HITZE LUPO S Product guide

Dear Customer,

Thank you for purchasing a Hitze freestanding stove!

IT IS ESSENTIAL TO READ THE OPERATING AND INSTALLATION

INSTRUCTIONS IN

FULL BEFORE FIRST USE

AND

CHECK THE COMPLETENESS OF THE PRODUCT

.

1

Table of contents

1.

INTRODUCTORY

INFORMATION

...............................................................................................2

1.1. General information.......................................................................................................................2

1.2. In order to comply with the necessary safety rules, it is necessary to................................... 2

1.3. Never ..............................................................................................................................................3

1.4. Hitze is exempted from civil and criminal liability in the event of ........................................... 3

1.5. Purpose of the cooker......................................................................................................... 3

1.6. Construction and operation of the cooker..................................................................................6

2.

TRANSPORT, ASSEMBLY, INSTALLATION OF THE COOKER

....................................................7

2.1. Transport and handling ..................................................................................................... 8

2.2. Assembly .......................................................................................................................................8

2.3. Substrate recommendations.....................................................................................................10

2.4. Flue pipe......................................................................................................................................11

2.5. Connection to flue pipe..............................................................................................................11

2.6. The flue system shall meet the following features.................................................................12

2.7. Ventilation of the cooker ............................................................................................................13

2.8. Installation of the cooker ...........................................................................................................13

2.9. Connection of hot air distribution system (DGP) .................................................................. 14

3.

STARTING UP ................................................................................................................................16

3.1. Preparation for commissioning.................................................................................................16

3.2. Firing up the cooker......................................................................................................... 16

4.

USE .....................................................................................................................................................17

4.1. Fuel types ....................................................................................................................................17

4.2. Adding fuel ..................................................................................................................................17

4.3. Preventing the escape of fumes ............................................................................................. 18

4.4. Glass cleanliness........................................................................................................................18

4.5. Operation in adverse climatic and transitional conditions ....................................................18

4.6. Ash disposal................................................................................................................................18

4.7. General comments.....................................................................................................................19

5.

CONSERVATION ...........................................................................................................................20

5.1. Recommended periodic cleaning of the cooker.............................................................. 21

6.

FAULTS AND ANOMALIES DURING OPERATION

........................................................................22

6.1. The most common anomalies and how to resolve them..................................................... 22

7.

NAMEPLATE ...................................................................................................................................23

8.

INSPECTION

CARD

.......................................................................................................................24

2

NOTES:

The device must not be used by children.

Never leave children or pets unattended around a burning or just

extinguished hearth.

Use protective gloves to open the oven door after and during use.

Danger of burns (hearth parts can be very hot).

1.

NEWS

INTRODUCTION

Warmth from Nature

- these words perfectly encapsulate the Hitze brand philosophy. In line with this philosophy,

we manufacture fireplaces and cookers that burn wood or wood pellets, which are the least environmentally

damaging raw materials. Thanks

to

modern

technology, we have developed innovative solutions that are

characterised by their modern design and high

heating efficiency.

We wish you trouble-free operation and plenty of warmth!

Before installing and connecting the cooker to the chimney system, it is essential to read the

Operating and Installation Instructions and to check the completeness of the product components.

The information contained in the Operating and Installation Instructions will ensure the correct operation of the

cooker and will help to avoid damage and accidents due to improper use.

If you have any doubts or operating problems, please contact your point of sale or the Manufacturer.

In order to improve the product, the Manufacturer reserves the right to make changes to the drawings,

photographs and descriptions, as well as to the parameters of the equipment without prior notice and at any

time. It is forbidden to copy the Operating and Assembly Instructions in whole or in part without authorisation

from the Manufacturer. Keep the operating and assembly instructions out of the reach of children.

In the event of damage, loss or destruction of the User's Manual and Installation Manual, please

request a copy from the point of sale or from the Manufacturer, providing the identification details

of the appliance.

1.1.

Information general

Security

Compliance with the following rules will enable the cooker to operate correctly, avoiding damage and

accidents

caused by improper use.

1.2.

To maintain the necessary safety rules :

▪

Before installing or maintaining the cooker, read and understand the Operating and Installation Instructions;

▪

Install the cooker in the most convenient position taking into account current building and fire regulations;

▪

installation, maintenance and functional testing of the system should be carried out by qualified specialists;

▪

use the appliance for its intended purpose;

▪

It is imperative that the cooker is adequately ventilated and supplied with air at the place of installation;

▪

Place the clothes dryer at least 1.5 m away from the cooker (fire hazard);

▪

check the permissible load on the floor (floor, ceiling) at the intended location of the cooker (taking into

account the total weight of the unit including its installation);

▪

provide a suitable chimney installation to guarantee safe use (e.g. a chimney made of non-combustible

materials with low heat absorption);

▪

avoid installing the cooker in rooms where there are B-gas appliances, hoods (with and without extractor

hoods), heat pumps, collective ventilation ducts, numerous active smoke ducts, as well as

3

A

Zd

D

in the vicinity of stairwells and rooms with equipment capable of creating negative pressure;

▪

avoid direct contact with the cooker (the appliance gets

very

hot during operation

) and if

necessary use suitable protective equipment (clothing, heat-resistant gloves);

▪

Install the cooker in a room with fire protection, equipped with a fresh air supply and smoke extraction;

▪

in the event of any difficulties, contact the dealer or manufacturer (in the event of repair, request original

spare parts);

▪

periodically check and clean the flue pipe in accordance with the regulations in force;

▪

Include operating and installation instructions in case the unit is sold or rented.

1.3.

Never belongs:

▪

resist and climb on the cooker;

▪

use the appliance in the event of faults or malfunctions;

▪

leave flammable materials within 1.5m of the cooker;

▪

light fires with flammable materials and burn waste.

1.4.

Hitze is exempt from civil and criminal liability in the event of:

▪

use of the cooker not in accordance with the Operating and Installation Instructions;

▪

modification of the cooker and unauthorised substitution of non-original parts (these actions lead to

immediate cancellation of the guarantee);

▪

injury and material damage caused by incorrect installation and maintenance (not in compliance with the

Operating and Installation Instructions).

