Hitbox CT 520 User manual

- 2 -

CONTENTS

1. Contents............................................................................................................................1

2. Safety warning...................................................................................................................2

3. Machine description..........................................................................................................3

4. Technical parameters table.................................................................................................4

5. Panel function description..................................................................................................4

6. Installation instruction.......................................................................................................6

7. Operation introduction......................................................................................................8

8. Maintenance .....................................................................................................................9

9. Notes before checking........................................................................................................9

10. Precautions.....................................................................................................................10

11. Questions to be run into during Cutting...........................................................................11

12. Troubleshooting and fault finding....................................................................................12

13. Explosive view.................................................................................................................16

- 2 -

CONTENTS

1. Contents............................................................................................................................1

2. Safety warning...................................................................................................................2

3. Machine description..........................................................................................................3

4. Technical parameters table.................................................................................................4

5. Panel function description..................................................................................................4

6. Installation instruction.......................................................................................................6

7. Operation introduction......................................................................................................8

8. Maintenance .....................................................................................................................9

9. Notes before checking........................................................................................................9

10. Precautions.....................................................................................................................10

11. Questions to be run into during Cutting...........................................................................11

12. Troubleshooting and fault finding....................................................................................12

13. Explosive view.................................................................................................................16

- 3 -

2.SAFETY WARNING

On the process of welding or cutting, there will be possibility of injury, so please

take protection into consideration during operation. For more details please

review the Operator Safety Guide, which complies with the preventive

requirements of the manufacturer.

Electric shock——May lead to death !!

Set the earth fitting according to applying standard.

Forbidden to touch the bare electric parts and electrode with uncovered skin, wet gloves or

clothes.

Make sure you are insulated from the ground and the workshop.

Make sure you are in safe position.

Gases and fumes——May be harmful to health!

Keep your head out of the gases and fumes.

When arc welding, ventilators or air extractors should be used to avoid breathing gases.

Arc rays——Harmful to your eyes, burn your skin.

Wear suitable protective mask, light filter and protective garment to protect eyes and body.

Prepare suitable protective mask or curtain to protect looker-on.

Fire

Welding spark may cause fire, make sure there is no tinder stuff around the welding area.

Noise——Excessive noises will be harmful to hearing.

Use ear protector or others means to protect ear.

Warn looker-on that noise is harmful to hearing.

Malfunction——When trouble happens, contact with authorized professionals.

If trouble happens during installation and operation, please follow this manual instruction to

check up.

- 4 -

If you fail to fully understand the manual, or fail to solve the problem with the instruction,

you should contact the suppliers or the service center for professional help.

WARNING!

Electric leakage protecting switch should be added when using the machine!!!

3.MACHINE DESCRIPTION

The welding machines are rectifiers adopting the most advanced inverter technology, which can

apply in plasma cutting system of using pressing air.

The development of inverter welding equipment benefits from the development of the inverter

power supply theory and components.

3.1 CT series welding machine is the latest multi-purpose machine developed by our company. It

is suitable for all kinds of metal cutting machines, argon arc welding and manual arc welding. Its

biggest feature is that it can cut stainless steel, alloy steel, carbon steel, and other non-ferrous

metals with cutting function, or it can weld stainless steel and carbon steel products with DC

function. For example: for the welding of scooters, bicycles and other products.

3.2 CT series welding machine is also based on our company's unique high-frequency inverter

technology, compared with the traditional machine, small size, light weight, high conversion

efficiency, energy saving; Compared with imported machine, cheaper, more adaptable to power

grid. To highlight the use of two inverter technology, the pure square wave output, so that the

arc stiffness is good, heat concentration, reverse cleaning ability, wide cleaning range, small

current is not easy to break the arc, etc., to ensure the excellent welder Welding characteristics.

3.3 The welding machine is also equipped with a foot pedal current regulating device, so that the

welder can free the hand to adjust the current with the foot; thus, the current can be quickly

heated when the welding is initial and the wire is added, and the current is reduced at the end of

the welding. Welding pattern formation; the use of the pedal helps to improve welding efficiency,

reduce welding difficulty and ensure welding quality.

WARNING!

The machine is mainly used in industry. It will produce radio wave, so the worker

should make fully preparation for protection.

- 4 -

If you fail to fully understand the manual, or fail to solve the problem with the instruction,

you should contact the suppliers or the service center for professional help.

WARNING!

Electric leakage protecting switch should be added when using the machine!!!

3.MACHINE DESCRIPTION

The welding machines are rectifiers adopting the most advanced inverter technology, which can

apply in plasma cutting system of using pressing air.

The development of inverter welding equipment benefits from the development of the inverter

power supply theory and components.

3.1 CT series welding machine is the latest multi-purpose machine developed by our company. It

is suitable for all kinds of metal cutting machines, argon arc welding and manual arc welding. Its

biggest feature is that it can cut stainless steel, alloy steel, carbon steel, and other non-ferrous

metals with cutting function, or it can weld stainless steel and carbon steel products with DC

function. For example: for the welding of scooters, bicycles and other products.

3.2 CT series welding machine is also based on our company's unique high-frequency inverter

technology, compared with the traditional machine, small size, light weight, high conversion

efficiency, energy saving; Compared with imported machine, cheaper, more adaptable to power

grid. To highlight the use of two inverter technology, the pure square wave output, so that the

arc stiffness is good, heat concentration, reverse cleaning ability, wide cleaning range, small

current is not easy to break the arc, etc., to ensure the excellent welder Welding characteristics.

3.3 The welding machine is also equipped with a foot pedal current regulating device, so that the

welder can free the hand to adjust the current with the foot; thus, the current can be quickly

heated when the welding is initial and the wire is added, and the current is reduced at the end of

the welding. Welding pattern formation; the use of the pedal helps to improve welding efficiency,

reduce welding difficulty and ensure welding quality.

WARNING!

The machine is mainly used in industry. It will produce radio wave, so the worker

should make fully preparation for protection.

