Hiten 2H User manual

VERTICALTURRETMILLINGMACHINE

OPERATIONMANUAL

Model:2H4H5H

Themachinehasbeeninspectedandfoundtobeuptothe

standard,thenapprovedforex‐factory.

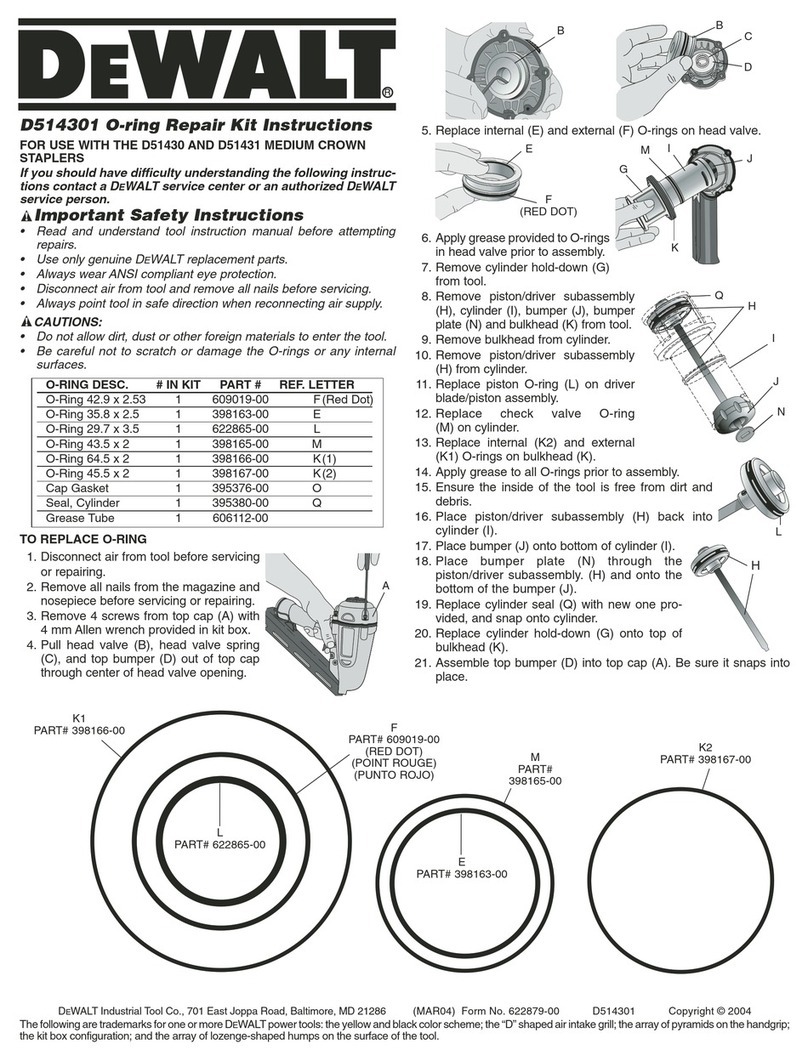

No.Inspectionitemfiguretolerancemeasured

G1

Straightness

ofknee

vertical

movement(W

axis)

a)inthecross

andvertical

surface(YZ)

Within0.025at

300arbitrary

length

measurement

b)ina

longitudinal

andvertical

surface(ZX)

G2

Squarenessof

uppersurface

oftableto

knee

movement

Rightandleft

direction

Per/0.025/300

Forwardand

backward

direction

0.025/300

G3

Squarenessof

vertical

movementof

thespindle

headwith

tablesurface

Rightandleft

directionPer0.020/125

Forwardand

backward

direction

0.020/125

G4Flatnessofworktable

0.040in1000

length,foreach

additional1000

lengthof

workingtable,

tolerancevalues

increasedby

0.005

G5

Parallelismofrightandleft

movementoftabletoits

uppersurface

0.02/300max.