1.5.

Purpose

cooker

The cookers provide an additional source of heat in the rooms in which they are located. These appliances

have a fixed-burner hearth, with manual fuel loading, closed with a standard (hinged) door. The main fuel is

seasoned hardwood (beech, hornbeam, birch) with a moisture content of less than 20%. During combustion,

heat energy is released from the combustion chamber by convection and radiation.

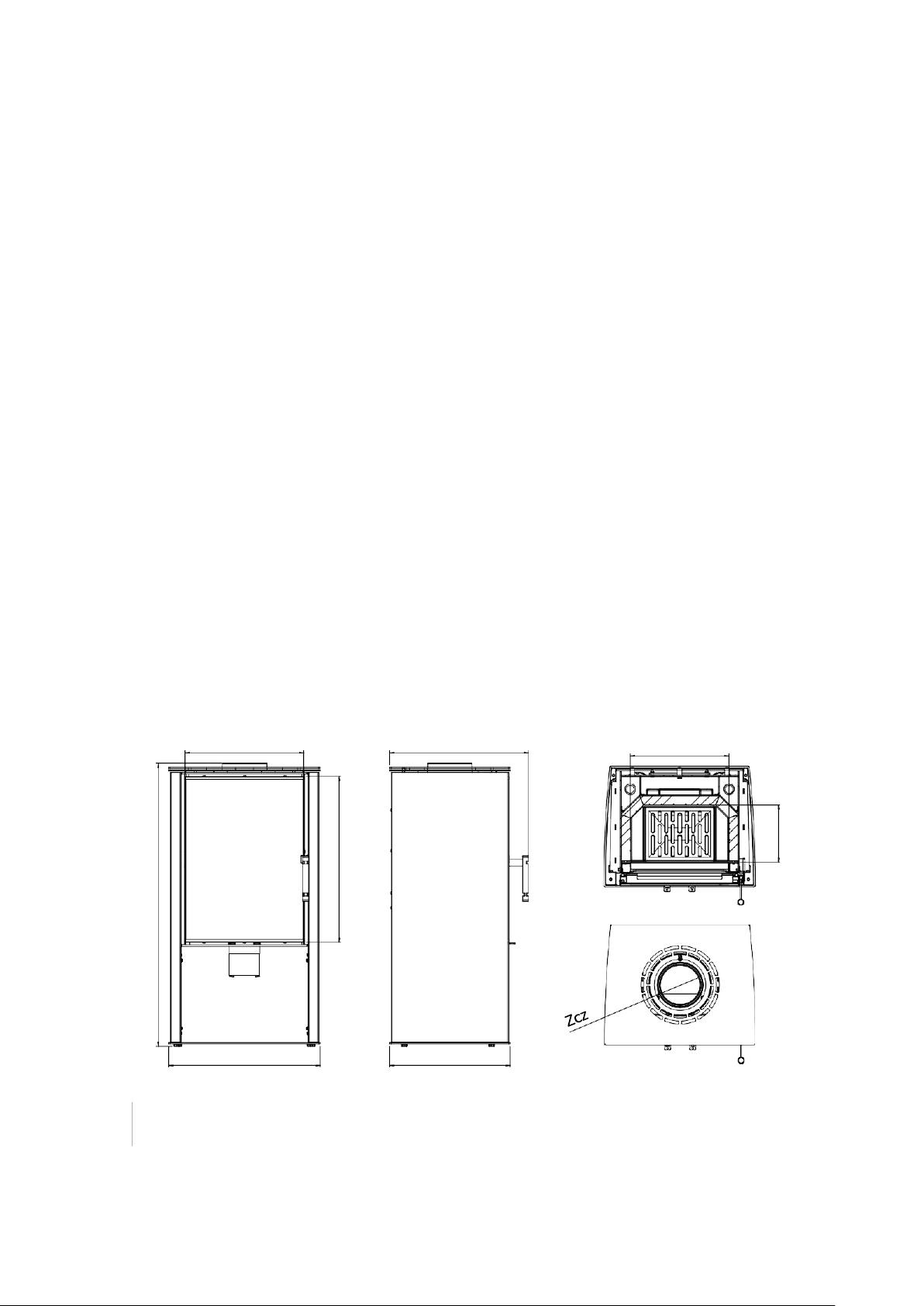

X C E

Fig.

1

LUPO dimensions

B

Y

F

4

Dimensions [mm]

