Hitbox ARC160D Technical manual

2/18

Z2A5 SC-A0

DIRECTORY

1. SAFETY-------------------------------------------------------------------------------------------------------------------3

2. SYMBOL EXPLANATION--------------------------------------------------------------------------------------------4

3. PRODUCT OVERVIEW-----------------------------------------------------------------------------------------------5

4. FUNCTION OVERVIEW---------------------------------------------------------------------------------------------- 5

5. PERFORMANCECHARACTERISTICS------------------------------------------------------------------------- 5

6. ORDER INFORMATION----------------------------------------------------------------------------------------------6

7. TECHNICAL PARAMETERS----------------------------------------------------------------------------------------7

8. ELECTRICAL SCHEMATIC DIAGRAM--------------------------------------------------------------------------8

9. OPERATION CONTROL AND DESCRIPTION-----------------------------------------------------------------8

10.SYSTEM CHARACTERISTICS-------------------------------------------------------------------------------------9

11. INSTALLATION, DEBUGGING AND OPERATION---------------------------------------------------------10

11.1 Connection of switching box--------------------------------------------------------------------------------10

11.2 Installation----------------------------------------------------------------------------------------------------------10

11.3 Operation-----------------------------------------------------------------------------------------------------------11

11.4 Welding parameters table (for reference only)---------------------------------------------------------11

12. CAUTION--------------------------------------------------------------------------------------------------------------12

12.1 Working Environment------------------------------------------------------------------------------------------12

12.2 Safety Tips----------------------------------------------------------------------------------------------------------12

13. BASIC KNOWLEDGE OF WELDING--------------------------------------------------------------------------12

13.1 Welding Process of MMA--------------------------------------------------------------------------------------13

13.2 Tools for MMA-----------------------------------------------------------------------------------------------------13

13.3 Basic Operation of MMA---------------------------------------------------------------------------------------14

14. MAINTENANCE------------------------------------------------------------------------------------------------------16

15. TROUBLESHOOTING---------------------------------------------------------------------------------------------17

15.1 Common Malfunction Analysis and Solution:----------------------------------------------------------16

APPENDIX A: PACKING, TRANSPORTATION AND STORAGE-------------------------------------------18

A1. Packing---------------------------------------------------------------------------------------------------------------18

A2. Transportation------------------------------------------------------------------------------------------------------18

A3. Storage---------------------------------------------------------------------------------------------------------------18

APPENDIX B: REVISION HISTORY---------------------------------------------------------------------------------18

3/18

1. SAFETY

Beware of electric shock!

Install grounding device according to application standard.

Do not touch live parts with naked skin, wet gloves or wet clothes.

Be sure you are insulated from ground and workpiece.

Cover the cover plate of the machine before power on to avoid an electric shock.

Confirm the safety of your working position.

Beware of fire hazard!

Please install the machine on non-combustible materials to avoid a fire.

Make ensure there are no inflammables near the welding position to avoid a fire.

Beware of explosion!

Do not install the machine in an environment with explosive gas to avoid an explosion.

Replacing the components can be dangerous.

Only professionals can replace the components of the machine.

Make sure there are no foreign bodies such as wire leads, screws, gaskets and metal bars falling into the machine

inside when replacing the components.

Make sure the connecting wires inside the machine are correctly connected after replacing the PCBs, and then the

machine can be run. Otherwise, there is a risk of damage to property.

Carrying or moving the machine can be dangerous.

Cut the inputpower off via the switching box before moving the welding machine.

The handle can only be used for moving the welding machine by hand in short distance, and it cannot be used for

lifting. Otherwise, personal injury or property damage may be caused by a drop.

Make sure that the flying rings are tightened, and that the machine enclosure and cover are fixed when moving the

welding machine with a crane,

Two lifting belts should be used when lifting the welding machine, and the angle formed by the lifting belt and the

vertical should be smaller than 15°.

Do not apply any stress on the operation panel and cover when moving the welding machine. Otherwise, personal

injury or property damage may be caused by a drop.

Do not install and run the welding machine when the machine is damaged or lacks any components. Otherwise, fire

hazard or personal injury may be caused.

Precautions for operation

Smoke-may be harmful to your health!

Keep your head away from the smoke to avoid inhalation of waste gas in welding.

Keep the working environment well ventilated with exhaust or ventilation equipment

when welding.

Arc radiation-may hurt youreyes and burn yourskin!

Use proper mask and wear protective clothing to protect your eyes and body.

Use proper mask or curtain to protect onlooker from being injured.

4/18

Magnetic field can makecardiac pacemaker a bit wonky.

People with cardiac pacemaker should consult the doctor before carrying out welding.

Stay away from the power source to reduce the affect of magnetic filed.

Improper use and operation may result in a fire or an explosion.

Welding spark may result in a fire, so please make ensure there are no inflammables

near the welding position, and pay attention to fire safety.

Ensure there is fire extinguisher nearby, and make sure someone has been trained to

operate the fire extinguisher.

Do not cut closed container.

Do not use this machine for pipe thawing.

Hot workpiececancause severe scald.

Do not touch hot workpiece with bare hands.

Cool the welding torch for a while after continuously working.

Excessive noise does great harm to people’s hearing.

Wear ear covers or other hearing protectors when welding.

Give warning to onlooker that noise may be potentially hazardous to hearing.

Moving parts may injure yourbody.

Please keep away from moving parts (like fan).

Each door, panel, cover, baffle plate, and protective device the like should be closed and

located correctly.

Seek professional support when trouble strikes.

When trouble strikes in installation and operation, please inspect according to related

contents in this manual.

If you still cannotunderstand fully, or you still cannot solve the problem, please contact

the dealer or the service center of JASIC to obtain professional support.

Precautions for discard

Pay attention to the following when discarding the welding machine:

Burning the electrolytic capacitors in the main circuit or on the PCBs may cause an explosion.

Burning the plastic parts such as the front panel may produce poisonous gas.

Dispose it as industrial waste.

2. SYMBOL EXPLANATION

Matters to be noticed in operation

Objects to be speciallydescribedandpointed out

It is prohibited to dispose the electrical waste together with othercommon wastes. Please

protect the environment.