0.04

Parallelismofforwardand

backwardmovementoftable

toitsuppersurface

G6Runoutofspindlea)0.01

b)0.01

G7

Mainspindle

taperhole

run‐out

Atfixedend

oftestbar0.01

Atpoint3000.02

G8

Squarenessof

uppersurface

oftableto

centrelineof

spindle

Rightandleft

directionPer0.025/300

Forwardand

backward

direction

0.025/300

G9Straightnessoftablecentralor

benchmarkTslot

Inany500

measuring

lengthis

0.010,the

maximum

tolerance0.030

G10

Parallelismofrightandleft

movementoftabletosideof

middleTslotoftable

0.015/300

max.0.04

G11

Squarenessofforwardand

backwardmovementoftable

tosideofmiddleTslotof

table

Per3000.02

G12

Parallelismofforwardand

backwardmovementof

overarmwithtablesurface

0.035/300

G13

Parallelismofleftandright

movementofswivelturret

withtablesurface

0.035

SKU HT-2H001 HT-4H002 HT-5H003

Operation Info

Max. Drilling Capacity (steel) 1-1/4" 1-1/4" 1-1/4"

Max. Drilling Capacity (lron) 1-1/2" 1-1/2" 1-1/2"

Max. End Milling Capacity 1" 1" 1"

Max. Face Milling Capacity 3" 3" 3"

Max. Distance Spindle to Column 17-29/32" 21-27/32" 21-27/32"

Max. Distance Spindle to Table 15-3/4" 18-7/8" 21-21/32"

Longitudinal Table Travel (X-Axis) 23-5/8" 29-15/16 33-7/8"

Cross Table Travel (Y-Axis) 12-19/32" 15-3/4" 15-3/4"

Knee Table Travel (Z-Axis) 15-3/4" 15-3/4" 17-23/32"

Ram Travel 11-13/16" 15-3/4" 15-3/4"

Spindle Travel 5" 5" 5"

Head Swivel (Left / Right) 90° 90° 90°

Head Tilt (Front / Back) 45° 45° 45°

Turret or Column Swivel 360° 360° 360°

Spindle Info

Spindle Taper R8 R8 R8

Number of Spindle Speeds 16 16 16

Spindle Speeds 80 - 5440 RPM 80 - 5440 RPM 80 - 5440 RPM

Quill Auto. Feed 0.0015, 0.003,

0.006 in./rev. 0.0015, 0.003,

0.006 in./rev. 0.0015, 0.003,

0.006 in./rev.

Table Info

Table size 9" × 42" 10" × 50" 10" × 54"

T-Slots 3 @ 2½ centers,

5/8" wide 3, @ 2½ centers,

5/8" wide 3, @ 2½ centers,

5/8" wide

X/Y-Axis Travel per Handwheel Revolution 0.2" 0.2" 0.2"

Z-Axis Travel per Handwheel Revolution 0.1" 0.1" 0.1"

Electrical

Power Requirement Three-phase

220V 60 Hz Three-phase

220V 60 Hz Three-phase

220V 60 Hz

Amps 10A 10A 10A

Horsepower 3 HP 3 HP 3 HP

Shipping

Packing Size (L x W x H) 56.3" x 56.3" x

78.7" 64.2" x 61" x

82.7" 67" x 63" x 86.6"

Net Weight 1984.5 lbs 2469.6 lbs 2822.4 lbs

Shipping Weight 2160.9 lbs 2668.05 lbs 3042.9 lbs

CONTENTS

CHAPTER1.SAFETYINFORMATION

■ 1‐1IMPORTANTSAFETYINFORMATION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐1

■ 1‐2SAFETYRULESDURINGAND/ORBEFOREOPERATION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐2

■ 1‐3SAFETYDURINGELECTRICALCONNECTIONORDISCONNECTION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐3

■ 1‐4DESCRIPTIONFORTHESAFETYFUNCTIONOFTHISMACHINE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐3

■ 1‐5SAFETYINSPECTION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐4

CHAPTER2.INSTALLATION

■ 2‐1SAFETYPRECAUTIONS‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐5

■ 2‐2INSTALLATION/CLEANING‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐6

■ 2‐3MACHINEDIMENSION‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐7

■ 2‐4FOUNDATIONPLAN‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐8

■ 2‐5POWERSUPPLY‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐9

■ 2‐6INITIALSETTING‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐10

CHAPTER3.OPERATION

■ 3‐1SWIVELTURRET‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐11

■ 3‐2MOVERAMSLIDE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐11

■ 3‐3CLAMPINGTABLE,SADDLEANDKNEE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐12

