hivolt HAR12S User manual

1

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

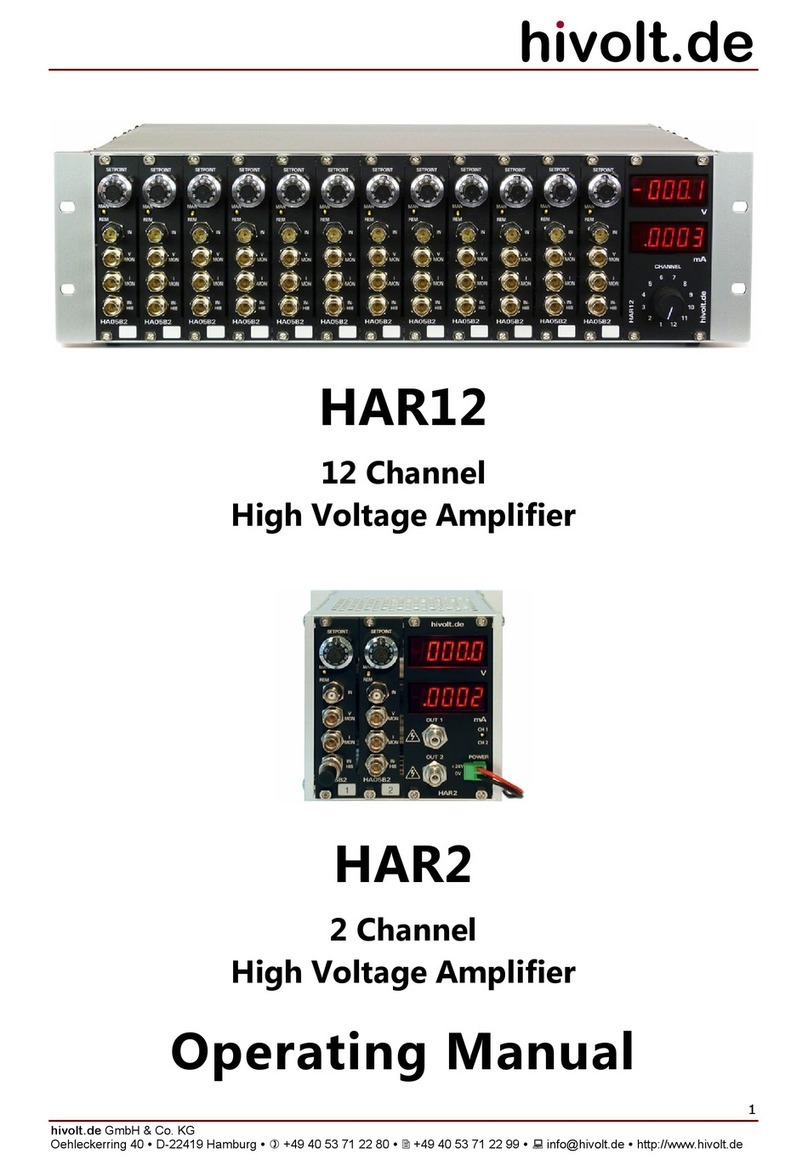

HAR12S

12 Channel High Voltage Amplifier Mainframe

HAR2

2 Channel High Voltage Amplifier Mainframe

HA05B2

High Voltage Amplifier ±500V

Operating Manual

2

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

1WARNINGS 3

2OVERVIEW 5

3DESCRIPTION 5

3.1 Block Diagram 6

3.2 Control Voltage Input 7

3.3 Monitor Outputs 7

3.4 INHIBIT 8

3.5 Loading Conditions 8

3.6 Interlock 9

3.7 Connector INTERLOCK 9

4TECHNICAL DATA 10

4.1 Ambient Conditions 11

4.2 Mechanical Specifications 12

5OPERATION 13

5.1 Initial Check 13

5.2 Warning Notices 13

5.3 Temperature Compensation 13

5.4 Power Supply 14

5.5 Ventilation 14

5.6 Wall Mounting HAR2-W 14

5.7 Rack Mounting HAR12 15

5.8 Functional Test 15

5.9 Output connections 15

5.10 Output Connectors 15

5.11 External Connectors 16

5.12 Internal Connectors 16

5.13 Grounding 16

5.14 Troubleshooting 17

5.15 Maintenance 17

5.16 Cleaning 17

6DECLARATION OF CONFORMITY 18

3

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

1Warnings

Caution! This device produces dangerous voltage above 500V.

Due to capacitive charging, dangerous voltages can still be present in the set-up even after the

amplifier has been switched off!

Please respect the following rules before every activation of the high voltage amplifier:

The device should be operated only by skilled personnel, in accordance with the local regulations

and the instructions given in this manual.

The device may only be operated as a component of an overall structure that fully complies with

the regulations for working with high voltage systems.

Before switching the unit on, the experiment setup must be checked, and safety should be

assured. High voltage areas have to be blocked and secured.

In case of suspected damage or malfunction, the device should immediately be put out of service,

and it should be secured against unintentional or accidental operation.

The safety ground must always be connected! The grounding nut on the rear panel must be

connected to the grounding point of the setup and to protective earth. Local regulations about

grounding should be taken into account.

The output connectors must only be operated when the unit is switched off.

High voltages may still exist even after the switch-off of the device due to capacitive charge!

Capacitances connected to the outputs of the device can possibly remain charged to dangerous

voltages, even after switching off the device

Before removing any covers disconnect the unit from the power supply!

Before touching the output or working on the experimental setup, disconnect the unit from the

power supply!

No wires or similar objects may project into the device through the ventilation slots

Fuses have to be replaced by types as rated on the nameplate on the rear of the unit.

Personal safety must be given the highest priority!

4

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

1 Warnhinweise

Achtung! Dieses Gerät erzeugt gefährliche Spannungen über 500V.

Vor jeder Inbetriebnahme des Hochspannungsverstärkers sind u. a. folgende Regeln zu beachten:

Die Inbetriebnahme darf nur von einer Elektrofachkraft im Sinne der Berufsgenossenschaft der

Feinmechanik und Elektrotechnik vorgenommen werden.

Vor der Inbetriebnahme muss die Bedienungsanleitung gelesen und verstanden worden sein.

Es sind die einschlägigen Bestimmungen und Vorschriften des Gesetzgebers, der

Berufsgenossenschaft und des VDE zu beachten, insbesondere

-DIN-VDE 104 "Errichten und Betreiben elektrischer Prüfanlagen"

(s. auch BGI 891 "Errichten und Betreiben von elektrischen Prüfanlagen")

-Unfallverhütungsvorschrift DGUV Vorschrift 3 / BGV A3

"Elektrische Anlagen und Betriebsmittel"

Das Gerät darf nur als Bestandteil eines im Ganzen den Vorschriften für den Umgang mit

Hochspannung genügenden Gesamtaufbaus betrieben werden!

Vor jedem Einschalten des Geräts ist der Versuchsaufbau zu überprüfen und sicherzustellen, dass

es zu keiner Gefährdung kommen kann. Die Hochspannung führenden Bereiche müssen

vorschriftengerecht abgesperrt oder anderweitig gesichert sein!

Sollte der Verdacht bestehen, dass das Gerät beschädigt ist oder Fehlfunktionen zeigt, ist es

umgehend außer Betrieb zu setzen und gegen beabsichtigten oder unbeabsichtigten Betrieb zu

sichern.

Der Erdbolzen auf der Rückplatte des Geräts muss mit dem Zentralen Erdpunkt des

Versuchsaufbaus und dem Schutzleiter verbunden werden. Die örtlichen Vorschriften über Erdung

sind zu beachten.

Die Ausgangssteckverbinder dürfen nur bei spannungsfrei geschaltetem Gerät betätigt werden!

Bei Arbeiten am Versuchsaufbau oder bei Berühren der Ausgangsanschlüsse ist das Gerät zuvor

von der Spannungsversorgung zu trennen.

Vor dem Öffnen des Geräts ist das Gerät von der Spannungsversorgung zu trennen.

Es dürfen keine Objekte – wie Drähte o. ä. durch die Lüftungsschlitze in das Gerät Hereinragen.

Im angeschlossenen Versuchsaufbau können evtl. vorhandene Kapazitäten auf Hochspannung

aufgeladen werden. Diese können auch nach Abschalten des Geräts noch gefährliche Spannungen

führen.

Sollte ein Ersatz der Netzsicherungen erforderlich sein, so ist sicherzustellen, dass nur

Sicherungen der angegebenen Nennstromstärke und Nennspannung als Ersatz verwendet

werden.

Der Personensicherheit ist höchste Priorität einzuräumen!

5

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

2Overview

This manual covers the following models:

HA05B2 single channel high voltage amplifier module family

HAR12S 12-channel high voltage amplifier mainframe (SHV output connectors)

HAR2 2-channel high voltage amplifier mainframe (SHV output connectors)

table top unit

HAR2-W 2-channel high voltage amplifier mainframe (SHV output connectors)