- 5 -

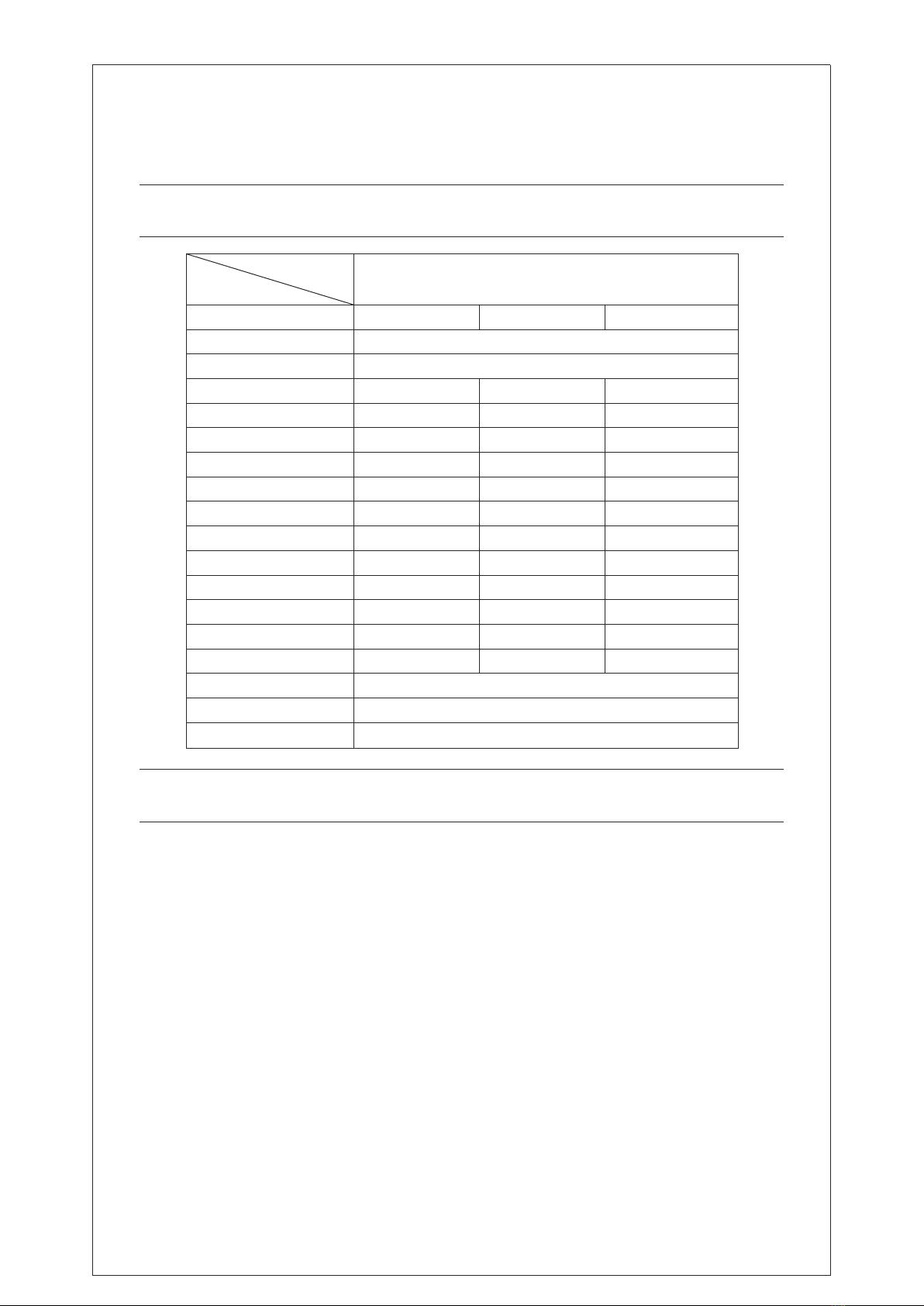

4.TECHNICAL PARAMETERS TABLE

5.PANEL FUNCTION INSTRUCTION

5.1 Button function

Option function button: When the function button is selected as “CUT” mode or the indicator

light is CUT, it can cut the iron plate for the cutting function; when the function button is set to

“TIG” mode or the indicator light is for TIG, it is DC argon arc welding. It can weld stainless steel,

iron, copper and other metals.

MMA/CUT/TIG function button: it is manual melt arc when the function button selected as

“MMA”.

5.2 Parameter adjustment (by the arrow button)

5.2.1 Pre-flow gas time parameter adjustment:In order to ensure the welding effect, argon is

required to arrive earlier than the current during welding. This parameter is to adjust the

interval between the argon out and the arc.

5.2.2 Current adjustment: it is welding current

Model

Parameters

CT-520DPC

Mode

CUT

TIG

MMA

Input voltage

(

V

)

Single Phase AC220

±

15%

Frequency (Hz)

50/60

Rate input current(A)

35

36

48

Current Range(A)

10-50

5-200

10-200

No-load voltage(V)

250

65

65

Rate output voltage

(V)V

98

28

18

Gas after flow

(

S

)

0-10

0-10

/

Remote control

/

/

/

Ignition way

HF

HF

TOUCH

Efficiency(%)

80

80

80

Duty cycle(%)

30

25

20

Power factor

0.76

0.76

0.76

Insulation Class

H

H

H

Housing Protection

Class

IP21S

IP21S

IP21S

Weight

(

kg

)

9.4

Dimensions(mm)

445*185*270

Max welding thickness

(mm)

14

- 6 -

5.2.3 Attenuation parameter adjustment:When completing a section of welding and ending the

arc, in order to ensure good forming, the current is required to gradually decrease to stop. This

parameter is used to adjust the decay time of the current.

Note:When using the "foot pedal" control, this knob is turned counterclockwise to "0"

5.2.4 After flow gas time parameter adjustment:The workpiece after welding is oxidized by the

heat, so after the welding is stopped, the argon gas blown by the welding torch is used for a

certain period of time. This parameter is the time after the exhaust gas is adjusted, and the

maximum time can be 10 seconds.

5.2.5 In “MMA” mode,only the welding current, the hot start, arc force, and other functions do

not work.

5.3 Indicator light

Overheat protection indicator: When the welder is working continuously, for a long time or at a

high current, the overheat protection function is set to prevent damage to the device due to

internal heat. When the light is on, the digital display shows -E2, stop working, but not Shut

down, after about 2-3 minutes the device can be automatically restored.

