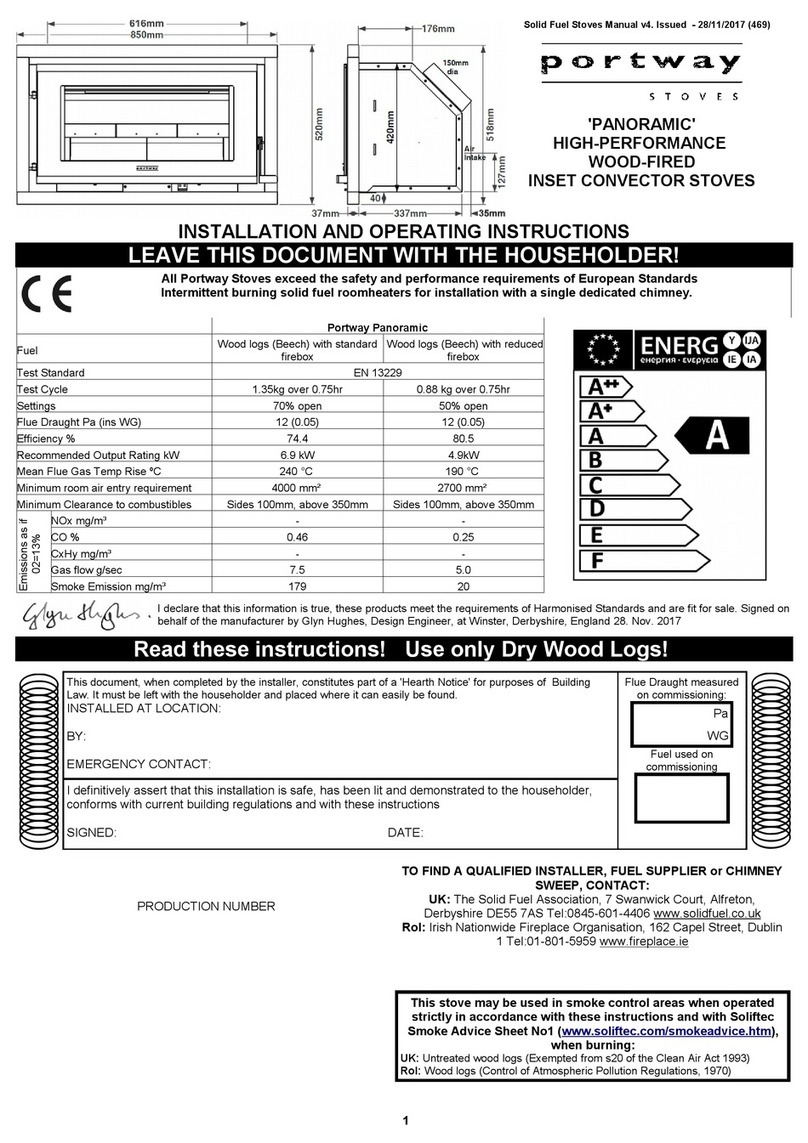

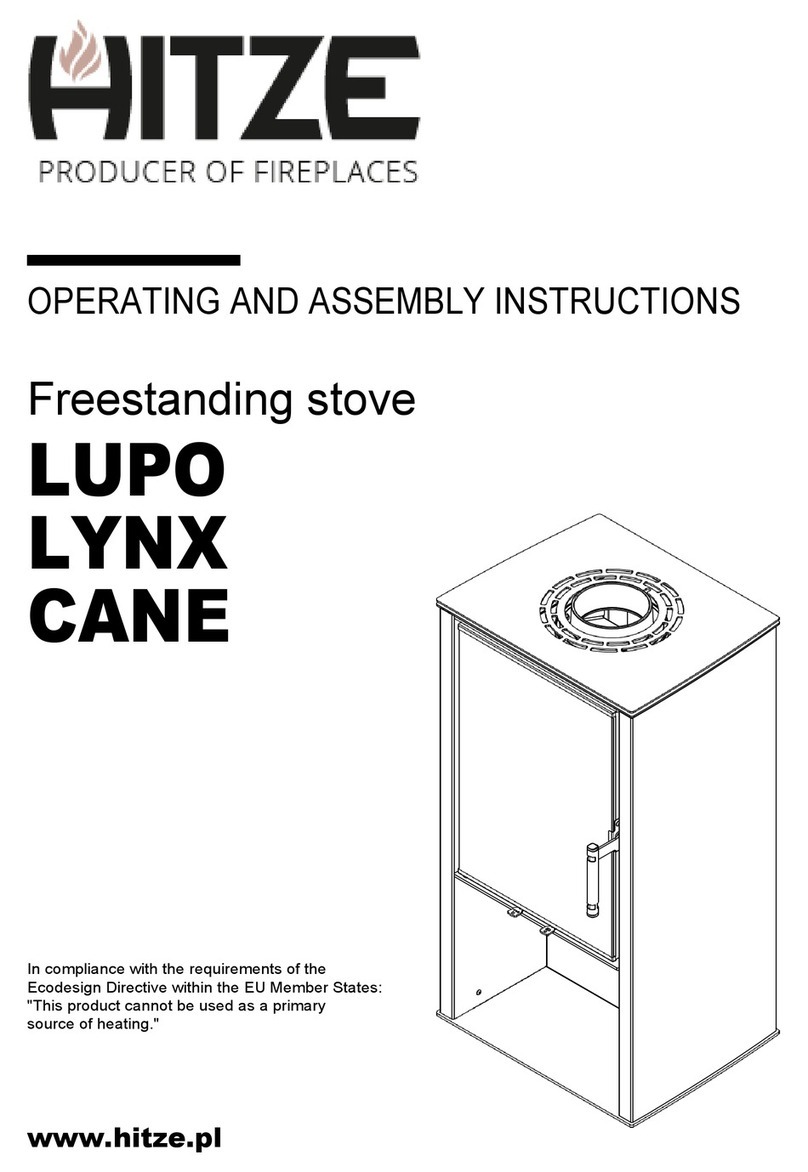

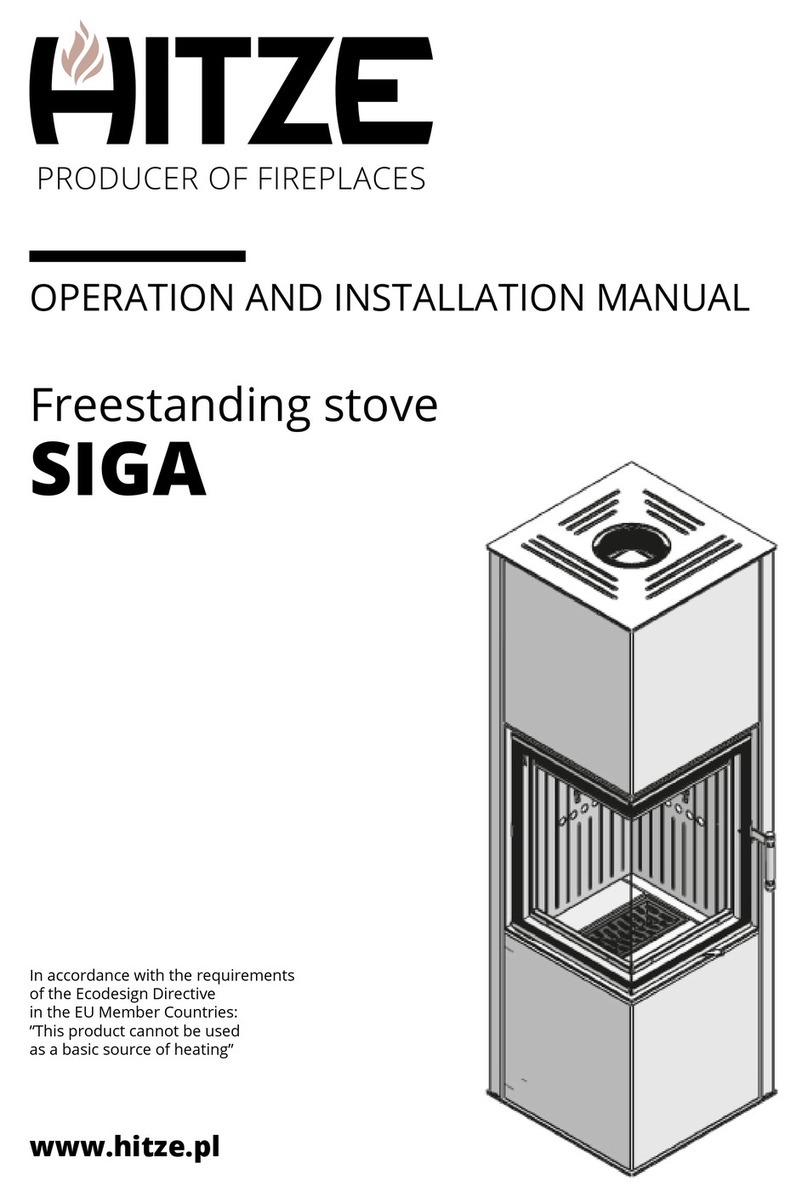

Construction:

The cooker is made of boiler steel grade P256GH, 3mm thick. The inside of the combustion chamber is lined

with a ceramic insert to keep the heat

4

. The design allows the flue gases to be led out through the upper or

rear wall of the cooker. The flue

1

is 150mm in diameter. The front of the cooker consists of a steel door

made of a special profile

7

and profiled sheet metal, heat resistant glass

16

, and a handle

14

. The door is

bolted to slats fixed to the body of the cooker.

Activity

description

:

There are two air intake systems inside - primary and secondary. The quantity of incoming primary air is

regulated by the lower inlet damper located on the front of the cooker under door

13

. The air then flows

around ash pan

6

and enters combustion chamber

4

through grate

5

.

The amount of secondary air is regulated by the upper damper

17

on the front of the cooker. The air is

directed to the upper part of the combustion chamber

4

. The air quantity is adjusted by moving the lever to the

left in order to open the air chamber.

