Hobby-Wing QUICRUN Series User manual

Model QUICRUN 10BL60 SENSORED

Cont. / Peak Current

Motor Type Supported

Car Applicable

60A / 380A

Sensored / Sensorless Brushless Motor

1/10th Touring Car/Buggy/F1/Drift Car & 1/12th On-road

≥8.5T (1/10 On-road), ≥13.5T (1/10 Off-road)

≥13.5T (1/10 On-road), ≥17.5T (1/10 Off-road)

Motor Limit (Note) 4-6 cells NiMH / 2S LiPo

8-9 cells NiMH / 3S LiPo

Battery 4-9 cells NiMH, 2-3S LiPo

BEC Output

Cooling Fan 6V (The cooling fan gets its power supply from the built-in BEC)

Dimensions / Weight 33 x 28 x 31.5mm (w/ Fan) / 59g (w/ Wires, w/o Fan)

6V@2A, Linear Mode

QUICRUN 10BL120 SENSORED

120A / 760A

Sensored / Sensorless Brushless Motor

1/10th Touring Car/Buggy/F1/Drift Car, and etc.

≥3.5T (1/10 On-road), ≥4.5T (1/10 Off-road)

≥8.5T (1/10 On-road), ≥10.5T (1/10 Off-road)

4-9 cells NiMH, 2-3S LiPo

6V@3A,Linear Mode

Powered by the battery

43 x 36 x 33mm (w/ Fan) / 105g (w/ Wires & Fan)

Specifications

CAUTIONS

ATTENTION

Sensored motor wiring

When using sensored brushless motor, please connect the “SENSOR” port of the ESC and the the “SENSOR”

port of the motor with a sensor wire.

For sensored brushless motor, the #A, #B, #C wires of the ESC MUST be connected with the motor wire #A, #B,

#C respectively. Do not change the wires sequence optionally! (#A is Blue, #B is Yellow, #C is Orange.)

Sensorless motor wiring

When using sensorless brushless motor, the #A, #B, #C wires of the ESC can be connected with the motor wires

freely (without any order). If the motor runs in the opposite direction, please swap any two wire connections.

Please disconnect the battery from the ESC after running the car!

C

A

B

Sensor port of motor

Battery

Switch

Electronic Speed Controller

Receiver

Motor

Blue (A)

Yellow (B)

Orange (C)

Capacitor

Sensor wire

In order to make sure the ESC fits the throttle range of your transmitter, you must calibrate it when begin to use a new ESC, or a used transmitter if some of its settings have been changed,

like the Throttle Trim, D/R, EPA or other parameters. Otherwise, the ESC cannot work properly. Besides, we strongly recommend users to enable the “failsafe” function of the transmitter, set

the “F/S” of the throttle channel to the Shutdown mode or set the protection value to the neutral position, so the car can be stopped if the receiver fails to get the radio signals from the

transmitter. Please calibrate the throttle range according to the following steps.

01

Features

02

Begin to Use a New Brushless ESC

03

Program the ESC

Recommended Power System

IMPORTANT

CAUTIONS

Congratulations and thanks for purchasing the QUICRUN series electronic speed

controller (ESC). The power system for RC model can be very dangerous, so please

read this manual carefully. Since we have no control over the installation, application,

use or maintenance of this product, in no case shall we be liable for any damages,

losses or costs.