LUPO S

LUPO M

LUPO L

Width

A

502

657

992

Height

B

940

940

940

Overall depth

C

465

465

465

Carcase depth

D

400

400

400

Firebox width

E

326

481

816

Burner depth

F

190

190

190

Air intake diameter

Zd

100

100

100

Flue diameter

Zcz

150

150

150

Glazing width

X

390

545

880

Glazing height

Y

545

545

545

Table

1

LUPO dimensions

E

A

C

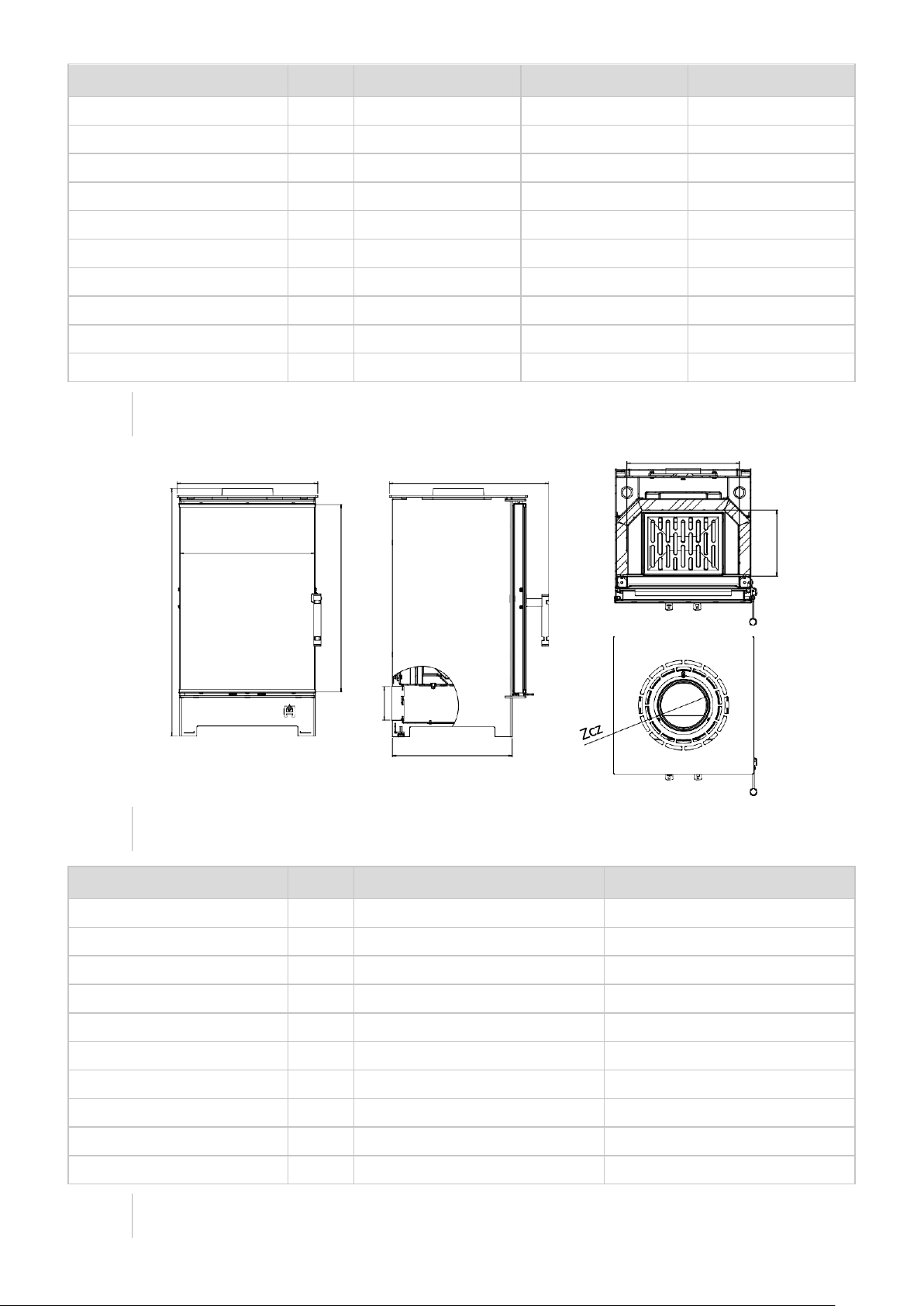

Fig.

2

LYNX cooker dimensions

Dimensions [mm]

LYNX

S

LYNX

B

Width

A

407

453

Height

B

720

760

Overall depth

C

465

506

Carcase depth

D

346

433

Firebox width

E

326

326

Burner depth

F

190

190

Air intake diameter

Zd

100

100

Flue diameter

Zcz

150

150

Glazing width

X

390

365

Glazing height

Y

545

515

Table

2

LYNX cooker dimensions

X

D

B

Y

ZD

F

5

E

A C

Fig.

3

CANE dimensions

Dimensions [mm]

CANE

S

CANE

SF

Width

A

550

550

Height

B

1020

1020

Overall depth

C

465

465

Carcase depth

D

400

360

Firebox width

E

326

326

Burner depth

F

190

190

Air intake diameter

Zd

100

100

Flue diameter

Zcz

150

150

Glazing width

X

390

390

Glazing height

Y

545

545

Table

3

CANE dimensions

D

Zd

X

B

Y

F

6

20

1

2

3

4

16

5

19

6

15

7

14

8

9

13

18

10

11

12

Technical data:

parameter

s

unit

LUPO S,

CANE S, CANE SF

LYNX S, LYNX B

LUPO M

LUPO L

Rated power

kW

6,5

8,8

11

Heating load range

kW

3-8,5

4,5-11,5

5,5-14

Maximum fuel loading weight

kg

1,5

2

2,5

Average fuel consumption

kg/h

1,9

2,6

3,3

Thermal efficiency

%

83,5

83

82

CO emissions (at 13% O2)

g/m3

1,08

1,001

0,921

Pollen emissions (at 13% O2)

g/m3

0,038

0,033

0,028

Average flue gas temperature

˚C

239

235

230

Dimensions of the fireplace glass

mm

390x540

540x540

880x540

Maximum length of billets

mm

350

400

400

Weight

kg

112

140

194

Fuel type

Recommended seasoned hardwoods (beech, birch, hornbeam)

Fuel moisture

between 12 and 20

Table

4

Technical data

1.6.

Construction and operation of cooker

7

1.

flue

2.

deflector

3. flue cap

4.

afterburning system

5.

combustion chamber with

insert

ceramic

6.

cast iron grate

7.

air intake

8.

ashtray

9. special profile doors

10.

back

plate

11.

base plate

12.

adjustment lever

secondary air damper

13.

throttle control lever

primary air

14.

side protection

15. decor glass

16.

handle

17. air curtain

18.

levelling screws

19.

connection of the DGP system

20.

connection of the DGP system

Fig.

4

Construction of the

furnace

Construction:

The cooker is made of boiler steel grade P256GH, 3 mm thick. The inside of the combustion chamber is lined

with a ceramic heat preserving insert

5

. The design allows the flue gases to be led out through the upper or

rear wall of the cooker. The air intake

7

is 100mm in diameter, the flue

1

150mm. The cooker is suitable for

use with a hot air distribution system (DGP)

18,19

. The front of the cooker consists of a steel door

made of

special profile 9 and profiled sheet metal, heat resistant glass 15, and a handle 16, which, thanks to its

special

design, remains cool while burning. The door is bolted to slats fixed to the cooker body.

Activity

description

:

The air enters the cooker through an inlet grille

7

. There are two air inlet systems - primary and secondary.

The amount of incoming primary air is regulated by the right-hand regulation lever on the front of the cooker

under the door

13

. The air then flows around the ash pan

8

and enters the combustion chamber

5 through

the

grate

6

.

