HK Instruments DPT-Ctrl-MOD Series User manual

Copyright HK Instruments 2022 www.hkinstruments. Installaonversion8.02022

INSTALLATION

INSTRUCTIONS

Pressure and flow controllers

DPT-Ctrl-MOD Series

• READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO

INSTALL, OPERATE OR SERVICE THIS DEVICE.

• Failuretoobservesafetyinformaonandcomplywithinstruconscan

result in PERSONAL INJURY, DEATH AND/OR PROPERTY DAMAGE.

• Toavoidelectricalshockordamagetoequipment,disconnectpower

beforeinstallingorservicinganduseonlywiringwithinsulaonratedfor

fulldeviceoperangvoltage.

• Toavoidpotenalreand/orexplosiondonotuseinpotenally

ammableorexplosiveatmospheres.

• Retaintheseinstruconsforfuturereference.

• Thisproduct,wheninstalled,willbepartofanengineeredsystemwhose

specicaonsandperformancecharacteriscsarenotdesignedor

controlledbyHKInstruments.Reviewapplicaonsandnaonalandlocal

codestoassurethattheinstallaonwillbefunconalandsafe.Useonly

experiencedandknowledgeabletechnicianstoinstallthisdevice.

Thankyouforchoosing an HK InstrumentsDPT-Ctrl-MOD series air han-

dling controller with dierenal pressure or airow transmier. The DPT-

Ctrl-MODseriesPIDcontrollersareengineeredforbuildingautomaonin

theHVAC/Rindustry.With thebuilt-incontrollerofthe DPT-Ctrl-MOD it

ispossibletocontroltheconstantpressureorowoffans,VAVsystemsor

dampers.Whencontrollingairow,itispossibletoselectafanmanufacturer

oracommonmeasuringprobethathasaK-value.

TheDPT-Ctrl-MODincludesanInputterminalthatenables the reading of

mulple signals such as temperature or control relays over Modbus. The

Input terminalhas oneinputchanneldesignedto accept 0−10V,NTC10k,

Pt1000,Ni1000/(-LG),andBININ(potenalfreecontact)signals.

DPT-Ctrl-MODseriesdevicesarecommonlyusedinHVAC/R

systems for:

•Controllingdierenalpressureorairowinairhandlingsystems

•VAVapplicaons

•Controllingparkinggarageexhaustfans

SPECIFICATIONS

Performance

Accuracy (from applied pressure):

Model2500:

Pressure<125Pa=1%+±2Pa

Pressure>125Pa=1%+±1Pa

Model7000:

Pressure<125Pa=1.5%+±2Pa

Pressure>125Pa=1.5%+±1Pa

(Accuracyspecicaonsinclude:generalaccuracy,

linearity,hysteresis,longterm

stability,andrepeonerror)

Overpressure:

Proofpressure:25kPa

Burstpressure:30kPa

Zero point calibraon:

ManualpushbuonorModbus

Response me:

