INDEX

Important Notice...................................................................................................................................................2

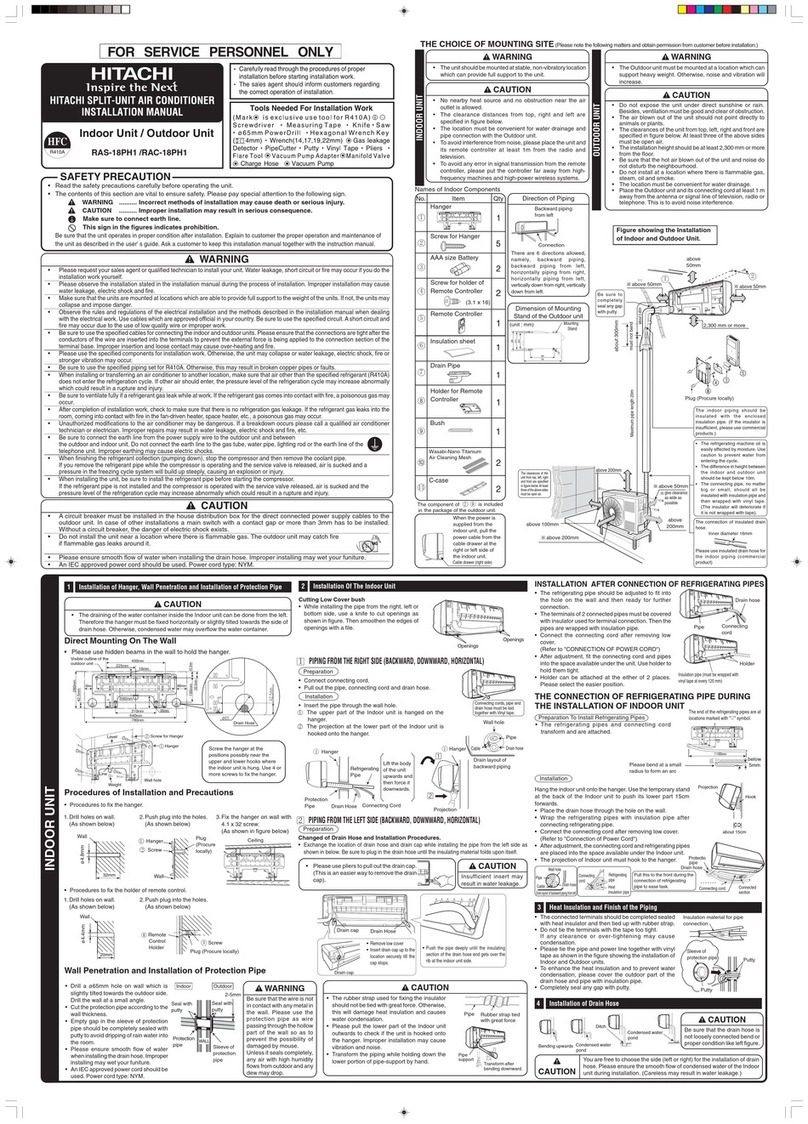

1 Safety Summary .............................................................................................................................................3