The amount of secondary air is regulated by the left lever

12

on the front of the cooker. The air is directed to

the upper part of the combustion chamber

4

to postcombust the flue gases which improves the thermal

efficiency and reduces the amount of pollutant-.

The air volume is adjusted. The air volume is adjusted by pulling the lever to open the air inlet, and pulling it in

to close the air inlet.

The cooker is also equipped with an air curtain 17 to help keep the glass clean. Above the

combustion

chamber

there is a special ceramic plate called deflector

2

, which enhances the heat exchange. During combustion,

the hot gases flow around the deflector and then through the flue

1

and the ducts into the chimney. The

environment around the cooker is heated in two ways - the air surrounding the insert is heated (convection)

and escapes through the ventilation slots in the furnace casing. In addition, heat radiates directly from all hot

parts of the cooker.

2.

TRANSPORT, ASSEMBLY, INSTALLATION COOKER

The device complies with EN 13229:2002 and is CE certified.

Before assembling, installing and operating the cooker, read the following

Operating and

Installation Instructions

carefully

and follow the instructions given therein. This will ensure a

safe and

efficient operation of the cooker. Failure to observe these Operating and Installation

Instructions may invalidate the warranty and endanger the user's life and limb.

National and local regulations and standards must be observed during assembly, installation and operation, in

particular:

▪

Regulation of the Minister of Infrastructure of 12.04.2002. Dz.U.Nr75, poz. 690 with amendments of 07.05.2004.

r. Dz.U.Nr109, pos. 1156;

▪

Standard PN - B - 03406 :1994 Heating. Calculation heat demand;

▪

Standard PN - 89 / B - 10425 Smoke, flue and ventilation ducts made of brick;

▪

Standard PN - 78 / B - 03421.Ventilation and air conditioning. Design parameters of indoor air;

▪

Standard PN-EN 13229:2002 "Fireplace inserts including open fires for solid fuels. Requirements and

tests".

8

It is a requirement that the cooker is installed by a qualified person or company and that technical

acceptance is carried out by a master chimney sweep and a fire specialist.

Sequence of work for cooker installation:

▪

Preparing the location where the cooker is to be installed, checking the load-bearing capacity of the ground

▪

connecting the cooker to the chimney and making an air intake;

▪

using the cooker and observing whether there are any faults or anomalies (approximately 2 weeks).

2.1.

Transport and handling

▪

The cooker is delivered pre-assembled, fixed to a pallet and wrapped in stretch foil;

▪

transportation of the cooker should be done in an upright position;

▪

After unpacking, check the cooker for transport damage;

▪

Unpack the cooker close to the installation site; take care when moving it (preferably with a trolley) (pay

attention to the door and the glass);

▪

cooker packaging materials are not toxic or harmful; they should be recycled or stored by the user;

▪

in order to relieve the load on the cooker, in the event of installation in a difficult location, the ceramic

inserts (which cover the firebox) may be removed; after installation, each element must be correctly put

back in place.

2.2.

Assembly

The design of the cooker allows 2 configurations. The flue can be on the rear wall or the top.

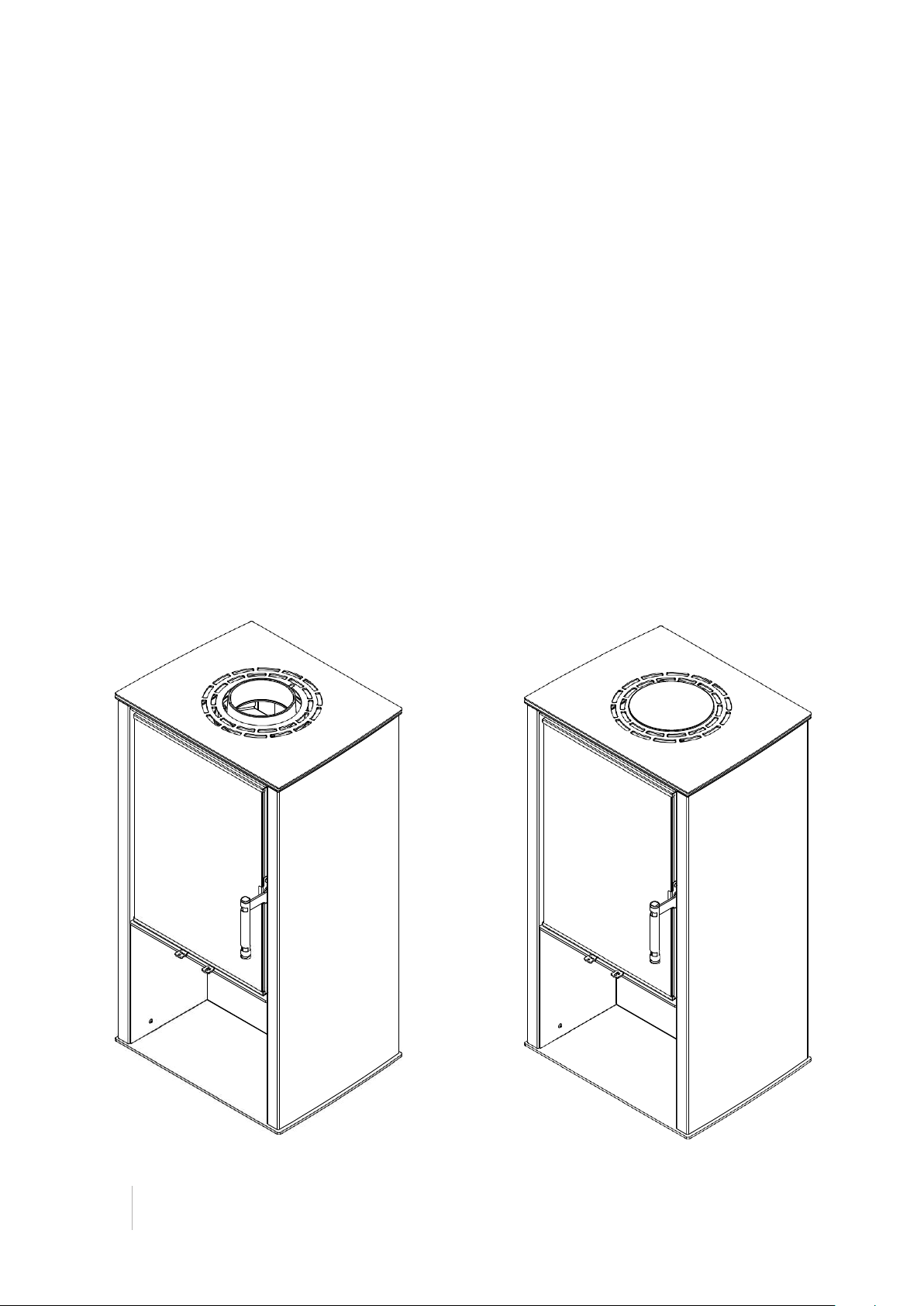

Fig.