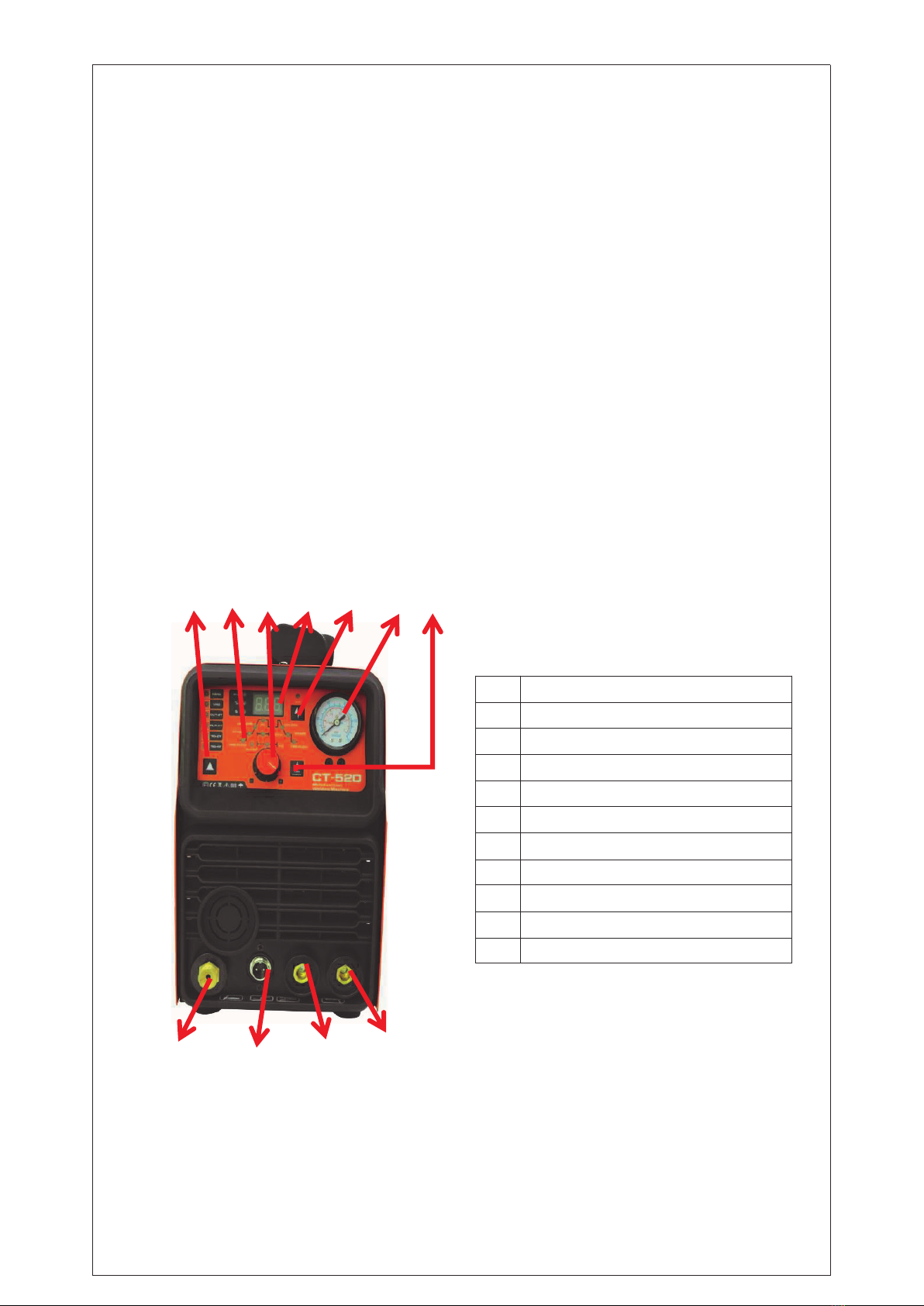

CT-520 panel schematic:

1 2 3 4 5 6 7

8 9 10 11

1

Welding mode selection button

2

Function parameter selection

3

Adjust knob/Confirm button

4

Display

5

High frequency button

6

Barometer display

7

Gas check button

8

Cutting torch/TIG torch connector

9

Aviation socket

10 Earth clamp connector

11

Electrode holder connector

- 6 -

5.2.3 Attenuation parameter adjustment:When completing a section of welding and ending the

arc, in order to ensure good forming, the current is required to gradually decrease to stop. This

parameter is used to adjust the decay time of the current.

Note:When using the "foot pedal" control, this knob is turned counterclockwise to "0"

5.2.4 After flow gas time parameter adjustment:The workpiece after welding is oxidized by the

heat, so after the welding is stopped, the argon gas blown by the welding torch is used for a

certain period of time. This parameter is the time after the exhaust gas is adjusted, and the

maximum time can be 10 seconds.

5.2.5 In “MMA” mode,only the welding current, the hot start, arc force, and other functions do

not work.

5.3 Indicator light

Overheat protection indicator: When the welder is working continuously, for a long time or at a

high current, the overheat protection function is set to prevent damage to the device due to

internal heat. When the light is on, the digital display shows -E2, stop working, but not Shut

down, after about 2-3 minutes the device can be automatically restored.

CT-520 panel schematic:

1 2 3 4 5 6 7

8 9 10 11

1

Welding mode selection button

2

Function parameter selection

3

Adjust knob/Confirm button

4

Display

5

High frequency button

6

Barometer display

7

Gas check button

8

Cutting torch/TIG torch connector

9

Aviation socket

10

Earth clamp connector

11

Electrode holder connector

- 7 -

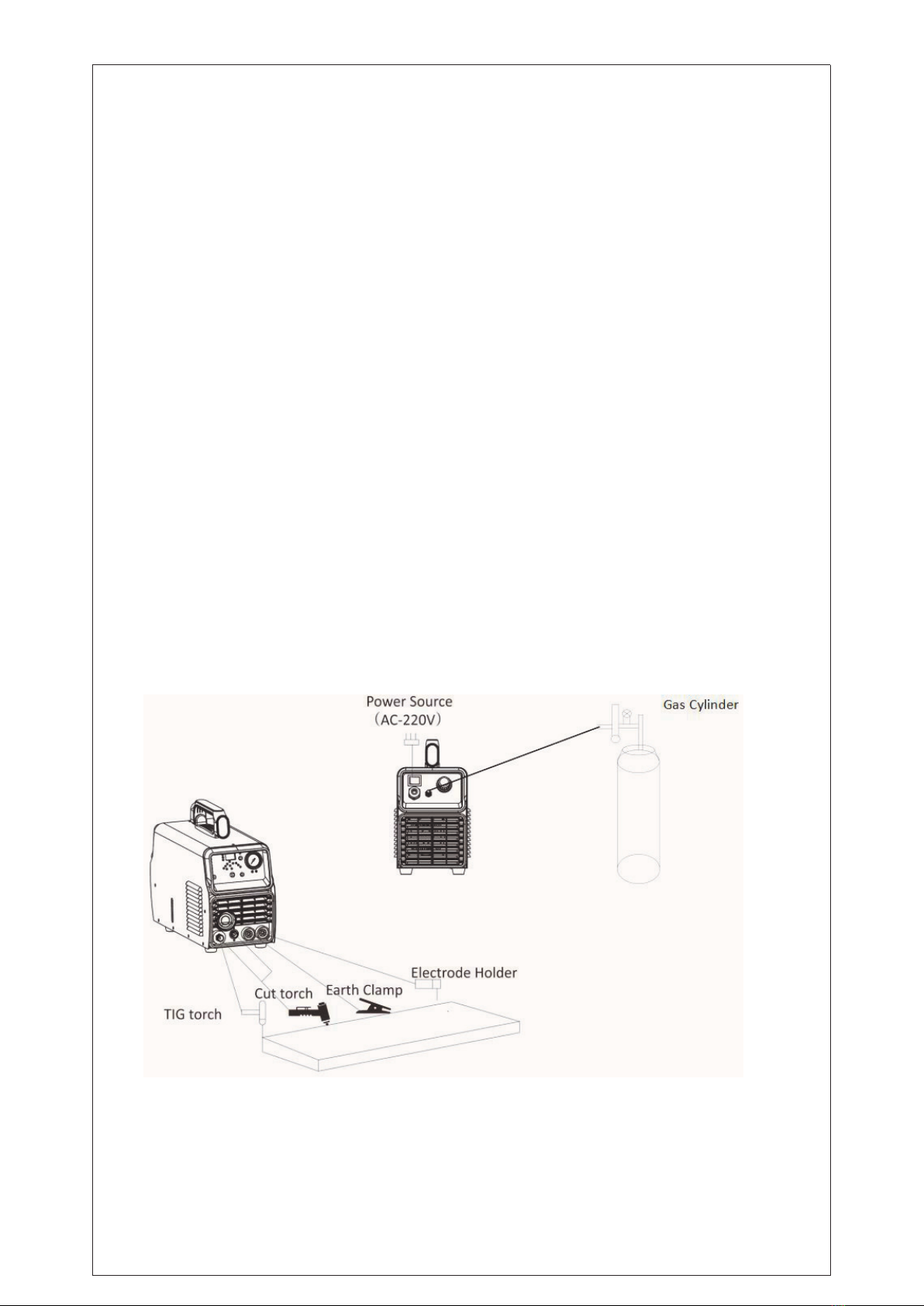

6.INSTALLATION INSTRUCTION

The machine is equipped with power voltage compensation device. When the power voltage

fluctuates between±15% of rated voltage, it still can work normally.

When the machine is used with long cables, in order to prevent voltage form going down, bigger

section cable is suggested. If the cable is too long, it may have great affluence on the arc-striking

or other performance of cutting system, e.g. the HF arc-striking performance get weak or the

system work abnormally. So cables of configured length are suggested.

6.1 Make sure intake of the machine is not blocked or covered to avoid malfunction of cooling

1

Welding mode selection

2

Function selection

3

Indicator light

4

Adjust knob / parameter button (press the knob

light to flash, turn the knob to adjust the

indicator to adjust the parameter position,

press the knob again, rotate the knob to adjust

the parameter when the light is not flashing)

5

Gas check button

6

High frequency button

7

Display

8Barometer display

- 8 -

system.

6.2 Connect the protective gas source. The gas supply passage shall include a gas cylinder, an

argon gas pressure reducing flowmeter and a gas pipe. The connecting portion of the gas pipe

shall be fastened with a hose clamp or other articles to prevent argon gas leakage and air ingress.

6.3 Ground the cables with section area no less than 6mm2to the housing, the way is connecting

screw in the back of the power source to ground device, or make sure ground terminal of power

socket is firmly connected. Both ways can be used for absolute safety.

6.4 Plug the quick plug of the loop cable into the quick socket of the welder panel with a polarity

of "+" and follow The hour hand is tightened tightly, and the ground wire clamp at the other end

clamps the workpiece

6.5 When using the foot switch control, connect the two-core aviation and three-core aviation

plugs of the foot switch to the three-core air socket of the local panel.

6.6 According to the input voltage level of the welding machine, connect the power line to the

distribution box of the corresponding voltage level. Do not connect the wrong voltage. Also

ensure that the error of the power supply voltage is within the allowable range.

6.7 When using manual arc welding, install the electrode holder as shown. After the above work

is completed, the welder is finished. In the installation work, welding is available.

- 8 -

system.

6.2 Connect the protective gas source. The gas supply passage shall include a gas cylinder, an

argon gas pressure reducing flowmeter and a gas pipe. The connecting portion of the gas pipe

shall be fastened with a hose clamp or other articles to prevent argon gas leakage and air ingress.

6.3 Ground the cables with section area no less than 6mm2to the housing, the way is connecting

screw in the back of the power source to ground device, or make sure ground terminal of power

socket is firmly connected. Both ways can be used for absolute safety.

6.4 Plug the quick plug of the loop cable into the quick socket of the welder panel with a polarity

of "+" and follow The hour hand is tightened tightly, and the ground wire clamp at the other end

clamps the workpiece

6.5 When using the foot switch control, connect the two-core aviation and three-core aviation

plugs of the foot switch to the three-core air socket of the local panel.

6.6 According to the input voltage level of the welding machine, connect the power line to the

distribution box of the corresponding voltage level. Do not connect the wrong voltage. Also

ensure that the error of the power supply voltage is within the allowable range.

6.7 When using manual arc welding, install the electrode holder as shown. After the above work

is completed, the welder is finished. In the installation work, welding is available.

- 9 -

7.OPERATION INTRODUCTION

7.1 Use AC TIG welding function description:

7.1.1 Turn on the power switch and the fan inside the machine starts to rotate.

7.1.2 Press the function button and select the desired function to operate.

7.1.3 Turn on the argon switch and adjust the gas flow to the rated standard (see flow meter).

7.1.4 Adjust the ratio of positive and negative current time according to the degree of oxidation

of the surface of the workpiece to be welded.

7.1.5 Press the switch on the torch and the solenoid valve starts. You will hear the high-frequency

spark discharge in the welder. At the same time, there is argon gas flowing out of the torch nozzle.