■ 3‐4MAINPARTOFMILLINGHEAD(WITHSTEPPULLEYCONTROLLED)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐13

■ 3‐5MAINPARTOFMILLINGHEAD(WITHVARIABLESPEEDMOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐14

■ 3‐6MAINPARTOFMILLINGHEAD(WITHININVERTERCONTROLLED

VARIABLE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐15

■ 3‐7SPINDLESPEED(WITHSTEPPULLEYCONTROLLER)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐16

■ 3‐8SPINDLESPEED(WITHVARIABLESPEEDMOTOR&INVERTERCONTROLLERD

VARIAVLE‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐17

■ 3‐9FINEHEADFEED‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐18

■ 3‐10AUTOMATIONFEED‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐18

■ 3‐11SPINDLESPEEDSELECTION(WITHSTEPPULLEYCONTROLLED)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐19

■ 3‐12SPINDLESPEEDSELECTION(WITHVARIABLESPEEDMOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐20

■ 3‐13SWINGMILLINGHEADFORWARD&BACKWARD‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐21

■ 3‐14SWINGMILLINGHEADLEAF‐SIDE&RIGHT‐SID‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐22

CHAPTER4.MAINTENANCE

■ 4‐1MILLINGHEADLUBRICATIONSYSTEM‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐23

■ 4‐2AXIALLUBRICATIONSYSTEMX/Y/Z‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐24

■ 4‐3LUBRICATIONSYSTEM‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐25

■ 4‐4GIBADJUSTMENT‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐26

■ 4‐5BACKLASHADJUSTMENT(XAXIS)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐27

■ 4‐6BACKLASHADJUSTMENT(YXIS)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐28

■ 4‐7CLOCKSPRINGREPLACEMENT‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐29

■ 4‐8COLLETALIGNINGSCREWREPLACEMENT(R8)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐30

■ 4‐9ADJUSTINGSPINDLEBEARINGANDREPLACEBEARING(NT30#)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐31

■ 4‐10REMOVEMOTOR‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐32

■ 4‐11DRIVINGEELTREPLACEMENT(WITHSTEPPULLEYCONTROLLED)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐33

■ 4‐12BRAKEDRUM&TIMINGBELTREPLACEMENT(WITHSTEPPULLEYCONTROLLED)‐‐‐33

■ 4‐13DRIVINGBELTREPLACEMENT(WITHSTEPVARIABLESPEEDMOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐34

■ 4‐14DRIVINGBELTREPLACEMENT(WITHVARIABLESPEEDMOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐35

■ 4‐15BRAKEDRUMREPLACEMENT(WITHVARIABLESPEEDMOTOR)‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐35

■ 4‐16FEEDTRIPADJUSTMENT‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐36

CHAPTER5.PARTSLIST

■ 5‐1HEADTOPHOUSINGASSEMBLYSTEPPULLEY/A001~A087‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐38

■ 5‐2HEADTOPHOUSINGASSEMBLYFORVARIABLESPEED/VS001~VS155‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐42

■ 5‐3HEADTOPHOUSINGASSEMBLYFORINVERTERCONTROLLEDVARIABLESPEED/EVS1

~EVS103‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐48

■ 5‐4MACHINEHEADASSEMBLY/B001~B192‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐52

■ 5‐5X.YAXISLEADSCREWASSEMBLY/D001~D028‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐59

■ 5‐6BASICMACHINEASSEMBLY/2C001~2C133‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐61

CHAPTER6.ELECTRICALDIAGRAM‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐66

**INTRODUCTION**

THISMANUALHASBEENCAREFULLYPREPARED,PLEASESTUDYIT

THOROUGHLYBEFORETRYINGTOOPERATETHEMACHINE.

**AFEWMINUTESGIVENTOREADINGTHISMANUAL

CAREFULLY,COULDENSUREYOUACHIEVEMAXIMUMPERFORMANCE

FROMTHEMACHINE&REDUCETHERISKOFINJURYTOTHEOPERATOR

ORDAMAGETOTHEMACHINEORWORKPIECE.

EVERYEFFORTHASBEENMADEDURINGCONSTRUCTION&TESTINGTO

ENSURETHISMACHINEMEETSINTERNATIONALQUALITY&

PERFORMANCEREQUIREMENTS.WEWISHITSERVESYOUWELL.

1

CHAPTER1.SAFETYINFORMATION

1‐1IMPORTANTSAFETYINFORMATION:

A. Applicationofthemillingmachine

Themillingmachineisdesignedandconstructedforthecuttingofmetaland

similarmaterials.

Themachineisalongwithallthenecessarysafetyrequirements.Onlyfully

trained&fullyqualifiedoperatorsshouldbeallowedtooperatethismachine.

B. Prohibition:

‐Untrainedoperatorsareprohibitedfromusingthismachine.

‐Modificationsthatchangethefunctionorspecificationofthismachineis

prohibited.

