HLP Data BMS4S User manual

1

1

BMS4S user manual 1.4

Valid for software version 1.4.55

BMS4S DIY kit: ......................................................................................................................................... 1

Introduction ............................................................................................................................................ 2

Normal usage .......................................................................................................................................... 2

Basic configuration .................................................................................................................................. 3

Additional Commands ............................................................................................................................. 9

System Commands ................................................................................................................................ 13

Installation ............................................................................................................................................ 14

Equipment connection description ....................................................................................................... 16

Testing ................................................................................................................................................... 19

4SBalancer............................................................................................................................................. 20

I/O description ...................................................................................................................................... 22

BMS4S DIY kit:

The basic kit contains: 1: a BMS4S PCB, 2: and a box to mount it a in. Beside this you might also need

3: three temperature sensitive resistors, 4: a push-button for temporary charging level setting, 5: a

12 V LED for low SoC early warning, 6: a Bluetooth radio for communication with BMS4S, 7: an

adapter for serial to USB connection to BMS4S, and 8: a buzzer/alarm.

2

2

There is also an automatic balancer available, 4Sbalancer:

However, we do not think this is a necessity. Most installation will work fine if the battery bank is

manually balanced once or twice a year with a 3.6 V LiFePO4 charger.

Introduction

BMS4S is versatile battery management system that can be used in many different configurations. It

is designed to supervise four LiFePO4 cells and automatically control that they are kept within

specified boundaries. It can be used with default configuration straight out of the box, but can also

easily be changed and used in a completely different setup. There are few limitations built into it.

You will find a description on how to install the BMS4S in chapter “Installation”, with more details on

exactly how to connect all wires in chapter “Equipment connection description”. After installation

you should test that it is working as expected. This is described in chapter “Testing”.

During normal usage there is not much you need to do, but there are some things that can be of

interest for most users. This is described in chapter “Normal usage”.

How you use your cellular phone to connect to BMS4S is described in chapter “Normal usage”.

Available commands are described in three places: “Basic configuration”, “Additional commands”

and “System commands”. All commands are built from one or two small letters, so in the Basic

configuration chapter the commands can be derived from the printout, the capitals in each line is

the command to use to change that setting. To give any commands that changes any settings you

must first unlock the device with command du=1234. Default PIN is 1234, but you should change this

after installation to your own one, command dp=nnnn. All system commands are protected by

another level of protection since you can make BMS4S completely useless by a single bad system

command. To unlock system commands, use command: fu=1632. Do not use any system command if

you have not read the user manual carefully first. But there is always a way to get back to the

original settings from factory, see command: fr.

And you can always get a command summary when connected to BMS4S with command: h.

Normal usage

BMS4S is switched on as long as it has power on terminal +12V. Normal usage is to take a look at the

LED every now and then. If it is blinking twice, then there is less than 20% energy left in the

batteries. If it is blinking once, it is less than 10%. You can change this to start the blinking at any

level of charge. Command sl=nn.

3

3

Beside the LED you have the push-button. When you are on your way home and the boat will be

unused for a while, then your batteries lifetime will increase if they are not left fully charged. Then

press it until you see 3 long blinks on the LED. This will decrease the voltage when BMS4S will stop

charging with 0.10 V, which equals approx. 80% SoC when using default settings. Or keep in pressed

until 4 long blinks on the LED. This to achieve approx. 60% SoC (decreases the stop-voltage with 0.15

V).

When you press the push-button for a single long blink, three things will happen: the charging

voltage will be reset, if an alarm is beeping it will be rest and you will wake up the Bluetooth radio

(if you set it to switch it off instead of sleep, see command wm) that you can connect your cellular

phone to. BMS4S has two ways of communication: a socket to plug in a FTDI adapter and a socket to

plug in a bluetooth module of type HM-10 or equivalent. You connect with e.g. “Serial Bluetooth” on

an android phone and with “BLE Terminal” on an I-phone. These are available for free on Google

play and Apple appstore. When installed, scan, find and connect to the Bluetooth device.

If you give the command p (print) you will get a printout looking like this:

U=3.264 3.268 3.262 3.266 13.060 I=-1.335 SoC=35

This (U=…) means that all four cells have 3.26 V each, adding up to 13.06 V. Next, I=…, means that

right now there are 1.335 A leaving the batteries (this only works if you have connected BMS4S to a

current shunt, but that is not necessary for it to work). And SoC=… means that BMS4S estimates

current state of charge to 35 % based on the last 15 minutes (can be changed with te=nnn). Using

voltage and load gives a very rough estimate on higher SoC levels, but to use it as an early warning

system when SoC is getting low works well. And it does not require regular synchronizations like a

coulomb-counter based meter does.

Another thing that is good to check every now and then is command pe (print extreme point log).

See the description of it in chapter “Additional commands”. It will give you information about hoe

your batteries are performing.

Basic configuration

The starting point before changing anything is to take a look at current configuration. You do the

with command ps (print setup):

WorkMode= 1

BatterySize= 100 Ah

BatteryUse= 30 Ah

BatteryCharging= 250 A

TimeEstimate= 900 s

TimeBeep= 200 ms

TimeRelay= 300 ms

TimeprecharGe= 0 s

VoltBalance= 3.500 V

VoltDifference= 0.000 V

BalanceInit= 0.000 Ah

BalanceAmount= 0 %

4

4

StartLedblinking= 20 %

VoltWarn= 3.100 V

VoltLow= 3.050 V

VoltVerylow= 3.000 V

VoltswitchOnagain= 3.100 V

TimeLow= 15 s

VoltswitchOnagain= 3.100 V

VoltAbsorb= 3.500 V

TimeAbsorb= 1200 s

VoltHigh= 3.600 V

TimeHigh= 5 s

TimeChargeoff= 14400 s

VoltResumecharge= 3.250 V

TimeWarning= 120 s

Templow1= 5 C

Tempwarn2= 50 C

Temphi3= 60 C

Temptarget4= 95 C

Temphi5= 100 C

Tempres6= 90 C

Limit-start0= 25

Limit-step1= 25

Limit-step2= 10

Limit-step3= 2

TimePrintout= 0 s

TimeMemlog= 315/600 s

The first block of lines describes some basic setup of BMS4S:

WorkMode= 1: this means that a current shunt is connected.

The value to set is calculated by adding the values for the following features:

0 workmode normal

+1 there is shunt connected

+2 measures 12V only

+4 supervised and supervising another BMS4S

+8 xtemp is used to supervise a battery

+16 xtemp is used to supervise an alternator

+32 switch off Bluetooth instead of sleep, will save some 3 mA

+64 Swedish CSV (comma separated values in printouts for import into Swedish excel)

+128 always count coulomb even if balancing is ongoing, reports might be biased

+256 only p at tp= instead of both p and po, useful at certain test-cases

+512 power off when high bat temp, normally only charging will be stopped

+1024 all off port = charge on for bistable charging relay (no very low volt relay available)

5

5

+2048 precharge on port BC1 (no automatic balancing possible), use if supervised mode

So, if you e.g. have connected a current shunt and have two BMS4S supervising each other

you shall give the command wm=5.

BatterySize= 100 Ah: size of installed LFP bank. Change with bs=nnn as implied by the capital letters.

But before you can start changing anything you must unlock the device by command (device

unlock) du=1234. You should change this to your own PIN by command (device pin) dp=nnnn. If you

have forgotten your PIN, you can set a new one within 30 seconds after you have switched on the

power to BMS4S. You can remove the PIN by command dp=0 (not recommended). (note, all

commands are given with small letters)

BatteryUse= 30 Ah: You use 30 Ah every 24 hour which means that you get out of power after 3

days without charging. Used to estimate SoC if no current shunt is connected. Change with

command bu=nnn. The same applies to all commands below, the capital letters in the printout imply

the command to use when changing the setting. If BatteryUse is set too high, SoC estimates will also

be too high.

BatteryCharging= 50 A: the most common charging method will charge with 50 A. Used to estimate

unbalance between cells if no current shunt is connected. If you are using automatic balancing using

coulomb-counting, you should also install a shunt to ensure that the unbalance-estimates are as

good as possible (see chapter “Equipment connection description” below).

TimeEstimate= 900 s: The Soc estimate is based on the last 900 seconds (15 minutes).

TimeBeep= 300 ms: each beep will be 300 ms long. If you have a really loud beeper you might want

to shorten this to achieve a bearable sound level.

TimeRelay= 300 ms: when the bi-stable relay is operated it is done with a 300 ms long pulse

TimeprecharGe= 0 s: if you have equipment with high start-up current you might want to pre-charge

them before operating the relay. If you set this timer between 1 and 10 s you will get a pulse to use

for a small relay with a resistor parallel to the real relay that will soft-start the equipment. This pulse

comes on either the port “Osup” or “BC1”, see command wm=nnnn.

The second block of lines describes how balancing will be handled.

VoltBalance= 3.500 V: There are two ways to use the connected 4sbalancer (sold separately). Both

uses this value as the starting point when the balancing procedures are initiated. This value shall

normally not be set below 3.4 V. If you do not have a 4sbalancer these settings will be used to

calculate how big the unbalance is.

VoltDifference= 0.000 V: This is the first and simplest balancing alternative. If this value is set

(recommended value: 0.050 V) then when the first cell has passed the BalanceVolt-value (during

charging) and the voltage difference between two cells exceeds the VoltDifference-value the

balancing will start and proceed as long as the BalanceVolt-value is exceeded and the unbalance

remains. But since the balancing current is low (0.2 A) and that balancing is done only while

charging, this method only works when the battery bank is reasonable well matched (all cells have

close capacity values). Otherwise, the second method is recommended. (Or you can replace the

6

6

resistors in the 4sbalancer with ones with lower resistance (the ones installed are on 33 ohm each)

to increase the current to be able to handle larger unbalances. But then ensure that the produced

heat can be ventilated away)

BalanceInit= 0.000 Ah: This is the second balancing alternative. When the first cell passes

BalanceVolt-value during charging (and VoltDifference is set to 0.000) coulomb counting starts and

continues until the last cell passes it. If the difference between the best and the worse cell then

exceeds the BalanceInit-value (recommended value: 0.5% of the total battery capacity, i.e. 0.500 Ah

for a 100 Ah battery bank) the balancing will start and continue until the calculated balancing value

is balanced away. It is recommended that you have installed a way to measure the current if you use

this method. See chapter “Equipment connection description” how to do that. Note: VoltDifference

must be set to 0 (vd=0) to activate this balancing alternative.

You can see the coulomb counters with the sort Coulomb (As) with command po, and all calculated

results presented in Ah with command pe. You can use this information to manually balance the

cells with a 3.6 V charger.

BalanceAmount= 0 %: when balancing starts, it will aim to reduce the difference with the

percentage stated here. The recommended start value 25% is to ensure that it does not overshoot

the target. This is especially important if no shunt is connected, since it then bases the coulomb

counting on what value is set for BatteryCharging. If you find multiple similar entries in the “extreme

point log” (command pe) before an unbalance is cured, you can increase this with e.g. 25% to speed

up the process.

The third block of lines describes how and when a low voltage event shall be handled, i.e. when

shall the loads be disconnected.