5/18

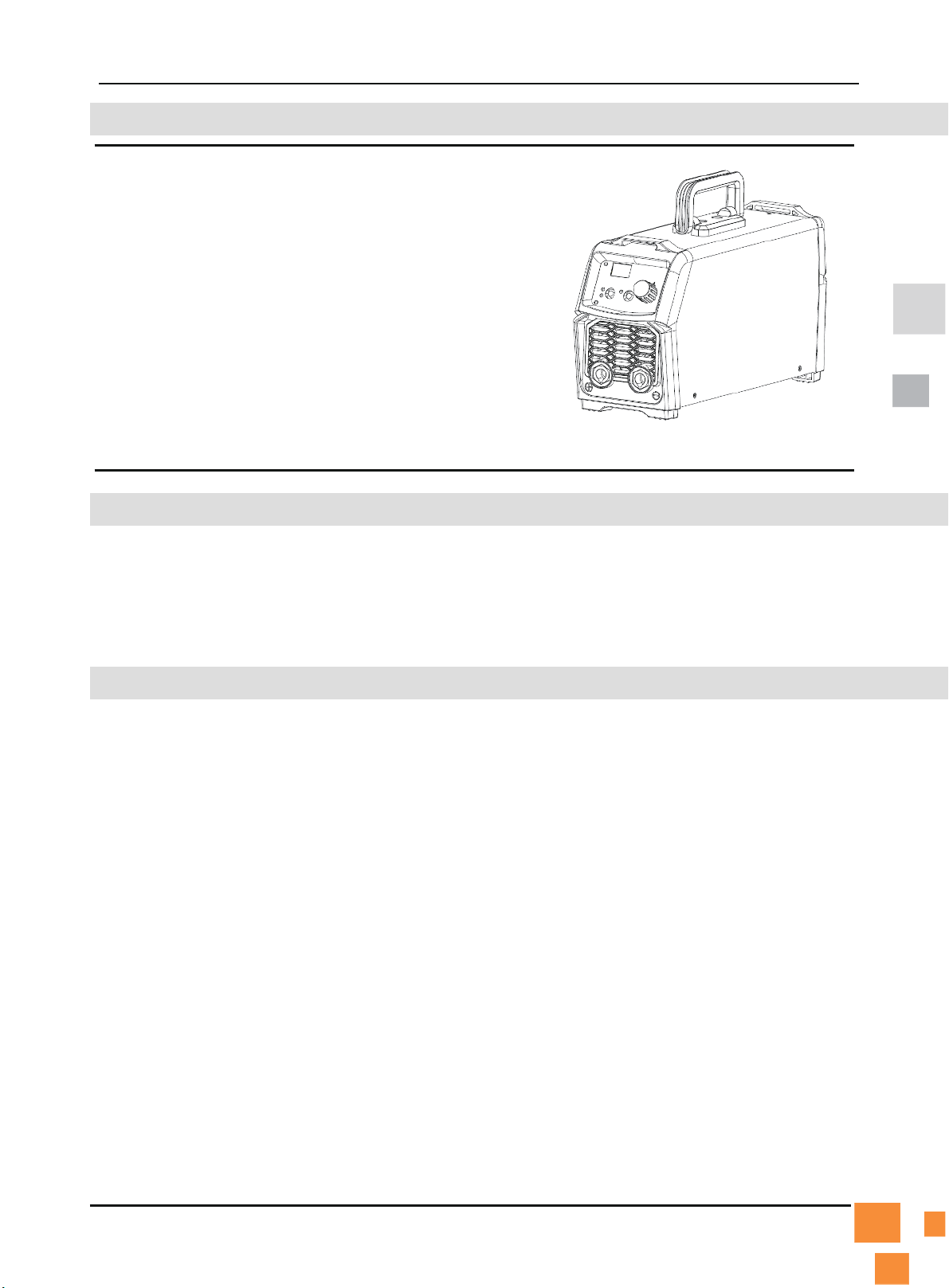

3. PRODUCT OVERVIEW

Unique electric structure and air channel design in this

series of machines can speed up the heat rejection of the

power device as well as improving the duty cycles of the

machines. The unique heat rejection efficiency of the air

channel can effectively prevent the power devices and

control circuits from being damaged by the dust absorbed

by the fan, and the reliability of the machine is greatly

improved thereby.

The machine adopts streamline shape. Frontand rear

panels andhandle are sprayed with rubber oil which gives

good touch feeling.

Fig 1

4. FUNCTION OVERVIEW

Various function designs

Hot start arc ignition function: make the arc ignition in MMA welding easier and more reliable.

Self-adaptive arc force technology: obviously improve the performance of the machine in

long-cable welding and contribute to long-distance welding.

5. PERFORMANCE CHARACTERISTICS

Advanced IGBT inverter technology

Inverting frequency of 42-52 kHz greatly reduces the volume and weight of the welder.

Great reduction in magnetic and resistance loss obviously enhances the welding efficiency

andenergy saving effect.

Working frequency is beyond audiorange, which almost eliminates noise pollution.

Leading control mode

Advanced control technology meets various welding applicationsand greatly improves the

welding performance.

It can be widely used in acid and basic electrode welding.

Easy arc starting, less spatter, stable currentand good shaping.

Nice shape and structure design

Frontand rear panels in shape of streamline make the whole shape nicer.

Excellent insulating property.

Waterproof, antistatic andanticorrosion.