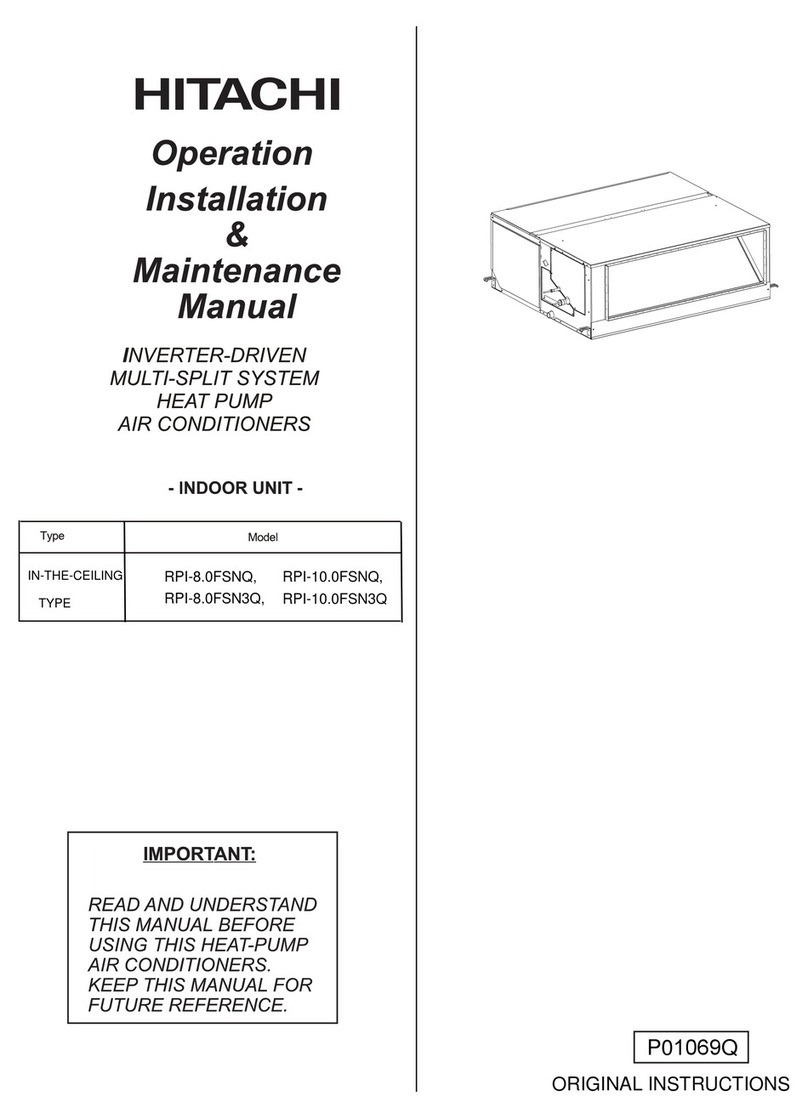

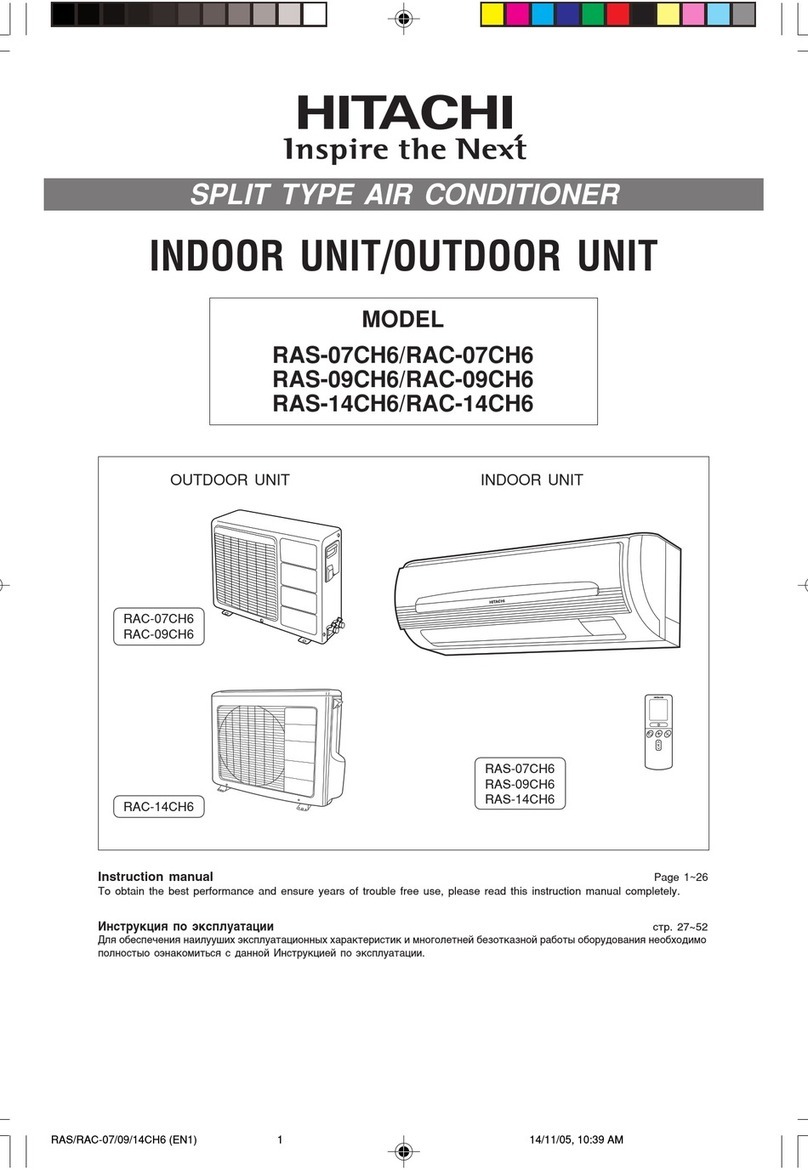

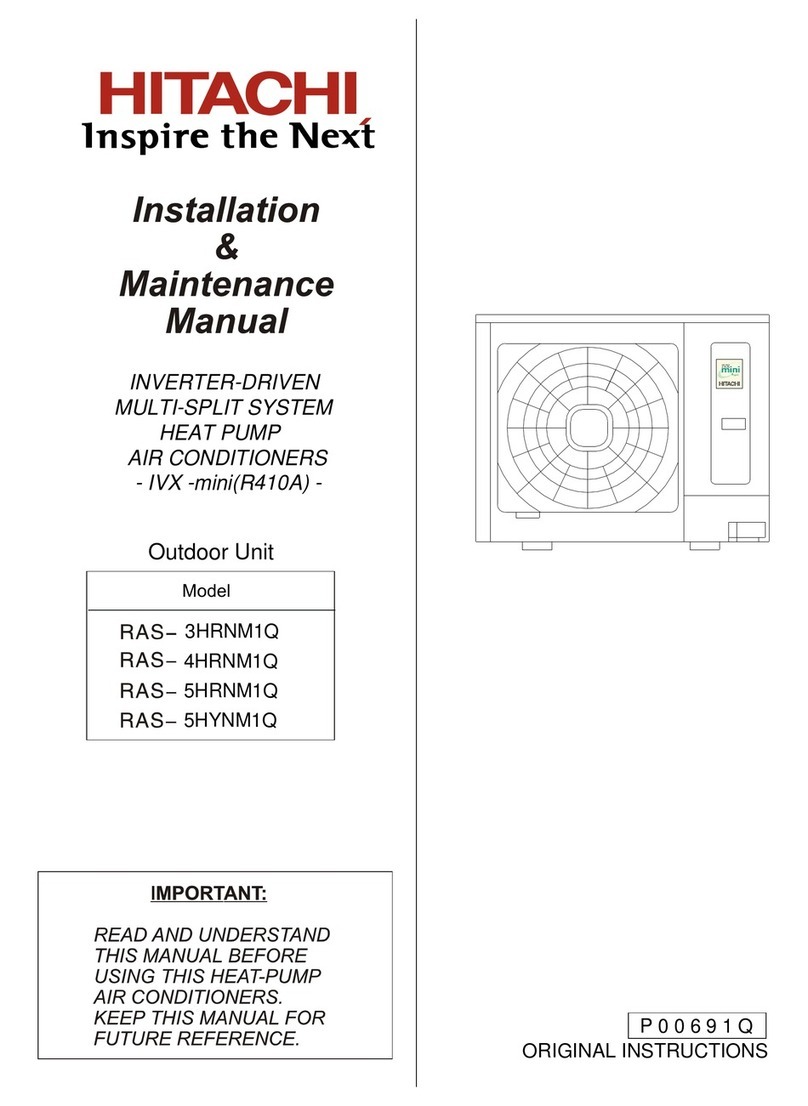

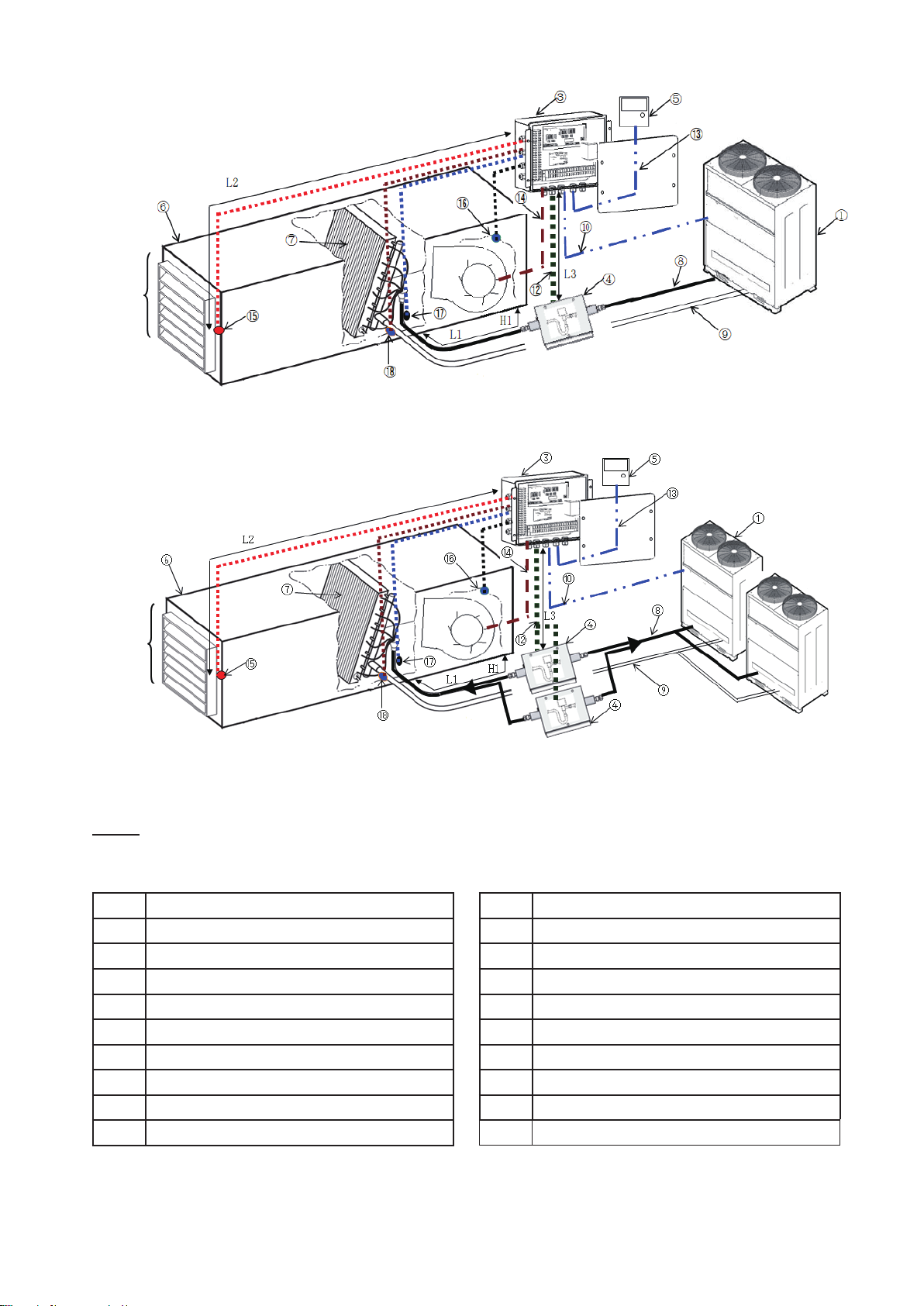

2 System Description.........................................................................................................................................5

2.1 System Overview ...................................................................................................................................5

2.2 Product Line-up......................................................................................................................................7

2.3 Factory-Supplied Accessories................................................................................................................8

2.4 Limitation of Installation and AHU ..........................................................................................................9

2.5 CapacityControlMode......................................................................................................................... 11

3 Transportation and Handling.........................................................................................................................16