‐Operationofthismachinebeforereadingthroughthisinstructionmanual,is

prohibited.

C. Airbornenoiselevel:

‐Theairbornenoiselevelduringoperationisabout70~75Db(A).

D. lighting:

‐Appropriatelightingmustbeprovided,accordingtolocalregulation.

‐Minimumlightingforthismachineis300LUX,iftherearenoanylocalother

localregulations.

E. Environment:

1. Ambientairtemperature:+41℉~+131℉infreeair,andtheaverageambient

airtemperatureoveraperiodof24hoursshallnotexceed+122℉

2. Humidity:30%~95%.

3. Altitude:upto1000mabovemeanseelevel.

4. Transportation&storagecondition:‐77℉~+131℉,andforshortperiodsnot

exceeding24hoursupto+158℉

2

1‐2SAFETYRULESDURINGAND/ORBEFOREOPERATION

A. Besuretheinstructionmanualarefullyunderstood.

B. Usesafetyprotectiveequipmentsuchassafetyshoes,goggles,clothes,etc.

C. Worktablenearthemachinemustbestrongenoughtopreventaccidentsandbe

surearticleswillneverslipoffthetablesurfacetointerferewiththeactof

machining.

D. Toolsandanyunnecessaryitemsarenotallowedtobeplacedonthemachine

table,movingparts,orsimilarlocations.

E. Beforeoperatingswitches,alwayscheckiftheswitchesaretherightonesand

nevertouchaswitchaccidentallyoritmaycausemalfunctionsordanger.

F. Donotoperateswitcheswithgloveson.Thiscouldcausemalfunctionsoreven

danger.

G. Donottouchswitcheswithwethands,anelectricshockcouldoccur.

H. Warmupthemachinebeforeuse,especiallythespindleandfeedingaxesby

runningthemfor10to20minutes.Itisveryimportantformaintainingmachine

accuracy.

I. Ifjobistobedonebytwoormoreoperators,thefunctionofeachmustbewell

known,whatactionwillbedoneandwhatdangermayoccur,beforethenext

stepistaken.

J. Toolsshouldconformtothemachine‘sspecifications,suchasdimensions,weight

andtypes.

K. Gripworkpiecessecurelytominimizemovementorvibrationbetweenworkpiece

andcuttingtooloritmayinjurepersonnel,ordamagethemachineorworkpiece.

L. Nevertouchtoolnoseandcuttingchipswithbarehands.

M. Nevertrytotouchaturningworkpieceorspindleinanyway.

N. Stopthemachinebeforereplacingaworkpieceandprovideplentyofdistance

betweenworkpieceandtooltoavoidimpactbetweenworkpieceandtoolduring

thechangeover.

O. Intheeventofpowerfailure,turnoffthemaincircuitbreakerimmediately.

P. Afterpowerfailureoranemergencystop,itisnecessarytoreturntoreference

pointofthethreeaxes.

Q. Donotchangeelectricalsettingsunlessnecessary.Ifsuchchangesare

unavoidable,recordtheoriginalvaluessothattheycanbereturnedtotheir

originalsettingsifneeded.

R. Beforereplacingafuseorelectricpart,turnoffthemachineandkeeparecordof

them,forfuturereference.

S. Ifunspecifiedlubricantisused,itmayresultinmalfunctionsordamagetothe

machine.

T. Limitswitches,proximityswitches,interlockmechanismsincludingfunctional

partsandothersafetydevicesshouldnotberemovedormodified.

U. Disposeoffiltermaterialandpossibleworkingfluidaccordingtothelocal

regulation.

V. Pleasekeeptheinstructionmanualnearthemachineorinapositioneasytobe

3

reachedbytheoperator,andkeepthemforavailable&ingoodconditionforuse.

W. Pleasealwaysquotethemachinemodelandserialnumberinorderforustodeal

withanyrequest,asquicklyaspossible.

X. Themachinesurfaceissmearedwithanti‐rustprotectionwhendelivered.It

shouldbecarefullycleaned&thensmearedwithprotectionoil.

1‐3SAFETYDURINGELECTRICALCONNECTIONORDISCONNECTION

A. Electricalconnection:

1. Acablewiththreewiresissuppliedtoconnectyourmachineinto3phase

powersupply.

2. Theexactpowersourcevoltage,frequency,andnumberofphaseshallbe

checkedaccordingtotheinstallationdiagramandcircuitdiagram.

