Part 1: Building the PCB

Soldering notes

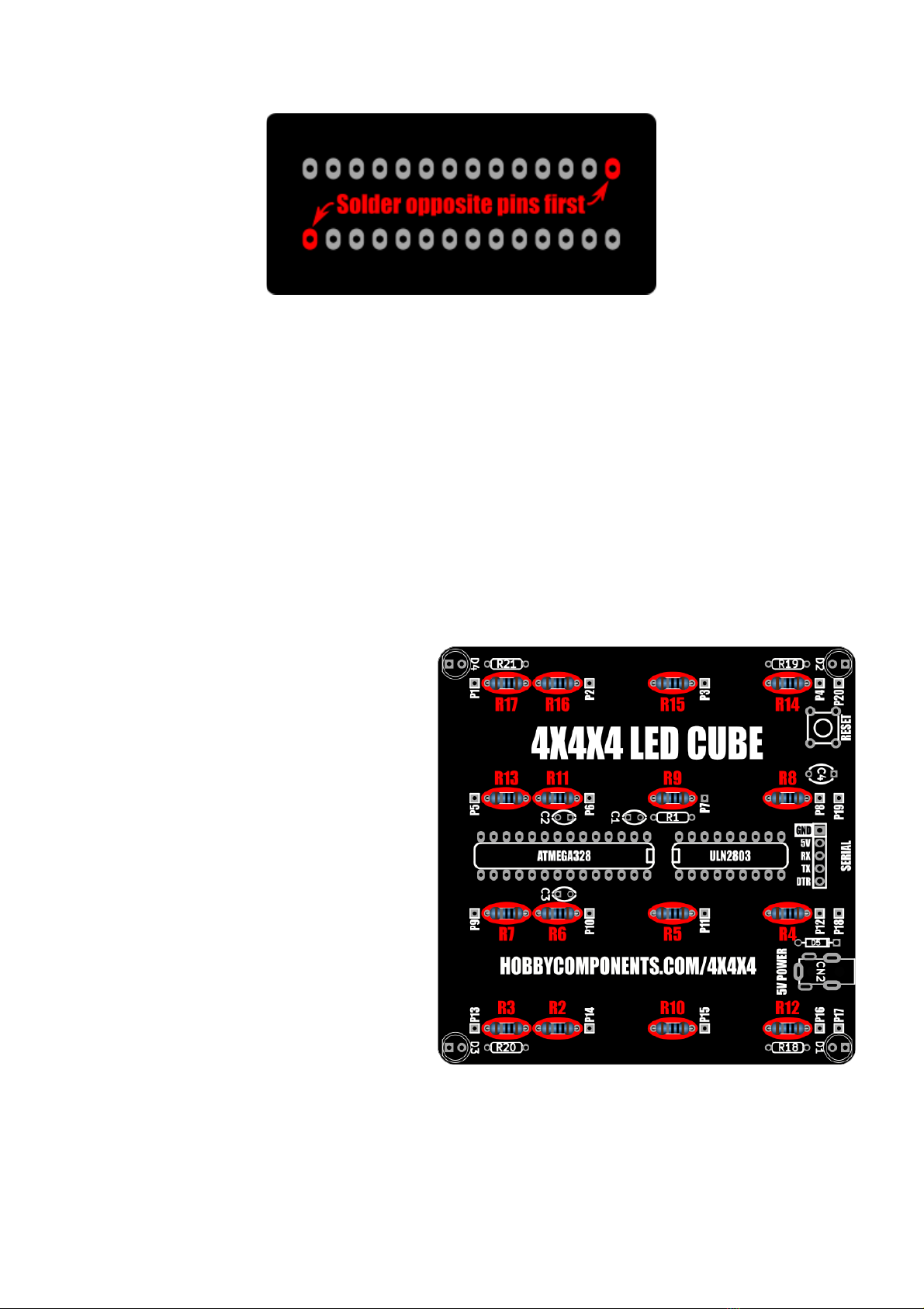

Take the PCB out of your kit and you’ll notice that one side of the PCB has white silkscreen

printed on it with the other side being completely blank. All components, apart from the male

to female sockets, will be soldered to the silkscreen side of the PCB.

Soldering tips:

When soldering components to a circuit board it is always best to start with the smallest

components first. This helps keep the board flat and stops access to pads from being

restricted by larger components. We have deliberately ordered the steps within the guide so

that components are soldered in order of height.

The first step is to start by soldering the resistors. In your kit these will be marked

appropriately. The orientation of most of the components doesn’t matter but we will point out

any components where the orientation does matter. In these cases it is important to make

sure you have them inserted correctly.

Unless otherwise stated, solder components to the PCB by inserting their legs through the

appropriate pad holes on the silkscreen side of the PCB, then flip the PCB and solder the

component legs to the PCB pads on the opposite side (non-silkscreen side).

For components with flexible legs like resistors and capacitors you can keep them held in

place by splaying the legs outwards slightly. Once soldered any excess leg can be trimmed

using a pair of snips or side cutters.