ATTENTION

1

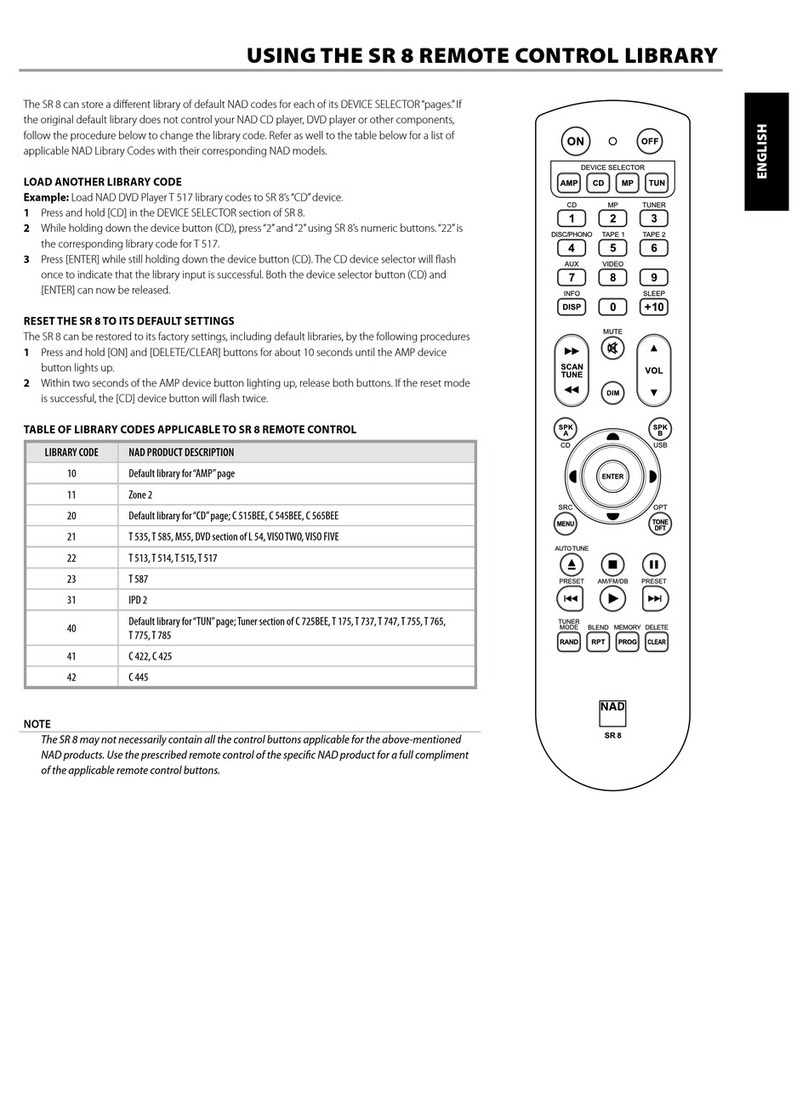

Set the ESC by the SET button

1

Set the ESC by Program Card

2

Set the Throttle Range

2

• In the ESC setting process, the motor will emit “Beep” tone at the same time

when the LED is flashing.

• If the “N” is bigger than the number “5”, we use a long time flash and long

“Beep—” tone to represent “5”, so it is easy to identify the items with the big

serial number.

For example, if the LED flashes as the following:

“A long time flash + 1 short time flash” (Motor sounds “B—B”) = the No. 6 item,

“A long time flash + 2 short time flash” (Motor sounds “B—BB”) = the No. 7 item,

“A long time flash + 3 short time flash” (Motor sounds “B—BBB”) = the No. 8 item,

and so on.

The Program Card is optional equipment which needs to be purchased separately. It has 3 digital

LEDs to display the programmable items’ number and the options’ number. It is portable and

very easy to use.

(For detailed information, please refer to the user manual of the program card).

ATTENTION

Enter the 2nd item

"Drag Brake Force"

Hold the SET key

Switch on the ESC

Red LED flashes

Green LED flashes

once

Green LED flashes

twice

Green LED flashes

3 times

Green LED flashes

N times

Release

SET key

Release

SET key

Press

SET key

Press

SET key

Press

SET key

Press

SET key

Release

SET key

Release

SET key

Red LED flashes once, choose "0%"

Red LED flashes twice, choose "5%"

Red LED flashes 3 times, choose "10%"

Red LED flashes 4 times, choose "20%"

Red LED flashes 5 times, choose "40%"

Red LED flashes 6 times, choose "60%"

Red LED flashes 7 times, choose "80%"

Red LED flashes 8 times, choose "100%"

Red LED flashes once, choose "None"

Red LED flashes twice, choose "2.6V"

Red LED flashes 3 times, choose "2.8V"

Red LED flashes 4 times, choose "3.0V"

Red LED flashes 5 times, choose "3.2V"

Red LED flashes 6 times, choose "3.4V"

Red LED flashes once to choose

Red LED flashes twice to choose

Red LED flashes 3 times to choose

"Forward with brake"

"Forward / Reverse with brake"

"Forward / Reverse"

Enter the 3rd

item"Low Voltage

Cut-Off"

Enter the Nth item

Enter the 1st item

"Running Mode"

Turn off the ESC

Turn on the transmitter

Hold SET key for 3 seconds

Hold SET key for 3 seconds

Hold SET key for 3 seconds

Hold SET key for 3 seconds

......The following steps are just like the above setps......

Finish programming, switch off the ESC, and then switch it on

04

Reset All Items to Default Values

At any time when the throttle is located at neutral position (except in the throttle calibration or parameters program process), press and hold the “SET” key for over 3 seconds, the red LED and green LED will blink

simultaneously , which means each programmable item has be reset to its default value. It needs to be restarted to complete the whole process.

Press the SET key to choose the

programmable value, the RED LED

flashes for several times, the times

presents the serial number of the

value you are choosing.

Enter the corresponding

programmable item, the

red LED flashes for

several times, the times

presents the current

value of this item.

Press SET key to choose the value,

the flash times of the RED LED

means the option number.

(Once means the 1st option,

twice means the 2nd option, etc.)

USER MANUAL

10BL60 / 10BL120 Sensored

Brushless Electronic Speed Controller

1. Turn on the transmitter, and set parameters (of the throttle channel) like “D/R, “EPA”, “ATL” to 100% (if there is no LCD display

on the transmitter, please adjust the corresponding knob to its limit). Set the throttle trim to 0 (if there is no display, then adjust the

knob to the neutral position). For FUTABA

TM

and similar transmitters, set the throttle direction to “REV”, while the throttle direction

of others to “NOR”. Please disable the built-in ABS brake function in your transmitter.