Note: When welding for the first time, you need to press and hold the switch for a few seconds

before soldering until all the air in the air path is drained. After you stop welding, there will still

be argon flow out in a few seconds. This is specially designed to ensure that the solder joints are

protected before cooling. Therefore, after use, the welding position must be kept for a while after

the arc is extinguished. Open the welding torch.

7.1.6 Adjust the “pre flow”,“post flow”and “down slop”times according to actual needs.

7.1.7 Keep the tungsten electrode and the welding workpiece at a distance of 2-4mm. Press the

torch control switch to generate high-frequency discharge between the torch electrode and the

workpiece. After the ignition starts, the high-frequency arc spark in the welder It disappears

immediately and you can start working.

7.2 Use DC TIG welding function description:

7.2.1 Turn on the power switch and the fan inside the machine starts to rotate.

7.2.2 Press the function key to select the TIG function.

7.2.3 Turn on the argon switch and adjust the gas flow to the rated standard (see flow meter).

4. 5, 6, 7, and 8 in the same description.

7.3 Use DC MMA welding function description:

7.3.1 Turn on the power switch and the fan inside the machine starts to rotate.

7.3.2 Place the "TIG/MMA" switch in the "MMA" position. Determine the appropriate welding

current based on the thickness, station and process conditions of the welded workpiece.

7.3.3 The welding eledctrode clamped by electrode holder can be welded.

- 10 -

WARNING:

It is strictly forbidden to insert or remove any cable or connector in use during the

welding process. This operation will endanger personal safety and cause serious

damage to the equipment.

8.MAINTENANCE

WARNING:

Power must be turned off for all checking and maintenance, before opening the

housing, make sure the power plug is disconnected.

8.1 Remove dust by dry and clean compressed air regularly, if welding machine is operating in

environment where is polluted with smokes and pollution air, the machine need removing dust

everyday.

8.2 Pressure of compressed air must be inside the reasonable arrangement in order to prevent

damaging to small components of inter-machine.

8.3 Check inter circuit of welding machine regularly and make sure the cable circuit is connected

correctly and connectors are connected tightly (especially insert connector and components). If

scale and loose are found, please give a good polish to them, then connect them again tightly.

8.4 Avoid water and steam enter into inter-machine, if they enter into machine, please dry

inter-machine then check insulation of machine.

8.5 If welding machine will not be operated long time, it must be put into packing box and store

in dry environment.

8.6 When wire machine operates for every 300 hours, the electric carbon brush and armature

rectifier should be polished, the reducer should be cleaned, and lubricator should be added to

the turbo and bearing.

9.NOTES BEFORE CHECKING

WARNING

Blind experiment and careless repair may lead to more problems and make formal check and

repair more difficult. When the machine is electrified, the bared parts contain life-threatening

voltage. Any direct and indirect touch will cause electric shock, and severe electric shock will

lead to death.

- 10 -

WARNING:

It is strictly forbidden to insert or remove any cable or connector in use during the

welding process. This operation will endanger personal safety and cause serious

damage to the equipment.

8.MAINTENANCE

WARNING:

Power must be turned off for all checking and maintenance, before opening the

housing, make sure the power plug is disconnected.

8.1 Remove dust by dry and clean compressed air regularly, if welding machine is operating in

environment where is polluted with smokes and pollution air, the machine need removing dust

everyday.

8.2 Pressure of compressed air must be inside the reasonable arrangement in order to prevent

damaging to small components of inter-machine.

8.3 Check inter circuit of welding machine regularly and make sure the cable circuit is connected

correctly and connectors are connected tightly (especially insert connector and components). If

scale and loose are found, please give a good polish to them, then connect them again tightly.

8.4 Avoid water and steam enter into inter-machine, if they enter into machine, please dry

inter-machine then check insulation of machine.

8.5 If welding machine will not be operated long time, it must be put into packing box and store

in dry environment.

8.6 When wire machine operates for every 300 hours, the electric carbon brush and armature

rectifier should be polished, the reducer should be cleaned, and lubricator should be added to

the turbo and bearing.

9.NOTES BEFORE CHECKING

WARNING

Blind experiment and careless repair may lead to more problems and make formal check and

repair more difficult. When the machine is electrified, the bared parts contain life-threatening

voltage. Any direct and indirect touch will cause electric shock, and severe electric shock will

lead to death.

- 11 -

NOTICE: In the period of guarantee maintenance, if user makes wrong check and repair

for malfunction

of welding/cutting machines without our permission, the free maintenance guarantee

offered will be invalid

10.PRECAUTIONS

10.1 Surroundings

10.1.1 The welding operation should be carried out in a relatively dry environment, and the air

humidity should generally not exceed 90%.

10.1.2 The ambient temperature should be between -10C and 40C.

10.1.3 Avoid welding in daylight or rain, and do not allow water or rain to seep into the welder.

10.1.4 Avoid welding work in dusty areas or in corrosive atmospheres.

Avoid gas-shielded welding operations in environments with strong air flow.

10.2 Safety

10.2.1 Overvoltage, overcurrent and overheat protection circuits have been installed in our

welding machine. When the grid voltage, output current and internal temperature exceed the set

standard, the welder will automatically stop working; but excessive use (such as voltage over

High) will still cause damage to the welder, so you still need to pay attention to the following

matters

10.2.2 Ensure good ventilation

Our welding machine is a small welding machine. When operating, there is a large working

current, and natural ventilation can not meet the cooling requirements of the welding machine.

Therefore, a fan is installed to effectively cool the welding machine to make it work smoothly.

The user should confirm that the ventilation is not covered or blocked, and the distance between

the welder and the surrounding objects should be no less than 0.3 meters. The user should

always pay attention to maintain good ventilation, which is better for the welder and guarantees

a longer service life. very important.

10.2.3 No current overload

The user should remember to observe the maximum allowable load current (relatively selectable

load continuation rate) and keep the welding current not exceeding the maximum allowable load

current.

Current overload will significantly shorten the life of the welder and may even burn the welder.

10.2.4 No too high voltage

The power supply voltage is listed in the “Main Performance Parameters”table. Under normal

circumstances, the voltage automatic compensation circuit in the welder will ensure that the

welding current is kept within the allowable range. If the power supply voltage exceeds the

allowable value, the welder will be damaged and the user should fully understand the situation

and take appropriate precautions.

10.2.5 A grounding screw is attached to the rear of each welder and marked with a grounding

- 12 -

mark. Before use, use a cable with a section larger than 6mm2 to reliably ground the welder's

casing to discharge static electricity or prevent accidents due to electric leakage.