1.0−20s,selectableviamenuorModbus

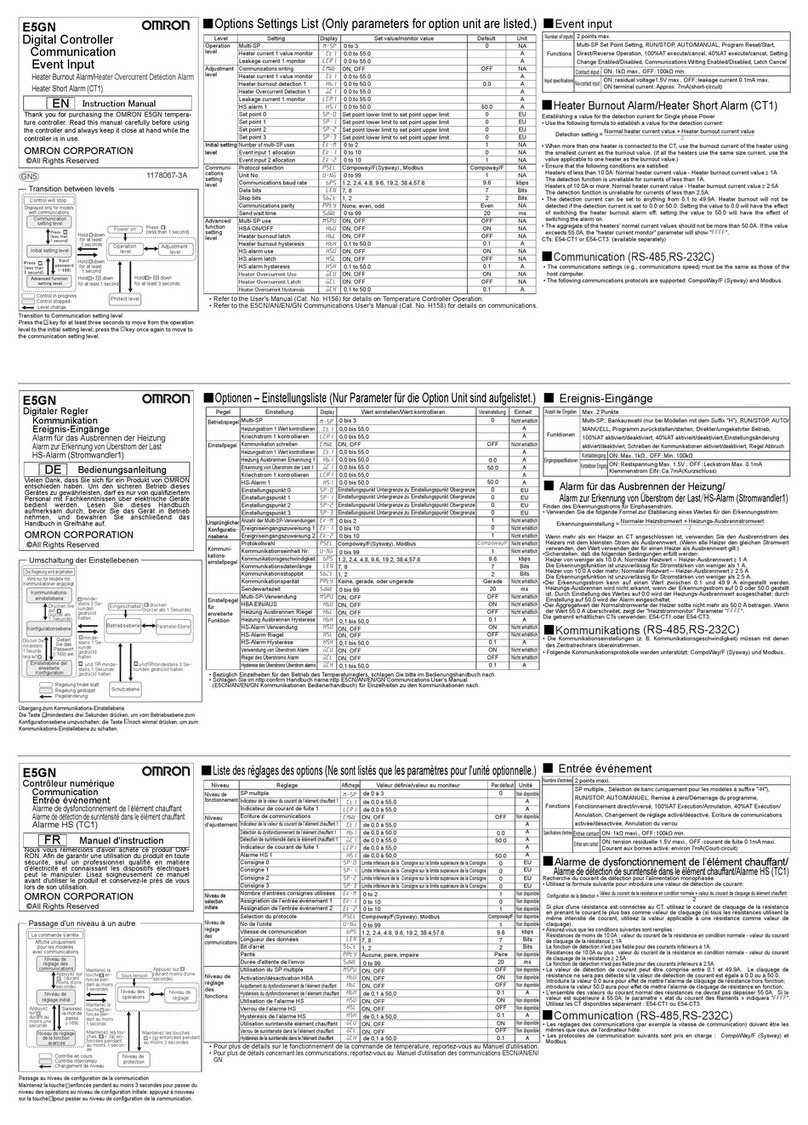

Communicaon

Protocol:MODBUSoverSerialLine

TransmissionMode:RTU

Interface:RS485

Byteformat(11bits)inRTUmode:

Codingsystem:8-bitbinary

Bitsperbyte:

1startbit

8databits,leastsignicantbitsent

rst

1bitforparity

1stopbit

Baudrate:selectableinconguraon

Modbusaddress:1–247addressesselectablein

conguraonmenu

Technical Specicaons

Media compability:

Dryairornon-aggressivegases

Controller parameter (selectable via menu and

Modbus):

Setpoint0...2500(model2500)

0...7000(model7000)

P-band 0...10000

I-gain 0...1000

D-factor0...1000

Pressure units (selectable via menu):

Pa,kPa,mbar,inWC,mmWC,psi

Flow units (selectable via menu):

Volume: m3/s, m3/hr,cfm,l/s

Velocity:m/s,/min

Measuring element:

MEMS,noow-through

Environment:

Operangtemperature:-20...50°C

Temperaturecompensatedrange0...50°C

Storagetemperature:-40...70°C

Humidity:0to95%rH,noncondensing

Physical

Dimensions:

Case:102.0x71.5x36.0mm

Weight:

150g

Mounng:

2each4.3mmscrewholes,onesloed

Materials:

Case: ABS

Lid:PC

Pressure inlets: Brass

Protecon standard:

IP54

Display

2-linedisplay(12characters/line)

Line1:Direconofcontroloutput

Line2:Pressureorairowmeasurement,

selectableviamenu

Ifinputisselected,line2showsalso

inputinformaon(forexample

temperature)

Size:46.0x14.5mm

Electrical connecons:

4+4posionspring-loadedterminals

Wire:0.2–1.5mm2(16–24AWG)

Cable entry:

Strainrelief:M16

Knockout:16mm

Pressure ngs

5.2mmbarbedbrass

+Highpressure

−Lowpressure

Electrical

Supply voltage:

24VACorVDC,±10%

Power consumpon:

<1.0W

Output signal:

viaModbus

Control output:

0-10V

Input signal:

0−10V,NTC10k,Pt1000,Ni1000/(-LG)orBININ

Conformance

Meetstherequirementsfor:

CE: UKCA:

EMC: 2014/30/EU S.I.2016/1091

RoHS: 2011/65/EU S.I.2012/3032

WEEE: 2012/19/EU S.I.2013/3113

INTRODUCTION WARNING

APPLICATIONS

RoHS

COMPLIANT

Copyright HK Instruments 2022 www.hkinstruments. Installaonversion8.02022

SCHEMATICS

INSTALLATION

STEP 1: MOUNTING THE DEVICE

1)Mountthedeviceinthedesiredlocaon(seestep1).

2)Openthelidandroutethecablethroughthestrainreliefandconnectthe

wirestotheterminalblock(s)(seestep2).

3)Thedeviceisnowreadyforconguraon.

