Remote Controller

Figure showing the installation of Indoor Unit

CAUTION CAUTION

The installtion

height of indoor

unit must be 2.3m

or more.

In case the pipe lenght is more than 5m, add refrigerant

R22 at 35 gram per every meter exceeds. However,

pipe lenght shall not exceed 50m.

Be sure to

completely

seal any

gap with

putty.

The indoor piping should be

insulated with the enclosed

insulation pipe. (If the

insulator is insufcient, please

use commercial products).

O

The difference in

height between the

indoor and outdoor

unit should be kept

below 30m.

O

The connecting

pipe, no matter big

or small, should

all be insulated

with insulation pipe

and then wrapped

with vinyl tape.

(The insulator will

deteriorate if it is

not wrapped with

tape).

Drain Pipe

Must be installed

seperately.

Insulate indoor part

of pipe to prevent

condensation.

Bush

Bush

Drain Pipe

Dimension of Mounting Stand

of the outdoor unit

Mounting Stand

(unit : mm)

Opening of False Ceiling and Suspension Bolts

Dimension of Opening

860 to 910

(Dimension of

Suspension Bolts)

4-Positions of

Suspension Bolts

Dimension of Opening

860 to 910

(Dimension of

Suspension Bolts)

840 (Unit Size)

Air Panel

Drain Piping

Connection Side

Piping Connection

Side

Fig. 1 Opening of False Ceiling and Suspension Bolts

(1) Determine the nal location and installation direction of the indoor unit

paying careful attention to the space for the piping, wiring and maintenance.

(2) Cut out the area for the indoor unit in the false ceiling and install suspension

bolts, as shown in Fig. 1.

(3) Check to ensure that the ceiling is horizontally level, otherwise drainage

can not ow.

(4) Strengthen the opening parts of the false ceiling.

(5) Mount suspension bolts, as shown in Fig. 2

* For Concrete Slab

* For Steel Beam

150 to 160mm Insert

(100 to 150kg)

Concrete

Anchor Bolt

(W3/8 or M10)

I Beam

Suspension Bolt

(W3/8 or M10)

Fig. 2 Mounting the Suspension Bolts

Mounting Position of the Indoor Unit

4-Suspension Bolts

M10 or W3/8 (Field-Supplied)

Surface of

Ceiling

W-Nut (Field Supplied)

Washer (Accessary)

10 Min.

* indicates the dimension between lower face of

indoor unit and surface of ceiling.

Fig. 3 Mounting Position

Liquid Pipe Connection

Drain Pipe Connection

118 (Drain Pipe)

(for Cable)

(Liquid Pipe Connection)

(Gas Pipe Connection)

Gas Pipe Connection

Wiring Hole (ø 32.5 Hole)

(for Spare)

Wiring Hole (30x30)

Fig. 4 Indoor Unit and Air Panel

Mounting the Indoor Unit

(1) Mounting the nuts and washers to the suspension bolts.

Suspension Bolt (Field Supplied)

Nut (Field Supplied)

4 *Washer with Insulation (Accessary)

Suspension Blacket (Attaced Indoor Unit)

5 *Washer (Accessary)

Nut (Field Supplied)

Surface of Ceiling

Approx. 52

Approx. 50

Fig. 5 Mounting Nuts and Washers

* Put the washer so that the surface with insulation can faces downwards.

(2) Lift the Indoor Unit by hoist, and do not put any force on the drain pan.

(3) Secure the indoor unit using the nuts, washers.

Suspension Bolt

Suspension Bracket

Drain Pan

Fig. 6 Mounting the Indoor Unit

NOTE

If a false ceiling has already benn installed, complete all piping and wiring work

inside the ceiling before hooking-up the indoor unit.

Adjusting the Space between Indoor Unit and False Ceiling Opening

CAUTION

O Check the level of the drain pan using a water level to avoid incorrect opera-

tion of the drain discharge mechanism in the indoor unit. The drain piping

side of the indoor unit must be approximately 5mm lower than the other part.

O Tighten the nuts of the suspension brackets after the adjustment is completed.

Apply LOCK-TIGHT paint* to the bolts and nuts in order to prevent them

from loosening. If not done, abnormal noises or sounds may occur and the

indoor unit may fall down.

LOCK-TIGHT paint*: Paint the lock bolts and nuts. Adjust the indoor unit to the

correct position while checking with the checking scales (factory-supplied).

(1) Pattern Board for installation is printed on the packing.

Cut off the checking scale for dimension of opening from packing.

Checking Scale for

Dimension of Opening

Packing

(Corrugated Board)

Pattern Board

for installation

(2) Adjust the position of indoor unit, as shown below by using checking scale.

Indoor Unit (Viewed from Bottom Side)

Surface of Flange

Surface of Ceiling

Indoor Unit

Slub

10 to 3510 to 35

10 to 35

10 to 35

(a) For Ceiling already Completed with Panels

Attach the scale to the

bottom side of the unit

Attach the scale to the

face of ceiling

Checking Scale for

Dimension of Opening

Adjust the height of the ceiling

and the unit at each corner.

Check the dimension of opening

at each side

(b) Ceiling Not Completed with Panels yet

Pattern Paper

for Installation

Dimension for

Opening

Dimension for

Opening

Suspension Bolt

Indoor unit

Screw (M6)

Surface of Ceiling Pattern Board

for Installation

Installation Details for Air Panel

OThe details of installation work for air panel shall be according to the Instal-

lation Manual for Air Panel.

OCheck to ensure that the connection of connectors between the indoor unit

and the air panel.

Names of Outdoor Components

No. Qty

Item

INDOOR UNIT