right to close the air inlet.

The cooker is also equipped with an air curtain

8

to help keep the glass clean. Above the combustion

chamber there is a special ceramic plate called deflector

3

and a steel deflector

9

which enhance the heat

exchange. During combustion, the hot gases flow around the deflectors and then into the chimney via the flue

1

and ducting. The environment around the cooker is heated in two ways - the air surrounding the insert is

heated (convection) and escapes through the ventilation slots in the cooker casing. In addition

, heat radiates

directly from all hot parts of the cooker.

2.

TRANSPORT, ASSEMBLY, INSTALLATION COOKER

The device complies with EN 13229:2002 and is CE certified.

Before assembling, installing and operating the cooker, read the following Operating and

Installation Instructions carefully and follow the instructions given therein. This will ensure

safe and efficient operation of the cooker. Failure to observe these Operating and Installation

Instructions may invalidate the warranty and endanger your health or life.

National and local regulations and standards must be observed during assembly, installation and operation, in

particular:

▪

Regulation of the Minister of Infrastructure of 12.04.2002. Dz.U.Nr75, poz. 690 with amendments of 07.05.2004.

r. Dz.U.Nr109, pos. 1156;

▪

Standard PN - B - 03406 :1994 Heating. Calculation heat demand;

▪

Standard PN - 89 / B - 10425 Smoke, flue and ventilation ducts made of brick;

▪

Standard PN - 78 / B - 03421.Ventilation and air conditioning. Design parameters of indoor air;

▪

Standard PN-EN 13229:2002 "Fireplace inserts including open fires for solid fuels. Requirements and

tests".

It is a requirement that the cooker is installed by a qualified person or company and that technical

acceptance is carried out by a master chimney sweep and a fire specialist.

Sequence of work for cooker installation:

▪

Preparing the location where the cooker is to be installed, checking the load-bearing capacity of the ground

▪

connecting the cooker to the chimney and making an air intake;

▪

using the cooker and observing whether there are any faults or anomalies (approximately 2 weeks).

2.1.

Transport and handling

▪

The cooker is delivered pre-assembled, fixed to a pallet and wrapped in stretch foil;

▪

transportation of the cooker should be done in an upright position;

▪

After unpacking, check the cooker for transport damage;