Safety precautions

·Perform grounding

Do not connect the earth wire to a gas pipe, water pipe, lightning rod or telephone earth wire.

Defective grounding could cause an electric shock.

·Do not install the unit in a place where inflammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it could cause an explosion.

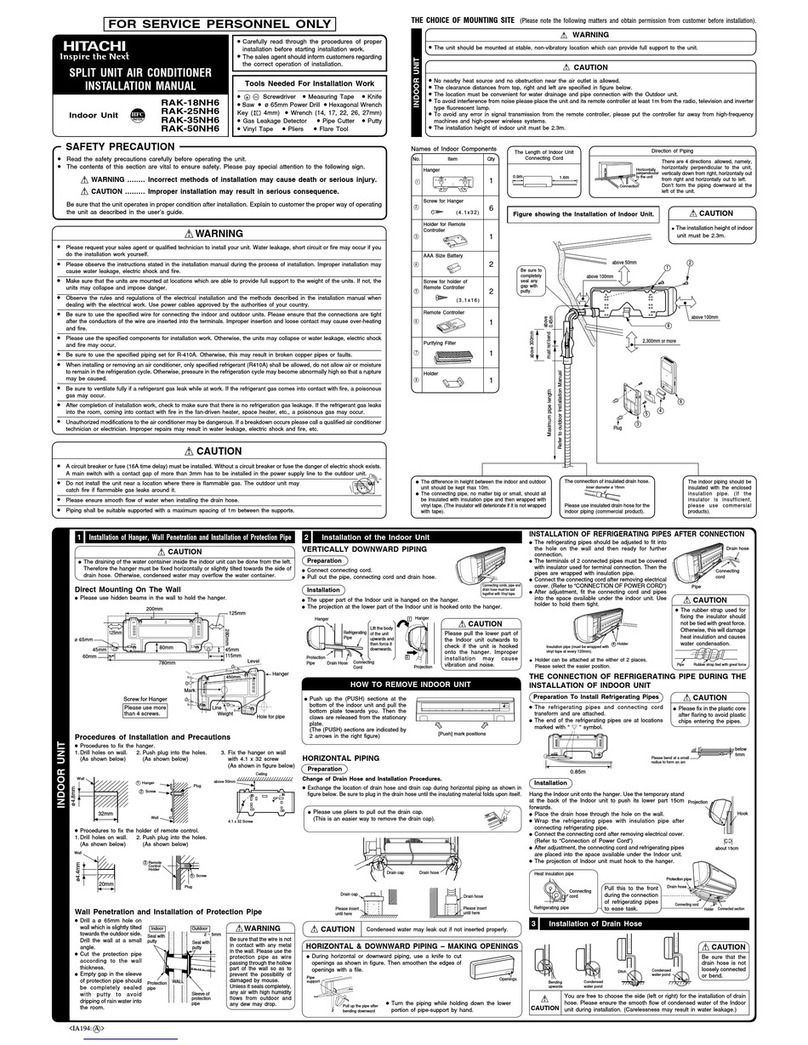

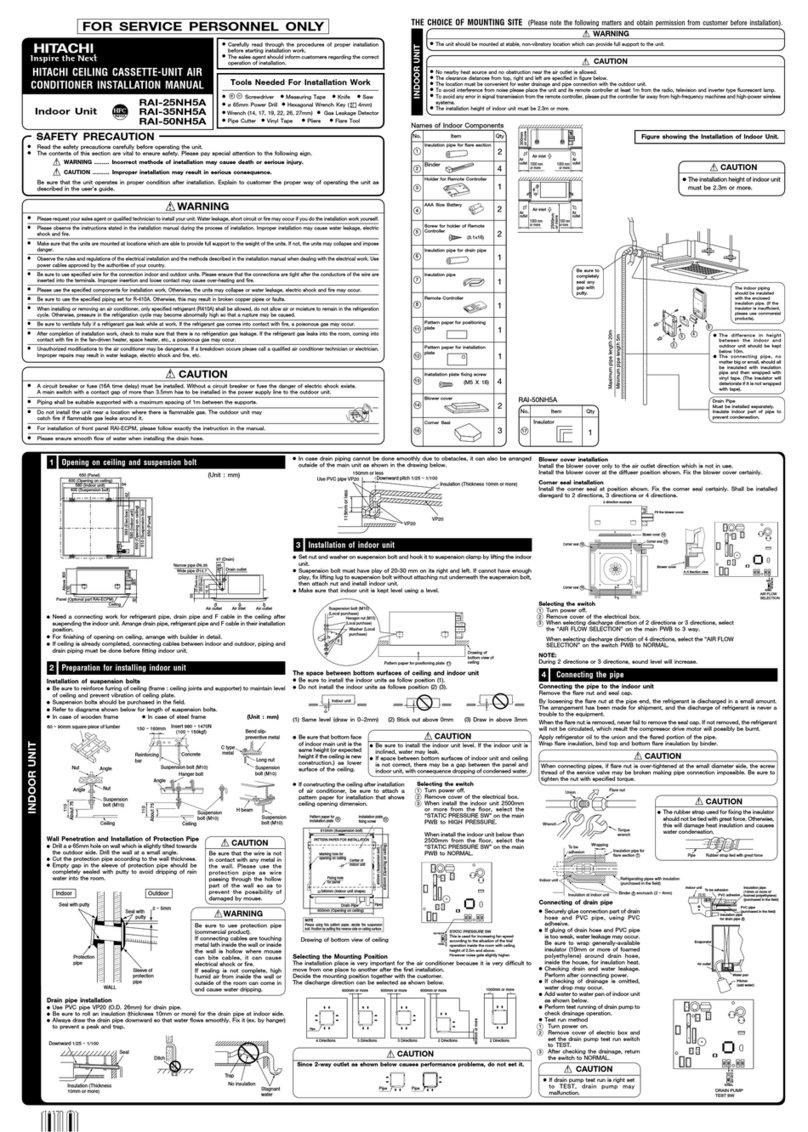

·Fasten a flare nut with a torque wrench as specified in this manual.

When fastened too tightly, a flare nut may break after a long period, thereby causing refrigerant leakage.

·Install an earth leakage breaker depending on the installation place(where it is humid).

If an earth leakage breaker is not installed, it could cause an electric shock.

·Perform the drainage/piping work securely according to the installation manual.

·If there is a defect in the drainage/piping work, water will drop from the unit and household items

will get wet and damaged.

CAUTION

2

·Do not let air enter the refrigeration system or discharge refrigerant when moving the air conditioner.

·The installation instructions for appliances that are intended to be permanently connected to fixed

wiring, and have a leakage current that may exceed 10 mA, shall state that the installation of a

residual current device (RCD) having a rated residual operating current not exceeding 30 mA is

advisable.

·This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

·If the appliance is fixed wiring, the appliance must be fitted with means for disconnection from the

supply mains having a contact separation in all poles that provide full disconnection under over

voltage category III conditions, and these means must be incorporated in the fixed wiring in

accordance with the wiring rules.

·If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

·The appliance shall be installed in accordance with national wiring regulations.

·Servicing shall only be performed as recommended by the equipment manufacturer.

