Version February 2018

10 EN HÜRNER CNC ECO 315 User’s Manual

HÜRNER Schweisstechnik GmbH

Nieder-Ohmener Str. 26

35325 Mücke,

Germany

3.5 Overview of the Welding Process

After the thermoplastic material, the pipe diameter, and the wall

thickness were entered, the machine computes all parameters that

are critical for the welding process, taking into account the selected

welding standard (e.g., DVS, PIPA, NEN). The entire welding process

is automatically controlled, monitored, and its data logged and saved

to a welding report.

The saved welding data can subsequently be downloaded to a USB

mass storage media as a short or extended report in the PDF format

or the HÜRNER database format DataWork. Parameters applicable to

the welded joint and traceability data on the processed parts can be

entered either on the alphanumeric keypad on the front panel or read

from a transponder chip card. Reading bar codes with a scanning pen

or handheld scanner is available optionally.

For your convenience, the machine can be specifically costumized in

a Configuration Menu (see section 4.2).

The welder performs the welding process in the following manner:

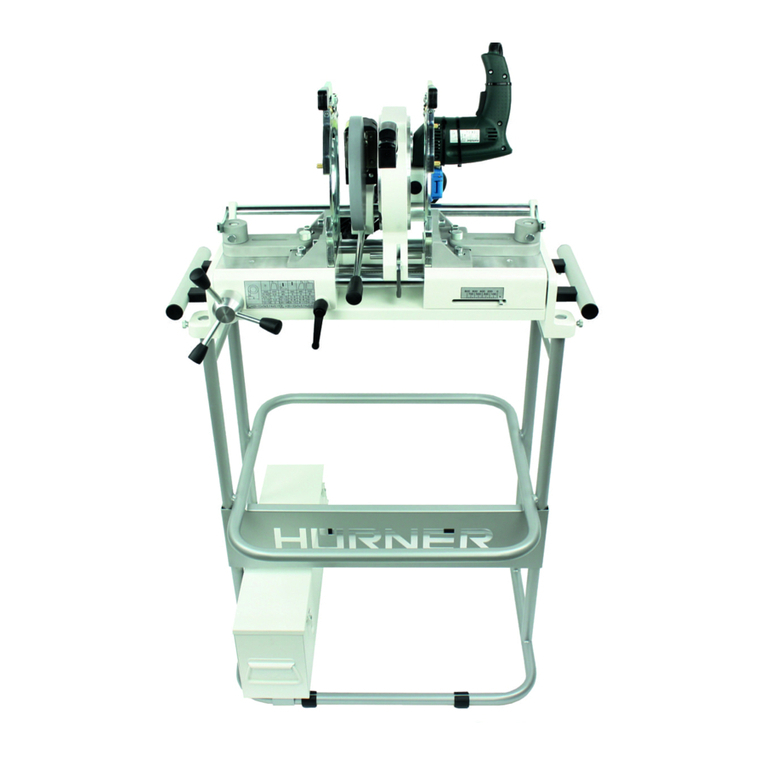

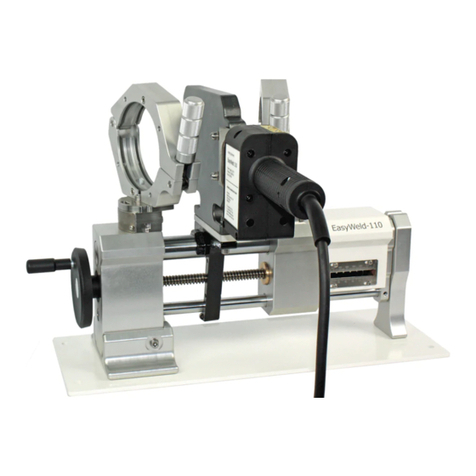

• Pipesareclampedintotheframe.

If pipes with an outside diameter smaller than the maximum

dimension of the machine are welded, select the reducer set

needed. The 8 individual inserts of the set that matches the out-

side diameter of the pipe to be welded have to be attached to

the clamps of the machine chassis using the provided bolts.

• Themandatory and optionalcomponent traceabilitydata and

the data on the components are entered in the screen menus.

• Pipebuttsareworkedusingthepipefacingtool.

• Pipealignmentischeckedaccordingtotheinformationdisplayed

on the screen.

• Thetechnicaldataontheweldingprocessitselfareenteredorre-

used from the preceding welding operation, provided the manual

input of these data is enabled in the Configuration Menu.

• Theheatingelementisinsertedaftercleaningitandcheckingits

temperature.

• Aftertheheatingelementwasinserted,thepipescloseinauto-

matically on it at the predefined build-up pressure.

• Duringthebuild-upstagetheweldbeadbuildsup.Whenthe

bead size, as required under the selected standard, is achieved,

the welder has to confirm successful bead build-up. (If Automode

(see Section 4.2) is enabled, the successful bead build-up is de-

tected automatically; the machine computes the build-up time

depending on the parameters of the parts to be jointed.)

• Themachinethenmovesonautomaticallytotheheatingstage.

• Aftertheheatingstage,themachineautomaticallymovesthe

movable carriage apart and the welder has to remove the heat-

ing element from in-between the butts.

• Aftertheremovaloftheheatingelement,themachineautomati-

cally closes the pipes in on each other.

Movement Pushbutton on Machine Chassis

This pushbutton that allows moving the carriage of the machine makes

welding easier for the operator when the hydraulic and control unit

is not next to the basic machine chassis. The pushbutton enables the

welder, without leaving the chassis during the welding process, to

confirm various states (e.g., end of butt facing, pipe offset check, bead

build-up, heating element insertion) that otherwise would have to be

confirmed by pressing the START/SET key on the control unit.