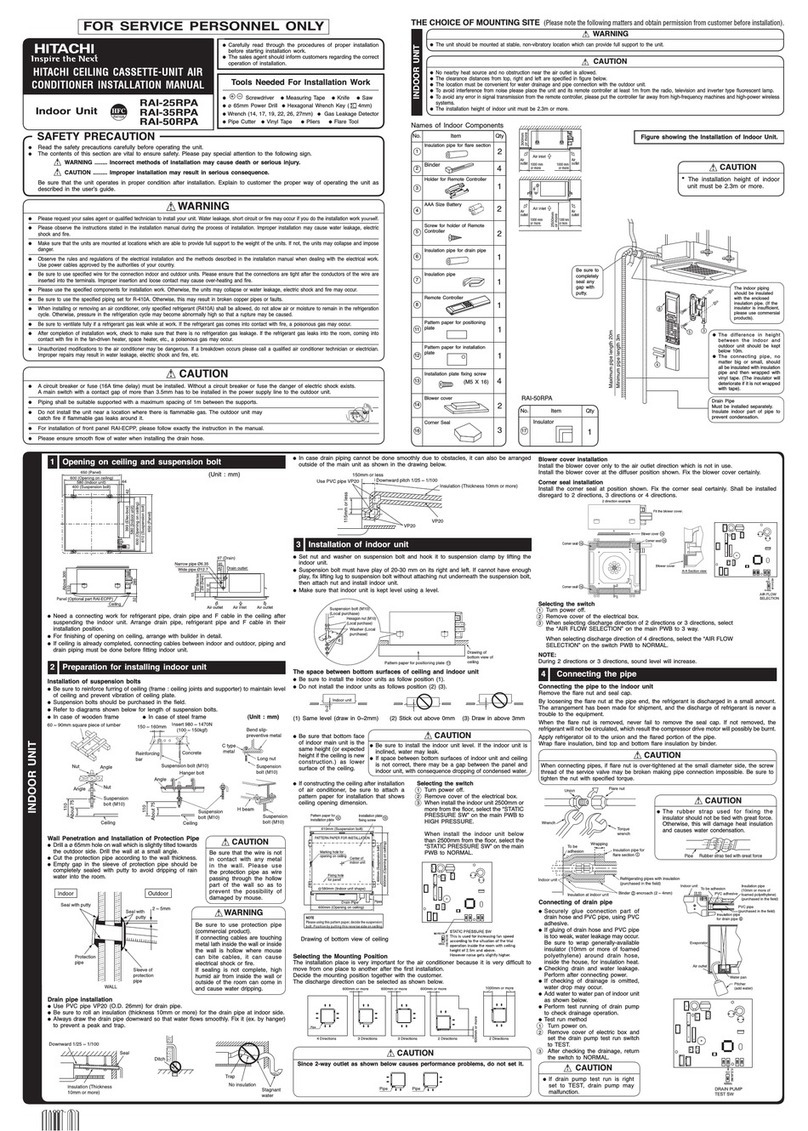

3.1 Transportation ......................................................................................................................................16

3.2 Installation Location..............................................................................................................................16

3.3 Dimension Data....................................................................................................................................16

3.4 Installation Method ...............................................................................................................................16

3.5 ThermistorInstallation..........................................................................................................................18

4 Refrigerant Piping Work................................................................................................................................19

4.1 Piping Materials....................................................................................................................................19

4.2 Piping Connection ................................................................................................................................19

5 ElectricalWiring ............................................................................................................................................20

5.1 GeneralCheck .....................................................................................................................................20

5.2 ElectricalWiringConnection ................................................................................................................20