Safety Instructions

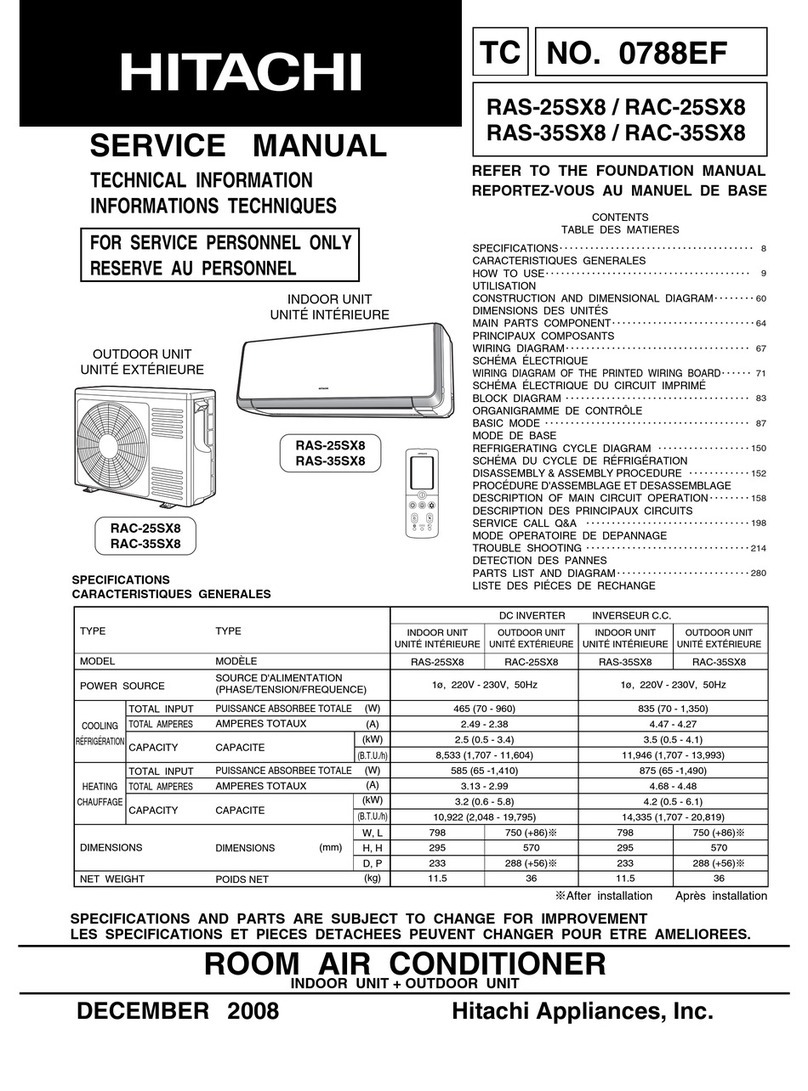

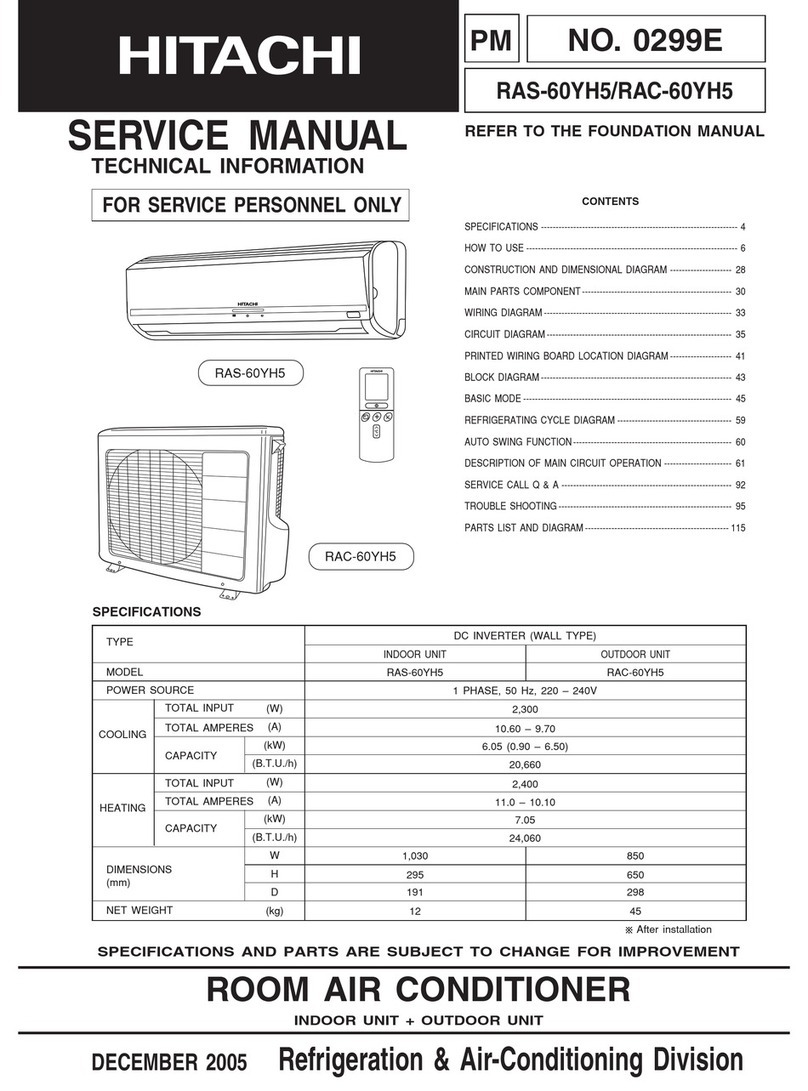

·The method of connection of the appliance to the electrical supply and interconnection of separate

components is detailed in below part. The wiring diagram with a clear indication of the connections

and wiring to external control devices and supply cord is detailed in below part. The cord of the

H07RN-F type or the electrically equivalent type must be used for power connection and

interconnection between outdoor unit and indoor unit. The size of the cord is detailed in below part.

·In order to avoid a hazard due to inadvertent resetting of the thermal cut-out, this appliance must not

be supplied through an external switching device, such as a timer, or connected to a circuit that is

regularly switched on and off by the utility.

·It is necessary to allow disconnection of the appliance from the supply after installation. The

disconnection may be achieved by incorporating a switch in the fixed wiring in accordance with the

wiring rules. During service and when replacing parts, be sure to disconnect the appliance from its

power source. If the disconnection is not foreseen, and provide a disconnection with a locking system

in the isolated position.

·Details of type and rating of fuses, or rating of circuit breakers / ELB is detailed in below parts.

·The information of dimensions of the space necessary for correct installation of the appliance

including the minimum permissible distances to adjacent structures is detailed in below parts.

·This appliance is intended to be used by expert or trained users in shops, in light industry and

on farms, or for commercial use by lay persons.

·Instructions on additional charging of refrigerants are detailed below.