StartLedblinking= 20 %: when SoC gets below 20% the LED will start blinking as an early warning, 2

blink for 10-19 % and 1 blink for 0-9 %.

VoltWarn= 3.100 V: this is the first level of protection. At 3.100 V the buzzer/alarm will start beeping

“low voltage”. It is now time to start the engine and start charging to prevent that any loads get

disconnected.

VoltLow= 3.050 V: this is when the “not necessary” loads will be disconnected via the bi-stable relay.

VoltVerylow= 3.000 V: this is when all loads will be disconnected. You can use this e.g. if you have a

second bi-stable relay isolating the batteries completely. If BMS4S is not disconnected it will go into

low power mode and only do the most important tasks in a slow paste, like switching on the system

again once charging has brought the voltage up to VoltswitchOnagain.

TimeLow= 15 s: the above voltages must be below the values for 15 seconds before the action is

taken. If you use high power things like thrusters and starters for longer continues time than this you

might want to extend this time, command tl=nn.

VoltswitchOnagain= 3.100 V: when the voltage har reached this level after a low-voltage event the

system will go back to normal again.

The fourth block of lines describes when charging shall be discontinued.

7

7

VoltAbsorb= 3.500 V: Normally LFP cells are fully charged at 3.6-3.65 V. Some chargers miss settings

adopted for LFP, so they will not manage to get the voltage that high. Then you can set an

“absorption” level that it can reach, and the let it stay there for a time. Here this time starts at 3.5 V.

TimeAbsorb= 1200 s: and this timer will keep the charger on for 1200 s (20 min) before charging is

stopped

VoltHigh= 3.600 V: All charging sources that can achieve 3.6 V will be stopped at that voltage. 3.6 V

corresponds to approximately 90 % SoC when charging is done with 0.4 C, and is a good compromise

between battery usage and battery life length.

TimeHigh= 5 s: but the first cell must exceed the set voltage in more than 5 s before the action is

taken.

TimeChargeoff= 280/14400 s: the total time it will be switched off is 14400 s (4 hours) and so far it

has been switched off for 280 s. If it is set to 65500 it means it will never switch on charging, then it

is only VoltResumecharg that will do that.

VoltResumecharg= 3.200 V: if the voltage drops down to this level, charging will resume even if

TimeChargeoff has not elapsed.

TimeWarning= 120 s: if the voltage has not gone down below the set high voltage 120 s after

charging has been switched off, BMS4S will start beeping “high voltage”.

The fifth block of lines describes battery temperature limits.

Templow1= 5 C: if charging is started with battery temperature lower that this a “low temperature

charging” will start beeping, and charging will be stopped for a preset time (see command tc). If you

do not have any temperature sensors installed on the batteries, their temperature will be reported

as 20 degrees.

Tempwarn2= 50 C: if battery temperature exceeds 50 degrees Celsius a “high battery temperature”

will start beeping.

Temphi3= 60 C: if battery temperature exceeds 60 degrees Celsius a charging will be switched off for

a preset time (see command tc).

The sixth block of lines describes when and what to do when the alternators temperature is

getting high.

Temptarget4= 95 C: when the alternator exceeds 95 degrees Celsius, BMS4S will regulate down

charging current and keep the temperature around 95. However, the temperature is a slow feedback

on how much power the alternator generates, so the temperature will fluctuate a bit around the set

value. Therefore, it is important to set a max-value (Temphi5) where charging will pause if the

regulation is too slow. This regulation will only work if your alternator has a voltage sense cable, and

you have installed a temperature sensor on the alternator.

Temphi5= 100 C: when the alternator temperature exceeds 100 degrees Celsius, all charging will

pause. This will only work if you have installed a temperature sensor on the alternator.

8

8

Tempres6= 90 C: when the alternator temperature has come down to 90 degrees Celsius, charging

will resume if it has been paused.

Limit-start0= 25: When Temptarget4 is reached, the first step is to find the state where regulation

kicks in.

This indicates the starting point. Values between 20 and 100 is normally ok. This, and the following

limit-steps are available only to be able to tune the algorithm to your alternator if the default does

not work properly. If the regulation starts too slow (Temphi4 pauses charging) then decrease Limit-

start0 and Limit-step1 with steps around 10% until it works ok. If the temperature oscillates with

increasing amplitude until Temphi4 pauses charging, then decrease Limit-step2 with around 10%.

And if the temperature oscillates but stays below Temphi4, then decrease Limit-step3 with one (but

never to 0) until the oscillation is slow. It will never be possible to get an absolute stable

temperature since the temperature is a feedback on how much current that has been produced the

last seconds, not on what is produced right now. If you need help, run the engine until the alternator

is hot, connect to bms4s and give command ps, and then tp=10 and collect the printouts for 10

minutes. Send these then to [email protected] and we will take a look and return

recommendations on regulation-settings.

Limit-step1= 25: This is how fast BMS4S shall look for the kick-in point. Values between 20 and 50 is

normally ok.

Limit-step2= 10: This is how fast BMS4S shall react when the alternators temperature differs more

than 3 degrees Celsius from target.

Limit-step3= 2: This is how fast BMS4S shall react when the alternators temperature differs less than

3 degrees Celsius from target.

And the last block contains features useful to understand how your system is performing.

TimePrintout= 0 s: if e.g. command tp=5 is given, then the command p and po will automatically be

given every 5 s. This is useful when testing, and will prevent that the Bluetooth interface is powered

off. So, if you want the Bluetooth interface to stay on all the time, tp=65500 can be given. This will

however increase the power consumption with around 10 mA.

TimeMemlog= 315/600 s: this means that voltage and current will be logged every 600 s (10 min).

