Spectronik MGPR User manual

MINIATURE GAS

PRESSURE REGULATOR

MGPR

USER GUIDE

VERSION 2.2 SEPTEMBER 2022

Failure to follow these safety instructions could result in gas leakage, injuries, damage

to the Miniature Gas Pressure Regulator (MGPR) or other property.Read all the safety

information below before using MGPR.

Handling Handle MGPR with care.MGPR is not designed for extreme conditions, rough handling, vibration, shock

or drop.Keep MGPR away from heat, flame, strong sunlight, water, dust, soil or mud.Do not use adamaged

MGPR.

Repairing Do not troubleshoot, disassemble or tamper with MGPR.Do not attempt to repair or replace any

component by yourself.

Hydrogen Follow all local rules and regulations for safe handling, storage and usage of Hydrogen gas.Do not

smoke when operating MGPR.It is recommended to operate in awell-ventilated environment.

Pressure Never operate beyond MGPR’s rated inlet pressure of 350bar.

Connectors and ports Never force a connector into a port or apply excessive pressure.If the connector and port

do not join with reasonable ease, they probably do not match.Check for obstructions and ensure that the

connector matches the correct port.

High-consequence activities MGPR is a customized system with pending safety tests and certifications. It is not

intended for use where the failure of the system could lead to death, personal injury or severe environmental

damage.

Disclaimer Every effort has been made to ensure that the information in this manual is accurate.This manual

serves to adequately recommend safe operating procedures but shall not be treated as comprehensive.Do not

use MGPR in any other way than the one recommended in this manual. Spectronik reserves the right to change

system specifications, appearance or discontinue the product at any time.

Warranty Spectronik warrants the included hardware product and accessories against defects in materials and

workmanship for 1 year after delivery. Spectronik does not warrant against normal wear and tear, nor damage

caused by accident or abuse.

To obtain service, contact support@spectronik.com

SAFETY, HANDLING & SUPPORT

© 2022 Spectronik Pte. Ltd., All Rights Reserved.

Spectronik, the ‘S’ logo, and PROTIUM are registered trademarks of Spectronik Pte. Ltd.

WARNING:

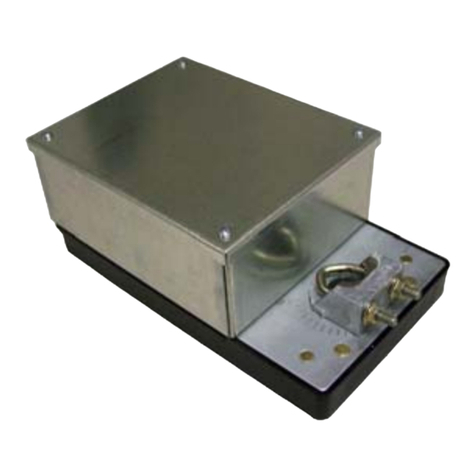

ITEM DESCRIPTION

1MGPR 6Gas outlet port

NPT ¼ to PU 8mm

2On/Off manual valve 7Refueling port with cap

M12 x 1.25

3Carbon fiber cylinder plug

M18 x 1.5 8Refueling adapter

4Gas pressure transducer socket 9Refueling hose mating plug

M12 x 1.25

5

Gas pressure transducer

NPT 1/8 (to MGPR)

M12 x 1 (to receptacle)

10 Refueling port mating plug

M12 x 1.25

1OVERVIEW

CHAPTER 1 | OVERVIEW

* ID17 CS3 EPDM O-ring may or may not be required depending on user’s gas cylinder thread. Included

as spare part in the shipment.

2

1

3

4

5

6

8

9

10

*

7

ITEM DESCRIPTION

11 Gas pressure transducer receptacle

M12 x 1 14 Threaded socket to Hydrogen source

NPT 1/4

12 Stainless steel refueling hose 15 Spare O-rings

13 Refueling hose mating socket

to (9) M12 x 1.25

CHAPTER 1 | OVERVIEW

15

14

13

11

12

MGPR

Gas media Hydrogen

Rated inlet pressure 350bar

Min inlet pressure 10bar

Gas outlet pressure (@ rated flow) 0.45-0.75bar (factory set during order)

Max outlet pressure (@ zero flow) Gas outlet pressure + 0.3bar

Rated flow rate 40 SLPM

Operating temperature [-20,85]oC

Operating lifetime 10,000 cycles

Outer body material Al 2A14-T6

Core internal material SS 316/ H62/ TC4

Core sealing material PTFE

Sealing gasket material NBR

Dimension 75 x 85 x 58 mm

Weight 270g

Connection to gas cylinder M18 x 1.5

Connection to pressure sensor NPT 1/8

Connection to refueling hose M12 x 1.25

Gas outlet connector NPT 1/4 to PU 8mm

2SPECIFICATIONS

CHAPTER 2 | SPECIFICATIONS

1. Prepare the necessary adapter to link the threaded socket to Hydrogen source (14). This adapter is

not provided due to the different connector standards of Hydrogen source cylinders worldwide.