6/18

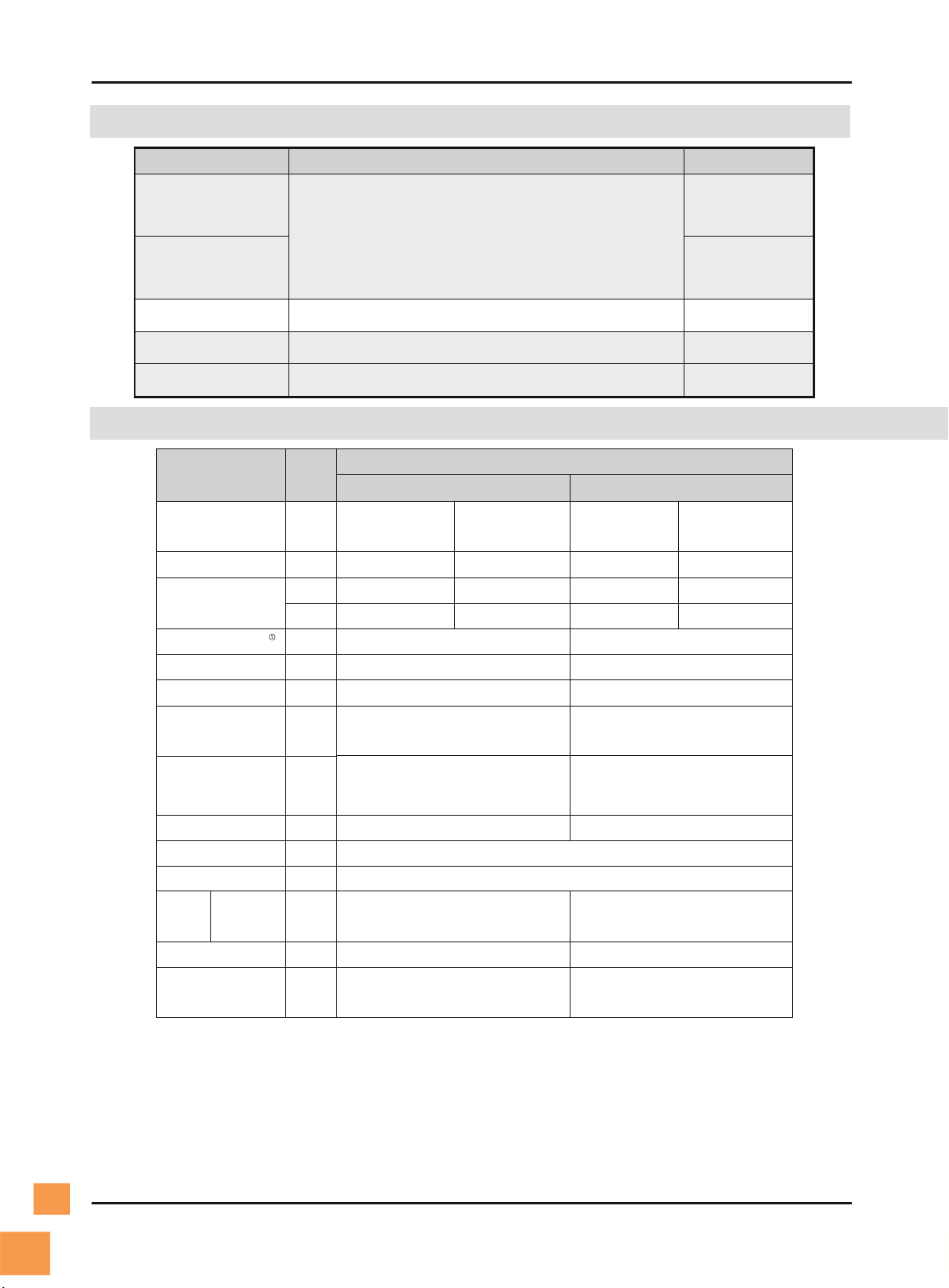

6. ORDER INFORMATION

ModelFunction Configuration Product Code

ARC160D

Hot start arc ignition

self-adaptive arc force

Anti-stick

MMA/Lift-TIG

VRD

Z2A4

ARC200D Z2A5

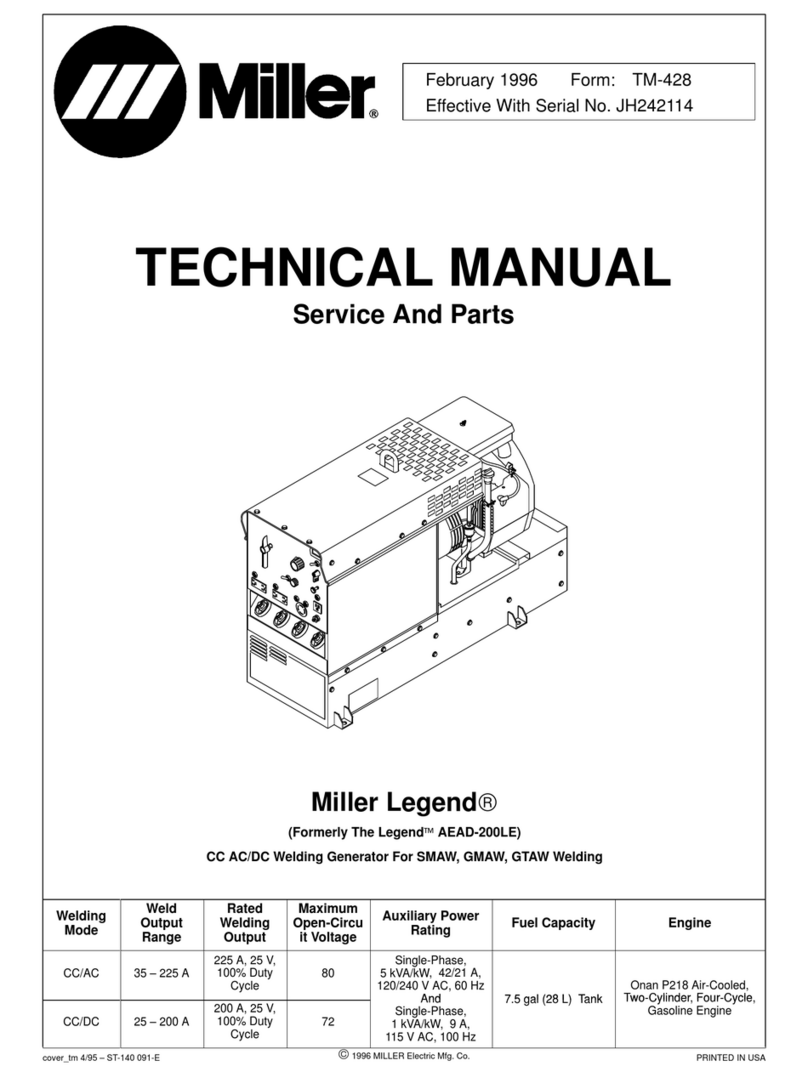

7. TECHNICAL PARAMETERS

Technical

Parameter Unit

Model

ARC160D ARC200D

Rated input

voltage

V

AC120V±15%

50/60HZ

AC240V±15%

50/60HZ

AC120V±15%

50/60HZ

AC240V±15%

50/60HZ

Rated input power KVA 5 7.1 6 9.4

Welding current

range

A20-120 20-160 20-140 20-200

V20.8-24.8 20.8-26.4 20.8-25.6 20.8-28

Rated duty cycle①%20 20

No-load voltage V 85 85

Overall efficiency % 85 85

Housing

protection grade

IP 21S 21S

Power factor cosφ0.7 0.7

Insulation grade H H

Standard IEC60974-1

Noise db <70

Size

with

handle②mm 305* 112* 190 mm 335*112*190 mm

Weight kg 3.560 4.220

Applicable

electrode

mm 1.0-3.2 1.0-5.0

“①”- under the environment temperature of 40℃“②”- Not every piece of machine has the same design. Differences may exist uponcustomers’ requirements.