The log is started by command tm and can be printed with command pm. 315 is the time since last

log entry was saved.

A command summary and description of blinks and beeps are always available with command h:

h help

l print settings

p print voltage

ba= balance amount (%)

bi= balance initiate diff (A/100)

bs= battery size (Ah)

bu= battery usage (Ah)

bt= bluetooth 0=off, 1=sleep, 2=on

ce clear extreme points log

cm clear memory log

dl device lock

dp= set device pin

du= device unlock

fr factory reset

fu= factory settings unlock

pd print debug

pe print extreme-point log

pm print memory log

po print other info

ps print settings

9

9

pv print version

rb reboot

rp reprogram

sl= set led blink-level (%)

wm= set work mode

t1= temp low charging (C)

t2= temp high battery warn (C)

t3= temp high battery (C)

t4= temp target (C)

t5= temp high pause charging (C)

t6= temp resume charging (C)

ta= time absorb (s)

tb= time beep (ms)

tc= time of charging pause (s)

te= time for soc estimate (s)

th= time high (s)

tl= time low (s)

tm= time memory log (s)

tp= time print volt (s)

tr= time relay (ms)

tw= time before warning beep (s)

va= volt absorb (V)

vb= volt balance (V)

vh= volt high (V)

vo= volt power on again (V)

vr= volt resume charging (V)

vw= volt warning (V)

vl= volt low (V)

vv= volt very low (V)

AT AT command

a1-4= adjust battery volt

l0= initial value

l1= initial search step for charge limit

l2= second search step for charge limit

l3= third search step for charge limit

s1-4= set battery volt

sc= set current (A)

sf= save factory data

sm= set missing current

ss= set float size

sv= set verbose

wm=0 workmode normal

+1 shunt connected

+2 12V only

+4 supervised

+8 x is bat temp

+16 x is alt temp

+32 BT hard off

+64 Swedish CSV

+128 always count coulomb

+256 only p at tp=

+512 power off when high bat temp

+1024 all off port = charge on

+2048 precharge on port BC1

1 blink SoC 0-9

2 blink SoC 10-19

...

10 blink SoC 90-99

2 beep low temp charging

3 beep high battery temp

4 beep low voltage

5 beep high voltage

6 beep device failure

Additional Commands

What you normally do is described chapter “normal usage” and chapter “basic configuration”, so

you have the explanation of the important commands there. Here you have a few more commands

that can be of use.

AT AT-command

This is the exception to the statement “all commands are written with small letters”.

The Bluetooth radio this device was designed for entered AT-mode (mode where it accepts

commands) when no device is connected over the radio. So, if you want to change

something in the Bluetooth-radio you can give it e.g. a command like this: AT+NAMEMyBMS.

As soon as this is sent you will be disconnected which will get the Bluetooth device into AT

10

10

mode. Half a second after you have given the command, BMS4S will sent it to the radio.

When this is done you will see a blink on the LED. After that you have 10 seconds to

reconnect to get the response that the radio gave to your command. Unfortunately, not all

bluetooth devices work exactly the same. If this does not work, check the manual for the

bluetooth device you have and see if there are any other way to change its settings. But you

do not have to change anything, it will work fine anyway.

ce Clear Extremepointlog

will clear all entries from the log.

cm Clear Memorylog

will clear all entries from the log. You can add a text with 12 characters e.g. to state when

the logging was started. Example:

cm=24/12-09:30

p Print

will produce a printout of cell-voltage, total voltage, current and estimated SoC. Example:

U=3.283 3.283 3.283 3.284 13.133 I=0.000 SoC=41

pe Print Extremepointlog

Command pe will give a printout like this:

HVE , 3.599 , 3.600 , 3.598 , 3.599 , 14.396 , 77.130 ,

HVA , 3.517 , 3.520 , 3.518 , 3.520 , 14.074 , 14.970 ,

LVE , 2.997 , 2.996 , 2.996 , 2.997 , 11.986 , -1.663 ,

UBC , 3.563 , 3.564 , 3.563 , 3.555 , 14.264 , 75.622 , 0.720 , 0.720 , 0.810 , 0.010 ,

UBI , 3.563 , 3.564 , 3.563 , 3.565 , 14.254 , 75.622 , 0.720 , 0.720 , 0.810 , 0.010

UBE , 3.277 , 3.277 , 3.277 , 3.277 , 13.109 , -1.204 ,

VBI , 3.480 , 3.500 , 3.499 , 3.497 , 13.976 , 75.622,

This time the log contained six entries, can store around 50 entries. The log is cleared by

command ce. The first four numbers in all lines are the voltage of each cell when the event

happened. The fifth is the total voltage, and the sixth is the current at the event.

HVE means “high voltage event”, HVA “high voltage absorption event” (timeout has

happened in VoltAbsorbtion phase, see command va), LVE “low voltage event”.

UBC means “unbalance calculation” and the four last numbers are the amount of energy

that were charged into each cell at the latest cell balance measurement (done by coulomb

counting), with the sort Ah. This counting starts when the voltage passes VoltBalance . So

right now, there is an unbalance of 0.8 Ah (0.810-0.010) between cell 3 and cell 4, where cell

3 is the best charged one. UBI means “unbalance calculation and balancing initiated”

(balancing will only work if a balancing board has been installed). UBE then means that the

initiated balancing has ended. If an UBE is missing after an UBI then the system has been

switched off before the balancing ended, which is nothing to worry about. If there are

enough remining unbalance the process will restart at the next unbalance-calculation. If

there are multiple UBI in sequence with the same order of unbalance this indicates that you

can increase how much of the unbalance you try to remove each time. Then you can

11

11

increase the BalanceAmount (ba=nn, see “Basic configuration”) with steps around 25% each

time.