3. Thecorrectdirectionsofspindleshouldbecheckedafterconnecting.

B. Electricaldisconnection:

1. Thedisconnectioniscarriedoutbyhand‐operateddisconnectingdevice,

whichisonthedoorofcontrolboxasanoptionorconnectedbeforethe

powersource.

2. Besuretodisconnectthismachinefrompowersource,whenyouwantto

stopthejobformaintenanceoradjustment.

C. Grounding:

Thegroundingofthismodeliscarriedoutbyconnectingtheyellow/green

terminalofsupplycabletothegroundingterminalofpowersource.Besureto

groundyourmachinebeforeconnectingmachinetopowersourceinanysituation.

WARNING!

DONOTDISCONNECTGROUNDINGTERMINALBEFOREDISCONNECTINGPOWER

SOURCE

D. Whereaportionofthemachineanditsassociatedequipmentischangedor

modified,mustbeapprovedbythemanufacturerfirst,andfollowingretestshall

becarriedoutinaccordancewiththeclausesofen60204‐1,1992edition:

‐Continuityoftheprotectivebondingcircuit.(SUBCLAUSE20.2)

‐Insulationresistancetests.(SUBCLAUSE20.3)

‐Voltagetests.(SUBCLAUSE20.4)

‐Functionaltests.

1‐4DESCRIPTIONFORTHESAFETYFUNCTIONOFTHISMACHINE

Thefollowingsafetyfunctionsareequippedwiththismachinebesuretocheckand

ensurethecorrectfunctionbeforeyoustarttooperateyourmachine:

A:Thehand‐operatedpowerdisconnectiondevice:

Itisconstructedtodisconnectmachinefrompowersourcewhentheoperatorintend

tostopoperationformaintenance,repair,and/orwhiletheendofwork.The

4

correctionisthatthedoorofcontrolcabinetcouldbeopenonlywhenthisswitchof

thisdeviceisswitchedoff,andafterthisdeviceisswitchedoff,itispossibletobe

lockedwithsomeappropriatelocking.assoonasthisdeviceisswitchedoff,noany

operationispossibleandtherewouldbenoanyelectricityonthecontrolcircuit

exceptthewringbeforethisdevice.

B.Theemergencystopdevice:

Itisconstructedtostopmachineasfastaspossiblewhileinemergencysituation.as

soonasthisdeviceisactuated,anymovementwillbestoppedinashorttime.after

theactuationofemergencybutton,thefurtheroperationispossibleonlywhenthis

buttonisdisengagedandtherestartkeyisactuated.Besuretocheckthatmachine

actionwillstopimmediatelyafterthisbuttonispushedandwillnotcauseanyaction

whenthisbuttonisdisengaged.

1‐5SAFETYINSPECTION

Toensuresafety,itisnecessarytodothefollowinginspectionsforthismachineafter

installation.

A. Checkifthetransportationprocedurehasinfluencedtheaccuracyandfunctions

ofthemachine.

B. Checkifthefoundationofthemachineisappropriate.

C. Checkifthefactoryhasthecorrectthunder‐preventingsystemunder25.The

machine’spowerswitchshouldalsohaveearthwiringconnected.

D. Usethemultitestertocheckifthethree‐phasevoltageisstableandphasesarein

order.

E. Checkifspindlerotationisnormal

F. Checkifthecontrolpanelfunctionandpushbuttonarefunctioning(including

indicatorlamp,loadandrpmmeter).

G. Checkemergencystopfunction

H. Checkifsafetyprotectionaccessoriesarefunctioningwell.

I. Checkifotheraccessories,includinghydraulicandpneumaticones,are

connectedwell(includingtransformeretc.).

J. Checkiftheoilamountindicatorandtheairpressureindicatorarenormal.

K. Makesurenoobstacleisaroundmachineandcontrolsystem.

L. Makesurenopersonnelisindangerousarea.

5

CHAPTER2.INSTALLATION

2‐1SAFETYPRECAUTIONS

1. Besuretheinstructionmanualisfullyunderstood.Mustfollowinstruction

manualtooperatemachinecarefully.

2. Theoperatorwithouttrainingorbeingauthorizedisprohibitedtooperatethis

machine.

3. Setallcoversinpositionbeforeoperation.

4. Usesafetyprotectiveequipmentsuchassafetyshoes,goggles,clothes,etc.and

donotwearglovesorornaments.