2. Hold the SET button while sliding the switch to the ON position, and then release the “SET” button the moment when the Red

LED starts to blink. (If you don’t release the SET button in 3 seconds, the ESC will enter the program mode, in such a case, please

switch off the ESC and re-calibrate the throttle range again from Step 1.)

Hold down the

SET button.

Move the throttle stick to the neutral position and press

the SET button.

Turn on the

switch

Set the 3 points according to pictures

• The neutral point. • The end point of the forward direction. • The end point of the backward/brake direction.

When the process of calibration is finished, the motor can be started after 3 seconds.

The Green LED

flashes once and

motor emits

“Beep” tone.

Move the throttle stick to the end position of forward

and press the SET button.

The Green LED flashes

twice and motor emits

“Beep-Beep”

tone.

Move the throttle stick to the end position of backward

and press the SET button.

The Green LED flashes

thrice and motor emits

“Beep-Beep-

Beep” tone.

• High performance but low price, users can own this reliable race-ready ESC at an affordable cost.

• Compact size, suitable for various car chassis.

• Auto identification system can recognize sensored / sensorless brushless motors automatically.

• Core competition program for excellent control feel & multiple programmable items.

• 8 steps of timing adjustment greatly increase the output power of the motor, and unlock its maximum

potential.

• Proportional brake with 4 steps of Maximum Brake Force adjustment, 8 steps of Drag Brake Force

adjustment and 4 steps of Initial Brake Force adjustment.

• 9 steps of acceleration (punch) adjustment, from “soft” to “very aggressive” to fit for different kinds of

cars, tires and tracks.

• Multiple protections: Low voltage cut-off protection for Lipo or NiMH battery / Over-heat protection /

Throttle signal loss protection / Motor Lock-up protection.

• One-button (the “SET” button on the ESC) to set the ESC, and easy to reset all parameters to the factory

default settings.

• Compatible with the optional device - the portable Digital LED Program Card, especially convenient for

outdoor use.

Connections

ATTENTION

The reference gear ratios in the above form are based on the 1/10 RC cars with 2S Lipo and 0

timing ESC. If the ESC timing is increased, then the gear ratio needs to be increased

accordingly. Besides, please pay attention to the temperature of the ESC and the motor to

avoid any damage to the equipments.

Note: “T” indicates the limit value of motor turns when the ESC timing is set to 0 degree. The larger the timing, the more turns the motor needs. Please pay close attention to temperatures of the motor and the ESC to avoid any

damage to these two equipments.

Check the LED Status in Normal Running

3

a) When the throttle stick is in the neutral range, neither the Red LED nor the Green LED lights up.

b) When the car moves forward, the Red LED solidly lights; the Green LED also lights up when the throttle stick is at the top position (100% throttle).

c) When the car brakes, the Red LED solidly lights; the Green LED also lights up when the throttle stick is at the end position and the maximum brake force is set to 100%.

d) When the car reverses, the Red LED solidly lights; the Green LED also lights up when the throttle stick is at the end position and the maximum reverse force is set to 100%.

05

Programmable Items

Parameter List of QuicRun-10BL60SD:

(Italics in the form below indicate factory defaults)

06

Trouble Shooting

Trouble(s) Solution(s)Possible Causes

No battery voltage is input to the ESC. The switch of the ESC is damaged

The voltage of the battery pack is not in the normal range, it’s too high or too low.

The throttle signal wire is oppositely inserted or into the incorrect channel.

The wire connections between the ESC and the motor need to be changed.

The ESC is not suitable for the chassis.

Low voltage cutoff protection (Red LED blinks)

Thermal protection (Green LED blinks)

ESC detects abnormal signals from the sensor port of the motor and the ESC changes to

sensorless driving mode automatically.

Low battery discharge rate.

The motor RPM is too high (i.e. the motor runs too fast), and the gear ratio is too small.

The “Punch” setting is too high.

Check the connections between the battery and the ESC, re-solder the connectors if needed.

Change the switch.

Check the voltage of the battery pack.

Plug the signal wire (Rx lead) correctly into the throttle channel (usually Channel #2) of the receiver.

Swap any two wire connections between the ESC and the motor. (Note: This method is ONLY

available for SENSORLESS motor ) Please don't use the ESC for this special chassis.

Check the battery voltage. If still has some capacity, lower the cut-off threshold voltage;

if not, replace a new battery.

Wait several minutes to cool the ESC. Increase the gear ratio or the T number (Turns) of the motor.

Check the sensor wire connection.

The Hall sensors in the motor are damaged, please change the motor.

Use a battery pack with better discharge ability.

Use a low-speed motor, or increase the gear ratio.

Set the acceleration (punch) to the softer mode.

After power on, motor doesn’t work but emits “beep-beep-, beep-beep-”

alert tone. (there’s 1-second pause between 2 “beep-beep-”).

After power on, the Red LED turns solid red but the motor doesn’t work.

Turn on the switch, no LED lights up, and neither the motor nor fan works.

The car runs backwards when accelerating forward on radio.

The motor stuttering under heavy acceleration.

The car slows down and then stopped. The Red and Green LEDs blink

rapidly and synchronously when throttle stick in neutral.

The connections between the motor and ESC are not A-A, B-B and C-C;

The ESC is damaged

Check wiring & connections.

Contact the distributor for sales-after service.

The motor stutters and can’t start up.

The car suddenly slows down, then stops about 10 seconds later.

Option 1 Option 2 Option 3 Option 4 Option 5 Option 6 Option 7 Option 8 Option 9

Fwd/Br

0% 5% 10% 20% 40% 60%

Disable 2.6V/Cell 2.8V/Cell 3.0V/Cell 3.2V/Cell 3.4V/Cell

80% 100%

Fwd/Rev/Br Fwd/Rev

Level 5 Level 6 Level 7 Level 8 Level 9Level 4Level 3Level 2

Level 1

25% 50% 75%

25%

Equals Drag

Brake Force

50% 75% 100%

100%

0% 20% 40%

6%

(Narrow)

9%

(Normal) 12%(Wide)

0.00 deg 3.75 deg 7.50 deg 11.25 deg 15.00 deg 18.75 deg 22.50 deg 26.25 deg

1.Running Mode

2.Drag Brake Force

3. Low Voltage Cutoff

4. Start Mode (Punch)

5. Max.Drag Brake Force

6. Max. Reversing Force

7. Initial Brake Force

8. Throttle Range

9. Timing

Basic Items

Advanced Items

*Note

Note: Fwd= Forward, Rev=Reverse, Brk=Brake

Release the SET

button once the LED

flashes.

1. Running Mode: With “Forward with Brake” mode, the car can go forward and brake, but cannot go backward, this mode is suitable for competition; “Forward / Reverse with Brake” mode has reverse running function, which is suitable for daily training.

Note: “Forward/Reverse with Brake” mode uses “Double-click” method to make the car go backward. When you move the throttle stick from forward zone to backward zone for the first time (The 1st “click”), the ESC begins to brake the motor,

the motor slows down but it is still running, not completely stopped, so the backward action is NOT happened immediately. When the throttle stick is moved to the backward zone again (The 2nd “click”), if the motor speed is slowed down to zero

(i.e. stopped), the backward action will happen. The “Double-Click” method can prevent mistakenly reversing action when the brake function is frequently used in steering. By the way, in the process of braking or reversing, if the throttle stick is moved

to forward zone, the motor will run forward at once. “Forward/Reverse” mode uses “single-click” method to make the car reverse. When moving the throttle stick from neutral zone to backward zone, the vehicle reverses immediately, so this mode is

usually used by rock crawler.

2. Drag Brake Force: Set the amount of drag brake applied at neutral throttle to simulate the slight braking effect of a brushed motor while coasting.

3. Low Voltage Cut-Off: The function mainly prevents the Lipo battery from over discharging. The ESC detects the battery voltage at any time, if the voltage is lower than the threshold for 2 seconds, the output power will be reduced 70%, after 10

seconds the output power will be completely shut off and the red LED flashes in such a way: “☆-, ☆-, ☆-”. Please stop your car at the track side as soon as possible to avoid obstructing other racing cars.

Note: For NiMH battery, if the voltage of the whole NiMH battery pack is higher than 9.0V, it will be considered as a 3 cells Lipo battery pack; If it is lower than 9.0V, it will be considered as a 2 cells Lipo battery pack. For example, if a NiMH battery

pack is 8.0V, and the threshold is set to 2.6V/Cell, so it will be considered as a 2 cells Lipo battery pack, and the low-voltage cut-off threshold for this NiMH battery pack is 2.6x2=5.2V.

4. Start Mode (Also called “Punch” or “Acceleration”): Level 1 has very soft start acceleration, while level 9 has very quick start acceleration. From Level 1 to Level 9, the start force is increasing. If you choose “Level 7” to “Level 9”, you should use

good quality battery with powerful discharge ability, otherwise you cannot get the burst start effect as you want. If the motor cannot run smoothly (the motor is cogging), sometimes it is caused by the weak discharge ability, please use a better battery

or increase the gear ratio.

5. Maximum Brake Force: The ESC provides proportional brake function. The brake force is related to the position of the throttle stick. Maximum brake force refers to the force when the throttle stick is located at the end point of the backward zone.

A very large brake force can shorten the brake time, but it may damage the gears.

6. Maximum Reverse Force: Sets how much power will be applied in the reverse direction.

7. Initial Brake Force: It is also called “minimum brake force”, which refers to the force when the throttle stick is located at the initial position of the backward zone. The default value is equal to the drag brake force, so the brake action can be very

smoothly.

8. Throttle Neutral Range: This setting adjusts the width of the neutral range.

9. Timing: This function can be used to fine-tune the output power of the motor, the bigger the timing, the faster the motor runs or the larger output power of the motor. As the Boost Timing technology has been introduced into this ESC, so under the

sensored mode, adjust the ESC timing can greatly increase the motor speed. Therefore, please remember to enlarge the gear ratio of the chassis and carefully check temperatures of the motor and the ESC after increasing the timing.