VBI means that voltage based balancing has been initiated. It will stop when the voltage is

back under VoltBalance.

You can use this information to manually balance the cells with a 3.6 V LiFePO4 charger.

Here you can charge cell 4 with a 5 A 3.6 V charger for 10 minutes to even out the

unbalance. One reason not to have an automatic balancer built-in is that if it breaks down, it

can start discharging a cell uncontrolled. The second reason is that it takes time to create

unbalance, and therefore doing manual rebalance by charging all four cells individually one

or two times a year with the 3.6 V charger is normally sufficient since BMS4S will always

keep all cells within set boundaries.

But there is an automatic balancer available that is controlled by BMS4S. The HLPdata

4Sbalancer. It is built very robust with relays to control balancing. The reason is that if a relay

breaks down it normally does so in a disconnected state, which will not harm the batteries.

And the risk that it gets stuck in connected state is virtually zero with the low current that

flows through it.

pm Print Memorylog

will produce a printout of the memory-log started with command tm. The log can contain

288 entries. Example of log with two entries:

interval=600

3.249 , 3.247 , 3.253 , 3.248 , 12.997 , 0.000 ,

3.249 , 3.247 , 3.253 , 3.249 , 12.997 , -4.130 ,

Each line contains voltage on cell 1 to cell 4, system voltage, and current at that time. This

log is cleared when BMS4S is switched off, or by command: cm (Clear Memory log).

po Print Other info

will produce a printout of some other information that can be of interest:

volt high adjust=0.000 there is a push-button you can adjust down the end voltage

with 0.05, 0,10, 0.15, 0,20 or 2 V. Press the push-button

until 2 long blinks to set it to 0,05, 3 blinks for 0,1, 4 blinks

for 0,15, 5blinks for 0,2 and 6 blinks for 2 V (which will

always switch off charging). Keep it pressed until long

blinking stops to reset it to normal. It will also be reset when

BMS4S is switched off. This can be useful e.g. if you motor

home and want to leave the boat with less than fully

charged batteries.

charge is on Charging is allowed (normal state)

load is on Power consumption is not limited (normal state)

battery temp=20 Will always show 20 if no sensor is installed

x temp=20 Will always show 20 if no sensor is installed

alternator temp=20 Will always show 20 if no sensor is installed

charge-limit-state=0 there are several reasons charging is limited. When this is 1

to 4 it is limited due to the temperature of the alternator,

when 5 it is stopped for a preset time since the battery is

12

12

either fully charged, or battery temperature is too low or

too high for charging. 1 to 4 will of course only happen if you

have installed a temperature sensor.

push-level=0 A value showing representation of voltage on terminal

Gvolt. Lower value means higher voltage.

coulomb counters=0 0 0 0 Result of latest coulomb counting, sort is coulomb (As)

balancing: off Will list all cells currently being balanced (or none, as here)

buzzer: 0 State of the buzzer, silent right now

led-blink: 0 State of the LED, SoC level ok right now

pv Print Version

will produce a printout of the model and version of the installed software.

pd Print Debug

will produce a printout of the device internal memory. Used for debugging only.

rb ReBoot

Will force the device into a fault situation that will make the system supervision reboot the

device.

sc SetCurrent

Used to adjust the values used to calculate actual current. Must be set if you are using a

shunt different from the predefined one (50 mv = 500 A), and it doesn’t hurt to do it anyway,

it will improve the result. First start by stating that there is a shunt connected, command

wm=nn, see command wm for what nn shall be). Then definine the zero point: ensure no

load or charging sources are connected, and give command sc=0. Then connect a load of

known size and give command sc=-15.5 (if the load is 15.5 A). And lastly connect a known

charging source and give command sc=20.0 (if the source delivers 20 A).

sm SetMissingcurrent

Depending on how far from the battery your shunt is installed some of the first charging

current will be missed. I you want a more exact current measurement you need to find out

when BMS4S first detects charging, and enter this value here measured in Amps. The default

setting will normally work fine, so this is not necessary to do.

ss SetfloatSize

Set how many decimal digits you want presented. The resolution of voltage measurements is

0,004 V, so more than 3 digits make no sense, two is normally enough.

sv SetVerbose

Set level of information at printouts. Used for debugging.

tm TimeMemorylog

sets the time between each sample in the log. The log can contain more than 250 entries

which is enough for logging every 5 min (300 s) for almost 24 hours.

13

13

System Commands

Here are some commands that you should not use unless you know exactly what you are

doing. If you have done so anyway, look at command fr below to understand how to resolve

the problem.

a1(‑4) Adjust voltage for cell 1-4

If you are sure that BMS4S reports a faulty voltage on a cell you can adjust the value-

calculation with this command.

Example: a4=-0,005

fr Factory Reset

When you have done too much changes and want to come back to a known status, this will

reset the system to original settings as it was when it was shipped from the factory.

Example: fr

rp ReProgram

If there are some new functions released, this is used to update the BMS4S. Exact usage is

supplied together with the update package.

s1 (-4) Set voltage for cell 1-4

If you are sure that BMS4S reports a faulty voltage on a cell you can by this command set the

correct voltage of the actual cell.

Example s4=3.233

You can as an alternative set the accumulated value of that cell, the result will be the same

Example s4=13.3

sa Set All voltage

Can be used to set the voltage on all cells if they are perfectly aligned.

Example sa=3.233

14

14

Installation

When you start the electrical system looks something like above. You often have a starter battery

and a house battery. These are kept separate so that the starter battery is not used by the boat's

consumers, and they are charged via a charging distributor or a relay that switches on when the

engine is running. If you have bow thruster then you often also have a battery for it, placed in the

bow of the boat. All batteries, of course, have switches and fuses installed.