7/18

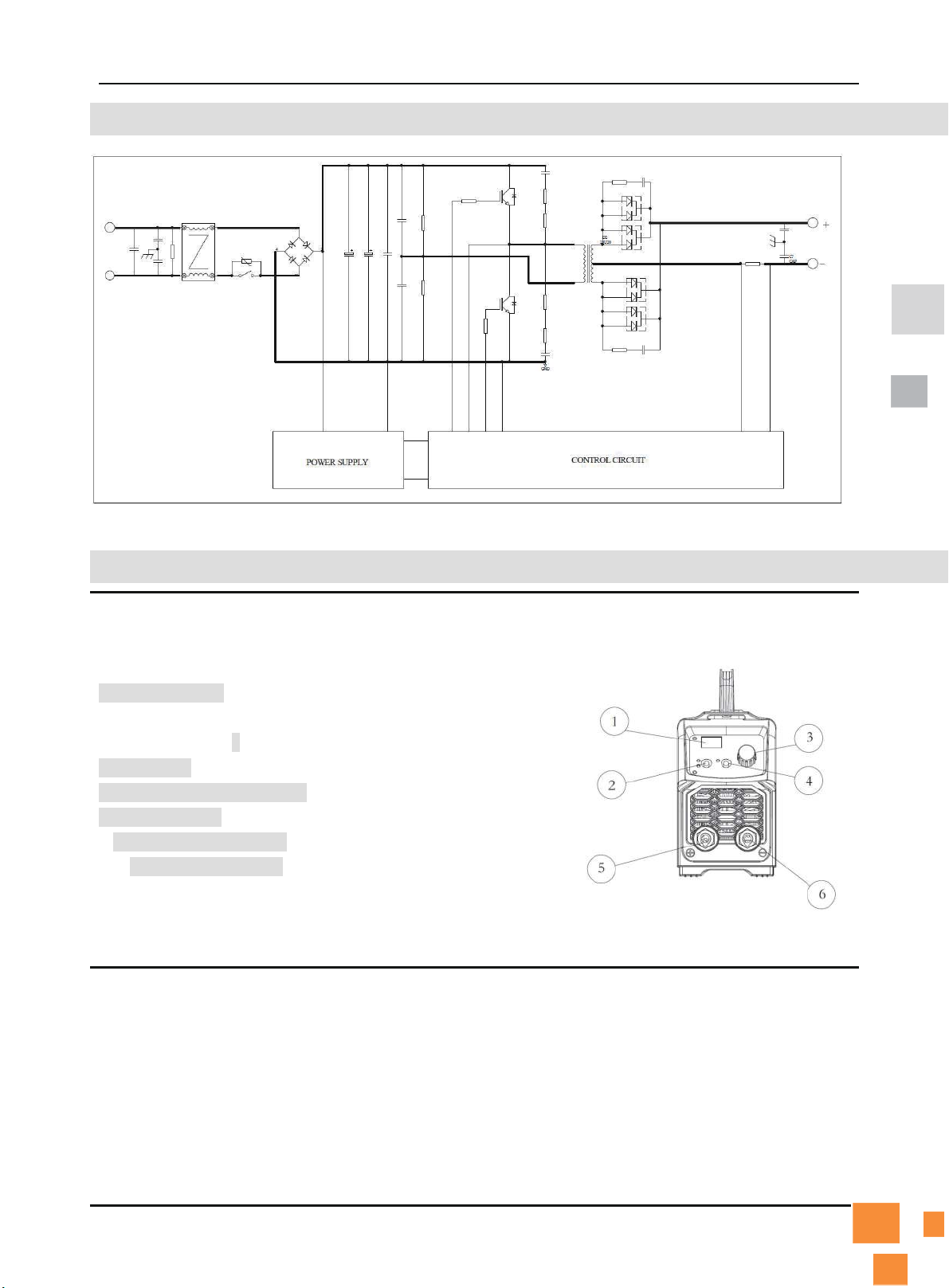

8. ELECTRICAL SCHEMATIC DIAGRAM

Fi

g. 1

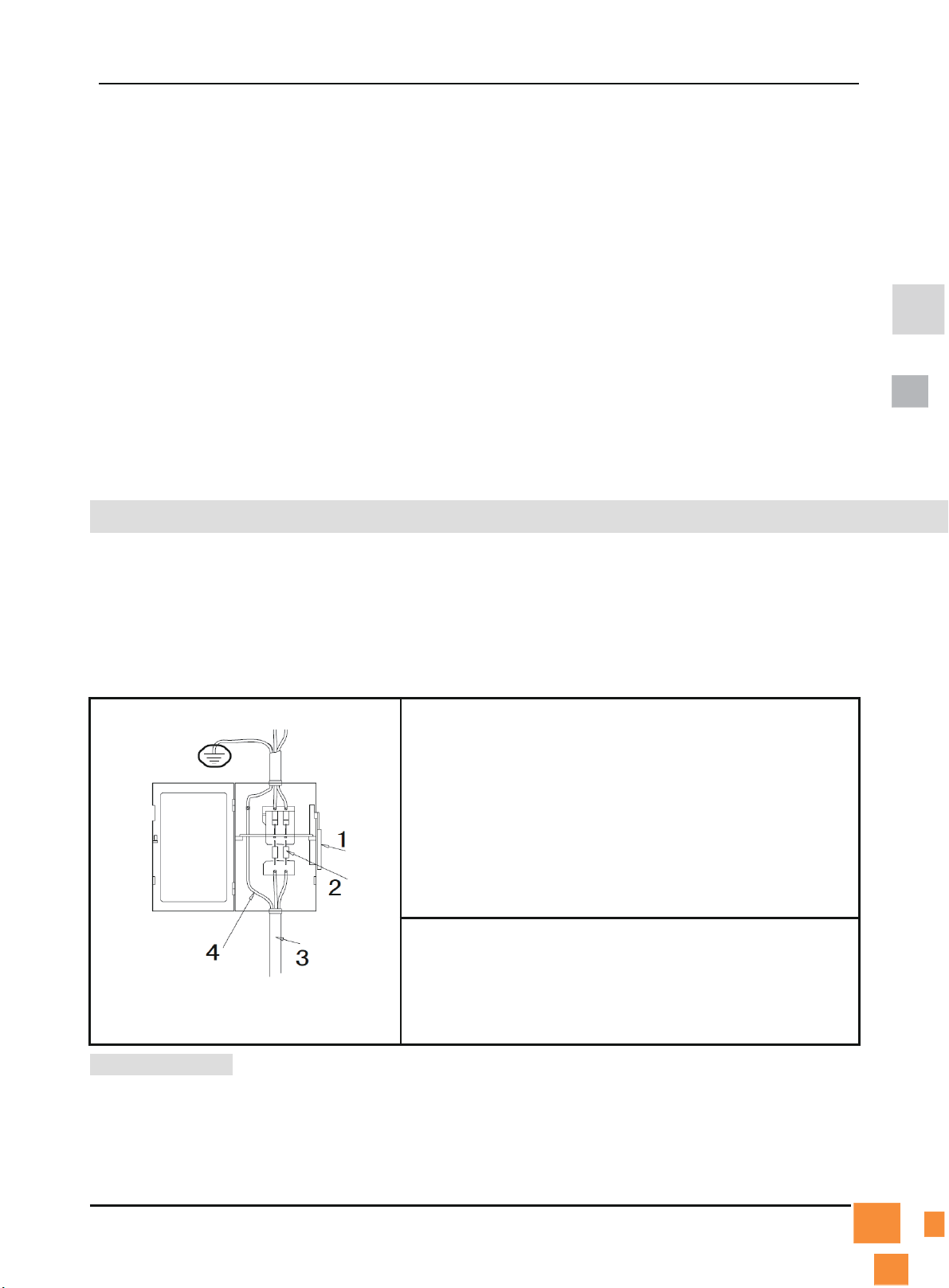

9. OPERATION CONTROL AND DESCRIPTION

1.Display meter: To show welding currentnormally. Showing

“E-1” indicates Over current protection, “E-3” indicates over

heating protection

2.TIG/MMA: To switch Lift-TIG/MMA welding mode

3. Welding current knob:To adjust the output current.

4. VRD switch: To turn ON/OFF VRD function

5. "+" output terminal: To connect the electrodeholder.

6. "-" output terminal: To connect the work clamp.

Fig. 2

8/18

7.Handle

8. Power input:power input cable.

9. Power switch: Power ON/OFF switch.

10. Cooling fan.

Fig. 3

10. SYSTEM CHARACTERISTICS

1) Duty cycle

Rated duty cycle refers to the percentage of the normal work time of the machine under rated maximum

currentholding in the period when taking 10 minutes as a period. The rated duty cycle of this series is

30%depending on different models.Using the welding machine continuously overrunning the rated load

may lead to overheating of the machine,and frequently using the machine overrunning the rated load

may accelerate the aging of the machine or even burn the machine.

2) Output characteristic

________ External characteristic of maximum output

................ External characteristic of minimum output

------------- Relationship with rated load

9/18

11. INSTALLATION, DEBUGGING AND OPERATION

Note: Please install the machine strictly according to the following steps.

Turn off the power supply switch before any electric connection operation.

The housing protection grade of this machine is IP21S, so do not use it in rain.

Please DO NOT use this machine for thawing frozen pipes.

11.1 Connection of switching box

Figure 2-1

1. Power switch of the switching box

2. Fuse (≥60A)

3. Input power cord of the welding machine

4. Yellow-greenearth wire (earth, not connect to the null

line)

Connect according to the figure on the left or in other

correct ways. Cut off the main power before connection.

Note: No operation with power on.

Ask professional electrician to do the connection.

Do not connect two welding machines to the same

switching box.

Please install leakage protector when using the machine

in damp working place, on steel tower or on steel plate.