5

Cooker

configuration

9

The operation of transferring the flue from the top plate to the rear wall is shown in the

drawing.

1.

view of the cooker in its

factory configuration,

2.

remove the top cover, cut a

hole in the rear panel with a

hacksaw or cut a hole for the

flue with pliers,

3.

Using an allen key, unscrew

the back plate,

4.

using an allen key, unscrew

the flue and cap.

in the rear wall of the cooker,

5.

put

the flue

and the cap in

place and screw them on,

6.

screw the rear panel in place,

put the top cover in place

together with the hob.

10

Fig.

6

Replacement of

flue pipe

11

Fig.

7

Tightening

the feet

2.3.

Recommendations for substrates:

▪

Before installing the cooker, check the load-bearing capacity of the floor (whether it meets the load-

bearing conditions for the type of appliance depending on its weight);

▪

the floor must be made of a non-combustible material at least 30 cm thick, with a strip of space in front of

the cooker door, at least 60 cm wide and extending beyond the edges of the door by at least 30 cm.

A

A

1

150mm

150mm

150mm

600mm

non-combustible/non-flammable material

400mm

300mm

400mm

300mm

Fig.

8

Recommendations for substrate and

space

10

2.4.

flue

The cooker requires a suitable cross-section of the flue pipe (flue duct) and a suitable height of the flue pipe.

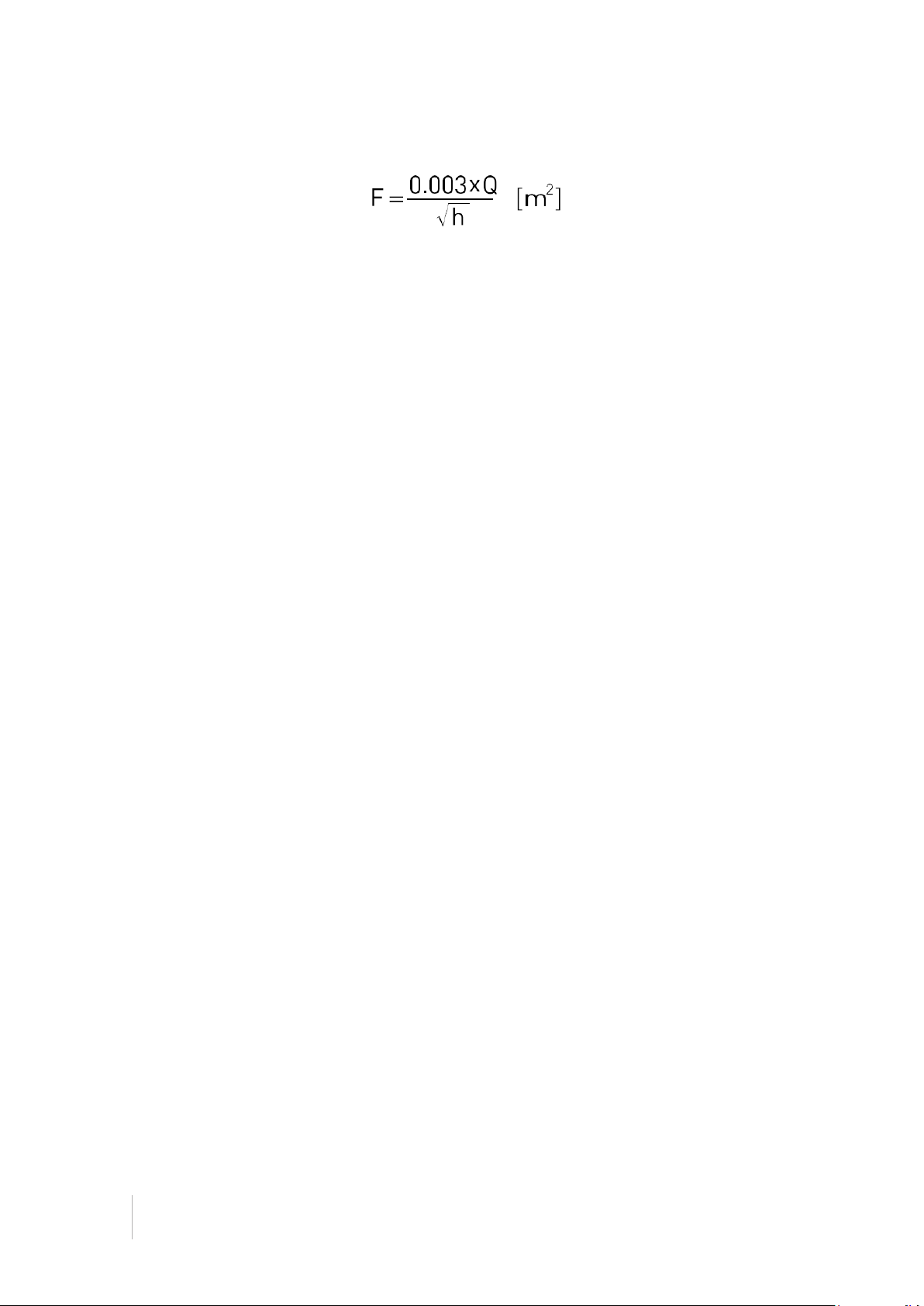

The cross-sectional area of the flue and smoke duct is determined according to the formula:

Where:

F - cross-sectional area of the flue and smoke duct [m2]; Q - rated thermal

output of the insert [kW];

h - chimney height [m].