WARNING!Applypoweronlyaerthedeviceisproperlywired.

1)Selectthemounnglocaon(duct,wall,panel).

2)Usethedeviceasatemplateandmarkthescrewholes.

3)Mountwithappropriatescrews.

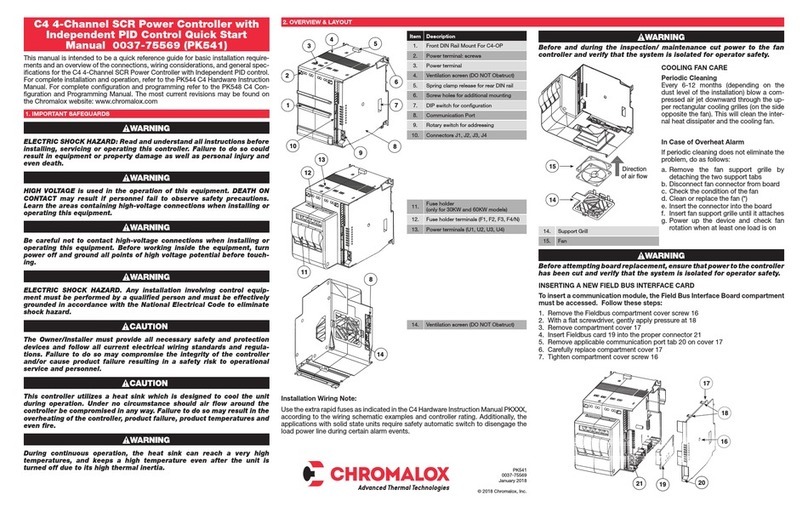

Display connecon

A

B

24 V

GND

LEDs

Joysck1

Joysck2

Joysck3

Select

Up

Down

Menu buons

Terminal

blocks

Pressure

sensor

Input terminal

configuraon

jumpers

Control out

Input

GND

GND

Figure 1a - Mounng orientaon

YES NO NO

STEP 3: CONFIGURATION

2)Zeropointadjustment.Formoreinformaon,seeStep4.

PRESS. UNIT

Pa

SELECT

UP

DOWN

SELECT

ZERO SENSORS

SELECT

UP

DOWN

3)Selectthefunconingmodeofthecontroller:PRESSUREorFLOW.

-SelectPRESSUREwhencontrollingdierenalpressure.

Gotopoint3.1.

-SelectFLOWwhencontrollingairow.

Gotopoint3.2.0.

CONTROL UNIT

PRESSURE

SELECT

UP

DOWN

When control unit PRESSURE is selected.

3.1)Selectpressureunitfordisplayandoutput:Pa,kPa,mbar,inWCormmWC.

Thengotopoint4.

When control unit FLOW is selected.

3.2.0)Selectthefunconingmodeofthecontroller

-SelectManufacturerwhenconnecngDPT-Ctrl-MODtoafanwithpressure

measurementtaps.

-SelectCommon probewhenusingDPT-Ctrl-MODwithacommonmeasurement

probethatfollowstheformula:

q=k∙√∆P(i.e.FloXact)

MANUFACTURER

Common probe

SELECT

UP

DOWN

Common probe Flakt Woods

SELECT

UP

DOWN

STEP 2: WIRING DIAGRAMS

ForCEcompliance,aproperlygroundedshieldingcableisrequired.

1)Unscrewthestrainreliefandroutethecable(s).

2)Connectthewiresasshowningure2aand2b.

3)Tightenthestrainrelief.

Figure 2a - Wiring diagram

A

B

24 V

GND

+Power Supply

24VDC / 24VAC

Control out

Input

GND

GND

Modbus

Figure 2b - Wiring diagram example for input signals

Input

GND

ntc10k J1

J2

J3

IN

Input ntc10k temperature:

Funcon04-Readinputregister3x0007

3.2.1)If

Commonprobe

selected:selectmeasurementunitsusedintheformula

(akaFormulaunit)(i.e.l/s)

b. If

Commonprobe

selectedinstep3.2.0:

EachcommonprobehasaspecicK-value.SelecttheK-valuefromcommonprobe

manufacturer’sspecicaons.

AvailableK-valuerange:0.001...9999.000

FORMULA UNIT

l/s

SELECT

UP

DOWN

3.2.2)SelectK-value

a.Ifmanufacturerselectedinstep3.2.0:

EachfanhasaspecicK-value.SelecttheK-valuefromfanmanufacturer’sspeci-

caons.