11.2 Installation

10 /18

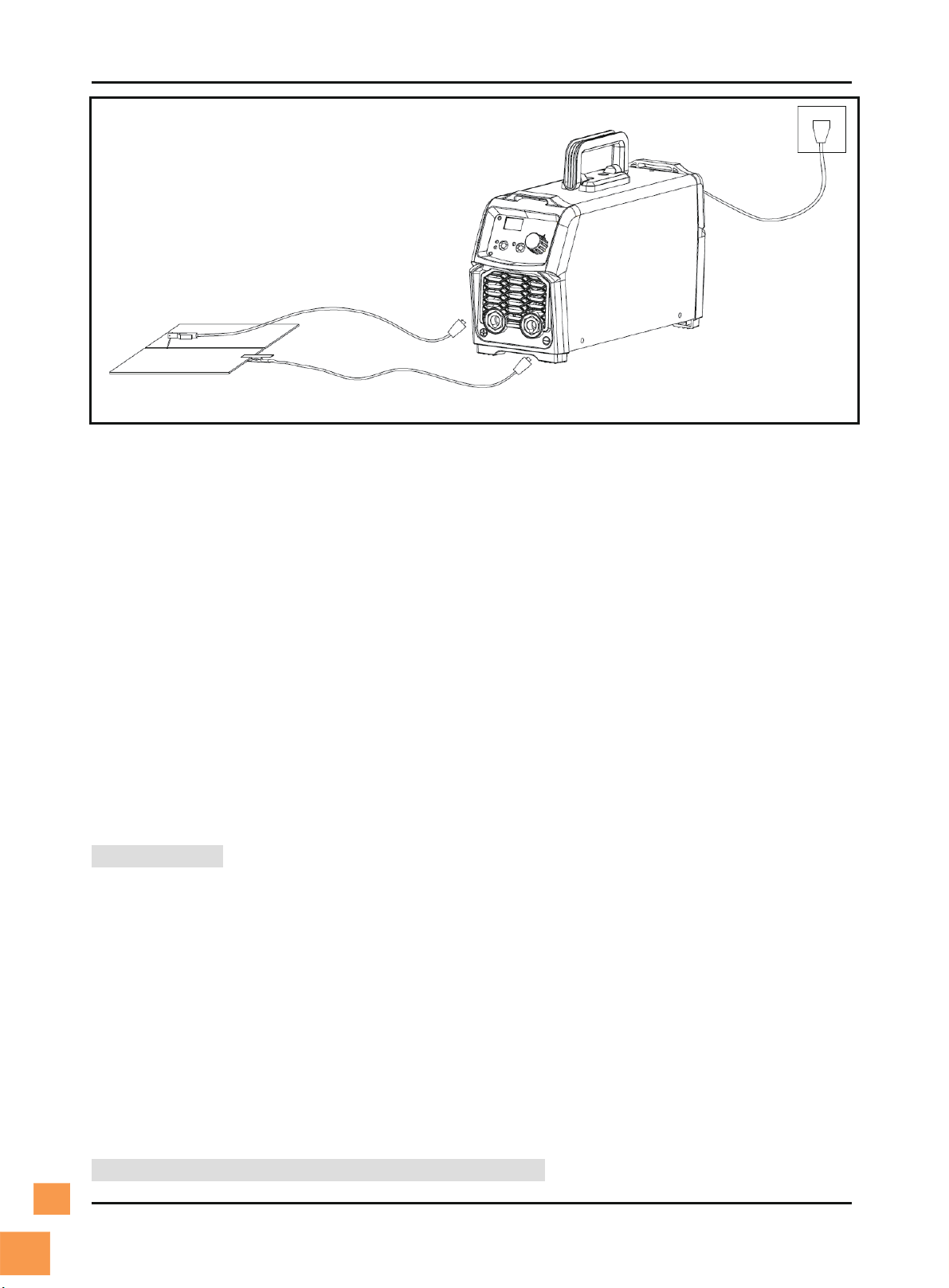

Fig.4 Schematic Diagram of MMA Welding

1) A primary power supply cable is available for this welding machine. Connect the power supply cable

to the rated input power.

2) The primary cable should be tightly connected to the correct socket to avoid oxidization.

3) Check whether the voltage value varies in acceptable range with a multi-meter.

4) Insert the cable plug with electrodeholder into the “+” socket on the front panel of the welding

machine,and tighten it clockwise.

5) Insert the cable plug with work clamp into the “-” socket on the front panel of the welding machine,

and tighten it clockwise.

6) Ground connection is needed for safety purpose.

The connection as mentioned above in 4) and 5) is DCEP connection. Operator can choose DCEN

connection according to workpiece and electrode application requirement. Generally, DCEP connection

is recommended for basic electrode, while there is no special requirement for acid electrode.

11.3 Operation

1) After being installed according to the above method,and the power switch being switchedon, the

machine is started with the power LED on and the fan working.

2) Pay attention to the polarity when connecting. Phenomena such as unstable arc, spatter, and

electrode sticking could happen if improper mode is selected. Exchange the polarity if necessary.

3) Select cable with larger cross-section to reduce the voltage drop if the secondary cables (welding

cable andearth cable) are long.

Preset the welding current according to the type and size of the electrode, clip the electrodeand then

welding can be carried out by short circuit arc ignition. For welding parameters, please refer to the below

table.

11.4 Welding parameters table (for reference only)

11 /18

Electrode Diameter

(mm)

Recommended Welding Current

(A)

Recommended Welding

Voltage (V)

1.0 20~60 20.8~22.4

1.6 44~84 21.76~23.36

2.0 60~10022.4~24.0

2.5 80~12023.2~24.8

3.2 108~148 23.32~24.92

4.0 140~180 24.6~27.2

5.0 180~220 27.2~28.8

6.0 220~260 28.8~30.4

Note: This table is suitable for mild steel welding.

12. CAUTION

12.1 Working Environment

1) Welding should be carried out in dry environmentwith humidity of 90% or less.

2) The temperature of the working environment should be between -10℃and 40℃.

3) Avoid welding in the open air unless sheltered from sunlightand rain. Keep it dry at all times and do

not place it on wet ground or in puddles.

4) Avoid welding in dusty area or environmentwith corrosive chemical gas.

5) Gas shielded arc welding should be operated in environmentwithout strong airflow.

12.2 Safety Tips

Over-current/over-heating protection circuit is installed in this machine. When the output current or inner

temperature exceeds the set standard, the machine will stop automatically. However, excessive use of

machine will lead to welderdamage. Therefore, please note:

1) Ventilation

This welder can create powerful welding current thathas strict cooling requirements that cannot be

met with natural ventilation. Therefore the internal fan is very important in enabling the machine to

work steadilywith effective cooling. The operator should make sure that the louvers be uncovered

andunblocked. The minimum distance between the machine andnearby objects should be 30cm.

Good ventilation is of critical importance to the normal performance andlifespan of the machine.

12 /18

2) Welding operation is forbidden while the machine is overload. Remember to observe the max load

current at any moment (refer to the corresponding duty cycle). Make sure that the welding current

should not exceed the max load current. Overload could obviously shorten the machine's lifespan,

or even damage the machine.

3) Over-voltage is forbidden.

Regarding the power supply voltage range of the machine, please refer to “Technical Parameters”

table. This machine is of automatic voltage compensation, which enables the maintaining of the

voltage range within the given range. In case that the input voltage exceeds the stipulated value, it

would possibly damage the components of the machine.

4) An earth terminal is available for the machine. Connect it with an earth cable (section≥6mm2) to

avoid the static and electric shock.

5) A sudden halt may occur with the yellow LED on the front panel on while the machine is of over-load

status. Under this circumstance, it is unnecessary to restart the machine. Keep the built-in fan

working to lower the temperature inside the machine. Welding can be continued after the inner

temperature falls into the standard range and the yellow LED is off. There may be something failed if

the yellow LED keeps illuminating.