wall mount unit

3Description

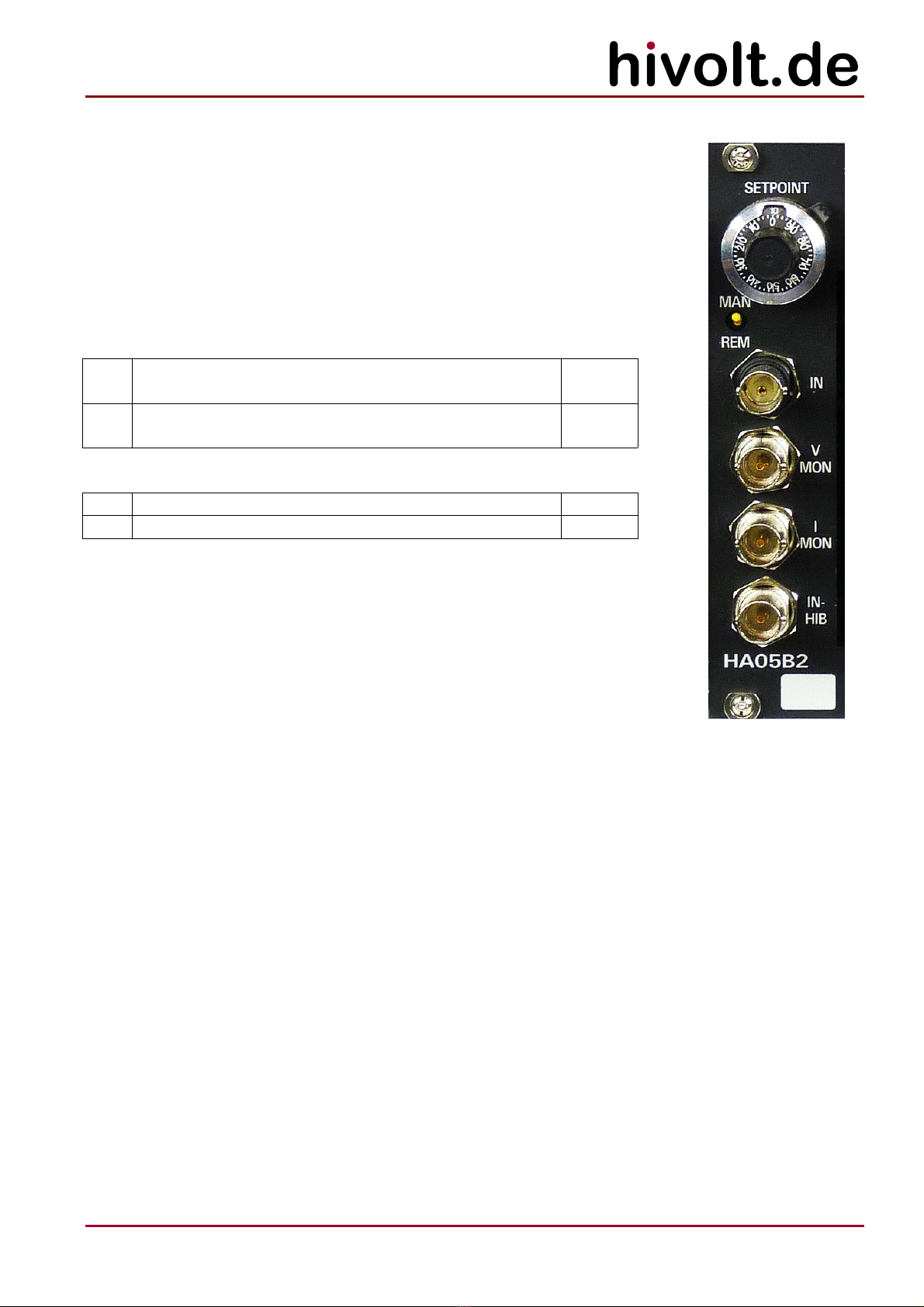

The high voltage amplifier channel module HA05B2 with bipolar output voltage is designed to drive

capacitive and resistive-capacitive loads.

The amplifier channels are characterized by high accuracy, very high stability and very low noise.

High precision electrostatic deflection or multi channel high voltage reference source are typical

applications.

A version with extended bandwidth is available: HA05B2_BA.

Output voltages of -500V to +500V at load currents of up to ±2mA are provided. The signal gain is 50,

the input voltage range is -10V…+10V.

The output voltages of each channel can be controlled by a control voltage (IN) or by a 10-turn

potentiometer (SETPOINT). Each channel is equipped with a precision high-speed voltage monitor

output, current monitor output and an inhibit input.

The amplifier outputs are protected against overload, short circuit, and transient overvoltage.

The HA05B2 is a 3U plug-in card intended to be mounted in a suitable subrack.

The HAR2/HAR2-W mainframes accommodate up to 2 amplifier channel modules HA05B2.

HAR2 is a table top unit, HAR2-W is a wall-mount type.

The 19"/3U HAR12 mainframe accommodates up to 12 amplifier channel modules HA05B2.

It features internal power supplies, cooling fans and a common Interlock input for all channels.

All mainframes contain two DVMs and the high voltage converters to feed the HA05B2 amplifier

channel modules.

Both the output voltage and the load current of each channel can be displayed on the DVMs.

A switch (CHANNEL) is provided for selection of the channel to be measured.

The HAR12 is supplied by mains voltage. The HAR2 models are supplied by an external 24VDC.

Customized and full custom models are available on request.

6

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

3.1 Block Diagram

1N

IN

-

10K0

A3

SETPOINT

I NHI B

+540V

A2

I-MON

A3

W2

1

2

3

X5

Spannungsregler V1 9

1K00

-10.0V

MAN

V24

VO

I NHI B

A4

V-MON

49R9

INHIB

-540V

X6

X7

CMR

X4

CW

CC W

+

REM

+10.0V

10R0 OFFSET

W1

1

2

3

The block diagram shows one amplifier channel.