K-VALUE

9000.000

SELECT

UP

DOWN

3.2.3)Selectowunitfordisplayandoutput:

Flowvolume:m3/s, m3/h,cfm,l/s

Velocity:m/s,f/min

FLOW UNIT

m3/s

SELECT

UP

DOWN

1)Presstheselectbuonfortwosecondstoopenthedevicemenu.

4)SelecttheaddressforModbus:1...247

ADDRESS

99

SELECT

UP

DOWN

ItisrecommendedtouseshieldedtwistedpaircableforModbuscabling.

Thecableshieldmustbeearthedonlyinonepoint,normally,attheendof

themaincable.

Copyright HK Instruments 2022 www.hkinstruments. Installaonversion8.02022

7)Selecttheresponseme:1...20s.

RESPONSETIME

4 s

SELECT

UP

DOWN

BAUD RATE

9600

SELECT

UP

DOWN

PARITY BIT

NONE

SELECT

UP

DOWN

5)Selectthebaudrate:9600/19200/38400.

6)Selecttheparitybit:None/Even/Odd

9)Selecttheinputtype.

Passivetemperaturesensors:PT1000/Ni1000/Ni1000LG/NTC10k

Voltageinput:VINPUT

Switchinput:BININ

Noinput:NONE

INPUT

PT1000

SELECT

UP

DOWN

10)Selectthesetpointofthecontroller(SP2isonlyavailablewithBININswitch

informaon):

CONFIGURATION CONTINUED

NOTE! Always zero the device before use.

Supplyvoltagemustbeconnectedonehourbeforethezeropointadjust-

mentiscarriedout.AccessviaModbusorbypushbuon.

1)Loosebothtubesfromthepressureinlets+and-.

2)Acvatethedevicemenubypushingthetheselectbuonfor2

seconds.

3)SelectZero sensorbypressingtheselectbuon.

4)WaitunltheLEDturnsoandtheninstalltubesagainforthe

pressureinlets.

STEP 4: ZERO POINT ADJUSTMENT

SELECT

STEP 5: INPUT SIGNAL CONFIGURATION

InputsignalscanbereadoverModbusviaDPT-MODRS485interface.

Signals Accuracy for measurement Resoluon

0...10V <0,5% 0,1%

NTC10k <0,5% 0,1%

Pt1000 <0,5% 0,1%

Ni1000/(-LG) <0,5% 0,1%

BININ(potenalfreecontact)

Thejumpersshould be set accordingtothe instruconsbelowandthe value

shouldbereadfromtherightregister.

Figure 3 - Input signal conguraon

J1

J2

J3

IN

J1

J1

J1

J2

J2

J2

J3

J3

J3

NTC10k / BIN IN

Pt1000 / Ni1000/(-LG)

0...10 V

D-VALUE

1.00

SELECT

UP

DOWN

15)Pushtheselectbuontoexitmenu.

SELECT

EXIT MENU SELECT

12)Selectproporonalbandaccordingtoyourapplicaon

specicaons.

P-VALUE

206

SELECT

UP

DOWN

13)Selectintegralgainaccordingtoyourapplicaonspecicaons.

I-VALUE

4.00

SELECT

UP

DOWN

14)Selectderivaonmeaccordingtoyourapplicaon

specicaons.

STEP 6: TEMPERATURE COMPENSATION

Thedeviceincludesanoutdoortemperaturecompensaonfunconthatcan

beenabledfromthemenu.Whenacvatedandanoutdoortemperaturesensor

isaached,theeecvesetpointofthedevicewillbemodiedtocompensate

forthecoldoutdoorair.Thismayresultinenergysavings.

If temperaturecompensaonis enabled, thedevicewill linearly decreasethe

user’s setpoint (REF FLOW/REF PRESSURE) by 0 % to TC DROP % from TC

START TE to TC STOP TE.

Thedeviceenforcesa+5°Cdierence betweenthe startand stoptempera-

tures.Thestarttemperaturemustbehigherthanthestoptemperature.

1)Connectandcongureanoutdoorairtemperaturesensor.Seestep5.

2)Enabletemperaturecompensaon.

4)Setthestoppingtemperatureforcompensaon.

TC STOP TE

-15 °C

SELECT

UP

DOWN

TEMP COMP

ON

SELECT

UP

DOWN

TC START TE

5 °C

SELECT

UP

DOWN

3)Setthestarngtemperatureforcompensaon.