Warning:the pressure gauge provided has amaximum pressure of 25MPa.It is assumed that the

Hydrogen source will be standard industrial steel cylinder with pressure of less than 20MPa and that filling

the carbon fiber cylinder will be by means of pressure cascade.If you are connecting directly to a gas

booster pump or higher source pressures, change the pressure gauge or bypass it completely.At any time,

do not operate higher than 35MPa.

2. Connect the refueling hose mating socket (13)to the refueling hose mating plug (9).

3. Open the refueling cap.Keep it in asafe place, do not lose it.Connect refueling port mating plug (10)

into the refueling port (7) of MGPR.Do not use excessive force at the end of the turns.

4. Turn on your Hydrogen source.

5. Slowly turn On the On/Off manual valve by turning it anti-clockwise.Hissing sound can be heard as gas

rushes in from the source into the carbon fiber cylinder. Continue turning the valve anti-clockwise until it is

fully opened (i.e. cannot be turned anymore).Do not use excessive force at the end of the turns.

6. The gas will now fill into the carbon fiber cylinder until it reaches equilibrium with the source.

7. If you are using agas booster pump, it can now be turned on.

8. At the end of the filling process, turn off your Hydrogen source.Close the On/Off manual valve by turning it

fully clockwise.Caution: at this point, there is still high pressure gas remaining in the refueling hose.Remove

your blocker at gas outlet port to release the remaining gas through the MGPR low pressure gas outlet

port.

9. Once all the gas is released, fully remove refueling port mating plug from the refueling port and put back the

refueling cap.

10. The carbon fiber cylinder is now ready for usage.

1. Visually check MGPR for obvious cracks or other physical damage.Warning:never use a faulty regulator.

2. Ensure that On/Off manual valve (2) is in the Off state (fully clockwise).Do not over-tighten.

3. Ensure that gas pressure transducer (5) is securely connected.If you do not wish to use the gas

pressure transducer, then ensure that the gas pressure transducer socket is sealed with the plug

provided.

4. Block the gas outlet port (6) either with the blocker provided or gas tubing and valve.

5. Connect MGPR to the carbon fiber cylinder by manually turning the threaded carbon fiber cylinder plug

(3) into its corresponding female socket at the cylinder neck.There is no need to apply excessive force at

the end of the turns.The carbon fiber cylinder is now ready for gas filling.Note:an ID17 CS3EPDM O-ring

(provided) may or may not be needed depending on your carbon fiber cylinder thread design.

3OPERATING PROCEDURES

3.2 FILLING THE CARBON FIBER CYLINDER

3.1 SETTING UP MGPR

CHAPTER 3 | OPERATING PROCEDURES

1. Remove the blocker at gas outlet port that was in place during gas filling process.

2. Connect the gas outlet port to your desired application, e.g. to the inlet of the supply valve of a fuel cell

system.

3. Open the On/Off manual valve by turning it anti-clockwise slowly until the end.Gas from inside the carbon

fiber cylinder will now flow out through the gas outlet port.

4. To turn off the gas at the end of usage, shut off the On/Off manual valve by turning it clockwise.

3.3 USING THE FILLED CARBON FIBER CYLINDER

CHAPTER 3 | OPERATING PROCEDURES

The MGPR can be used as alab bench-top equipment without being connected to a carbon fiber cylinder.

1. The low regulated output pressure at the gas outlet port is always open.Put ablocker to prevent gas from

coming out.

2. The On/Off manual valve serves to open or close the connection between your Hydrogen source which

enters the MGPR through the refueling port and the carbon fiber cylinder which is connected at the carbon

fiber cylinder plug.If you are not going to use acarbon fiber cylinder, make sure that the On/Off manual

valve is turned OFF (fully clockwise).Caution: unregulated high pressure gas will gush out from the carbon

fiber cylinder plug if the On/Off manual valve is not fully turned OFF.

3. Turn on your Hydrogen gas supply.Hydrogen gas will now flow through the refueling hose and enter the

MGPR through the refueling port.

4. Remove the blocker from the gas outlet port.Regulated low pressure Hydrogen gas will now come out

from the gas outlet port and can be channeled to your desired application, e.g. to the inlet of the supply

valve of a fuel cell system.

5. To turn off the gas at the end of usage, shut off your Hydrogen source directly.Reminder: the On/Off

manual valve on the MGPR is not in use in this configuration and shall be fully OFF (clockwise) at all times.

3.4 USING THE MGPR WITHOUT CARBON FIBER CYLINDER

Low

Pressure

Outlet

1st Stage Pressure

Regulator

On/Off

Manual Valve

Carbon Fiber Cylinder

Hydrogen

Source

2nd Stage Pressure

Regulator

CHAPTER 3 | OPERATING PROCEDURES

REMINDER

When not in use, keep MGPR in its original box and store it in a cool, dry place.

3.5 STORAGE

•Wear safety goggles and gloves at all times.

•Ensure connections are firm and secure, but do not use excessive force to over-tighten.

•Never operate MGPR at inlet pressure beyond 350bar.