Motor KV Gear Ratio

(1/10 on-road)

Gear Ratio

(1/10 off-road) Main Application

QUICRUN 3650SD 6.5T G2

QUICRUN 3650SD 8.5T G2

QUICRUN 3650SD 10.5T G2

QUICRUN 3650SD 13.5T G2

QUICRUN 3650SD 17.5T G2

QUICRUN 3650SD 21.5T G2

QUICRUN 3650SD 25.5T G2

5750

4560

3600

2850

2170

1800

1520

6.4 - 8.4

5.0 - 6.0

5.0 - 6.5

4.0 - 5.5

3.5 - 5.5

3.0 - 5.5

9.0 - 11.0

7.0 - 8.5

6.5 - 8.0

6.5 - 7.5

5.5 - 7.0

4.0 - 6.0

1/10th buggy racing

1/10th buggy racing, drift car

1/10th drift car/ Stock racing

1/10th Stock racing

1/10th Stock racing

1/10th Stock racing, F1, rock crawler

1/10th Stock racing, rock crawler

20170719

型号 QUICRUN 10BL60 SENSORED QUICRUN 10BL120 SENSORED

持续电流 / 峰值电流

支持电机类型

主要适用车型

60A / 380A 120A / 760A

无感无刷电机和有感无刷电机

1/10电房 / 电越 / 漂移车 / F1等

≥3.5T(1/10房车),≥4.5T(1/10越野车)

≥8.5T(1/10房车),≥10.5T(1/10越野车)

4-9 节镍氢电池,2-3 节锂电池

6V@3A,线性稳压模式

直接从电池取得工作电压

43 x 36 x 33mm(含风扇高度)/ 105g(含线材和风扇重量)

无感无刷电机和有感无刷电机

1/10电房 / 电越 /F1 / 漂移车以及1/12平路车

≥8.5T(1:10 房车),≥13.5T(1:10 越野)

≥13.5T(1:10 房车),≥17.5T(1:10 越野)

支持无刷马达T数 4-6 节镍氢或 2 节锂电

8-9 节镍氢或 3 节锂电

电池节数 4-9 节镍氢电池,2-3 节锂电池

BEC 输出电压

尺寸 / 重量 33 x 28 x 31.5mm (含风扇高度) / 59g (含线材重量,但不含风扇重量)

风扇工作电压 从BEC取得6V工作电压

6V@2A,线性稳压模式

(备注)

产品规格

CAUTIONS

ATTENTION

接有感无刷电机:当使用有霍尔传感器的无刷电机时,需要将电机上的传感器引线接到

SENSOR插座,电调通过检测SENSOR插座的信号自动判别是有感电机还是无感电机。

配合有感无刷电机使用时,电调输出线A、B、C要分别和电机线A、 B、C相连,不得随

意调换!(蓝线为A,黄线为B,橙线为C)

接无感无刷电机:当使用无霍尔传感器的无刷电机时,电调输出线A、B、 C可以和电机

线任意相连。 若转向不对,任意调转其中两条线即可。

电源正负极严禁反接,否则电调瞬间损坏。长时间不用时请拔下电池,以免造成意外。

电池

马达

蓝色(A)

传感器线

接收机

电调开关

无刷电子调速器

电机传感器插座

黄色(B)

橙色(C)

C

A

B

1. 打开遥控器,将油门通道的“D/R”、“EPA”、“ATL”等参数调到 100%(如遥控器无显示屏,则将对应旋钮调

到最大位置),油门通道的中点微调“TRIM”调为0 (如遥控器无显示屏,则将对应旋钮调到中间位置)。 FUTABA及类

似的遥控器需要将油门通道方向设为“REV”,其它品牌遥控器的油门通道方向应设为“NOR”。请务必关闭遥控器自

带的ABS刹车功能。

2. 电调开关置于OFF状态,持续按住SET按键不松开,将电调开关打到ON,电调上红色LED立即开始闪烁(同时马达鸣

叫 ),立即松开按键(如果未在3秒内及时松开按键,电调将进入参数设定模式,此时需从步骤1重新开始操作)。

马达鸣叫声音可能较小,在这种情况下,观察LED状态即可。

20170719

· 体积小巧,便于安装于各种车架;

· 自动识别有感无刷马达和无感无刷马达,对各种车用无刷马达具有良好的兼容性;

· 使用竞赛核心程序,具有一流的操控手感及丰富的调节选项;

· 性价比高,客户无需支付高昂的费用即可拥有一颗稳定可靠、操控性能极好的竞赛级电调;

· 8档进角调整功能,显著提升马达输出功率,发挥出马达最大潜能;

· 比例式刹车:4段最大刹车力度调节、8段拖刹力度调节、4段初始刹车力度调节;

· 9档启动加速度(Punch)调整功能,适应不同特性的车型、轮胎及场地;