7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

3.2 Control Voltage Input

The control voltage input (IN) is connected to a differential amplifier to

suppress common mode voltages between the external signal source and

the amplifier. Two jumpers (W1, W2) are provided on each amplifier module

HA05B2 in order to adapt the control voltage input to the signal source.

W1 connects the input signal reference via 10Ωto the amplifier signal

ground. W2 adjusts the amplifier gain to the output impedance of the signal

source.

W1

1-2 Floating signal source

Common mode voltage <1VRMS

Default

2-3 Grounded signal source (connected to PE)

Common mode voltage <5VRMS

W2

1-2 Output impedance of signal source <1ΩDefault

2-3 Output impedance of signal source 50Ω

Alternatively, the control voltage can be generated by means of a 10-turn

potentiometer (SETPOINT). The potentiometer supplies –10 V at the CCW

end position (0) and +10 V at the CW end position (10). Zero position is at 5.

Switching between internal and external control voltage is achieved by a

front panel switch (MAN / REM).

3.3 Monitor Outputs

Two BNC monitor outputs (V-MON / I-MON) provide actual values of output voltage and output current,

both of which are normalized to ±10 V.

The monitor outputs receive their signal through a compensated voltage divider. Current

measurement takes place differentially across a sense resistor in the output line. Due to differential

measurement, a certain drift of the measured output current over temperature and output voltage is

inevitable (refer to technical specifications).

The frequency response of V-MON is linear up to well above the upper cut-off frequency of the

amplifiers.

The monitor outputs are buffered and short-circuit-proof. They are able to drive capacitive loads

(coaxial cables), but are not designed to drive cables with a low-impedance termination.

8

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

3.4 INHIBIT

Each high voltage amplifier channel can be remotely switched off through the INHIB input. The input is

TTL-compatible. A LOW-signal turns on the amplifier. In case of open input or HIGH-signal, the

amplifier is turned off. For manual operation, a 50ΩBNC-termination resistor can be used to statically

turn the amplifier channel on.

The Inhibit signal drives a semiconductor switch, short-circuiting the output (approx. 100Ω) within

microseconds. The switch conducts independently of the internal supply voltage, even after the device

is switched-off.

The INHIB input is not suitable to achieve a safe state at the amplifier output. It must not be used for

safety relevant purposes.

3.5 Loading Conditions

The amplifiers are designed to drive any combination of resistive and capacitive loads.

Full output voltage is available for resistive loads ≥250kΩ. When driving capacitive loads the reactive

current must be taken into consideration. This current into the load capacitance depends on the

capacitance value and the slew-rate: iCL = CL* dv / dt.

The effective load capacitance consists of the connected load capacitance, the capacitance of the

output cable, and the capacitance internal to the amplifier. If the output current exceeds the peak

current capability of the amplifier module (refer to the specifications), the output voltage will become

distorted.

In case of larger load capacitances overshoot of the output may occur.

The achievable large-signal bandwidth strongly depends on the capacitance of the connected load.

Particularly with regard to the high speed versions of the amplifier modules, the cable capacitance

may become the dominant part of load capacitance. One meter of typical coaxial cable has a

capacitance of about 100pF.

Large capacitive loads driven by high frequency signals may result in a DC-offset superimposed on the

output voltage. This occurs if the final value of the desired output voltage can not be reached

periodically.

No damage to the amplifier modules will result from the different conditions mentioned.

9

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

3.6 Interlock

The HAR12 mainframe incorporate an interlock circuit through which the supply voltage of the high

voltage sources is switched. The interlock circuit is not provided on the HAR2 mainframes.

The interlock signal is available via the rear connector INTERLOCK on the subrack. It is a closed

circuit (break contacts). Its source voltage is 24VDC . The source voltage is provided on the INTERLOCK

connector. The voltage source is protected against overload or short circuit.

To enable the high voltage generators, signal +24V_IL (INTERLOCK.2) and IL (INTERLOCK.3) must be

connected by a jumper or a contact. The contact can be part of an external interlock circuit. The

quiescent current is 12mA typ.

When the interlock circuit is closed, the high voltage sources are switched on.

The device must be disconnected from the power supply before carrying out any operations on the test

setup or before touching the output terminals.

