Legal regulations

4

Legal regulations

Before riding your bicycle on the road, you should inform yourself about the applicable national

regulations in your specic country. In Germany, the applicable laws are the StVZO (German Road

Trafc Regulation) and the STVO (German Highway Code). In Switzerland, the applicable regulati-

ons are outlined in the guidelines for the technical requirements of road trafc in articles 213 to 218

(Verordnungen über die technischen Anforderungen an Strassenfahr zeuge).

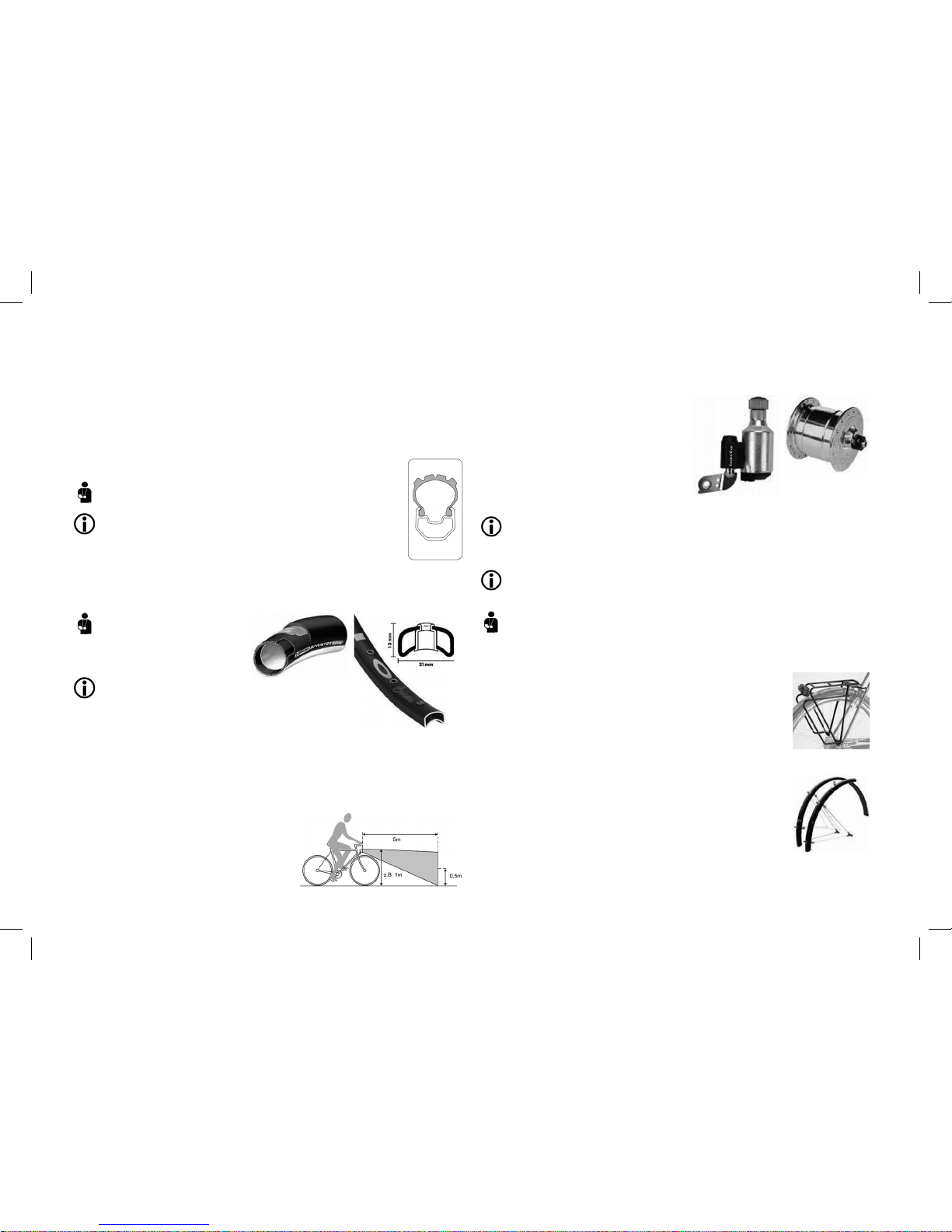

Ensure that your bicycle is truly in a roadworthy condition before every ride, and that the brakes are

optimally set up and the bell and light system correspond with the StVZO (German Road Trafc

Regulations). This includes white front and rear lights powered by a xed dynamo (6V, 3W), a clearly

audible bell and reectors. The reectors have to be set up as follows: front – white, large, may be

integrated into the light; rear – two red reectors, one may be integrated into the rear light; wheels

with two yellow reectors per wheel, alternatively white reecting rings in the tyre, rims or spokes;

peddles with one yellow reector per peddle – one reecting forwards and one reecting backwards.