10.2.6 If the welder exceeds the standard load continuation rate during operation, the welder

may suddenly enter the protection state and stop working. This means that the welder exceeds

the standard load continuation rate. Excessive heat energy triggers the temperature control

switch, causing the welder to stop working while being in front. The red indicator light on the

panel lights up. In this case, you do not have to unplug the power supply so that the cooling fan

can continue to work to cool the welder. When the red indicator light goes out, the temperature

drops to the standard range and the welding can be restarted.

11.QUESTIONS TO BE RUN INTO DURING CUTTING

The phenomena listed here may be related to the accessories, gases, environmental factors, and

power supply conditions you are using. Please try to improve the environment and avoid such

situations.

11.1 the solder joint is black

In such cases, the solder joint is not protected well and is oxidized. You can check as follows:

11.1.1 Confirm that the valve of the argon cylinder is open and has sufficient pressure. If the

pressure inside the bottle is less than 0.5MPa, it is necessary to refill the cylinder.

11.1.2 Check that the argon flow is on and has sufficient flow. To save gas, you can choose

different flow rates depending on the welding current process, but too small a flow rate may

result in insufficient shielding gas to cover the solder joints. We recommend that you do not let

the argon flow rate be less than 3l / min, no matter how small the current is.

11.1.3 The easiest way to check if there is gas is to use the hand to feel the gas flow from the

nozzle of the torch, check whether the gas path of the torch is blocked.

11.1.4 The gas path has a problem of poor sealing, or the purity of the gas is not high, which may

cause welding quality problems.

11.1.5 If the environment has strong air flow, it may also cause the welding quality to drop.

11.2 Difficut to ignite arc, and easy to break the arc:

Confirm that the tungsten you are using is of good quality. The discharge capacity of a poor

quality tungsten electrode may not meet the requirements.

A tungsten electrode that has not been sharpened is also less prone to arcing and causes arc

instability.

11.3 the output current does not reach the rated value:

Deviation of the supply voltage from the rated value will cause the output current value to be

inconsistent with the set value; when the supply voltage is lower than the rated value, the

maximum output current of the welder may also be lower than the rated value.

- 12 -

mark. Before use, use a cable with a section larger than 6mm2 to reliably ground the welder's

casing to discharge static electricity or prevent accidents due to electric leakage.

10.2.6 If the welder exceeds the standard load continuation rate during operation, the welder

may suddenly enter the protection state and stop working. This means that the welder exceeds

the standard load continuation rate. Excessive heat energy triggers the temperature control

switch, causing the welder to stop working while being in front. The red indicator light on the

panel lights up. In this case, you do not have to unplug the power supply so that the cooling fan

can continue to work to cool the welder. When the red indicator light goes out, the temperature

drops to the standard range and the welding can be restarted.

11.QUESTIONS TO BE RUN INTO DURING CUTTING

The phenomena listed here may be related to the accessories, gases, environmental factors, and

power supply conditions you are using. Please try to improve the environment and avoid such

situations.

11.1 the solder joint is black

In such cases, the solder joint is not protected well and is oxidized. You can check as follows:

11.1.1 Confirm that the valve of the argon cylinder is open and has sufficient pressure. If the

pressure inside the bottle is less than 0.5MPa, it is necessary to refill the cylinder.

11.1.2 Check that the argon flow is on and has sufficient flow. To save gas, you can choose

different flow rates depending on the welding current process, but too small a flow rate may

result in insufficient shielding gas to cover the solder joints. We recommend that you do not let

the argon flow rate be less than 3l / min, no matter how small the current is.

11.1.3 The easiest way to check if there is gas is to use the hand to feel the gas flow from the

nozzle of the torch, check whether the gas path of the torch is blocked.

11.1.4 The gas path has a problem of poor sealing, or the purity of the gas is not high, which may

cause welding quality problems.

11.1.5 If the environment has strong air flow, it may also cause the welding quality to drop.

11.2 Difficut to ignite arc, and easy to break the arc:

Confirm that the tungsten you are using is of good quality. The discharge capacity of a poor

quality tungsten electrode may not meet the requirements.

A tungsten electrode that has not been sharpened is also less prone to arcing and causes arc

instability.

11.3 the output current does not reach the rated value:

Deviation of the supply voltage from the rated value will cause the output current value to be

inconsistent with the set value; when the supply voltage is lower than the rated value, the

maximum output current of the welder may also be lower than the rated value.

- 13 -

11.4 The current cannot be kept stable during the use of the welder:

This situation may be related to the following factors:

11.4.1 The grid voltage changes.

11.4.2 Serious interference from the power grid or other electrical equipment.

11.5 cutting can not penetrate the steel plate:

11.5.1 Current regulation error.

11.5.2 The air pressure is insufficient.

12.TROUBLESHOOTING AND FAULT FINDING

CT-520

Fault

symptom

Remedy

The power

indicator does not

light, the fan does

not turn, no

welding output

1. The power switch is broken.

2. Confirm that the power grid connected to the input cable has power.

3. Check if the input cable has a break.

The power switch

indicator is on, the

fan does not turn

or rotates for a

few times to stop,

no welding output

1. It is possible to input the wrong connection on the 380V power supply, causing the

overvoltage protection circuit to start, and then reconnect it to the 220V power

supply and restart it.

2, 220V power is unstable (the input line is too long) or the input line is connected to the

power grid, causing the overvoltage protection circuit to start, increasing the wire

diameter of the grid input line or fastening the input line node. This phenomenon is

in shutdown 2 - After 3 minutes, the new boot will return to normal.

3. Continuously open and close the power switch in a short time, causing the

overvoltage protection circuit to start. Wait for 2-3 minutes and then restart it.

4. The wires between the switch and the power board are loose and retightened.

5. The main circuit 24V relay on the power supply board is not connected or damaged,

check the 24V power supply and relay.

The fan turns, the

abnormal

indicator light is

not bright, there is

no high-frequency

discharge "sa sa

sa" sound, and the

"arc welding" can

not start the arc.

1. The voltage of the positive and negative poles of the VH-07 plug-in of the multimeter

to the MOS board should be about DC308V.

2. The auxiliary power supply on the MOS board has a green indicator light. If the light is

not on, the auxiliary power supply is not working. Look for the fault point or contact the

dealer.

3. Check the poor connection of various patch cords in the machine.

4. Control circuit problems, find the cause or contact the dealer.

5. The control line on the welding torch is broken.

The abnormal

indicator light is

not lit, there is a

high-frequency

1. The welding gun cable is broken.

2. The ground wire is broken or not connected to the welded workpiece.

3. The positive output terminal or the welding torch gas output terminal is loose from

the connection inside the machine.

。

- 14 -

discharge "sa sa

sa" sound, no

welding output.

Abnormal

indicator light

does not light, no

high frequency

discharge "sa sa

sa" sound, "LIFT

TIG welding" can

start arc

1. The primary line of the arcing transformer has poor contact with the power board and

is retightened.

2. The discharge nozzle is oxidized or the distance is remote. The surface oxide film of

the discharge nozzle is treated or the distance of the discharge nozzle is adjusted to 1

mm.

3. The individual components of the high-frequency arc-ignition circuit are damaged,

and the replacement is found.

Abnormal

indicator light is

on, no output

1. It may be overcurrent protection. Please turn off the machine. When the abnormal

indicator light is off and then restarted, it can be restored.

2, may be overheat protection, do not need to shut down for 2-3 minutes, the machine

can naturally return to normal.

3. It may be that the inverter circuit is faulty. Please unplug the power supply plug of the

main transformer on the MOS board (near the fan VH-07 plug-in) and restart it:

(1) If the abnormality indicator is still on, turn off the power plug of the high-frequency

pilot arc power supply (near the fan VH-03 plug-in) and turn it back on:

a. If the abnormal indicator is still on, the individual FETs on the MOS board are

damaged.

b. If the abnormal indicator is not lit, the step-up transformer in the high-frequency

arc-rising circuit on the power supply board is broken and replaced.

(2) If the abnormal indicator does not light:

a. It may be damaged in the middle plate transformer. The primary inductance and Q

value of the main transformer can be measured by the bridge.

b. It may be that the transformer secondary rectifier is individually broken down, and

the same type of rectifier is found and replaced.

4. It may be that the feedback circuit is open.

Can not break the

oxide film when

welding aluminum

1. The welding gear selection is incorrect;

2. The duty cycle adjustment is too small;

3. The secondary inverter has field tube damage.

Tungsten needle

burnt seriously The duty cycle is adjusted too much to reduce the duty cycle.

- 14 -

discharge "sa sa

sa" sound, no

welding output.

Abnormal

indicator light

does not light, no

high frequency

discharge "sa sa

sa" sound, "LIFT

TIG welding" can

start arc

1. The primary line of the arcing transformer has poor contact with the power board and

is retightened.

2. The discharge nozzle is oxidized or the distance is remote. The surface oxide film of

the discharge nozzle is treated or the distance of the discharge nozzle is adjusted to 1

mm.

3. The individual components of the high-frequency arc-ignition circuit are damaged,

and the replacement is found.

Abnormal

indicator light is

on, no output

1. It may be overcurrent protection. Please turn off the machine. When the abnormal

indicator light is off and then restarted, it can be restored.

2, may be overheat protection, do not need to shut down for 2-3 minutes, the machine

can naturally return to normal.

3. It may be that the inverter circuit is faulty. Please unplug the power supply plug of the

main transformer on the MOS board (near the fan VH-07 plug-in) and restart it:

(1) If the abnormality indicator is still on, turn off the power plug of the high-frequency

pilot arc power supply (near the fan VH-03 plug-in) and turn it back on:

a. If the abnormal indicator is still on, the individual FETs on the MOS board are

damaged.

b. If the abnormal indicator is not lit, the step-up transformer in the high-frequency

arc-rising circuit on the power supply board is broken and replaced.

(2) If the abnormal indicator does not light:

a. It may be damaged in the middle plate transformer. The primary inductance and Q

value of the main transformer can be measured by the bridge.

b. It may be that the transformer secondary rectifier is individually broken down, and

the same type of rectifier is found and replaced.

4. It may be that the feedback circuit is open.

Can not break the

oxide film when

welding aluminum

1. The welding gear selection is incorrect;

2. The duty cycle adjustment is too small;

3. The secondary inverter has field tube damage.

Tungsten needle

burnt seriously

The duty cycle is adjusted too much to reduce the duty cycle.

- 15 -

CT-520

Fault symptom

Exclude

The fan does not rotate, the

digital meter has no display,

and there is no welding

output.

1. Confirm that the air switch is intact or closed.

2. Confirm that the power grid connected to the output cable has power.

3. The thermistor (four) on the power supply board is damaged (this is usually

caused by DC24V relay failure or poor contact contact).

4. The power board (base board) is faulty and there is no DC537V voltage output.

5. The auxiliary power supply on the control panel has failed.

The fan turns, the abnormal

indicator light is not bright,

there is no high-frequency

discharge "sa sa sa" sound,

and the "LIFT TIG welding"

can not start the arc.

1. Check all kinds of patch cords in the machine for poor contact.

2. Control circuit problems, find the cause or contact the dealer.

3. The control line on the welding torch is broken.

Abnormal indicator light is off,

there is high frequency

discharge "sa sa sa" sound, no

welding output

1. The welding gun cable is broken.

2. The ground wire is broken or not connected to the welded workpiece.

3. The positive output terminal or the torch gas output terminal is loose from the

connection inside the machine.

Abnormal indicator light is not

lit, no high-frequency

discharge "sa sa sa" sound,

arc welding can start arc

1. The primary line of the arcing transformer is in poor contact with the arcing

plate and is retightened.

2. The discharge nozzle is oxidized or the distance is remote. The surface of the

discharge nozzle is treated with an oxide film or the distance of the discharge

nozzle is about 1 mm.

3. Hand soldering argon welding conversion switch is damaged and replaced.

4. The individual components of the high-frequency arc-trigger circuit are

damaged, and the replacement is found.

Abnormal indicator light is on,

no output

1. It may be overcurrent protection. Please turn off the machine. When the

abnormal indicator light is off and then restarted, it can be restored.

2, may be overheat protection, do not need to shut down for 2-3 minutes, the

machine can naturally return to normal.

3. It may be that the inverter circuit is faulty. Please unplug the power supply plug

of the main transformer on the MOS board (near the fan VH-07 plug-in) and

restart it:

(1) If the abnormality indicator is still on, turn off the power plug of the

high-frequency pilot arc power supply (near the fan VH-03 plug-in) and turn it back

on:

a. If the abnormal indicator is still on, the individual FETs on the MOS board are

damaged.

b. If the abnormal indicator is not lit, the step-up transformer in the

high-frequency arc-rising circuit on the power supply board is broken and

replaced.