5. Mustnottouchrunningcutters.

6. Nevertrytotouchworkpieceorcleanchipswhilecuttersisrunning.

7. Keephead&handsclearfromrunningmachineparts.

8. Turnpoweroffbeforemaintenance.

6

2‐2INSTALLATION

METHOD1

Insert3/4 ” (whitworth)eye

boltintohole.Ensureboltis

fullysecuredbeforelifting.

Itisadvisabletoswivelhead

beforeliftingmachine.

METHOD2

Useropeslingasillustrated.

Insertpartsofsoftcloth

Betweenropeandmachine.

Itisadvisabletoliftthehead

beforeliftingthemachine.

CLEANING

1. Removerustpreventativebefore

movinganyslideways.

2. Thecoatingisbestremovedby

Usingparaffinappliedwithclean

rags.

3. Whenthecoatinghasbecome

Soft,removewithcleanrags.

4. Oilorgreasealllubricationpoints.

7

2‐3MACHINEDIMENSION

Unit:mm

ModelSpecifications2H(X6323)4H5H(X6325)5H(X6330)5H(X6333)

AOverallheight2006 (79”) 2235 (88”) 2130(84”)2180 (86”)

BOveralldepth1600 (63”) 2156 (85”) 2057(81”)

COverallwidth2156 (85”) 2540 (100”) 2235(88”)2970 (117”)

DMin.distance42 0 0

Max.distance405(16”) 405(18”)430(18‐1/2 ” )

EMin.distance0 0 0

Max.distance305(12”) 456(18”) 560(22”)

FMin.distance170(6‐3/4 ” ) 140 (5‐1/2 ” ) 108(4‐1/4 ” )

Max.distance482(19”) 609 (24”) 760(29‐7/8 ” )

GMin.distance228 (9”) 254 (10”) 285(11‐1/4 ” )

Max.distance 532(21”) 710 (28”) 895(35‐1/4 ” )

HMin.distance863(34”) 965 (38”) 965(38”)

Max.distance 1270 (50”) 1370 (54”) 1370(54”)