5)Setthemaximumdroppercentageforcompensaon.

TC DROP %

25.0

SELECT

UP

DOWN

8)SelecttheFixedOutput(OFF/0...100%),(seestep7FixedOutput).

10.1)IftheCONTROLUNITisselectedPRESSURE.

SELECT

UP

DOWN

REF PRES SP1

10 Pa

REF PRES SP2

100 Pa

10.2)IftheCONTROLUNITisselectedFLOW.

SELECT

UP

DOWN

REF FLOW SP1

25.000 m3/s

REF FLOW SP2

35.000 m3/s

11)SelecttheTEMPCOMP(OFF/ON),(seestep6,TemperatureCompensaon).

Copyright HK Instruments 2022 www.hkinstruments. Installaonversion8.02022

Thesellerisobligatedtoprovideawarrantyofveyearsforthedeliveredgoods

regarding material and manufacturing. The warranty period is considered to

startonthedeliverydateoftheproduct.Ifadefectinrawmaterialsorapro-

ducon aw isfound, theseller isobligated,whentheproduct issent tothe

sellerwithoutdelayorbeforeexpiraonofthewarranty,toamendthemistake

athis/herdiscreoneitherbyrepairingthedefecveproductorbydelivering

freeofchargetothebuyeranewawlessproductandsendingittothebuyer.

Deliverycostsfortherepairunderwarrantywillbepaidbythebuyerandthe

returncostsbytheseller.Thewarrantydoesnotcomprisedamagescausedby

accident,lightning,oodorothernaturalphenomenon,normalwearandtear,

improperorcarelesshandling,abnormaluse,overloading,improperstorage,in-

correctcareorreconstrucon,orchangesandinstallaonworknotdonebythe

seller.Theseleconofmaterialsfor devicespronetocorrosionis the buyer’s

responsibility,unlessotherwiseislegallyagreedupon.Shouldthemanufacturer

alterthestructureofthedevice,thesellerisnotobligatedtomakecomparable

changestodevicesalreadypurchased.Appealingforwarrantyrequiresthatthe

buyerhascorrectlyfullledhis/herduesarisenfromthedeliveryandstated

inthe contract.Thesellerwillgivea new warranty for goodsthathave been

replacedorrepairedwithinthewarranty,howeveronlytotheexpiraonofthe

originalproduct’swarrantyme.Thewarrantyincludestherepairofadefec-

ve partordevice, orifneeded, a newpartordevice, but not installaon or

exchangecosts.Undernocircumstanceisthesellerliablefordamagescompen-

saonforindirectdamage.

Register Parameter descripon Data Type Value Range

4x0001 Manufacturer 16bit 0...8

0=FläktWoods

1=Rosenberg,

2=Nicotra-Gebhardt

3=Comefri

4=Ziehl-Abegg

5=ebm-papst

6=Gebhardt

7=Nicotra

8=Commonprobe

4x0002 Formulaunit(ifmanufacturer

selecon=commonprobe) 16bit 0...5 0=m3/s,1=m3/h,2=cfm,

3=l/s,4=m/s,5=f/min

4x0003 K-factorintegral 16bit 0...9999 0...9999

4x0004 K-factordecimal 16bit 0...999 0...999

4x0005 Responseme 16bit 0...20 0...20s

4x0006 PIDcontrolunit 16bit 0...1 0=Pressure,1=Flow

4x0007 PIDpressureref 16bit -250...2500(model2500)

-700...7000(model7000)

-250...2500(model2500)

-700...7000(model7000)

4x0008 PIDowrefinteger 16bit 0...30000 0...30000

4x0009 PIDowrefdecimal 16bit 0...999 0...999

4x0010 PIDpvalue 16bit 0...10000 0...10000

4x0011 PIDiinteger 16bit 0...1000 0...1000

4x0012 PIDidecimal 16bit 0...99 0...99

4x0013 PIDdinteger 16bit 0...1000 0...1000

4x0014 PIDddecimal 16bit 0...99 0...99

4x0015 Overdrivevalue 16bit 0...100 0...100%

4x0016 Overdriveacve 16bit 0...1 0=O,1=On

4x0017 Temperaturecompensaon 16bit 0…1 0=O,1=On

4x0018 Temp.comp.startTE 16bit -45…50 -45…50°C

4x0019 Temp.comp.stopTE 16bit -50…45 -50…45°C

4x0020 Temp.comp.dropintegerpart 16bit 0…99 0…99%

4x0021 Temp.comp.dropdecimalpart 16bit 0…999 0.0…0.999%

4x0022 PIDPressureRefSP1 16bit -250...2500(model2500)