13. BASIC KNOWLEDGE OF WELDING

Manual metal arc welding, MMA for short, is an arc welding mode by manually operating electrode.

Equipment for MMA is simple, convenientand flexible to operate, andwith high adaptability. MMA is

applied to various metal materials with thickness more than 2mm and various structures, in particular to

workpiece with complex structure and shape, short weld joint or bending shape, as well as weld joints in

various spatial locations.

13.1 Welding Process of MMA

Connect the two output terminals of the welder to the workpiece and electrodeholder respectively, and

then clamp the electrode by the electrodeholder. When welding, arc is ignited between the electrode

and the workpiece, and the end of the electrodeand part of the workpiece is fused to form a weld crater

under the high-temperature arc. The weld crater is quickly cooled and condensed to form weld joint

which can firmly integrally connect two separate pieces of workpiece. The coating of the electrode is

fused to produce slag to cover the weld crater. The cooled slag can form slag crust to protect the weld

joint. The slag crust is removed at last, and the joint welding is finished.

13.2 Tools for MMA

Common tools for MMA include electrodeholder, welding mask, slag hammer, wire brush (see Fig. 5),

13 /18

welding cable and labor protection supplies.

a) electrodeholder b) welding mask c) slag hammer d) wire brush

Fig. 5 Tools for MMA

a) Electrodeholder: a tool for clamping electrodeand conducting current, mainly including 300A type

and500A type.

b) Welding mask: a shielding tool for protecting eyes and face from injuring due to arc and spatter,

including handholding type andhelmet type. Colored chemical glass is installed on the viewing window

of the mask to filter ultraviolet ray and infrared ray. Arc burning condition and weld crater condition can

be observed from the viewing windowduring welding. Thus, welding can be carried out by operators

conveniently.

c) Slag hammer (peen hammer): for the use of removing slag crust on the surface of weld joint.

d) Wire brush: for the use of removing dirt and rust at the joints of the workpiece before welding, as well

as cleaning the surface of weld joint and the spatter after welding.

e) Welding cable: generally cables formed from many fine copperwires. Electrodeholderand welding

machine are connected via a cable, and this cable is named as welding cable (live wire). Welding

machine and workpiece are connected via anothercable (earth wire). The electrodeholder is covered

with insulating material performing insulation andheat insulating.

13.3 Basic Operation of MMA

1) Welding joint cleaning

Rust and greasy dirt at the joint should be removed completely before welding in order to implement arc

igniting and arc stabilizing conveniently as well as ensure the quality of weld joint. Wire brush can be

used for condition with low requirement on dust removal; grinding wheel can be used for condition with

high requirement on dust removal.

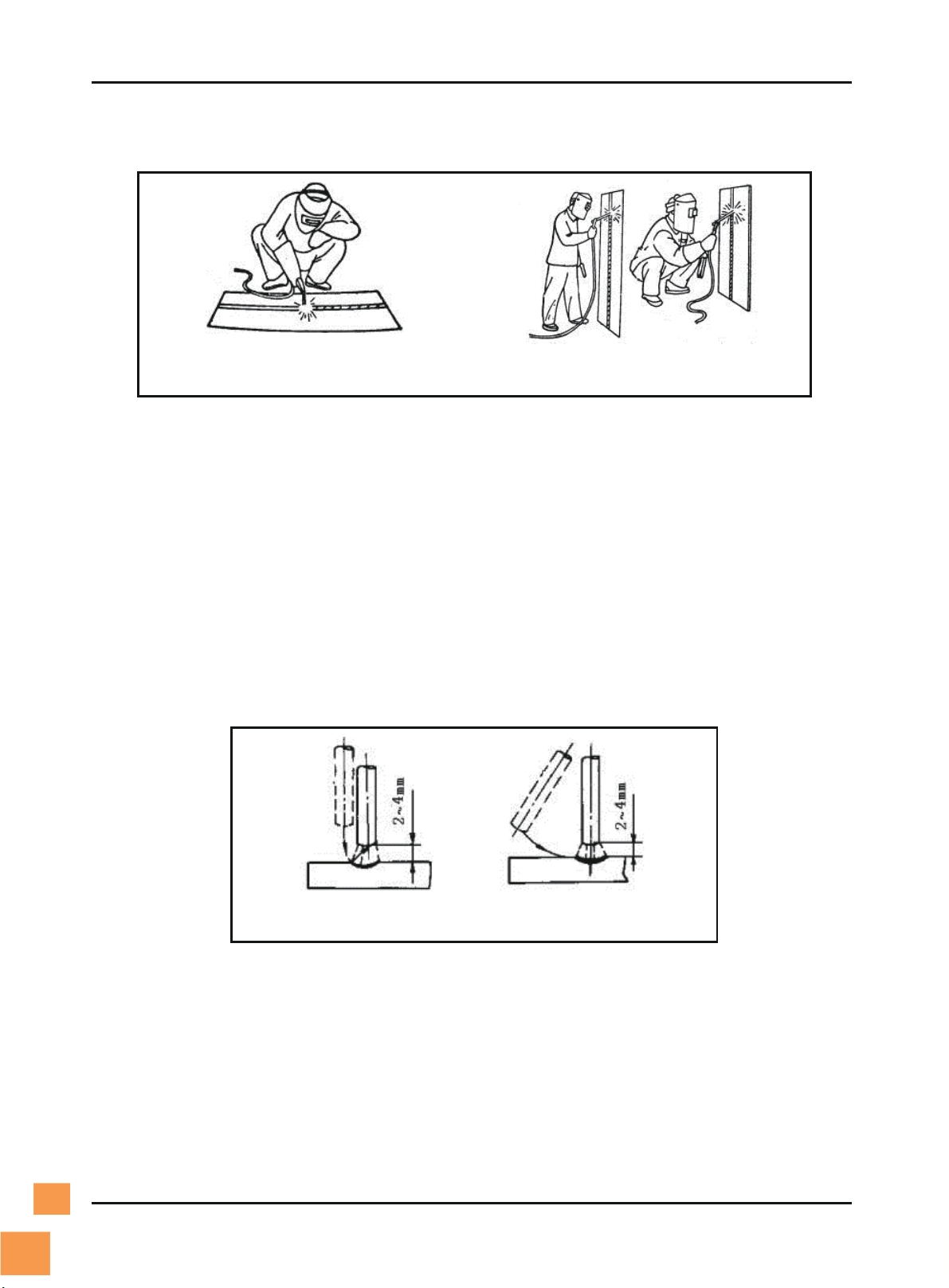

2) Posture in operating

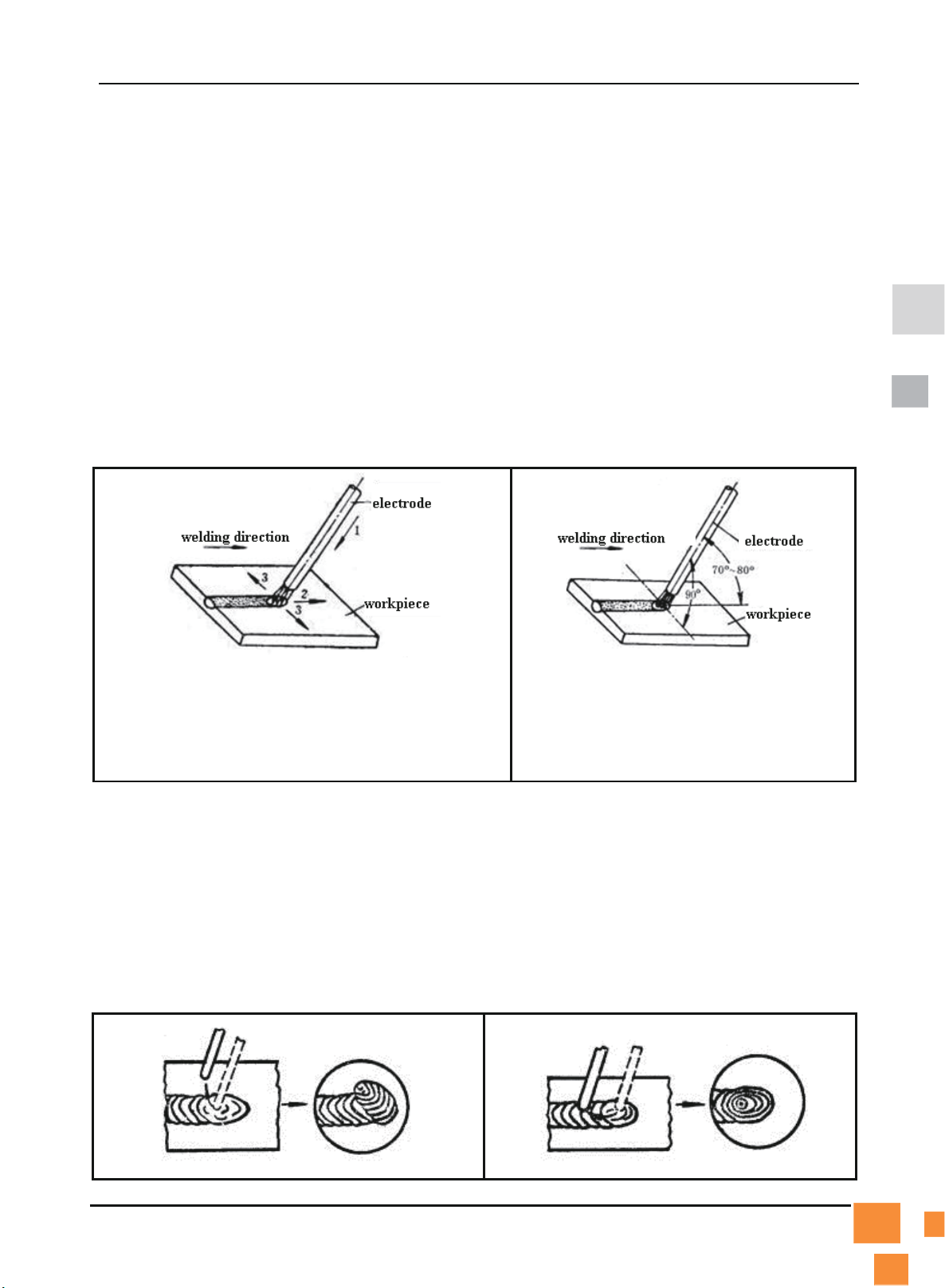

Take flat welding of butt joint and T-shaped joint from left to right as an example. (See Fig. 6) The

operator should stand at the right side of the working direction of weld joint with mask in the left handand

electrodeholder in the righthand. The left elbow of the operator should be put on his left knee to prevent

14 /18

his upper body from following downwards, and his arm should be separated from the costal part so as to

stretch out freely.

`

a) flat welding b) vertical welding

Fig. 6 Posture in welding

3) Arc igniting

Arc igniting is the process for producing stable arc between electrodeand workpiece in order to heat

them to implement welding. Common arc ignition mode includes scraping modeand striking mode. (See

Fig.7) During welding, touch the surface of the workpiece with the end of the electrode by scraping or

light striking to form short circuit, and then quickly lift the electrode 2~4mm away to ignite arc. If arc

ignition fails, it is probably because there is coating at the end of the electrode, which affects the electric

conduction. In this case, the operator can strongly knock the electrode to remove the insulation material

until the metal surface of the core wire can be seen.

a) striking mode b) scraping mode

Fig. 7 Arc ignition modes

4) Tack weld

For fixing the relative positions of the two pieces of weldmentand welding conveniently, 30~40mm short

weld joints are welded every certain distance in order to fix the relative positions of the workpiece during

welding assembly. This process is named as tack weld.

5) Electrode manipulation

The electrode manipulation actually is a resultant movement in which the electrode simultaneously

moves in three basic directions: the electrode gradually moves along the welding direction; the electrode

15 /18

gradually moves toward the weld crater; and the electrode transversely swings. (See Fig.8) Electrode

should be correctly manipulated in three movement directions after arc is ignited. In butt welding and flat

welding, the most important is to control the following three aspects: welding angle, arc length and

welding speed.

Welding angle: the electrode should be inclined in 70~80º forwards. (See Fig.9)

Arc length: the proper arc length is equal to the diameter of electrode in general.

Welding speed: proper welding speed should make the crater width of the weld bead about twice the

diameter of the electrode,and the surface of the weld bead should be flat with fine ripples. If the welding

speed is too high, and the weld bead is narrow and high, the ripples are rough, and the fusion is not well

implemented. If the welding speed is too low, the crater width is excessive, and the workpiece is easy to

be burned through. Besides, current should be proper, electrode should be aligned, arc should be low,

and welding speed should not be too high and should be kept uniform during the whole welding process.

1-downwards feed

2-move toward welding direction

3-transversely swing

Fig.8 Three basic movement directions of electrodeFig.9 Angles of electrode in flat welding