According to current regulations, the flue must not be smaller than 14x14 cm, or its diameter must be at least

15 cm. Stoves with a higher output require a larger flue pipe cross-section. The cross-section also depends

on the height of the chimney.

The cooker must be connected to a flue pipe or a riser pipe conforming to

current national standards.

The size of the chimney draught should be:

-

minimum draught - 6 ± 2 Pa;

-

AVERAGE, RECOMMENDED DRAINAGE - 12 ± 2 Pa

;

-

maximum draught - 15 ± 2 Pa.

NOTES:

For proper cooker operation it is necessary to ensure a correct draught in the

flue outlet:

▪

Insufficient chimney draught causes poor operation of the cooker, excessive burial of glass and excessive

contamination of the flue gas ducts; the overall heat output of the cooker is reduced (smoke leakage into

the room can occur);

▪

A draught that is too strong can contribute to over-intensive combustion, high fuel consumption and lead

to permanent damage to the cooker.

Regular inspection of the chimney by a chimney sweep is recommended.

2.5.

Connection to the flue:

▪

Before proceeding with the installation of the cooker, an expert's opinion and selection of the flue pipe in

terms of its technical parameters and condition must be carried out;

▪

The installation of the cooker may be carried out following a positive chimney sweep test of the flue pipe.

The flue pipe must comply with the applicable national or European standards.

In accordance with the operating and installation instructions provided, fit and connect the cooker to the

chimney (including installation of screen plates - if used - and insulation of the flue pipe).

The manufacturer does not recommend assembling and installing the appliance yourself. In order to ensure a

proper

and safe start-up of the appliance and the fulfilment of the guarantee conditions, the assembly and

start-up of the appliance must be commissioned by a person or a firm having the appropriate installation

qualifications. The fitter is obliged to confirm in the Warranty Card (entry and stamp) that the installation has

been carried out in compliance with the art. and valid legal regulations. Failure to do so will void the

manufacturer's warranty.

13

1

6

5

4

2

3

1

6

5

4

2

3

2.6.

The flue pipe system should meet the following features:

▪

the cross-section of the flue pipe must not be smaller than that of the flue pipe and must not narrow

towards the chimney (adapters may be used to increase the diameter from the flue pipe to the chimney);

▪

the flue pipe should be as short as possible and have as few bends as possible (increase flow resistance,

avoid condensation build-up);

▪

The cooker must not be connected to a flue pipe which is shared with another heating appliance;

▪

it is advisable to connect the cooker to a separate flue;

▪

the flue pipe may not have more than two inclinations of 45° up to a pipe height of 5m and 20° for pipe

heights of over 5m;

▪

the flue pipe must be made of non-combustible materials and be thermally insulated;

▪

the flue pipe insulation should have a fire resistance of at least 60 minutes;

▪

a straight section of pipe at least twice the diameter of the cooker flue should be used at the exit from the

flue;

▪

the joint should be made tight;

▪

The end of the chimney should allow for a smooth exit of the flue gases and be located at least 60 cm

above the highest point of the roof;

▪

the connectors must be made of stainless steel 1.4401 (316), heat-resistant or fire-resistant steel

adequately painted with a special paint and of an appropriate sheet thickness (heat-resistant and stainless

steel 1 mm thick and fire-resistant 2 mm thick) - the material should be characterised by resistance to

heat, acidity of the flue gas and condensate.

1.

flue pipe,

2. the cleanout,

3.

external air intake,

4.

rosette,

5. sealing mortar,

6.

non-combustible material.

Fig.

9

Diagram of the connection of the cooker to the flue

pipe

12

2.7.

Ventilation cooker:

▪

It is necessary to provide fresh air from outside by unsealing the windows so that there is a

constant supply of air. Too little fresh air from outside can cause poor combustion

(production of carbon monoxide) and, in the worst case scenario, air with carbon monoxide

can backflow through the ventilation ducts when the windows are tightly closed and there is

a risk of fume poisoning;

▪

The design of the cooker allows fresh air to be brought in from the outside (an air pipe with a diameter of

100mm is used). The pipe can be led from the wall behind the back of the cooker or, after turning the

base, from the floor. It is also possible to bring the air in directly from the room where the cooker is

located, provided that there is adequate ventilation to prevent the air supply from closing off automatically.

▪

it is assumed that the amount of air required to burn 1kg of wood is approximately 8 m³;

▪

when using an air distribution system to other rooms, in order to circulate the air freely, ensure that the

cooled air is returned to the room where the cooker is installed (otherwise the operating cycle of the

cooker may be disrupted and the heat distribution process may be impaired);

▪

When determining the location and installation of the unit, attention should be paid to the principles of

correct air circulation and air balance in the room;

▪

Ventilation must be provided in the room where the cooker is installed;

▪

To ensure adequate convection space (cooling of the cooker, heating of the air) the cooker should be

positioned at least 80 cm away from materials which could be distorted or damaged by the heat (furniture,

panelling, wallpaper, etc.).

Fig.

10

Air intake connection diagram

2.8.

Installation

cooker

The unit must be installed in accordance with current building code standards.

Installation and assembly of the cooker must be carried out by qualified professionals.

▪

The cooker must be positioned at a safe distance from any flammable products (it may be necessary to protect

the walls surrounding the cooker);

▪

The space in front of the cooker should be protected to prevent sparks which may fall out of the firebox

when adding fuel. The minimum safe area is 60 cm in front of the cooker and 30 cm to the sides from the

edge of the door. The surface can be protected with natural stone, floor tiles, or a dedicated glass base;

14

▪

Do not install the cooker in bedrooms, bathrooms or rooms where there is another heating appliance

without an independent air supply;

▪

The cooker is a unitary structure and does not require additional supports;

▪

The height (levelling) of the cooker can be adjusted by means of the feet (a maximum of 20 mm can be

unscrewed);

▪

If it is necessary to raise the cooker above the feet adjustment, make a masonry base and place the

appliance on it (do not remove the feet needed for levelling);

▪

If the door is not properly levelled, it will not work properly (it will not close properly);

Fig.

11

Safe area for flammable materials

2.9.

