−8−

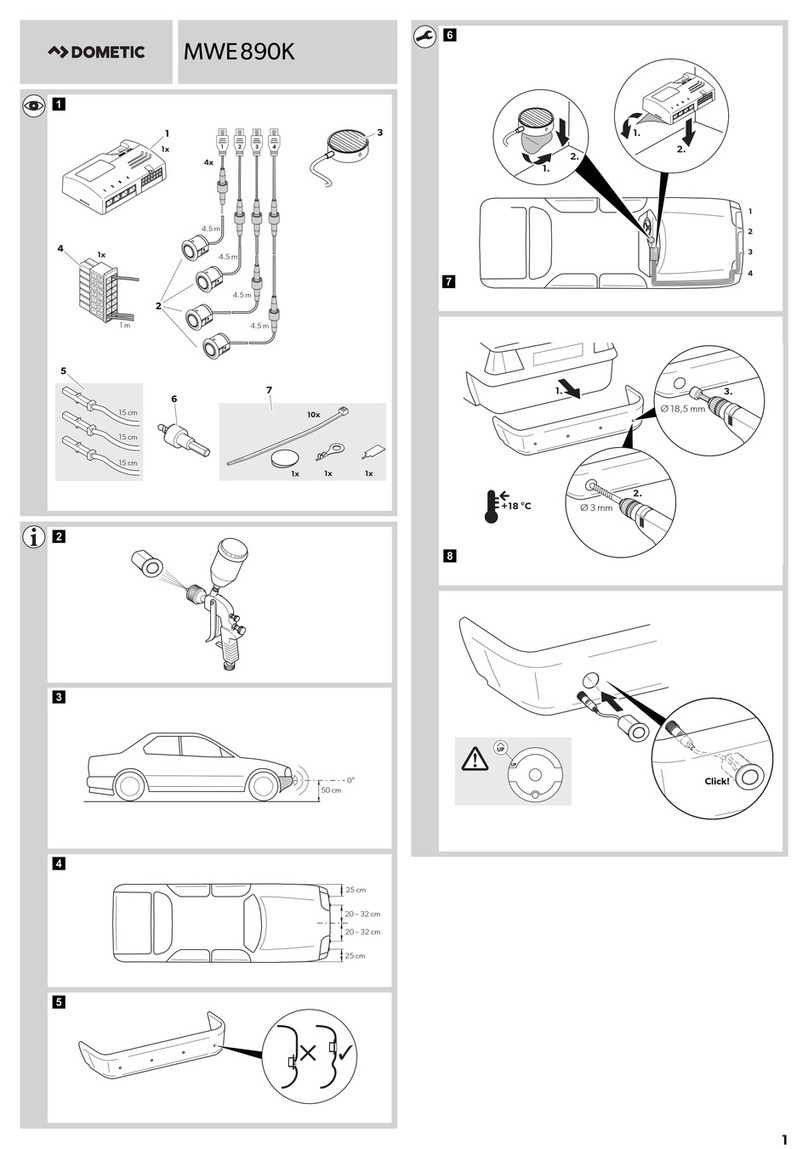

Parts List

Instruction Manual

Hardware Set

M6Bolt and Nut

M6Flat Washer

M6Lock Washer 1 each

Double‑Sided Tape

Splice Tie Wrap

Hose Clamp

Vacuum FilterT‑Fitting

4mm Hose

EVC Stepping Motor Extension Harness

EVC Display Unit

1

111 1

11

1 1Set 2

3 1 1Set 1Set

2 3 4

58

9 10 11 12

13 14

18

15 16

17

2.7m

φ6用

100mm…………Qty.5

1m

4‑4‑4mm 4mm ,6mm 1 each

1.0m

● Tools required for installation: Test Light or Volt Meter, Screwdriver, Socket Wrench,

Wire Cutters, Hose Cutters and Pliers.

● Retain all unused parts.

Power Harness

1

6mm Hose

1m

1801‑SA033

1801‑SA004

6mm……

4599‑RA016

4mm……

4599‑RA017

Main Harness

1.5m

Scramble Harness Input Signal Harness

12

1m1.5m

6 7

(1 for Speed & RPM,

1 for Throttle signal)

取付けは、必ず専門業者に依頼してください。

取付け前及びご使用前に必ずお読みになってください。

本書はお読みになった後も、本製品の側に置いてご活用ください。

ご使用中にわからないことや、不具合が生じた際に便利です。

21207‑023T

1998年○月○日発行

Ver.3‑1.0

E L E C T R O NI C VA L V E C O N T R O LL E R

HKS ELE CT T R O N IC S TE C H NO L O G Y

1

19 20

1

取付けは、必ず専門業者に依頼してください。

取付け前及びご使用前に必ずお読みになってください。

取付けは、必ず専門業者に依頼してください。

取付け前及びご使用前に必ずお読みになってください。

取付けは、必ず専門業者に依頼してください。

取付け前及びご使用前に必ずお読みになってください。

本書はお読みになった後も、本製品の側に置いてご活用ください。

ご使用中にわからないことや、不具合が生じた際に便利です。

取付けは、必ず専門業者に依頼してください。

取付け前及びご使用前に必ずお読みになってください。

本書はお読みになった後も、本製品の側に置いてご活用ください。

ご使用中にわからないことや、不具合が生じた際に便利です。

取付けは、必ず専門業者に依頼してください。

取付け前及びご使用前に必ずお読みになってください。

本書はお読みになった後も、本製品の側に置いてご活用ください。

ご使用中にわからないことや、不具合が生じた際に便利です。

車種別配線位置図

Connecting Manual

11

Quick Manual Function Manual

EVC機能解説

エンジン回転数

ブースト

●オフセットとは?

オフセットとは、AモードまたはBモードで設定した目標ブーストに対して実際のブーストがその

圧にならない場合に、値を調整することによって目標ブーストに安定させることができる機能です。

オフセット値を上げると実際のブーストは上がり、オフセット値を下げると実際のブーストは下

がります。排気バイパスタイプがスイングバルブタイプ、ポペットバルブタイプのどちらでも、

この関係性は変わりません。

目標ブースト(例:100kPa)

実際のブースト

(例:80kPa)

図1.オフセット100%の場合

エンジン回転数

ブースト

目標ブースト(例:100kPa)

実際のブースト

(例:100kPa)

図2.オフセット120%の場合

●スクランブルブーストとは?

スクランブルブーストとは、AモードまたはBモードで設定した目標ブーストに対して、設定した

ブーストを一定時間プラスことができる機能です。

スクランブルブースト設定モードで設定したブースト値に、実際のブーストがなるわけではあり

ませんので注意してください。

図3.スクランブル機能未使用の場合

エンジン回転数

ブースト

目標ブースト(例:80kPa)

実際のブースト

(例:80kPa)

エンジン回転数

ブースト

●ワーニングとは?ドロップブーストとは?

ワーニングとは、設定したワーニングブーストに対して実際のブーストがその値を超えた場合に、

画面および音で警告をするとともに目標ブーストを下げる機能です。

ドロップブーストとは、ワーニング作動時に目標ブーストの下げ幅を決定できる機能です。ドロ

ップブーストOFFではノーマルブーストに下がります。

ドロップブースト設定モードで設定したブースト値に、実際のブーストがなるわけではありませ

んので注意してください。

ワーニングブースト(例:120kPa)

ノーマルブースト

(例:60kPa)

図5.ドロップブーストOFFの

ワーニング作動時

実際のブースト

(例:60kPa)

エンジン回転数

ブースト

ワーニングブースト

(例:120kPa)

ドロップブースト設定値

(例:20kPa)

図6.ドロップブースト設定後の

ワーニング作動時

実際のブースト

(例:80kPa)

図4.スクランブル機能使用の場合

エンジン回転数

ブースト

目標ブースト

(例:80kPa)

スクランブル

開始ポイント

スクランブル

ブースト設定値

(例:20kPa)

実際のブースト

(例:100kPa)

目標ブースト

(例:100kPa)

目標ブースト

(例:100kPa)

E05121−K000??−00

Ver.

3−1.

01

スクランブル設定時間

操作クイックマニュアル

1.イグニッションスイッチを"ON"にする

エンジンキーを回してイグニッションスイッチを"ON"にしてEVCおよび車両から異音・異臭

がないことを確認してください。問題がなければそのままエンジンをかけてください。

E05121−K000??−00

Ver.3−1.

01

操作マークの説明 :短く押す :ボリュームを回す :1秒以上押し続ける

2.圧力単位を設定する

初めて使用する場合は、自動的に下図のような画面が表示されています。

ボリュームを回してブースト表示の圧力単位をPAS(kPa)またはPSIから選択してください。

設定が終了したらボリュームを押して決定してください。

2.排気バイパスタイプを設定する

ボリュームを回して排気バイパスタイプの設定を行ってください。

アクチュエータを使用するスイングバルブタイプの場合「ーS−」を、ウエストゲートを使用

するポペットバルブタイプの場合「ーPー]を選択してください。

設定が終了したらボリュームを押して決定してください。

3.ノーマル最大ブーストを設定する

EVC取付け後のノーマル最大ブーストの設定を行ってください。

手動での設定を行う場合は、ボリュームを回してノーマル最大ブーストを入力してください。