3.7 Connector INTERLOCK

Connector type: Phoenix Mini-Combicon, 5-pin

Mating connector: Phoenix Mini-Combicon, 5 circuits, FK-MCP1.5_ 5-ST-3.81

Pin Signal Direction Function

1 -

2 +24V_IL O 24V output for interlock circuit; protected against overload

3 IL I Interlock / bridge to +24V_IL

4 -

5 GND - Supply voltage GND

10

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

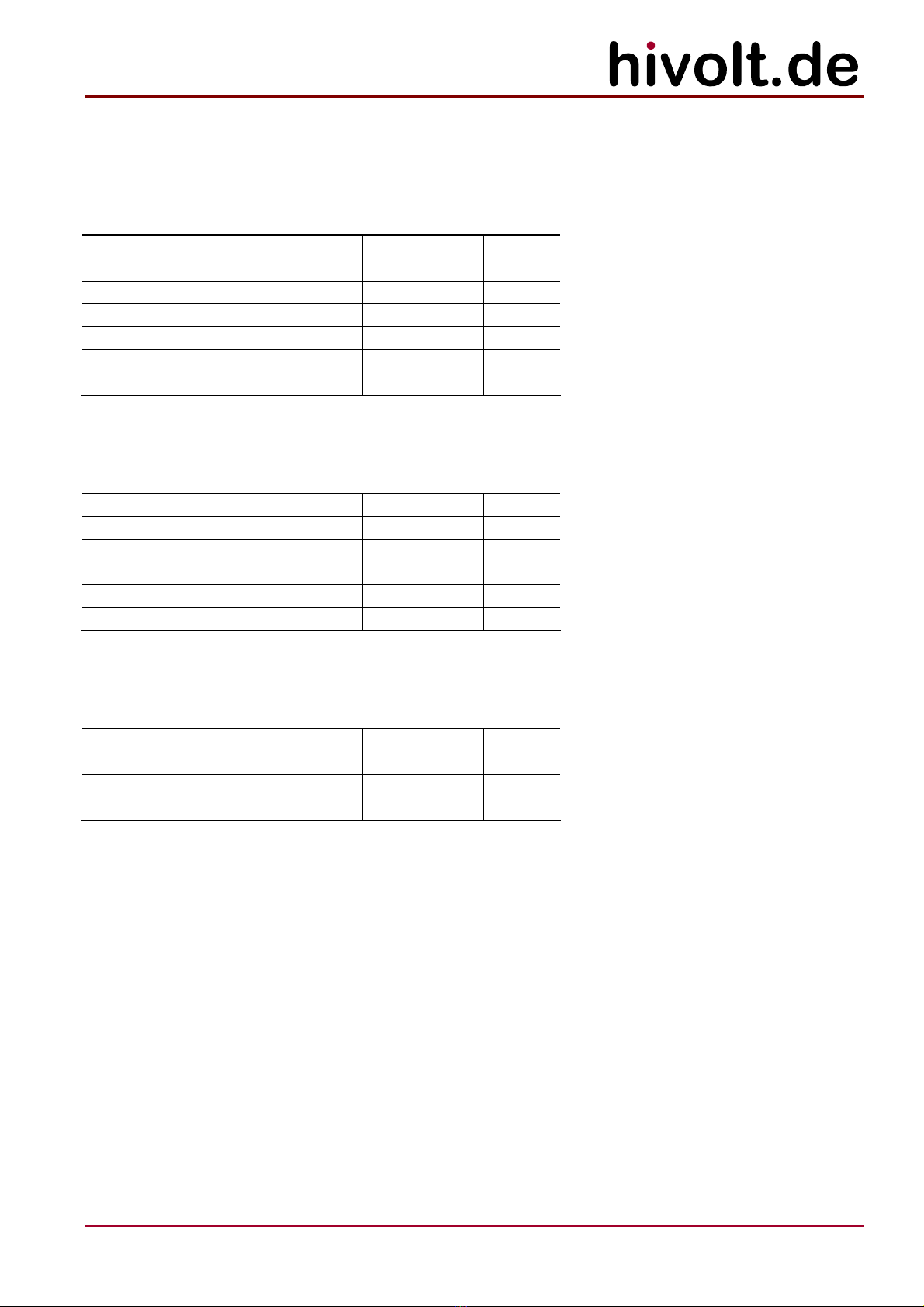

4Technical Data

Mainframe HAR12S – equipped with 12x HA05B2

Parameter Conditions

Mains voltage 95 – 265VAC

Mains frequency 47 – 63Hz

Input current VLine=115VAC, full load 1.0ARMS

VLine=230VAC, full load 0.5ARMS

Mains fuses F1, F2 T3.15A, 250V, IEC127-2/V

External fusing 16A

Protection category I

-Fuses F1, F2 are located within the mains connector unit on the rear.

-Signal ground and high voltage ground are connected to chassis ground / protective earth and the

earth connector (M4 bolt).

-The appliance conforms to protection category I. It must only be used on mains power sockets with

a ground connection.

Mainframe HAR2 / HAR2-W – equipped with 2x HA05B2

Parameter Conditions

Supply voltage 22.8 – 25.2VDC

Input current VIN=24VDC, full load 0.6ADC

Amplifier modules HA05B2 / HA05B2_BA

Parameter Conditions

Supply voltage, +VS+24VDC ±10%

Supply current, IS+VS= 24V < 80mA

Supply voltage, +VHV +525 - +550VDC

Supply current, I+VHV

-HA05B2

-HA05B2_BA

+VHV = +540V

< 3mA

< 10mA peak

Supply voltage, -VHV -525 - -550VDC

Supply current, I-VHV

-HA05B2

-HA05B2_BA

-VHV = -540V

< 3mA

< 10mA peak

Input voltage range IN Control input -10.0V – +10.0V

Max. input voltage IN Control input ±18V

Input resistance IN 50kΩtyp.