-700...7000(model7000)

-250...2500(model2500)

-700...7000(model7000)

4x0023 PIDPressureRefSP2 16bit -250...2500(model2500)

-700...7000(model7000)

-250...2500(model2500)

-700...7000(model7000)

4x0024 PIDFlowRefSP1integer 16bit 0...30000 0...30000

4x0025 PIDFlowRefSP1decimal 16bit 0...999 0...999

4x0026 PIDFlowRefSP2integer 16bit 0...30000 0...30000

4x0027 PIDFlowRefSP2decimal 16bit 0...999 0...999

4x0028 Flowunit(displayandPIDSP) 16bit 0...5 0=m3/s,1=m3/h,2=cfm,

3=l/s,4=m/s,5=f/min

Funconcode03-Readholdingregister,Funconcode06-Writesingleregister,

Funconcode16-Writemulpleregisters

Funconcode05-Writesinglecoil

Register Parameter descripon Dat a Type Value Range

0x0001 Zeroingfuncon Bit0 0...1 0=O,1=On

Thepartsleoverfrominstallaonshouldberecycled

accordingtoyourlocalinstrucons.Decommissioned

devicesshouldbetakentoarecyclingsitethatspecial-

izesinelectronicwaste.

STEP 9: MODBUS REGISTERS

RECYCLING/DISPOSAL

WARRANTY POLICY

Funconcode02-Readinputstatus

Register Parameter descripon Dat a Type Value Range

1x0001 Input:BININ Bit0 0...1 0=O,1=On

MODBUS REGISTERS CONTINUED

STEP 7: Fixed output

Fixedoutputsengscanbeenabledtosetthecontroloutputtoapresetvalue.Pri-

marypurposeofthisfunconalityistoenabletheadjustmentofairvalvesandter-

minalswithouttheDPT-Ctrlaecngtheductpressureorairow.Itcanalsoaidin

troubleshoongtheinstallaon.

1)Toenablethexedoutput,scrolltoitsposioninthemenu.

2)Presstheselectbuonandselectthedesiredxedoutputvalue.Theoutputwill

nowstayatthisvalueindenitely.Innormaloperaonmode(shownbelow),the

upperrowofthedisplaywillshowFIXEDxx%toindicatetheoutputisxed.

FIXED OUTPUT

OFF

SELECT

UP

DOWN

FIXED 50 %

184 Pa

3)Toenablethenormalcontroloutputanddisablethexedoutput,scrolltoits

posion,selectitandsetvaluetoOFF.

Fixed output funcon is also available via Modbus. (4x0016: Overdrive acve,

4x0015:Overdrivevalue)

Funconcode04-Readinputregister

Register Parameter descripon Dat a Type Value Range

3x0001 Programversion 16bit 0...1000 100...9900

3x0002 PressurereadingA 16bit -250...2500(model2500)

-700...7000(model7000)

-250...2500(model2500)

-700...7000(model7000)

3x0003 Input0...10V 16bit 0...100 0...100%

3x0004 InputPT1000 16bit -500...500 -50...+50°C

3x0005 InputNi1000 16bit -500...500 -50...+50°C

3x0006 InputNi1000-LG 16bit -500...500 -50...+50°C

3x0007 InputNTC10k 16bit -500...500 -50...+50°C

3x0008 Flowm3/s 16bit 0...10000 0...100m3/s

3x0009 Flowm3/h 16bit 0...30000 0...30000m3/h

3x0010 Flowcfm 16bit 0...30000 0...30000cfm

3x0011 Flowl/s 16bit 0...3000 0...3000l/s

3x0012 Velocitym/s 16bit 0...1000 0...100m/s

3x0013 Velocityf/min 16bit 0...5000 0...5000f/min

STEP 8: Using the 2SP-feature

2SP(setpoint)isafeaturewithabinaryinputtoselectbetweentwouser-adjustable

setpoints.Thedesiredsetpointcanbeselected,forexample,withweeklyclock,turn

switchorkeycardswitch.

1)SelectINPUT=>BININ. INPUT

BIN IN

SELECT

UP

DOWN

J1

J2

J3

NTC10k / BIN IN

2)Setthejumpersasshownbeside

todeterminetheinputsignal.

This manual suits for next models

2

Other HK Instruments Controllers manuals