15

15

The simplest way is to just replace the main battery with LFP cells, and connect them to BMS4S. You

also connect a buzzer/alarm to it. Then you move the voltage sense (often yellow) cable and connect

it to BMS4S. You also have to connect a bi-stable relay between the new main-battery and to

BMS4S. Then at last you connect the power to supply BMS4S from after the main switch (but before

the relay) so it is switched off when all other electricity is switched off.

There are two more items we think you should connect: a push-button and a led. Details on this and

where the wires are connected is described in Equipment connection description below.

The disadvantage with this setup is that the led batteries only get charged when the engine is

running, and during most of that time the LFP bank keep the voltage below 13.8 V, which is not

enough to get lead batteries fully charged.

Therefore, we recommend one more change: remove the power distributor and connect the three

cables together you get a setup looking like this:

Now the lead batteries have become backup for security and is not used during normal operation. It

is then enough to charge them every now and then, which can be done by simply switch them on.

They will then get some small current from the LFP that normally are giving 13.2 V, and of course

from the alternator when it is running. But since they are not used, they will always be available as

backup and fully charge. So how do you actually do this installation.

Here is a step-by-step instruction, but first a warning: NEVER CONNECT +12 V BEFORE – AND B0 ARE

CONNECTED. If you want to test the BMS4S before installation, connect – and B0 to battery minus

first, and then +12 and B12 to battery plus (and then command wm=2 to tell BMS4S that only 12 V is

connected). More details on each connection can be found in the next chapter.

16

16

1. Plan where to put the BMS4S, the relay, the buzzer/alarm, the led for low SoC warning and

the push-button for simple adjustment of charge level and to wake up the Bluetooth

interface.

2. Start with connecting the relay on the cable between the man panel and the LFP cells.

3. Connect the relay to Load OFF and Load ON on the BMS4S, and to - (minus, ground).

4. Connect the buzzer/alarm to 12V. Connect the other terminal Beep on the BMS4S.

5. Connect the 12 V led to BMS4S.

6. Connect the push-button between terminal Inpot and – (minus, ground)

7. Move the (often yellow) voltage sense cable from the generator to the Gvolt terminal on

BMS4S.

8. Prepare five cables between the LFP cells and the BMS4S, and press on connectors on the

battery side. Mark the cables on the battery side with labels: B12, B9, B6, B3, B0.

9. Connect the cables on the BMS4S side first. Make sure the B12V cable is connected into the

B12 terminal etc.

10. Connect the cables to the LFP cells. Make sure you place the cables on the right cell. Start

with B0.

11. Now it is just to connect power to BMS4S via the terminals +12V and – (minus/ground)

12. Now move the cables on the current distributor so they all are sitting on the same terminal

(unless you intend to keep a separate starter-battery).

13. Test the installation as described in chapter Testing below.

14. Start the engine and run it for a while. Test with a wet finger that the alternator does not

exceed 100 degrees. If it does it does probably not contain any protection against

overheating. See bullet 6 in chapter “Equipment connection description” on how to mitigate

that.

15. To maximize the capacity and life-length of your LFP cells you shall always charge them fully

when they have been unused for a while. Do that now with the 3.6 V LFP charger, one cell at

the time. (But do not leave them fully charged if they will be unused for a while. Discharge

them then to below 80% SoC to maximize life-length.)

16. Now you are ready to go. Enjoy a life with less worries about lack of electricity.

Equipment connection description

17

17

Here is a picture showing how equipment shall be connected to BMS4S. Please note that there are

no switches or fuses shown in the picture. All wires leaving a battery should have a switch and must

be properly fused close to the battery if there is a slightest risk that it can ever create a shortage or

overload, but that is outside the scope of this manual and you will have to find descriptions on how

to do this elsewhere. So, let us instead discuss how the equipment in the picture shall be connected

to BMS4S. We’ll take them one by one, but first a warning: NEVER CONNECT +12 V BEFORE – AND B0

ARE CONNECTED. If you want to test the BMS4S before installation, connect – and B0 to battery

minus, and then +12 and B12 to battery plus (and then command wm=2 to tell BMS4S that only 12 V

is connected).

1 You need five cables between BMS and the LFP cells. Mark them in one end with labels:

B12, B9, B6, B3 and B0. Start connecting the B0 wire in B0 on BMS4S and then connect it

to the battery minus terminal. Continue with B3 which shall be connected to + side of

the first cell. B6 to the second cells + terminal. B9 to the third, and B12 to the fourth

cells + terminal. Check each wire one extra time before connecting it to the battery.

2 Open up the wires between the battery and the main panel and connect the latching

relay so that it can disconnect all user equipment when a low voltage situation occurs.

Then connect the wires between the relay and BMS as in the picture, i.e. the wire that

switches off the relay to the Load OFF terminal, and the one switching it on to the Load

On terminal. The common wire is connected to ground. The control terminals for driving

the relays on BMS4S are of MOSFET type, and can drive 11 A momentarily and 3 A

continuously. You can of course use high power relays like Bluesea 500 A if you have

equipment with a high demand for power.

18

18

3 If you want to use a monostable relay, like KILOWAC EV200, you connect it to the Load

on terminal. For mono-stable relays you must also change the time the relay is pulled to

0, which means it is pulled all the time, command: tr=0. This also means that the Load

off terminal will always be in the opposite position of the Load on terminal. Mono-stable

relays will use current all the time it is connected, so bi-stable relays have a definite

advantage.

4 You can use any 12 V buzzer/alarm to get audio signals when something must be done,

as long as it uses less than 100 mA. You simply power it with 12 V and connect the minus

wire to the terminal marked Beep. If you want to use higher power equipment you

simply connect a normally open relay to the port and let it deliver the power.

5 Many modern alternators have a voltage sensing (often yellow) cable used to

compensate for the voltage drop in the cables between the alternator and the batteries.

If your alternator is missing such a cable it is probably a low power one, and it might be a

good idea to replace it to get improved charging since LFP batteries can recharge much

faster than lead-batteries does. The voltage sensing cable is simply moved from where it

was connected before to the terminal on BMS4S marked Gvolt. But if you still want to

use the existing alternator without a voltage sensing cable you have to open it up and

identify the two wires that is feeding the rotor with power. They will always go to the

two carbon brushes, sometimes built in to the regulator. You have to cut up one of these

and extend the two resulting wires outside of the alternator, and connect them to a

relay that is of type normally connected (NC). Then connect the relays control wires to

terminal Load OFF and – (ground) on the BMS4S. Now the relay will break up the power

feeding of the rotor when BMS4S activates it, and the alternator will stop producing

current. This way is also how you connect relays switching off charging from other

sources like solarpanels, wind generators etc.

6 Many modern alternators are also protected against overheating. A simple test is to run

it loaded for a while and then touch it with a wet finger. You hear directly if it is above

100 Celsius since the water then instantly boils. BMS4S can protect the alternator if it

doesn’t do it itself. Place the thermistor so the it touches the alternator and connect it as

shown in the picture, between the Gtemp terminal and ground (minus). Dependent on

where you place it you might have to adjust the temperature values: command t4=nn,

t5=nn and t6=nn.

7 The LED must be of 14V or 12 V type if you connect it as in the picture. Otherwise, you

must insert a 1 kOhm resistor in series with the diod. Note that the LED might be

sensitive to the polarity so you connect the right leg toward +12V. As an alternative you

can feed the diod from the +5 V terminal, then with a 470 Ohm resistor in serie.

8 The push-button is connected between the inpot terminal and – (minus/ground). It is

used to temporarily change the settings for charging, and to wake up a bluetooth radio

that is switched off.

9 If you want to automatically switch off the power to the fixed installed charger when the

battery is fully charged you can use a standard industrial relay with sufficient power

capability and connect it to terminal Charge OFF and ground (minus).

10 If you want to supervise the batteries temperature you connect a thermistor between

ports – (minus/ground) and Btemp on BMS4S and place it at the LFP cells.

11 If you have a low-side 50 mV shunt for 500 A connected on your minus side, you can

connect BMS4S to it as in the picture. Connect the side closest to the battery and

19

19

terminal SHTB, and the other at SHT. When it is connected you must inform BMS4S

about it, command wm=1. You can always calibrate it to adjust for other shunt values. If

you have no shunt, connect it to the two sides of the first cable on the battery’s minus

side if the expected voltage over it never will exceed 100 mV. Or push two needles into

the wire with 0.3 m in between if it is a 50 mm2 wire, or 0.2 m if it is a 30 mm2 wire.

Start with an idle system (no current) and zeroize it, command: sc=0. Then start charging

with a known current, e.g 20 A, then give the command: sc=20. And lastly switch on a

known load, e.g. 10 A and give command: sc=-10. The current measurement is not high

resolution, and is mainly used to roughly estimate SoC and the amount of unbalance

between the cells (by coulomb counting during charging).

12 If you want redundancy (if you have a very large/expensive LFP bank) you can install a

second BMS4S, either exactly the same way as the first one, or simplified by reducing

some of the duplicated equipment. The simplest working configuration is to only

connect +12V and a wire to the alarm/buzzer so that it can notify you if something fails.

Then you connect the two together by two wires going from Osup on one BMS4S to Isup

on the other, and vice versa. Then change working mode on both to “normal working

mode + is supervised by and supervising a second BMS4S”. Command wm=4 (5 if you

have a shunt installed). Make sure the two BMSM4S do not share the same fuse to avoid

a single source of failure. They are now supervising each other, and if one fails, the other

one will start beeping “device failure” while it still is supervising the LFP bank.

13 If you intend to keep the batteries connected all the time, also when leaving the boat for

long times, it can be wise to install a bi-stable relay that isolates the battery completely

in case of a low voltage incident. It shall be connected to terminal All OFF, and BMS54S

sends out a 1 s pulse when the voltage of the first cell goes below 2.8 V (can be changed

with vv=n.nnn). It is recommended that this relay switches off ALL consumers. You might

have to connect a capacitor in parallel with the relay of 100-300 uF to ensure that it is

finishes switching after the power is cut. This kind of high-current relay can of course

also be used as relay in point 2 above if you have equipment like high current inverters.

For thrusters and winches it is enough if the control buttons are powered from behind

the low-voltage relay, they use very little power.

Testing

Switch on the power and connect to BMS4S with your phone or PC over Bluetooth. Start with

checking that all voltages are reported correctly, command p. Then take a look at the settings to see

if there are anything you want to change, command ps. Now it is time to test the system. Firstly, we

test that the low voltage protection works:

1. Temporarily change the limits for when power to consumers is turned off and on:

command vo = 3.4 and vl = 3.4. To be able to change settings, the device must be

unlocked, command du = 1234.

2. After 15 seconds the relay shall cut off the electricity to the main panel.

3. If you have a very-low-voltage shutoff relay, temporarily set the very low voltage to 3.4,

command vv=3.4

4. After 15 seconds the relay shall cut off all power

20

20

5. Reset the voltage levels to the desired values (vl=3.05, vv=3.0 and vo=3.1). You might

have to switch on the very-low voltage-relay manually to do this, dependent on how you

have connected it.