DC Gain 50 ±0.2%

Output voltage range -500V – +500V

DC load current range static -2mA – +2mA

Peak output current

- HA05B2

- HA05B2_BA

dynamic, t < 1ms

> ±2mA

> ±8mA

Short circuit output current < ±4mA

11

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

Power bandwidth

- HA05B2

- HA05B2_BA

RL= 500kΩ, CL= 100pF,

DC – ≥500Hz

DC – ≥15000Hz

Internal output capacitance

- HA05B2

- HA05B2_BA

1200pF typ.

100pF typ.

Ripple, Noise

- HA05B2

- HA05B2_BA

RL= 500kΩ, CL= 100pF,

≤10mVPP / ≤1mVRMS

≤30mVPP / ≤3mVRMS

Output voltage stability RL= 500kΩ, control value via IN,

ΔTamb < ±10K, Δt = 24h

< ±100ppm f.s.

Load regulation IL= 0 -> 100% < 50ppm

Temperature coefficient

Output voltage

RL= 500kΩ, 10.00V via IN,

ΔTamb < ±10K

typ. 5ppm/K

Output offset voltage

-HA05B2

-HA05B2_BA

< ±20mV

< ±30mV

Scaling monitor output V-MON 10V 500V ±0.2% f.s.

Scaling monitor output I-MON 10V 2mA ±0.2% f.s.

Zero point stability I-MON VO= -500V - +500V,

ΔTamb < ±10K

< ±0.2% f.s.

Accuracy DVM (V/I) < ±0.2% f.s.

Zero point stability DVM (I) VO= -500V - +500V,

ΔTamb < ±10K

< ±0.2% f.s.

Input voltage INHIB INHIB = LOW

INHIB = HIGH

-15 - +1.5V

-2.4 - +15V

max. Input voltage INHIB 30VRMS / ±30VDC

Response time INHIB=>HIGH VO<50V, CL= 100pF < 10μs

Response time INHIB=>LOW VO<50V, CL= 100pF ca. 2.5ms

-Signal ground and high voltage ground are connected to the chassis ground / earth terminal.

4.1 Ambient Conditions

Parameter Conditions Min. Max. Unit

Ambient temperature

- Operation

- Storage and Transportation

0

-25

+0

+70

°C

°C

Relative humidity

- Operation

- Storage and Transportation

Not condensing

5

5

80

95

%

%

12

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

4.2 Mechanical Specifications

Mainframe HAR12S

Parameter Unit

Depth overall 370 mm

Depth case 345 mm

Width overall 481 mm

Width case 446 mm

Height 134 mm

Weight without amplifier modules 5.3 kg

Weight fully equipped 8.5 kg

Mainframe HAR2 / HAR2-W

Parameter Unit

Depth overall 263 mm

Depth case 239 mm

Width overall (HAR2-W) 178 mm

Width case (HAR2) 140 mm

Height 134 mm

Weight without amplifier modules 1.4 kg

Amplifier module HA05B2 / HA05B2_BA

Parameter Unit

Depth overall 200 mm

Width 129 mm

Height 30 mm

Weight 0.27 kg

13

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

5Operation

5.1 Initial Check

Once the product is delivered, please check the packaging and the device for possible transport

damage. Please check the device taken out of the packaging for any mechanical defects before the

unit is put into operation.

If the device has any signs of damage caused by transport, please immediately inform the shipping

company so that damages can be claimed.

5.2 Warning Notices

-For safe operation of this device it should be put into operation by a qualified electrician according

to this Operating Manual.

-The device may only be operated as a component of an overall setup that fully complies with the

regulations for working with high voltage systems.

-Output connectors may only be touched when the device is disconnected from the power supply!

Otherwise, there is a risk of electric shock.

-The test setup must be fully wired and protected against any contact before the device is put into

operation.

-The test setup must be checked each time before the device is put into operation to ensure that it

is not potentially dangerous. It should be checked that the high voltage connections are faultless

and the insulation of the wires is not damaged.

-The high-voltage areas must be blocked in accordance with regulations or secured by other

means.

-Once the test setup is connected, any existing capacitances can be charged to high voltage. They

may carry dangerous voltages even after the device is switched off.

-The ground bolt on the rear panel of the device must be connected to the central grounding point

of the test setup and to protective earth. Local regulations on grounding must be observed.

-No wires or similar objects may project into the device through the ventilation slots

-If it is suspected that safe operation is no longer possible, the device has to be taken out of

operation and secured against unintentional operation.

This symbol on the output terminals warns of the risk of electric shock.

5.3 Temperature Compensation

To avoid condensation within the device, it should be allowed to reach the room temperature. Please

unpack the product at least two hours prior to power-up.

14

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

5.4 Power Supply

The HAR12S mainframe is fed by mains voltage.

The HAR2 mainframe is fed by an external 24VDC / ±10% power supply. The power supply should be

able to source 1A output current minimum.