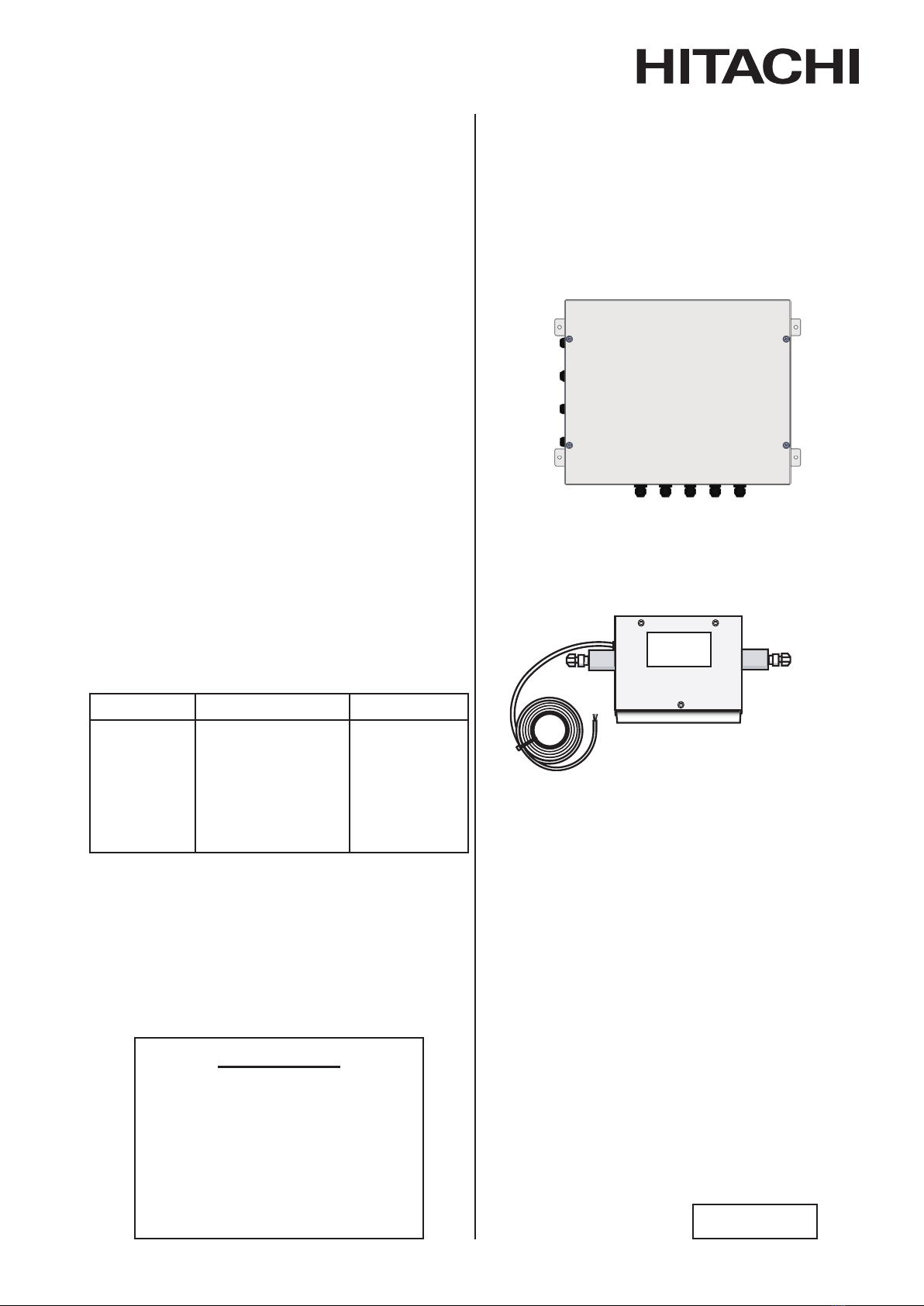

5.3 ControlBoxTerminalBlock ..................................................................................................................21

5.4 ExpansionValveBox............................................................................................................................21

5.5 TerminalBlockConnectionandRemarks ............................................................................................22

6 OptionalSettingandInput/OutputSetting ....................................................................................................23

6.1 OptionalSettingandInput/OutputSettingonWiredController............................................................23

6.2 InitializationofOptionalSettingandInput/OutputSettingbyWiredController ....................................23

6.3 OptionalSettingandInput/OutputSetting............................................................................................23

6.4 InputSetting .........................................................................................................................................26

6.4.1 RemoteControlON/OFFFunction .............................................................................................26

6.4.2 ControlbyField-SuppliedRoomThermostat(Settingindication01/02).....................................29

6.4.3 CoolingorHeatingOperationModeSetting(Settingindication07) ...........................................30

6.5 OutputSetting ......................................................................................................................................31

7 Setting of DIP Switches ................................................................................................................................32

8 Test Run........................................................................................................................................................33

9 Warranty Policy and Disclaimer ....................................................................................................................33