8

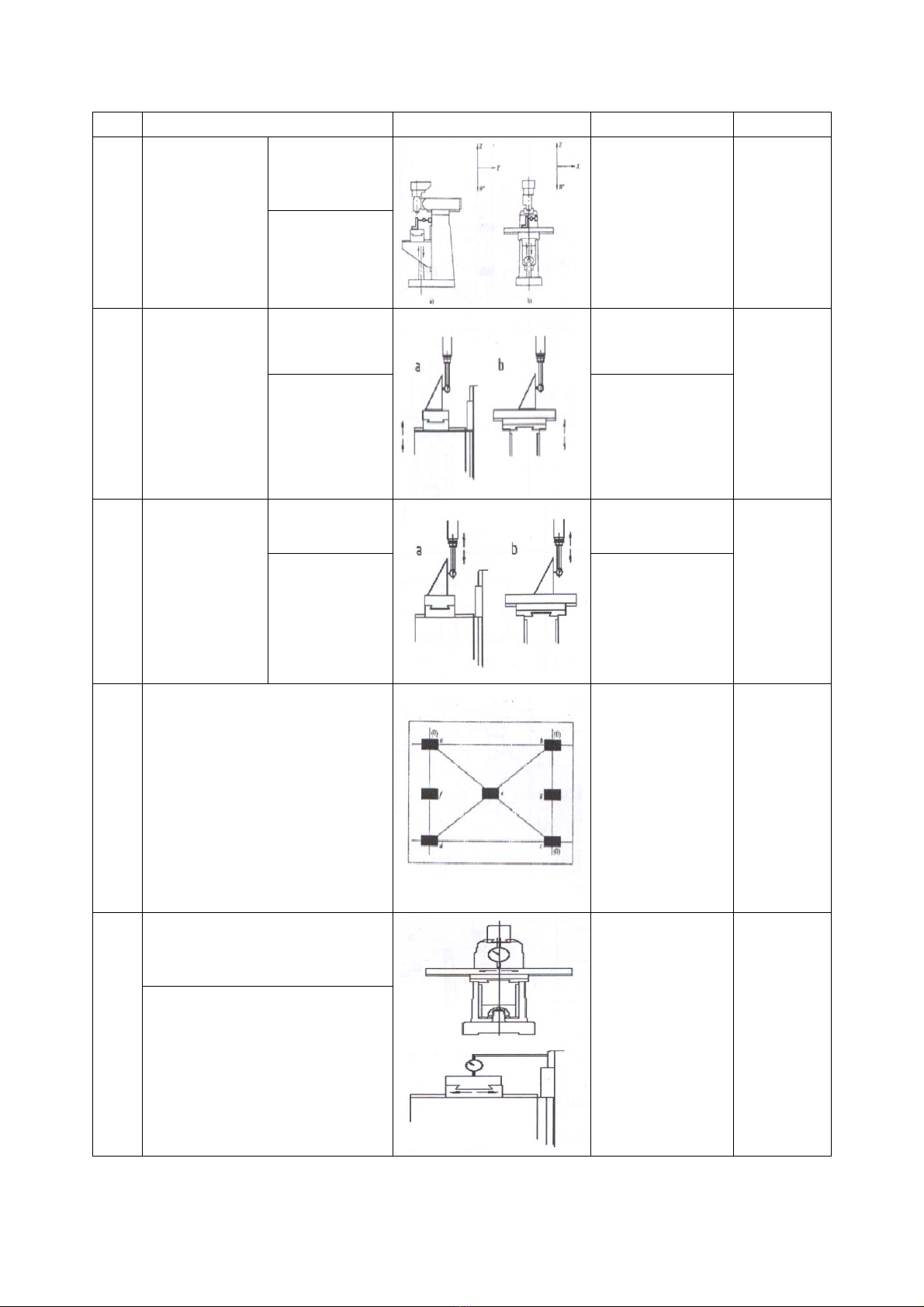

2‐4FOUNDATIONPLAN

Unit:mm

DIMENSION

MODELLAB

2H(X6323series)1500740520

4H5H(X6325series)1500889540

5H(X6330series)1570960540

9

2‐5POWERSUPPLY

A).Machinesuppliedwithelectricalbox

1. Checkandconfirmcorrectvoltagefromfactorypowersource.

2. Turnmachinemainpowerswitch“OFF”,connectmachinemainpowercable

andgroundwiretofactorypowersource.

3. Power“ON”machineandcheckmotorrotationdirection,ifitrotatesreverse,

switchmainpower2cablesconnectiontocorrectit.

B).Machinesuppliedwithoutcontrolpanel

1. Checkthemotorvoltagesagainstsupply.

2. Turnpower”OFF”,connectmainpowerandgroundwire,thenmachineis

ready.

3. Power“ON”machineandcheckmotorrotationdirection,ifitrotatesreverse,

switchmainpower2cablesconnectiontocorrectit.

10

2‐6INITIALSETTING

1. Ifthemachinewasdeliveredinacrate,theslidewayhandleshavebeen

takenoff.Theseshouldbere‐fitted.

2. Themachineheadwasturneddownforshippingpurpose,machinehead

mustbeturnedupbeforepositioning.

Howtoturnmachineheadup:

1) Loosen○

Ehexagonnutalittlebit,andturnmachinehead.

2) Onepersonholdmachinehead,andtheotherpersonturn○

Fhexagon

screwtoturnmachineheadup.

3. Tosetmillingheadsquaretotable(forhorizontalplane):

1) Anindicatormountedinaspindlenosetravellingina115MM(4.5”)90°

radus,thentighten○

Glockhandle.

2) Loosen○

Ehexagonnut(4PCS.),turn○

Fhexagonscrew,thenadjustthe

pointc&d.

4. Tosetmillingheadsquaretothetable(forcrossplane):

1) Anindicatormountedinaspindlenosetravellingina115MM(4.5”)90°

radius,thentighten○

Glockhandle.

2) Loosen○

Hadaptorlockingbolts(3PCS.),turn○

Iverticaladjustingworm

shaft,thenadjustthepointA&B.

NOTICE:X/Y/ZAXISARELOCKEDSEPARATELY,PLEASELOOSENRESPECTIVELOCKING

LEVER.

11

CHAPTER3.OPERATION

3‐1SWIVELTURRET

1. Usespannertoloosenthe4bolts.

2. Indextotherequiredsetting.

3. Tightenthe4bolts.

3‐2MOVERAMSLIDE

1. Usespannertoloosenthe2bolts.

2. Turnthehandletomovetheslide

tothedesiredposition.