5.5 Ventilation

The HAR12S amplifier subrack may be used in rack mounted or bench top applications. In either case,

sufficient space must be allowed for cooling air to reach the ventilation inputs on the front panels and

for the fan exhaust air to exit from the rear of the unit.

The HAR2 may not be covered when in use. The unit must not be used without the provided rubber-

feet mounted to the bottom side.

Sufficient space for ventilation must be kept below and above the unit when the HAR2-W is mounted.

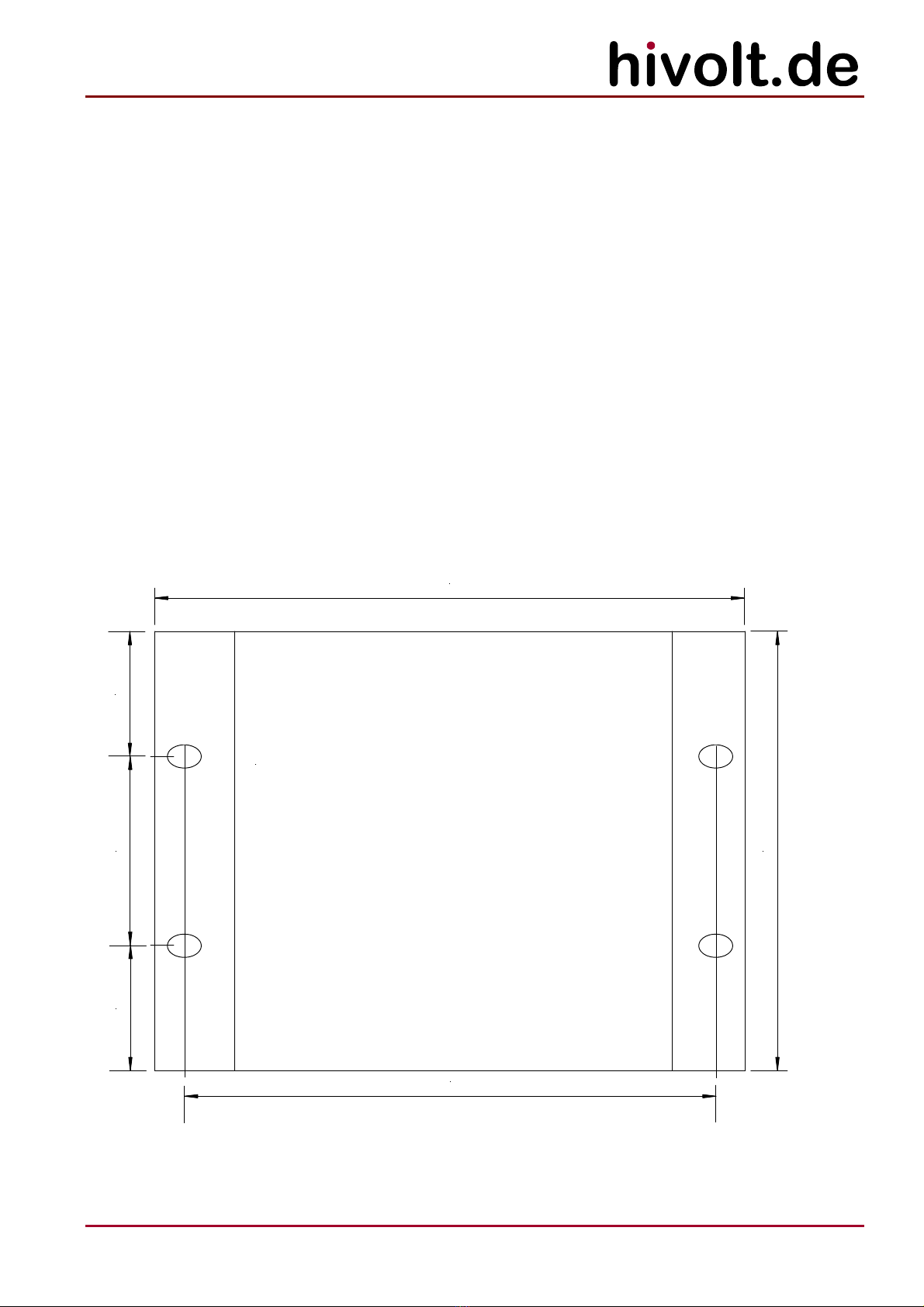

5.6 Wall Mounting HAR2-W

178mm

132,50 mm

4x

10,2x7mm

160,20mm

37,7mm 57,1mm 37,7mm

15

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

5.7 Rack Mounting HAR12

The HAR12 Amplifier Subrack is designed to fit in a standard 19" equipment rack. Use the rack mount

brackets at both sides of the front panel to install the unit into a 19" rack.

5.8 Functional Test

Before the device is finally put into operation in a setup, a short functional test is to be carried out.

It is necessary that the interlock circuit is closed (HAR12S).

1. Make sure that the supply voltage is disconnected.

2. Remove all input signal cables and the output cable from the device.

3. Connect the terminals +24V_IL (INTERLOCK.2) and IL (INTERLOCK.3) by means of a wire

link.