Connection of hot air distribution system (DGP)

The hot air distribution system (DGP) allows the convection heat generated by the cooker to be used to heat

other rooms. Different solutions are used depending on the output of the appliance and the installation

conditions. The choice of the right one should be left to a person or company with experience in this field. In

small single-storey houses, a simple gravity system works well. In larger areas, it is sometimes necessary to

use forced-air blowers in the system.

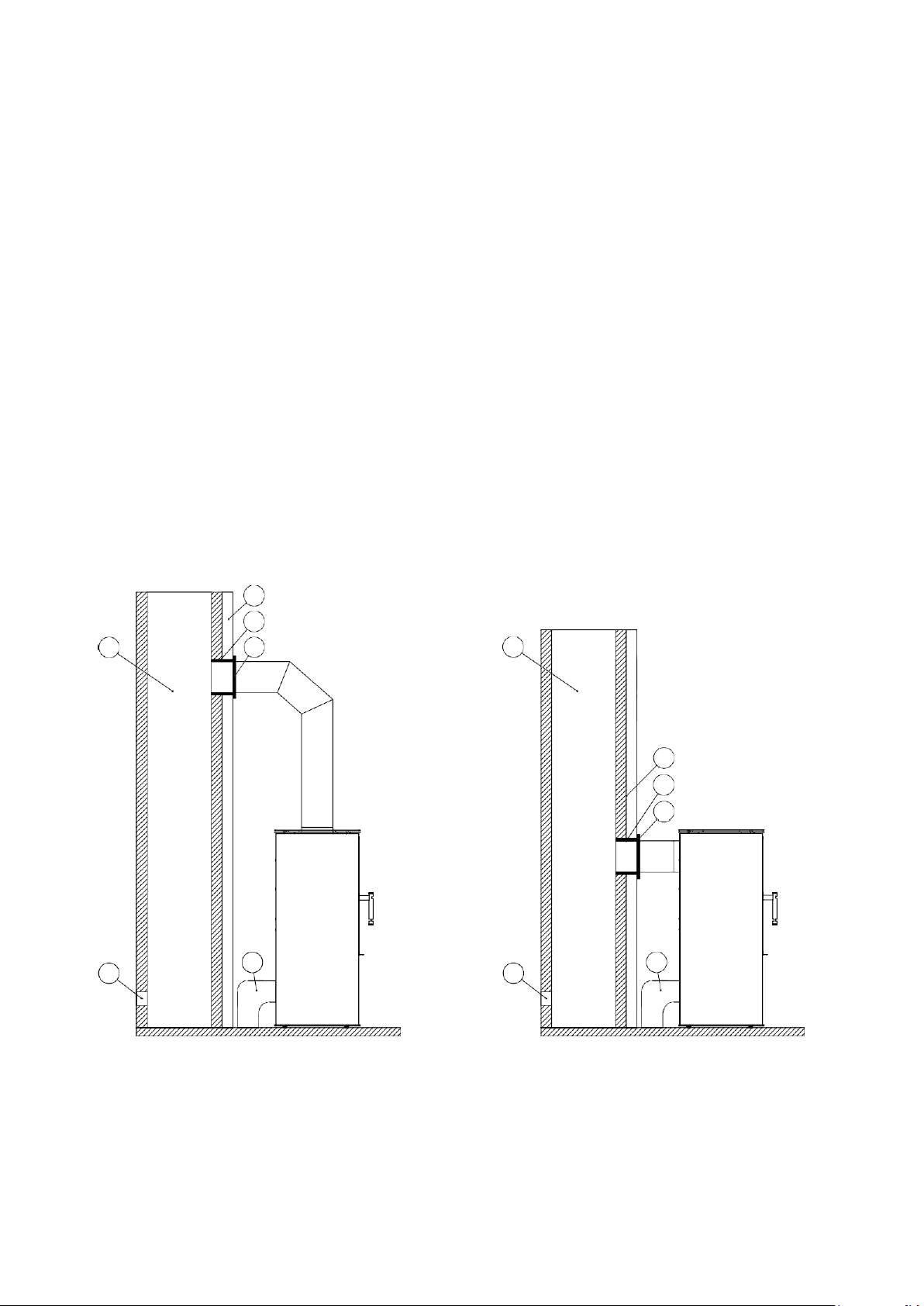

Free-standing cookers allow the DGP system to be connected to the cooker in two ways: from above (LUPO,

CANE, LYNX) or from below (LUPO, CANE). When installing from above, it is necessary to cut out sections of

the rear cover at the locations marked on the drawing. Unobstructed airflow is gained. When assembling the

pipes from below, a blower is required in the system to extract the heated air. The installation of the pipes is

carried out using special fittings with a diameter of 100mm. The cut-outs allow mounting to thin or thick metal

sheets.