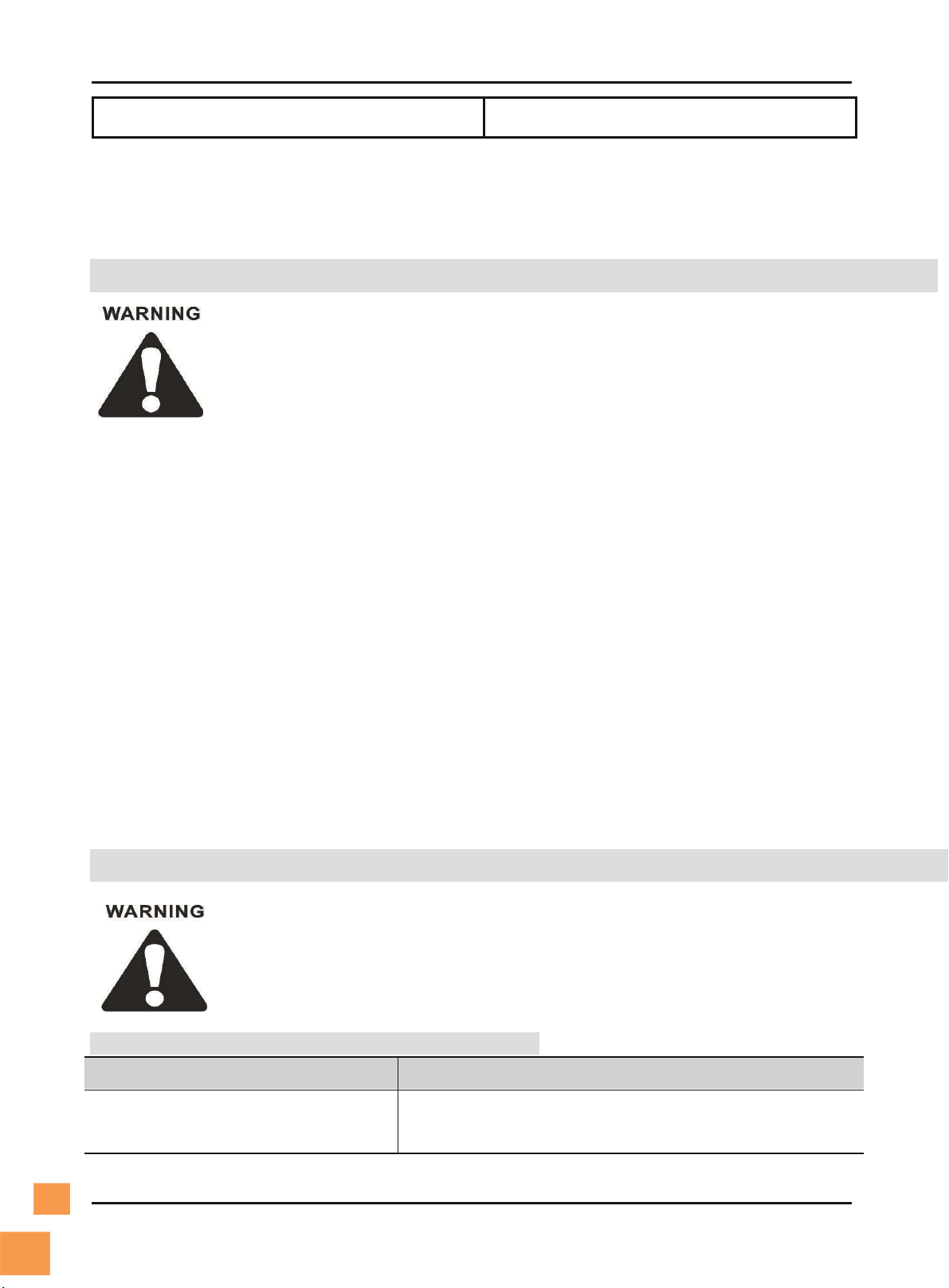

6) Arc extinguishing

Arc extinguishing is unavoidable during welding. Poor arc extinguishing may bring shallow weld crater

and poordensity and strength of weld metal by which cracks, air holes, slag inclusion and shortage the

like are easy to be produced. Graduallypull the end of the electrode to the groove and raise the arc

when extinguishing arc, in order to narrow the weld crater and reduce the metal andheat. Thus, defects

such as cracks and air holes can be avoided. Pile up the weld metal of the crater to make the weld crater

sufficiently transferred. Then, remove the excessive part after welding. The operation modes of arc

extinguishing are shown in the figure below.

16 /18

The following operation requires sufficient professional knowledge on

electric aspect and comprehensive safety knowledge. Operators should be

holders of validqualification certificates which can prove their skills and

knowledge. Make sure the inputcable of the machine is disconnected from

the electricity utility before uncovering the welding machine.

The following operation requires sufficient professional knowledge on

electric aspect and comprehensive safety knowledge. Operators should be

holders of validqualification certificates which can prove their skills and

knowledge. Make sure the inputcable of the machine is disconnected from

the electricity utility before uncovering the welding machine.

a) arc extinguishing at the outside of weld bead b) arc extinguishing on the weld bead

Fig.10 Arc extinguishing modes

7) Weldment cleaning

Clean welding slag and spatter with wire brush and tools the like after welding.

14. MAINTENANCE

1) Check periodically whether inner circuit connection is in good condition (esp. plugs). Tighten the

loose connection. If there is oxidization, remove it with sandpaper and then reconnect.

2) Keephands, hair and tools away from the moving parts such as the fan to avoid personal injury or

machine damage.

3) Clean the dust periodicallywith dry and clean compressed air. If welding environmentwith heavy

smoke and pollution, the machine should be cleaneddaily. The pressure of compressed air should

be at a proper level in order to avoid the small parts inside the machine being damaged.

4) Avoid rain, water and vapor infiltrating the machine. If there is, dry it and check the insulation of the

equipment (including that between the connections and that between the connection and the

enclosure). Only when there are no abnormal phenomenaanymore, can the machine be used.

5) Check periodically whether the insulation cover of all cables is in good condition. If there is any

dilapidation, rewrap it or replace it.

6) Put the machine into the original packing in dry location if it is not to be used for a long time.

15.TROUBLESHOOTING

15.1 Common Malfunction Analysis and Solution:

Malfunction Phenomena Causes and Solutions

Turn on the machine, the power LED is off, the

fan doesn't work, and no welding output.

(1) Check if the power switch is closed.

(2) No inputpower.

17 /18

Turn on the machine, the fan works, but the

output current is unstable and can't be

controlled by potentiometer when welding.

(1) The currentpotentiometer fails. Replace it.

(2) Check if any loose contact exists inside the machine. If any,

reconnect.

Turn on the machine, the power LED is on, the

fan works, but no welding output.

(1) Check if any loose contact exists inside the machine.

(2) Open circuit or loose contact occurs at the joint of output terminal.

(3) The Abnormity indicator LED is on.

a) The machine is under over-heating protection status. It can

recover automatically after the welding machine is cooled.

b) Check if the thermal switch is ok. Replace it if damaged.

c) Check if the thermal switch is loosely connected, and

reconnect it if necessary.

The electrodeholder becomes very hot.

The rated current of the electrodeholder is smaller than its actual

working current. Replace it with a bigger rated current.

Excessive spatter in MMA welding.Theoutputpolarity connection is incorrect. Exchange the polarity.

Breaker trips when turn on the machine Check primary rectifier bridge and IGBT

This product is being improvedunceasingly, so differences may appear in parts except for

functions and operation.Thanks for understanding.

APPENDIX A: PACKING, TRANSPORTATION AND STORAGE

A1. Packing

No. Name Unit Quantity

1User’s manual for ARC series (English) Volume 1

2Quick plug fittings Pack 2

3

4

5

“*”- Not all products have this part.

A2. Transportation

Equipment should be handled with care in transportation to avoid severe impact. Equipment should be

prevented from being affected with damp and caught in the rain in transportation.

A3. Storage

Temperature for storage: -10℃~+40℃Humidity for storage: relative humidity≤90%

Storage life: 12 months

Place for storage: ventilated indoor place without corrosive gas

APPENDIX B:REVISION HISTORY

18 /18

No. Description Version Time

1

2

3

4

5

6

Table of contents

Other Hitbox Welding System manuals

Popular Welding System manuals by other brands

EWM

EWM Phoenix 355 Progress puls MM TDM operating instructions

Miller Electric

Miller Electric Legend AEAD-200LE Technical manual

Lincoln Electric

Lincoln Electric Weld-Pak 140HD Technical specifications

OMG

OMG RhinoBond RBHW1 owner's manual

Miller

Miller Ultra HDV owner's manual

Silverline

Silverline 427677 manual

MAGNAWELD

MAGNAWELD monoTIG 160i user manual

iWeld

iWeld ARC 150 MINI user manual

Amada

Amada TL-180B Operation manual

Chicago Electric

Chicago Electric 45690 Assembly and operating instructions

Lincoln Electric

Lincoln Electric Harris 62-E operating instructions

Lincoln Electric

Lincoln Electric PRECISION TIG IM936 Operator's manual