4. Set all of the SETPOINT potentiometers to 10.0.

5. Set all input selector switches to REM.

6. Connect the unit to a grounded power outlet and turn the unit on (HAR12S);

connect the unit to a 24VDC power supply (HAR2)

7. Connect a 50ΩBNC-termination to the INHIB input at channel 1.

8. Select channel 1 (CHANNEL).

9. The voltage DVM should display about 0000 ±10;

the current DVM should display about 0000 ±10.

10. Set the input selector switch to MAN.

11. The voltage DVM should display about 500.0;

the current DVM should display about 0000 ±20.

12. Turn the SETPOINT-potentiometer to 0.

13. The output voltage changes from about +500V to about -500V.

14. Repeat the test with all the other channels.

15. Turn off the supply voltage.

5.9 Output connections

The outputs of the device supply a voltage of higher than 500V via SHV connectors. Connections to the

load should be provided only using connectors and cables with appropriate voltage rating.

Do not mate or unmate the output connector unless the device is switched off!

5.10 Output Connectors

Connector type: SHV

Connections to the loads should only be made using connectors and cables with appropriate voltage

rating.

The high voltage connectors may only be mated or unmated when the supply voltage is switched off!

Otherwise, there is a risk of an electric shock.

16

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

5.11 External Connectors

Signals: BNC

HV Outputs: SHV

Power line: IEC320-1 (HAR12S)

Earth: Bolt M4 (HAR12S)

Power supply: 2 pole Phoenix Combicon Connector (HAR2, HAR2-W)

Mating connector: 2 pole Phoenix Combicon Plug MSTB 2.5/2-ST-5.08

5.12 Internal Connectors

Internal connectors for HA05B2 plug-in modules (DIN41612, Type F)

Pins Signal

D2 B2 Z2 +VHV (+540V)

D4 B4 Z4 GND

D6 B6 Z6 VO (Amplifier output)

D8 B8 Z8 GND

D10 B10 Z10 -VHV (-540V)

D12 B12 Z12 GND

D14 B14 Z14 n.c.

D16 B16 Z16 n.c.

D18 B18 Z18 Internal connection, do not connect

D20 B20 Z20 Internal connection, do not connect

D22 B22 Z22 Internal connection, do not connect

D24 B24 Z24 Internal connection, do not connect

D26 B26 Z26 Internal connection, do not connect

D28 B28 Z28 Internal connection, do not connect

D30 B30 Z30 +VS (+24V)

D32 B32 Z32 GND

5.13 Grounding

The M4 ground bolt on the back panel of the device must be connected to the central grounding point

of the test setup and to protective earth (HAR12S).

17

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

5.14 Troubleshooting

If the device behaves unusual or erratic, please switch off the supply voltage and check the wiring of

the load and that of the control and monitoring signals. Check the connected load and the signal

source. Check the interlock circuit.

Do not attempt to locate any faults within the device. This can be dangerous to life due to the high

voltage used in the device. In such a case, please return the device to the manufacturer after

consultation.

Symptom Possible causes

Device will not turn on;

DVM displays will not light up

-No supply voltage present

-Fuses F1, F2 in the IEC inlet defective (HAR12S)

Output signal is distorted -Load capacitance too large for the desired slew rate

(see section 3.5 for load conditions)

Power supply and input signal

present but no output signal

-Examine the level of INHIB input signals

5.15 Maintenance

Depending on the cleanliness of the ambient air dust may accumulate within the unit possibly blocking

the airflow. In that case the accumulated dust has to be removed by taking out the amplifier modules

and blowing out the unit and the modules cautiously.

The manufacturer specified lifetime of the HAR12S fans is >50000h. After about 6 years of continuous

operation the fans might be replaced.

Type: Sunon MF60252V21000UA99

Caution: disconnect the unit from the power supply before removing any modules or opening any

covers.

Further regular maintenance is not required.

5.16 Cleaning

If necessary, wipe the device with a slightly damp cloth. Do not use abrasive detergents or solvents.

© hivolt.de GmbH&Co. KG, Hamburg, Germany

As of 07/2020

Document History:

Version Date Name Changes

1.0 10/2016 WM created

1.1 2020-07-16 WM updated layout and content

18

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

6Declaration of Conformity

We declare under sole responsibility that the products

Device: High Voltage Amplifiers

Series: HA05B2

Subrack: HAR12S, HAR2, HAR2-W

are in accordance with the following European directives:

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

and comply with the following European standards:

EN 61010-1:2010 Safety requirements for electrical equipment for

measurement, control, and laboratory use -

Part 1: General requirements

EN 61326-1:2013 Electrical equipment for measurement, control and

laboratory use -

EMC requirements - Part 1: General requirements

Classification: Group 1, Class B

Manufacturer:

hivolt.de GmbH & Co. KG

Oehleckerring 40

D-22419 Hamburg

2016-10-04

Wulf Müller

Managing Director

This manual suits for next models

2

Table of contents

Other hivolt Amplifier manuals