3. Lockandtightenthe2bolts.

12

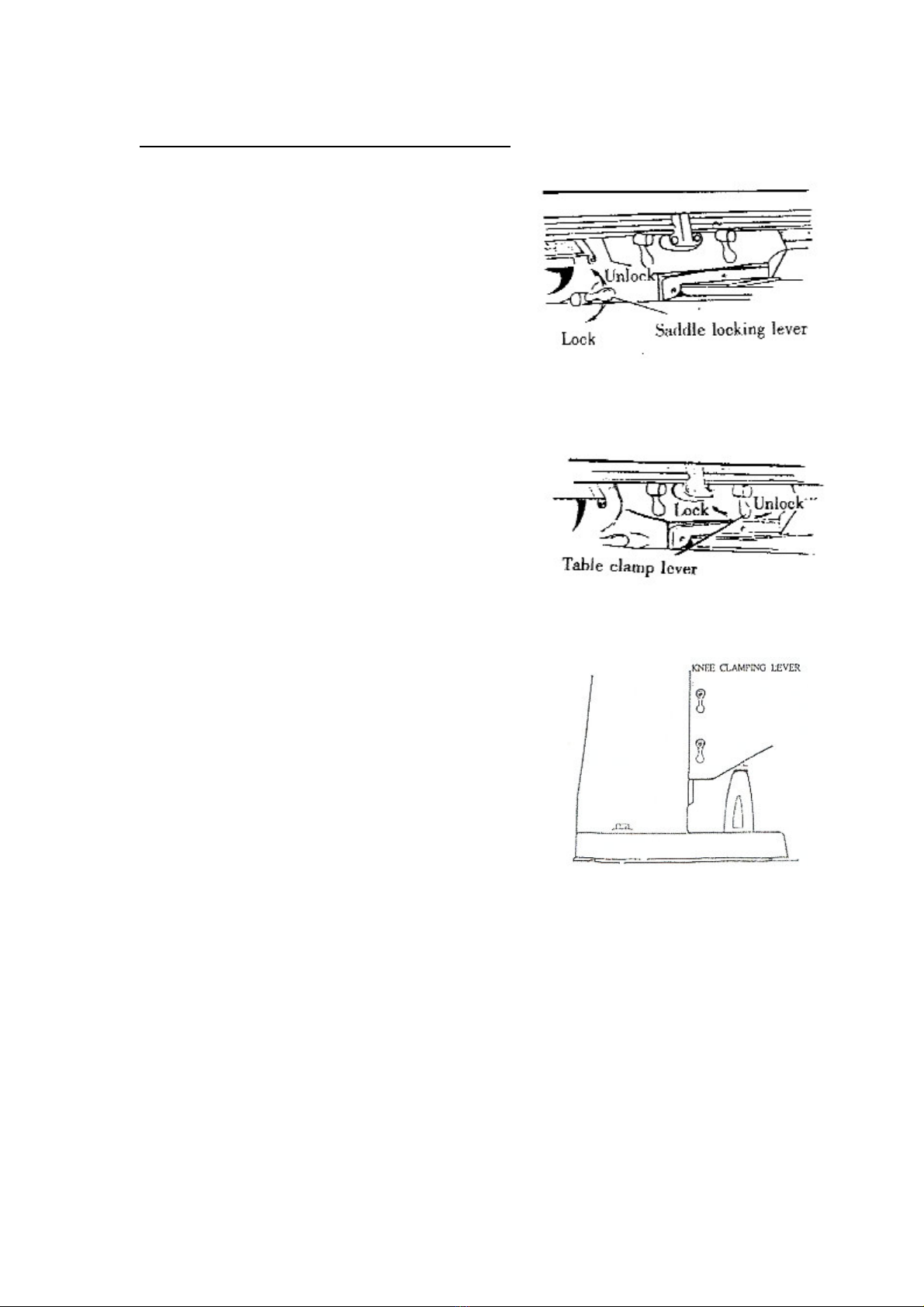

3‐3CLAMPINGTABLE,SADDLEANDKNEE

1. Whenmillingwithlongitudinal

Tablefeedonly,itisadvisableto

clampthekneetothecolumnand

thesaddletothekneeto

addrigiditytothese

membersandprovidefor

heaviercutswithaminimum

ofvibration.Thesaddle

lockingleverislocatedon

theleft‐handsideofsaddle.

2. Thetableclampleveris

locatedonfrontofsaddle

andshouldalwaysbe

clampedwhenlongitudinal

movementisnotrequired.

3. Thekneeclampinglever

isattheleftsideofthekneeand

shouldbedrawnupwardtoclamp

andwillnotlockthekneecompletely.

Leaveclampedatalltimesunlessusing

kneeinoperation.

This manual suits for next models

2

Table of contents