· 多重保护功能:电池低压保护、过温保护、油门失控保护、堵转保护;

· 可使用电调上的SET按键设置和更改电调参数,且有单键恢复出厂默认参数的功能;

· 兼容便携式车用电调编程设定卡(显示屏为数码管LED),设定卡具有友好的人机界面,

便于在赛场使用。

01

产品特色

02

首次使用车用无刷电子调速器

03

设置调速器参数

04

恢复出厂参数设定

连接电子调速器

CAUTIONS

感谢您购买QUICRUN(酷跑)系列有感无刷电子调速器!无刷动力系统功率强大,

错误的使用可能造成人身伤害和设备损坏。请您在使用设备前仔细阅读本说明书,

并严格遵守规定的操作程序。我们不承担因使用本产品而引起的任何责任,包括但

不限于对附带损失或间接损失的 赔偿责任;同时,我们不承担因擅自对产品进行

修改所引起的任何责任。我们有权在不经通知的情况下变更产品设计、外观、性能

及使用要求。

ATTENTION

1

利用电调上的SET按键进行参数设置

1

利用LED参数编程设定卡进行参数设置

2

设定油门行程

2

•

指示灯闪烁的同时,电机会发出鸣音“哔”,以便于识别。

•

当N≥5时,我们使用一次较长时间的指示灯闪烁(同时伴有一次较长时间的鸣音)来表

示数字“5”。

比如,电调内绿灯长闪一次(同时电机发出一次长鸣音“哔—”),表示进入第5设定项;

若电调内绿灯长闪一次再短闪一次(同时电机发出一次长鸣音“哔—”和一次短鸣音

“哔”),表示进入第6设定项,依次类推,第7设定项为“哔—哔哔”,第8设定项为

“哔—哔哔哔”,以此类推。

ATTENTION

行驶过程中指示灯(LED)状态说明如下:

1) 油门摇杆处于中点区域,红色和绿色LED均熄灭。

2) 前进时,红色LED恒亮;当油门处于正向最大(100%油门)时,绿色LED也会点亮。

3) 刹车时,红色LED恒亮;当油门处于反向最大且最大刹车力度设为100%时,绿色LED也会点亮。

4) 倒车时,红色LED恒亮;当油门处于反向最大且最大倒车力度设为100%时,绿色 LED 也会点亮。

接线及基本设置完成,电机已经可以正常运行

3

06

故障快速处理

故障现象 解决方法可能原因

1、电池电压没有输入到电调

2、电调开关损坏

电池组电压不在正常范围内

电调油门线插反或通道插错

1、电调输出线和电机线连接的线序错误;

2、该车架同主流车架的电机转向不一致。

接有感电机时,有感模式出现问题,已自动切换至无感模式

1、 电池放电能力不够;

2、 电机转速过高,减速比过小;

3、 电调启动加速度设置过高。

检查电源输入通路是否有焊接不良情况,并重新焊好。

检查电池组电压。

将电调的油门排线按正确方向插到接收机的“油门(TH)”通道(Throttle,通常为CH2)。

1、 如果是无感电机,将电机三条线中任意两条互换即可。

2、 如果是有感电机,则无法通过更换线序实现电机反转,本电调无法适配此特殊车架。

1、 查看感应线是否有松动或接触不良;

2、 马达内部的霍尔(HALL)感应器损坏。

1、 更换放电能力强的电池;

2、 更换为低速电机或将减速比增大;

3、 将电调启动加速度(Punch)设置得柔和一些。

上电后电机无法启动,发出“哔-哔-,哔-哔-”警示音

(每组双音间隔时间为1秒)

上电后红色LED恒亮,电机无法启动

上电后,指示灯不亮,电机无法启动,风扇不转

遥控器正向加大油门,车子反而倒退

电机低油门时正常,突然快速加大油门,电机有失去动力现象

油门在中点时,红绿灯同时快速闪烁,车速变慢

1、 电调与电机之间接线可能错误,必须一一对应,即A-A,B-B,C-C;

2、 电调故障;

1、 查看接线是否正确,各焊接点是否焊接良好。

2、 联系经销商处理维修事宜。

电机抖动,无法启动

1、 低压保护(闪红灯);

2、 过温保护(闪绿灯);

1、 如果是低压保护,请确认是否电池没电。如果电池还有电,应将保护点降低;

如果电池确实没电,则更换新电池。

2、 如果是过温保护,请采取更好的散热方式或增加齿比及马达T数。

跑的过程中,车速突然变慢,再过10秒左右停止

进入第2设定项

“拖刹力度”

按住“SET”键,然

后打开电调电源开关

电调上红灯闪烁

电调上绿灯闪烁1次

电调上绿灯闪烁2次

电调上绿灯闪烁3次

电调上绿灯闪烁N次

松开按键

松开按键

按SET键

按SET键

按SET键

按SET键

松开按键

松开按键

红灯闪一次,选择“0%”

红灯闪二次,选择“5%”

红灯闪三次,选择“10%”

红灯闪四次,选择“20%”

红灯闪五次,选择“40%”

红灯闪六次,选择“60%”

红灯闪七次,选择“80%”

红灯闪八次,选择“100%”

红灯闪一次,选择“正转带刹车”

红灯闪二次,选择“正反转带刹车”

红灯闪三次,选择“直接正反转”

红灯闪一次,选择“不保护”

红灯闪二次,选择“2.6V/CELL”

红灯闪三次,选择“2.8V/CELL”

红灯闪四次,选择“3.0V/CELL”

红灯闪五次,选择“3.2V/CELL”

红灯闪六次,选择“3.4V/CELL”

进入第3设定项

“电池电压保护

阀值”

进入第1设定项

“运行模式”

关闭电调电源开关,

开启发射机电源开关

按住SET键等待3秒

按住SET键等待3秒

按住SET键等待3秒

按住SET键等待3秒

……以上步骤同上……

在油门摇杆处于中立点位置的任意时刻(除进行油门校调或编程设定时),连续按住SET键3秒以上,可恢复出厂设定。红绿灯同时闪烁时表示恢复设定成功,出厂设定需重新上电方可生效。

单击“SET”键选择设定值,

红灯闪烁次数代表选择了该设定项

的第几个设定值

进入相应的设定项,红

灯闪烁,闪烁次数代表

该设定项当前设定值

单击“SET”键选择设定值,

红灯闪烁次数代表选择了该设

定项的第几个设定值

10BL60 / 10BL120 Sensored

车用无刷电子调速器

使用说明书

05

编程项目说明

QuicRun-10BL60SD参数表:

(斜体字表述出厂默认值)

1. 运行模式(Running Mode):“正转带刹车”模式下,车辆仅能前进和刹车,但不能倒车,该模式通常用于竞赛;“正反转带刹车”模式则提供了倒车功能,通常用于训练。“正反转带刹车”模式采用双击式倒车方式,即油门

摇杆在第一次从中点区域推至反向区域时,电机只是刹车,不会产生倒车动作;当油门摇杆快速回到中立点区域并第二次推至反向区域时,如果此时电机已停止,则产生倒车动作,如果电机未停止,则不会倒车,仍是刹车,需要

再次将油门回到中点并推向反向区,此时如果电机已经停止才会倒车,这样做的目的是防止车辆行驶过程中因多次点刹而造成误倒车。“直接正反转”模式采用单击式倒车方式,即油门摇杆从中点区域推至反向区域时,电机立即

产生倒车动作,该模式一般用于攀岩车等特种车辆。

2. 拖刹(Drag Brake)力度: 拖刹是指当油门摇杆从正向区域转入中点区域内时,对电机产生一个微量的刹车力,这样做可以模拟有刷电机的碳刷对电机转子的阻力,适合减速入弯等场合。

(值得注意的是,拖刹会消耗比较多的电量,选择合适的拖刹力度即可)。

3. 电池低压保护阈值(Low Voltage Cut-Off): 这项功能主要是防止锂电池过度放电而造成不可恢复的损坏。电调会时刻监视电池电压,一旦电压低于设定的阈值,在3秒内动力输出将逐步降为正常功率的30%,此时车手应立即

靠边退出比赛,以免阻碍赛道上的其他车辆或被后面快车撞到,10秒后动力将完全关闭。当进入电压保护后,电调内红色LED会以“☆-,☆-,☆-”方式闪烁。

4. 启动加速度(Start Mode / Punch): 可根据个人习惯、场地、轮胎抓地特性等条件,选择从1级(“非常柔和”)到9级(“非常劲暴”)等9种启动加速度。本功能可以防止启动时轮胎打滑,并可在竞赛过程中实现弹射追车的效

果。此外,使用“7级”—“9级”选项时,对电池的放电能力要求较高,若电池放电能力较差,不能提供瞬时大电流,则反而会影响启动效果。当启动时出现停顿或瞬间失去动力时,则可能是电池放电能力不足引起的,这时需

要降低启动加速度,或增大齿轮减速比。

5. 最大刹车力度(Brake Force): 电调提供比例式刹车功能,刹车力度的大小和油门摇杆的位置相关,最大刹车力是指油门摇杆处于刹车极限位置时所产生的刹车力。请根据车辆的具体情况及个人的使用习惯,选择合适的最大刹

车力参数。

6. 最大倒车力度(Reverse Force): 选择不同的参数值可以产生不同的倒车速度(一般情况下推荐使用比较小的倒车速度,以免因倒车太快而导致失控撞车)。

7. 初始刹车力度(Initial Brake Force): 也叫做最小刹车力度,是指在刹车初始位置作用于电机上的刹车力,在它的作用下可以达到类似点刹的效果,默认值是等于拖刹力度,以便形成柔顺的刹车效果。

8. 油门中立点区域宽度(NeutralRange): 请根据个人习惯进行调整。

9. 进角(Timing): 此选项具有调节马达输出功率的功能,进角越大则马达转速越高、输出功率越大。本电调使用了先进的Boost增压进角技术,在有感模式下,调整进角能够显著地提高马达转速。