(2) If the abnormal indicator does not light:

a. It may be damaged in the middle plate transformer. The primary inductance

and Q value of the main transformer can be measured by the bridge.

b. It may be that the transformer secondary rectifier is individually broken

down, and the same type of rectifier is found and replaced.

- 16 -

4. It may be that the feedback circuit is open.

Tungsten needle burnt

seriously

The duty cycle is adjusted too much to reduce the duty cycle.

Can not break the oxide film

when welding aluminum

1. The welding gear selection is incorrect;

2. The duty cycle adjustment is too small;

3. The secondary inverter has field tube damage.

- 16 -

4. It may be that the feedback circuit is open.

Tungsten needle burnt

seriously

The duty cycle is adjusted too much to reduce the duty cycle.

Can not break the oxide film

when welding aluminum

1. The welding gear selection is incorrect;

2. The duty cycle adjustment is too small;

3. The secondary inverter has field tube damage.

- 17 -

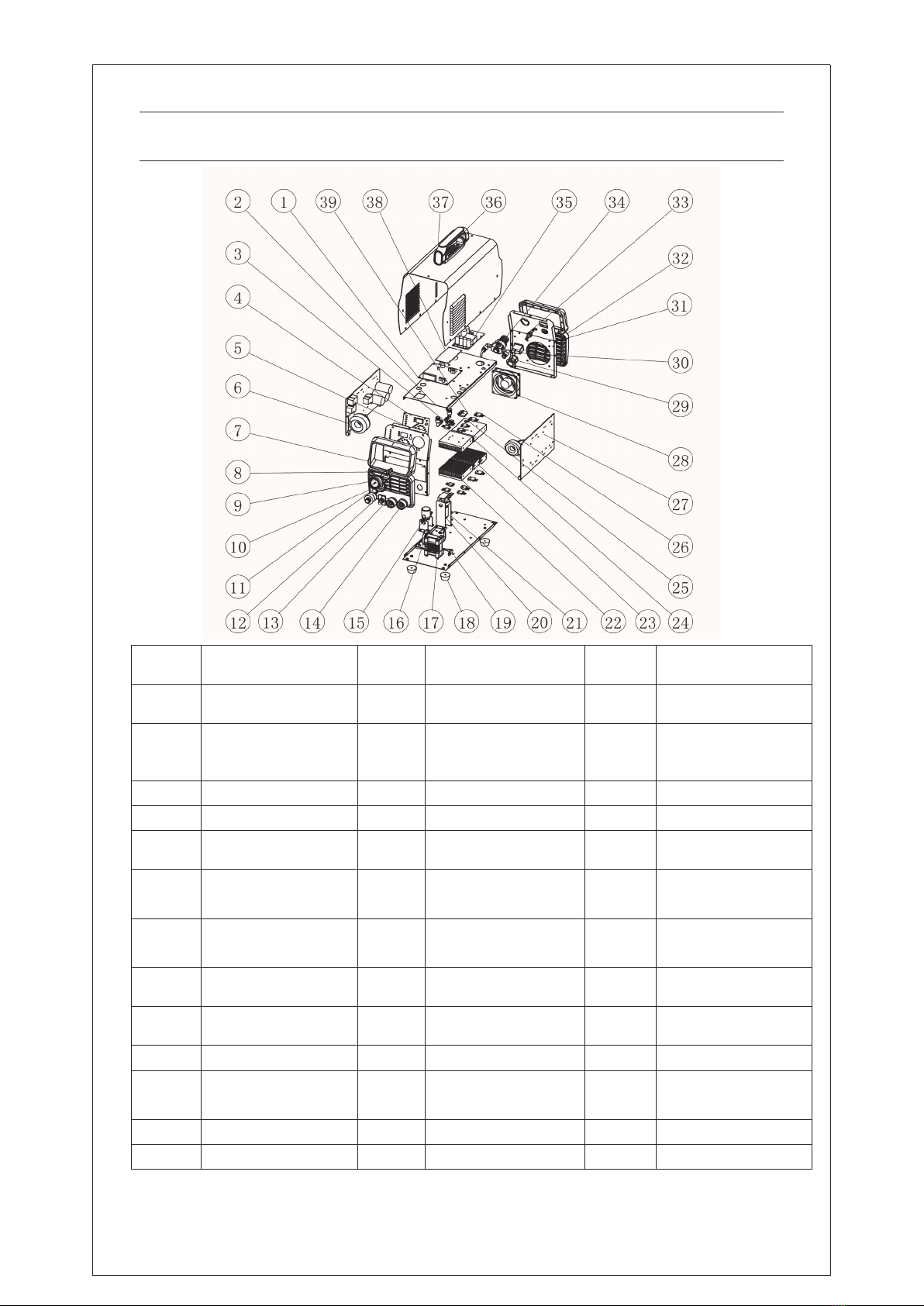

13.EXPLOSIVE VIEW

1 Control PCB 14 Quick connector socket 27 Inverter board 2

2 clapboard 15 Electromagnetic valve 28 Fan

3 Pressure gauge

connector

16 Electromagnetic valve

stand

29 Wire buckle

4 Display board 17 Arc ignition coil 30 Power switch

5 Front panel 18 Hinge 31 Rear panel

6 Inverter board 1 19 Bottom board 32 Down rear plastic panel

7 Upper front plastic

panel

20 Water separator 33 Gas inert

8 Quick air connector 21 Fixed bracket 34 pressure regulating

valve

9 Down plastic front panel 22 Radiator 1 35 Power PCB board

10 Pressure gauge mount 23 Radiator 2 36 Handel

11 Pressure gauge 24 Radiator 3 37 Metal casing

12 Gas and electricity

integrated connector

25 Temperature Switches 38 High frequency PCB

board

13 Insulation socket 26 IGBT 39 Rectifier bridge

Table of contents

Other Hitbox Welding System manuals

Popular Welding System manuals by other brands

Migatronic

Migatronic MWF 50 2 YARD instruction manual

HURNER

HURNER CNC ECO 315 user manual

Scheppach

Scheppach WSE5000-Multi Translation of the original operating manual

ims PRO

ims PRO TIG PRO 161 DC manual

GÜDE

GÜDE GPS-K AIR CUT 40 AK instructions

Parkside

Parkside PISG 80 A2 Assembly, operating and safety instructions, Translation of the original instructions