Only racing bicycles weighing less than 11 kg are allowed to use battery-powered head and rear

lights, and these must be carried with the bicycle at all times. All other bicycles have to use dynamo-

driven lights and each lighting system has to carry a stamp of ofcial approval. Here, the StVZO

applies. When making technical changes to the components on your bicycle, please note that

electrical parts may only be replaced with type-tested components.

Participating in public road trafc in Austria requires riders to comply with Act 146 / the so-called

bicycle act (Fahrradverordnung). This is outlined in the Austrian Federal Law Gazette (Bundesge-

setzblatt). Please ensure that before every ride your bicycle is in a roadworthy state, that the brakes

are perfectly set up and that the bell and light system comply with the StVZO. Only racing bicycles

weighing less than 11 kg are allowed to use battery-powered head and rear lights, and these must

be carried with the bicycle at all times. All other cyclists have to use dynamo-powered lighting sys-

tems, with every system having to hold the national seal of approval. The StVZO is applicable here.

When making changes to the components on your bicycle, please note that electrical parts may only

be replaced with type-tested components.

Complying with regulations

Usually, bicycles are intended for transporting one person at a time. If you are planning to transport

additional people or baggage then the regulations of the StVO apply. Here there are specic weight

restrictions depending on the size and type of the bicycle as well as the location of the rack (see

“technical information”).

If they are set up as stipulated by the StVZO,

Trekking bikes / ATBs are allowed to be ridden on public roads, paved trails and unsurfaced routes

City, touring, sports, childrens and youth bikes can be used on public roads and paved trails

Racing bikes/tness bikes can be used on public roads for training purposes. They may only be

ridden on asphalt surfaces!

Mountain bikes may be used off-road and on non-paved tracks. They may NOT be used in races

or for downhill! These types of bicycles are only permitted on public roads after the compulsory

equipment has been tted!

The guidelines laid down in the StVO and StVZO do not generally apply when using your bicycle in

competitions. However, all guarantees and liability regulations only apply as long as the bicycle is

being used in accordance with its conditions of use and safety guidelines. Otherwise all liability for

the manufacturer and retailer is nullied. This includes carrying too much weight on the bicycle, not

properly repairing damage, using the bicycle off-road and in competition as well as all uses not in

line with the conditions of use. This always includes:

Carrying too much weight•

Improper repairs of damage•

Use in competitions,•

as well as not adhering to the conditions of use and maintenance, doing jumps, riding down steps

and anything else that places extreme stress on the bicycle.

Instructions relating to your own safety

Every type of bicycle has a different load capacity which is listed in the “Technical information”

chapter. If a bicycle is subjected to excess load, this can lead to breaks in the handlebars, fork or

frame, for example. The maximum permitted load for the rack is usually stated on the rack itself. If

this is not the case, the maximum permitted amount for your rack will be listed in the “Technical in-

formation” chapter. Not all bicycles are suitable for installing children’s seats or bicycle trailers – your

specialist retailer can advise you in this area. In particular, frames and components made of carbon

are completely unsuited to carrying this additional weight! Bent or damaged components have to

be replaced; they could contain hairline cracks or be broken following a fall. Continuing to use them

could cause serious injury. Different types of rims (carbon, aluminum) require different types of brake

pads to work efciently. Otherwise this can cause accidents.

Please take your bicycle to a specialist to carry out repairs, servicing and setting up parts of the

bicycle.

As a rule, the following applies:

You should ride carefully in wet conditions, particularly those covered in wet leaves in autumn.•

Brake earlier and ride slower as the braking distance is considerably longer in these conditions.

Do not only use your lights when its dark, you should also use your lights at twilight and in foggy•

or rainy conditions. You can see and be seen better.

Do not overestimate yourself: your speed should match your abilities both on public roads as well•

as off-road.

The setup and functionality of the bicycle could change during transport – despite multiple checks

being carried out during production and the nal post-production check. Therefore, check the

following before the rst ride:

Screws, bolts and pedals are all secure•

Stem, handlebars and seat post are all safely secured and adhere to the minimum insertion length•

Test the setup of the brakes and their effectiveness•

Check that the wheels and quick releases are secure•

Check that the suspension components are working properly•

Gears and lights•

Air pressure and tires•

• Check the quick release locks before every ride, even if your bicycle was only left unatten-

ded for a short period of time!

Generally, a bicycle will change most in the rst 100 kilometers; the spokes will bed in, the brake

cables and gear cables settle into the housings and the bearings are broken in.

Therefore, it is important that you have your rst inspection carried out by a specialist retailer after

200–300 kilometers or 4–6 weeks. This should encompass: