ENGLISH

During operation:

• Avoid an extended period of exposure to a direct air ow.

• Do not insert ngers, rods or other objects into the air outlet

or inlet. As the fan is rotating at high speed, it will cause

injury. Before cleaning, be sure to stop the operation and turn

the breaker OFF.

•Do not use any conductor as fuse wire. This could cause a

fatal accident.

•During thunderstorms, disconnect and turn off the circuit

breaker.

•Do not attempt to operate the unit with wet hands. This could

cause fatal accident.

•Do not direct the cool air coming out from the air conditioner

to household heating appliances (stoves, electric kettles,

ovens, etc.), as this may affect their operation.

•Please ensure that the outdoor mounting frame is always

stable, rm and without defects. Otherwise, the outdoor unit

may collapse and cause damage and injury.

•Do not splash or direct water to the body of the units when

cleaning them, as this may cause short circuit.

•Do not use any aerosol or hair sprays near the indoor unit.

Their chemicals can adhere to the ns of the heat exchanger

and block the ow of evaporation water to the drain pan.

Water will drop on the tangential fan and splash out from the

indoor unit.

•Switch off the units and turn off the circuit breaker during

cleaning.

•Do not climb on the outdoor unit or put objects on it.

•Do not put water containers (like a vase) on the indoor unit. If

water drips into the unit, it will damage the inside and cause

short circuit.

•When operating the unit with the door and windows opened

(relative humidity constantly above 80%) and with the air

deector facing down or moving automatically for a long

period of time, water will condense on the air deector

and drip down occasionally. This will wet your furniture.

Therefore, do not operate under such condition for an

extended time.

•The preset room temperature cannot be achieved if the

amount of heat in the room exceeds the cooling or heating

capacity of the unit (for example, if more people enters in the

room, if heating equipment is used, etc.).

SAFETY PRECAUTION

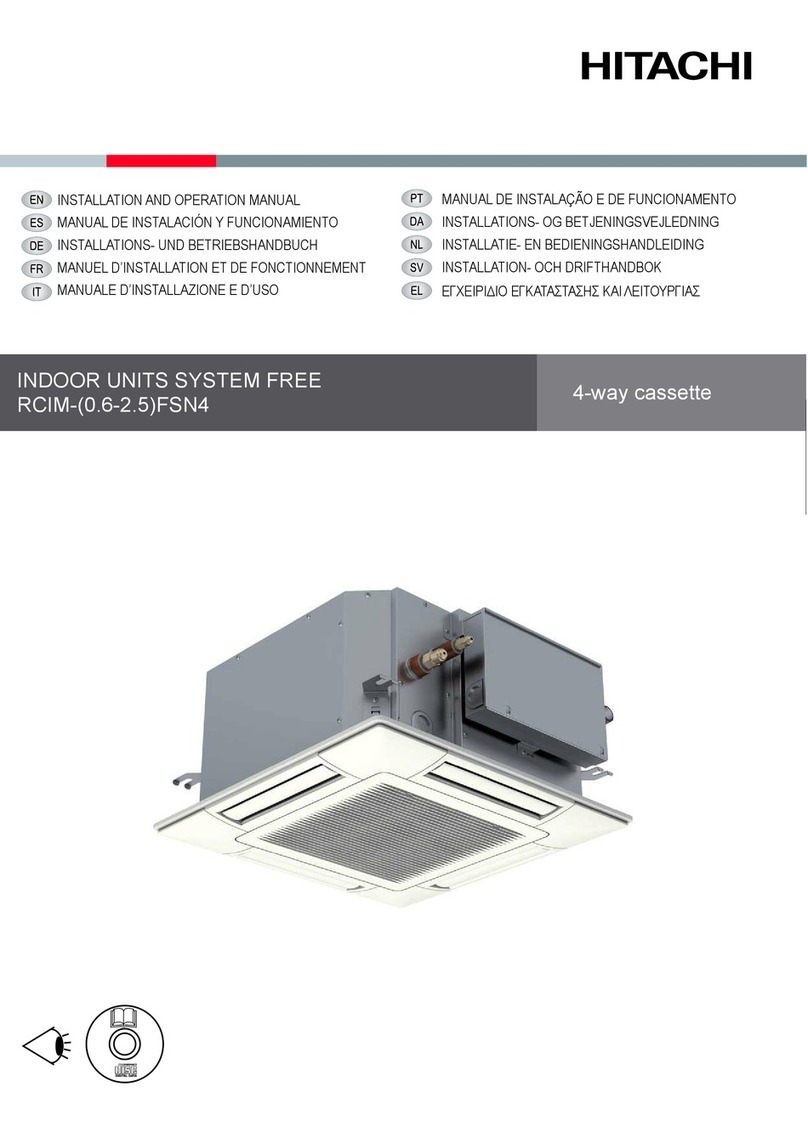

•Check that all the information necessary for the correct

installation of the system is included in the Installation and

Operation Manuals provided with the outdoor and indoor

units. Please contact your distributor if it is not the case.

•The installation of refrigerant tubing shall be kept to a

minimum. Refrigerant tubing outside the cabinet shall be

protected to avoid mechanical damage and shall not be

installed in an unventilated space. It shall not be handled

or used for carrying during moving of the units. Flexible

refrigerant connectors (such as connecting lines between

the indoor and outdoor unit) may be displaced during normal

operation.

Low temperature solder alloys, such as lead/tin alloys, are

not acceptable for pipe connections.

Brazed, welded or mechanical connection shall be made

before opening the valves to permit refrigerant to ow

between refrigerant system parts. When mechanical

connectors are reused indoors, sealing parts shall be

renewed. When ared joints are reused indoors, the are

parts shall be re-fabricated. Mechanical connections shall be

accessible for maintenance purposes.

If any part of the system is installed in an unventilated area,

it shall be so constructed that should any refrigerant leak, it

will not stagnate so as to create a re or explosion hazard.

Any required ventilation opening shall be kept clear of

obstruction. Compliance with national gas regulations shall

be observed.

ELECTRICAL INSTALLATION

•The electrical installation must be performed according to

this Installation Manual and all the relevant regulations and

standards. Failure to follow these instructions can result in

shortage of capacity and reduced performance, leading to

electric shock and re.

•Do not install the unit in the following places, as this may

lead to the occurrence of re, deformations, rusting or

operation failure:

-Places where oil is present (including oil for machinery)

-Places with a high concentration of sulphurous gas, such

as spas

-Places with a saline, acidic or alkaline atmosphere

-Places where ammable gases may be generated or

circulate

-Places where silicon gas is present (depositions of silicon

gas on the surface of the heat exchanger act as a water

repellent, resulting in condensate water splashing out of

the collection tray and into the electrical box)

SERVICING

•Do not carry out maintenance, service and repair operations

by yourself. These operations shall be performed only by

qualied workers with the suitable tools and resources.

•Work shall be undertaken under a controlled procedure so

as to minimise the risk of ignition. All maintenance staff and

other staff in the area shall be instructed on the nature of

work being carried out. Work in conned spaces shall be

avoided.

•Ensure that the conditions within the area have been made

safe by control of ammable material. The area shall be

checked with an appropriate refrigerant detector prior to

and during work, to ensure that a potentially ammable

atmosphere is detected. The leak detection equipment used

shall be suitable for use with ammable refrigerants (i.e.,

non-sparking, adequately sealed and intrinsically safe)

• Appropriate re extinguishing equipment shall be available

on hand if any hot work is to be conducted. Please have a

dry powder or CO2 extinguisher next to the charging area.

Any source of ignition which may lead to the risk of re

IMPORTANT NOTICE

PMML0477 rev.1 - 10/2017

3