•Carbon fiber cylinder will become warm when filled with Hydrogen gas.Never fill a carbon fiber cylinder too

quickly.If you are using a booster pump, it is advisable to pause the filling process every 30-50bar to prevent

over temperature.

Stainless steel 316 body

Welded configuration without sealing o-rings

10-90% proportional voltage output

Voltage reversal protection

Hydrogen gas pressure measurement

Hydraulic system pressure measurement

Pressure range: 0-50 MPaG

Output voltage (Io): 0.5-4.5VDC

Precision (including non-linearity, hysteresis, repeatability and calibration

error, 25oC and Vcc 24VDC): +/-0.5% F.S.

Long term stability: +/-0.25% F.S. per year

Pressure cycling: >= 5 x 106

Operating temperature: -40 to 120oC

Storage temperature: -40 to 105oC

Over pressure: 1.5X

Burst pressure: 2X

Response time: 10ms

Supply voltage (Vcc): 4.75-5.25VDC

Output load resistance: >= 10k.ohm

Over voltage: 16VDC

Reverse over voltage: -16VDC

Insulation resistance: >= 20M.ohm @ 100VDC

Ingress protection: IP65

Vibration: X/Y/Z, 20g, sine 11ms

Shock: 10g, 5-2000Hz

4GAS PRESSURE TRANSDUCER

CHAPTER 4 | GAS PRESSURE TRANSDUCER

4.1 FEATURES AND APPLICATIONS

4.2 TECHNICAL SPECIFICATIONS

CHAPTER 4 | GAS PRESSURE TRANSDUCER

Ensure that all system connections are secure and leak free. Hydrogen leakage may cause fire or explosion in

extreme cases.

If the pressure port of the transducer is blocked by a foreign object, do not use asharp tool to clear the

passage.It is recommended to dissolve the foreign object in asolvent instead.

Do not tamper with the device. Contact us for re-calibration purposes.

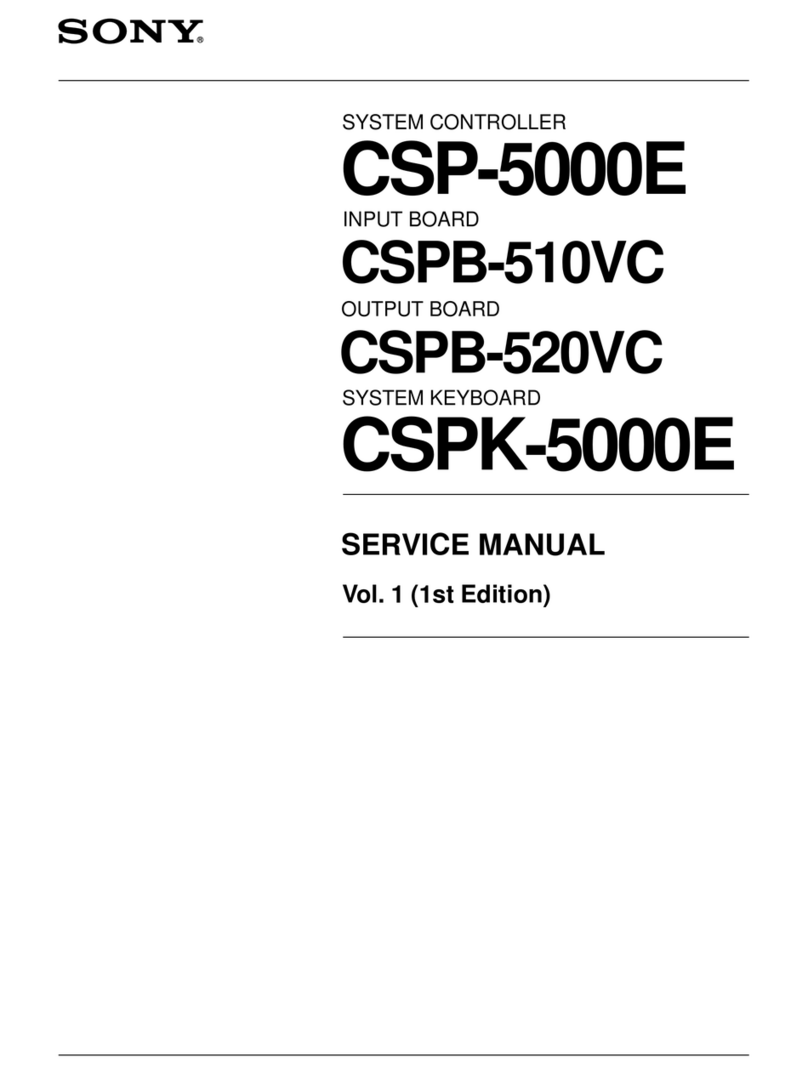

Dimensions in mm

Signal

(white)

5V+

(brown)

5V-

(blue) NC

1/8NPT

10.0

53

M12x1

Ø 14

1. Pin definition

V

2. Wiring diagram

Shield

Load Power

Supply

4.3 NOTES

Other Spectronik Controllers manuals