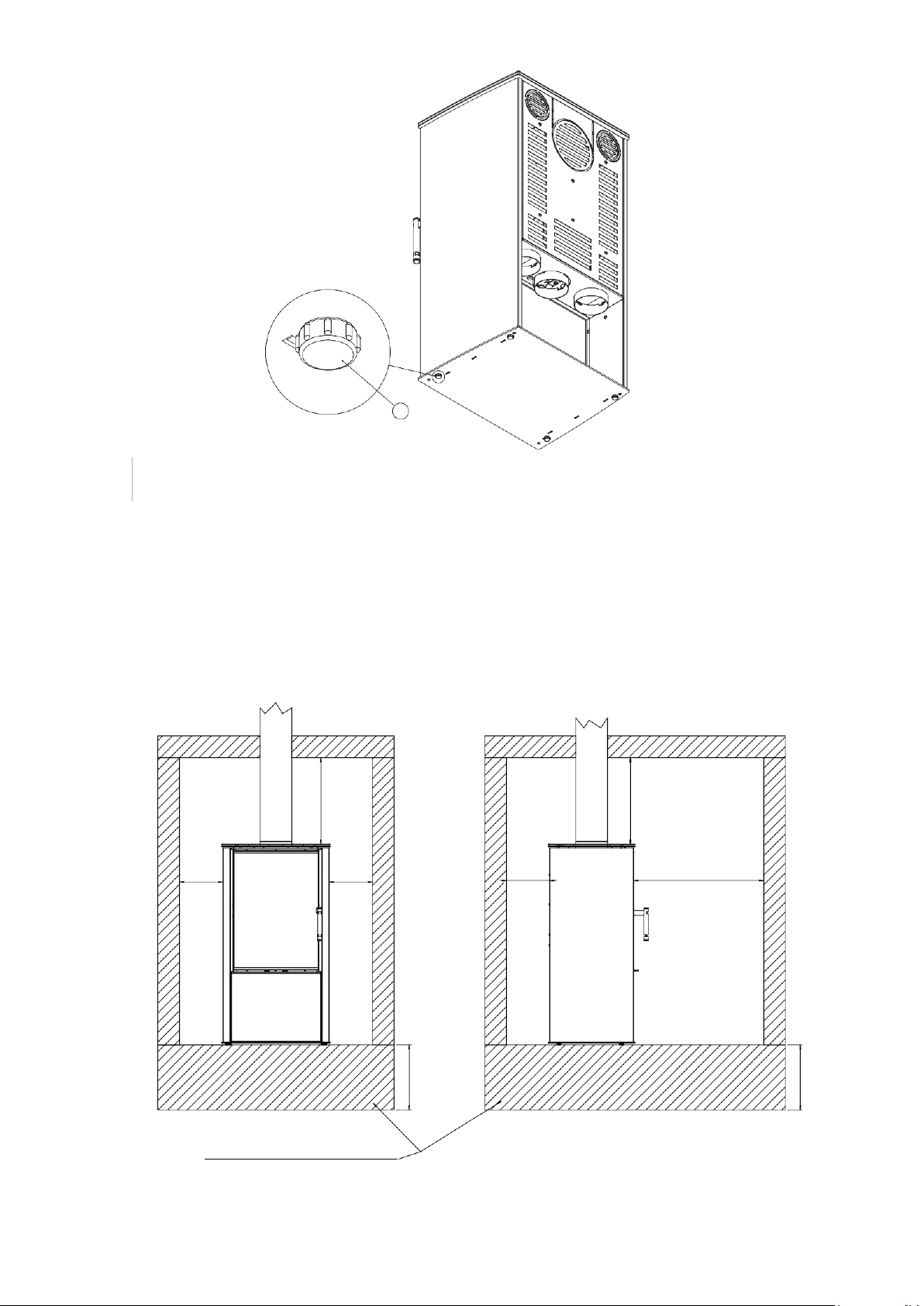

Fig.

12

Mounting connection with a diameter of 100 mm

B

B

A - min 1500mm

B - min 150mm

A

B

15

Fig.

13

The arrows indicate the cutting points before fitting the connectors when connecting from above

Fig.

14

Fig.

15

Correctly installed connectors when connected from the top of the cooker

Correctly installed connectors when connected from the bottom of the cooker

16

Pipes carrying the heated air to other rooms are placed on the properly installed connectors. For proper

operation of the system, cool air must be returned to the room where the cooker is located.

3.

STARTING UP

The initial start-up of the cooker, after it has been seated and properly connected to the chimney, must be

carried out by the installer or an authorised service technician. The user must be present during

commissioning so that he/she can be trained by the installer. The installer must refuse to commission the

cooker if he discovers an installation fault which endangers the safety of the user. Correct commissioning

must be confirmed in writing on the guarantee card.

3.1.

Preparation for launch

Before firing up for the first time:

▪

remove any stickers and other paper labels and accessories from the mantle body, ash pan or firebox that

could be the cause of a fire, this also applies to transport protection;

▪

Check that the deflector(s), ceramic pieces and grate are properly seated, and that they have not fallen out of

position during installation (If any seating faults are found, correct them. Otherwise the cooker may not operate

correctly. In cooker types where the door is fitted with a multi-paned glass, check that during transport or use of

the cooker the various parts of the glass have not come apart);

▪

check operation:

•

mechanism for regulating the air supply to the combustion chamber (cold-air dampers);

•

front door locking mechanism (hinges, handle);

3.2.

Firing up the cooker

Before firing up the cooker:

▪

put the thicker logs first in the firebox, then the smaller wood, and finally the small pieces (sub- sticks) -

light with fireplace matches or a lighter;

▪

open the primary air control to maximum and the secondary air control to minimum;

▪

the cooker door must be closed after lighting

;

▪

When the fire is burning well, use the air regulators to adjust the combustion air to a rather damped level

(this means that only a small proportion of the primary air is supplied under the cooker grate; the

secondary air damper is set at max. - the higher amount of air is supplied to the air curtain system, which

protects the glass from scorching and to the post-combustion system at the front of the cooker; opening

the air damper to 100% - as far as possible, results in very intensive combustion of the fire);

▪

it is advisable, in the final stage of combustion, to open the door and burn the remaining embers on the

grate with a poker in order to better burn the fuel;

NOTES:

As a large amount of air is fed under the grate and into the air curtain and

flue gas afterburning

system

, too much fuel in the combustion chamber results in the production of a large amount of

wood

gas

which results in a temporary sooting of the glass.

If the throttle is moved to the right as far as possible, the air supply to the combustion chamber is

completely cut off, resulting in a gradual extinguishing of the firebox.

If necessary, the grate is unclogged with a poker.

During the first hours of operation, it is recommended to operate the cooker at a low load, i.e. up to

50% of the

normal load.

The first ignition may be accompanied by condensation on the inner walls of the combustion

chamber. This phenomenon is normal and results from condensation of the water vapour contained in

the flue gases. It should disappear after the firebox has cooled down.

This manual suits for next models

6

Table of contents

Other HITZE Stove manuals

Popular Stove manuals by other brands

LogFire

LogFire LF6 Installation & operating instructions

PRITY

PRITY PLW11 Technical description and operation instructions

Pacific energy

Pacific energy Classic Gas Installation and operating insctruction manual

redpod

redpod FIRST 6 kW instruction manual

Euroheat

Euroheat EVO Aqua Installation & servicing instructions

Horse Flame

Horse Flame HF-577DU Installation and operation instructions