请注意: 在增加进角后,应加大车架的减速齿比,并留意马达和电调的温度,以免过温损坏电子设备。。

选项1

1. 运行模式

2. 拖刹力度

3. 电池低压保护阈值

4. 启动模式(Punch)

5. 最大刹车力度

6. 最大倒车力度

7. 初始刹车力度

8. 油门中立点

区域宽度

9. 进角

选项2 选项3 选项4 选项5 选项6 选项7 选项8 选项9

5% 10% 20% 40% 60%

不保护

正转带刹车

2.6V/Cell 2.8V/Cell 3.2V/Cell 3.4V/Cell

80% 100%

1级 2级 3级 4级 6级 8级 9级

25% 50%

75%

100%

25%

50% 75% 100%

0%

20% 40%

3.75度 7.50度 11.25度 18.75度 22.50度 26.25度

基本设定项目

高级设定项目

直接正反转

3.0V/Cell

5级

0%

等于拖刹值

6%(窄)

正反转

带刹车

9%(正常)

7级

0.00度

12%(宽)

15.00度

进入第N个设定项

,红灯闪烁若干

次,闪烁次数代

表该设定项当前

设定值

电调第一次使用或遥控器更改过油门“TRIM”微调、D/R、EPA等参数后,均需重设油门行程,不然可能会导致无法使用或误动作。 另外我们强烈建议同时开启遥控器的失控保护功能,将遥控器油门

通道的无信号保护(“F/S”)功能设置为关闭输出方式或将保护值设置为中点位置,使得当接收机无法收到遥控器信号后,电机能够停止运转。油门校调步骤如下图所示:

IMPORTANT

此时需要设定三个点:油门中点、正向最高点和反向最高点。

1) 油门摇杆留在中点位置,按一下SET键,红灯熄灭,绿灯闪烁1次,马达鸣叫“哔”1声,表示已存储中点位置;2) 油门摇杆打到正向最高点,按一下SET键,绿灯闪烁2次,马达鸣叫“哔-哔-”2声,表示已存储油门

正向最高点;3) 油门摇杆打到反向最高点,按一下SET键,绿灯闪烁3次,马达鸣叫“哔-哔-哔-”3声,表示已存储油门反向最高点;4) 油门行程校调完毕,三秒钟后,电机即可正常操作。

按住按键

摇杆置于中点,

按一下SET按钮。

开关打到ON

摇杆置于正向最高点,

按一下SET按钮。

摇杆置于反向最高点,

按一下SET按钮。

编程设定卡为车用电调的升级选配件,体积小巧,适合外场使用。其界面直观,参数读取和设定过程十

分简单快捷。调整参数时,只需将电调上的控制排线插入编程卡右上角标注着 -+ 的插座中,然后给

电调接上电源,数秒后该电调的各项参数即可显示出来。利用编程卡上的“ITEM”和“VALUE”按

键即可快速选择编程项目和参数值,然后按“OK”键后,新参数即可存入电调中。

上表中的参考齿比均为1:10电车在使用2S锂电池且电调进角为0度情况下的参考值。

如将电调进角加大,请适当增加齿比,并留意电机及电调的温度,以免温度过高而损坏设备。

ATTENTION

建议动力配置

红色LED闪烁时,

立刻松开按键。

绿灯闪烁一下,

马达鸣叫“哔”

1声。

绿灯闪烁二下,

马达鸣叫“哔-

哔-”

2声。

绿灯闪烁三下,

马达鸣叫“哔-

哔-哔-”

3声。

此处的马达T数是指在电调0度进角条件下电机T数的极限值,当电调进角加大后马达T数也需要相应增加。请留意马达及电调的温度,防止过温而造成设备损坏。

备注:

备注:

备注

设定完成︐关闭电调电源开关之后再次开启即可

电机T数 KV 参考齿比

(1:10 房车)

参考齿比

(1:10 越野) 主要应用

QUICRUN 3650SD 6.5T G2

QUICRUN 3650SD 8.5T G2

QUICRUN 3650SD 10.5T G2

QUICRUN 3650SD 13.5T G2

QUICRUN 3650SD 17.5T G2

QUICRUN 3650SD 21.5T G2

QUICRUN 3650SD 25.5T G2

5750

4560

3600

2850

2170

1800

1520

6.4 - 8.4

5.0 - 6.0

5.0 - 6.5

4.0 - 5.5

3.5 - 5.5

3.0 - 5.5

9.0 - 11.0

7.0 - 8.5

6.5 - 8.0

6.5 - 7.5

5.5 - 7.0

4.0 - 6.0

1/10 电越竞赛

1/10 电越竞赛,漂移车

1/10 漂移车 / STOCK 组竞赛

1/10 STCOK 组竞赛

1/10 STCOK 组竞赛

1/10 STCOK 组竞赛,F1,攀爬车

1/10 STOCK 组竞赛,攀爬车

This manual suits for next models

2

Other Hobby-Wing Remote Control manuals