6. The low-voltage relay shall immediately switch the power on again

If this works ok it is time to test the high voltage protection.

1. Start the engine

2. If the batteries are not fully charged, set the high voltage to 3.1 V, command vh=3.1

3. After 15 seconds the engine shall change sound and run more easily since the alternator

now has stopped to charge the battery. If you have installed a power shunt you can

verify that charging has stopped with command p, that will print voltage and current.

4. Prepare the command to reset the high voltage limit to 3.6 V, command vh=3.6, but do

not send it yet.

5. Wait 2 minutes, and the buzzer/alarm for high voltage will start sounding

6. Now send the prepared command to make the alarm stop.

7. Restart charging by pressing the push-button until the LED blinking stops. Will take

around 7 seconds.

8. You can also test that the charging stops also by temporarily changing the setting. Press

the push-button until you have seen 6 long blinks on the LED. Now you have temporarily

decreased the stop charging voltage with 2 volts, which definitely will stop charging

within the set delay. Doing it this way will not generate any high voltage alarm.

9. Restart charging by pressing the push-button until the LED blinking stops.

10. Stop the engine.

I this works ok, then test the low voltage warning

1. Set the warning blink level to 100 %, command sl=100

2. The lead shall start blinking with one blink for each 10% of state of charge in the battery,

i.e. if the SoC is 45 there will be 5 blinks, 2 seconds pause, 5 blink etc.

3. Reset the warning blink level to 20 % (or what you think it should be), command sl=20

And lastly, we test the charge level adjustment

1. Press the push-button until you see 3 long blinks on the LED.

2. Check that the system has noticed this, command po.

3. Check that in the printout contains: volt high adjust= -0.10 V

4. Do the same thing until you see 4 long blinks, po will give: volt high adjust = -0.15 V

5. Do the same thing until you see 6 long blinks, po will give: volt high adjust = 2.00 V,

which means that all charging (that BMS4S controls) will be stopped all the time

6. Press the push-button until it stops blinking and check that the line says: volt high adjust

= 0.00 V

4SBalancer

If you have a 3.6V charger it is normally enough if you use it to fully charge all cells one or two times

a year with it. Since BMS4S always act on the first cell reaching a boundary, there will be no harm

Other manuals for BMS4S

1

Table of contents

Popular Microcontroller manuals by other brands

Logic PD

Logic PD Zoom DM3730 user guide

Freescale Semiconductor

Freescale Semiconductor Kinetis K40 MCUs quick start guide

Silex technology

Silex technology SX-ULPGN-BTZ quick start guide

Holtek

Holtek TinyPower HT69F40A manual

Silicon Laboratories

Silicon Laboratories 4010-KFOBDEV-434 user guide

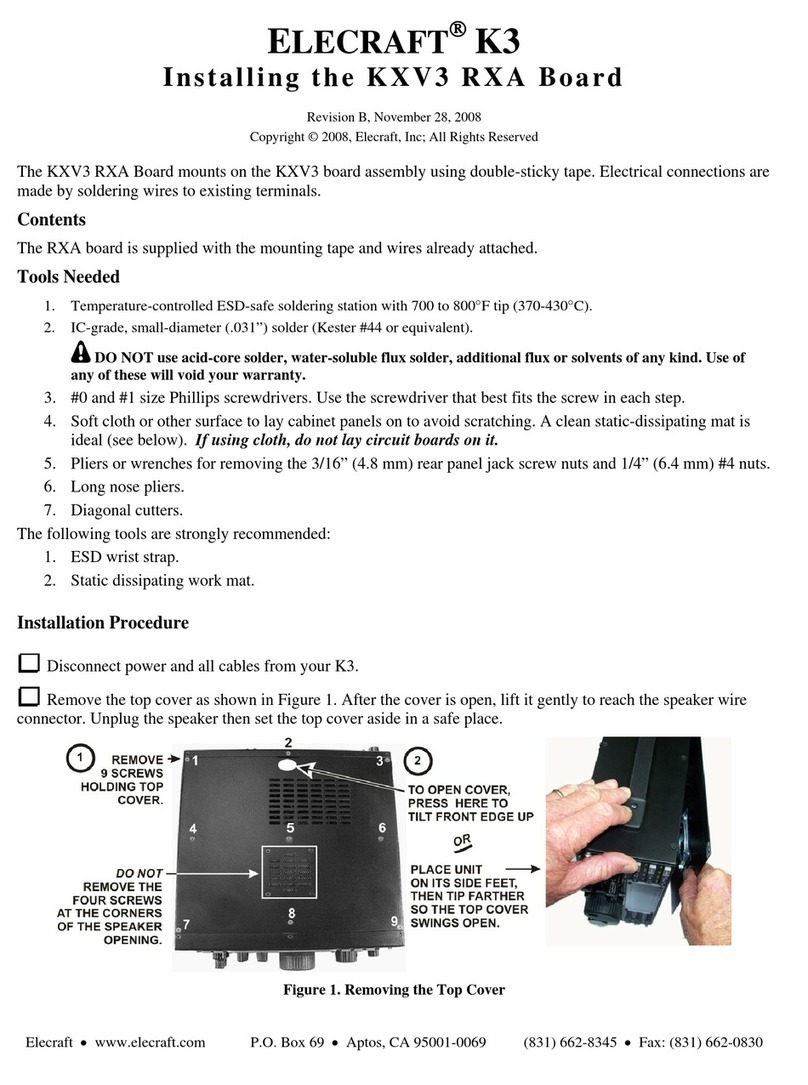

ELECRAFT

ELECRAFT K3 Installing