Operating Manual- Touchscreen and QR Code Scanner

Table of Contents

2 Hoffmann Machine Company, Inc. • 11-2018

1 Table of Contents

1TABLE OF CONTENTS...........................................................................................................................2

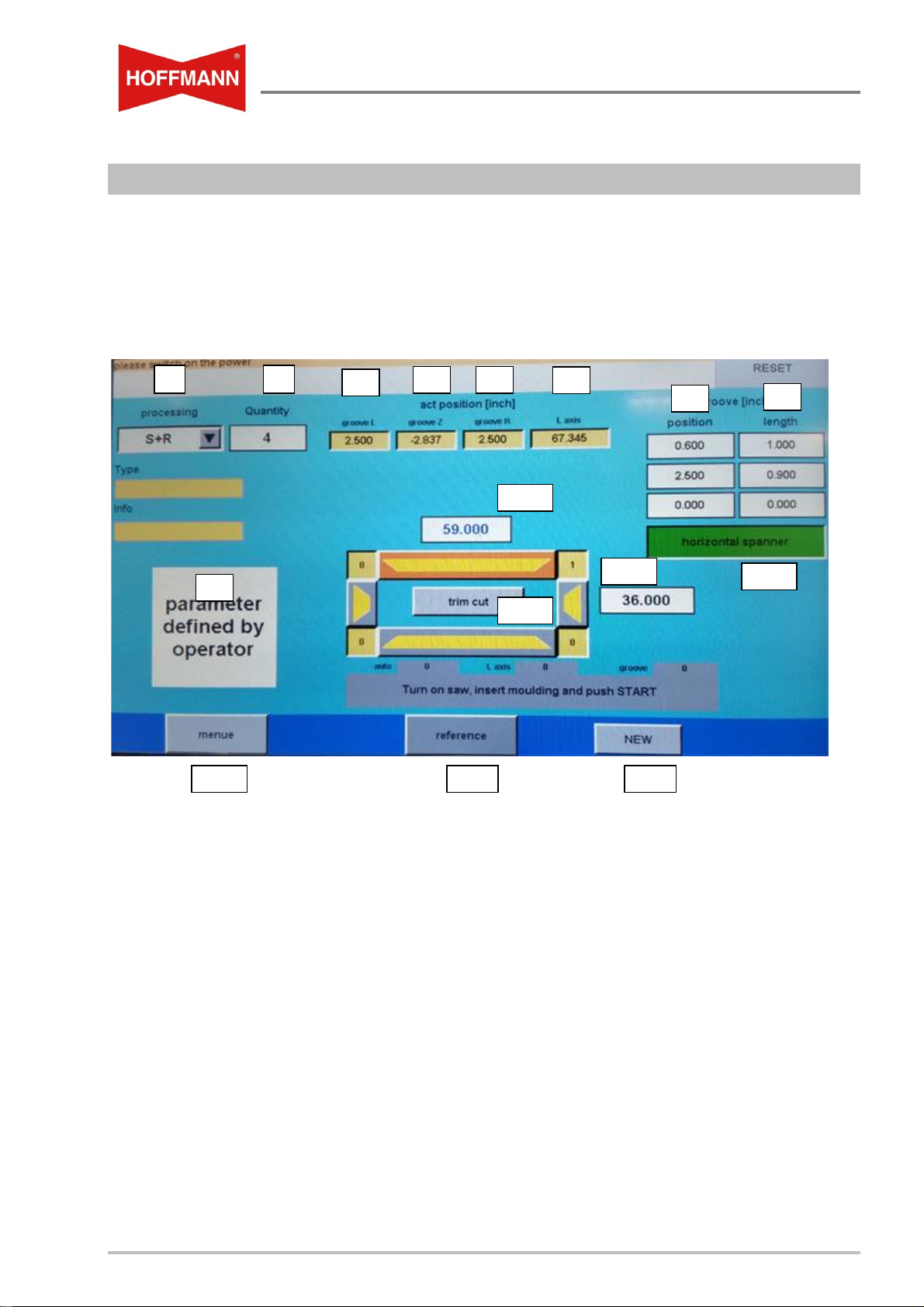

2MAIN MENU.............................................................................................................................................3

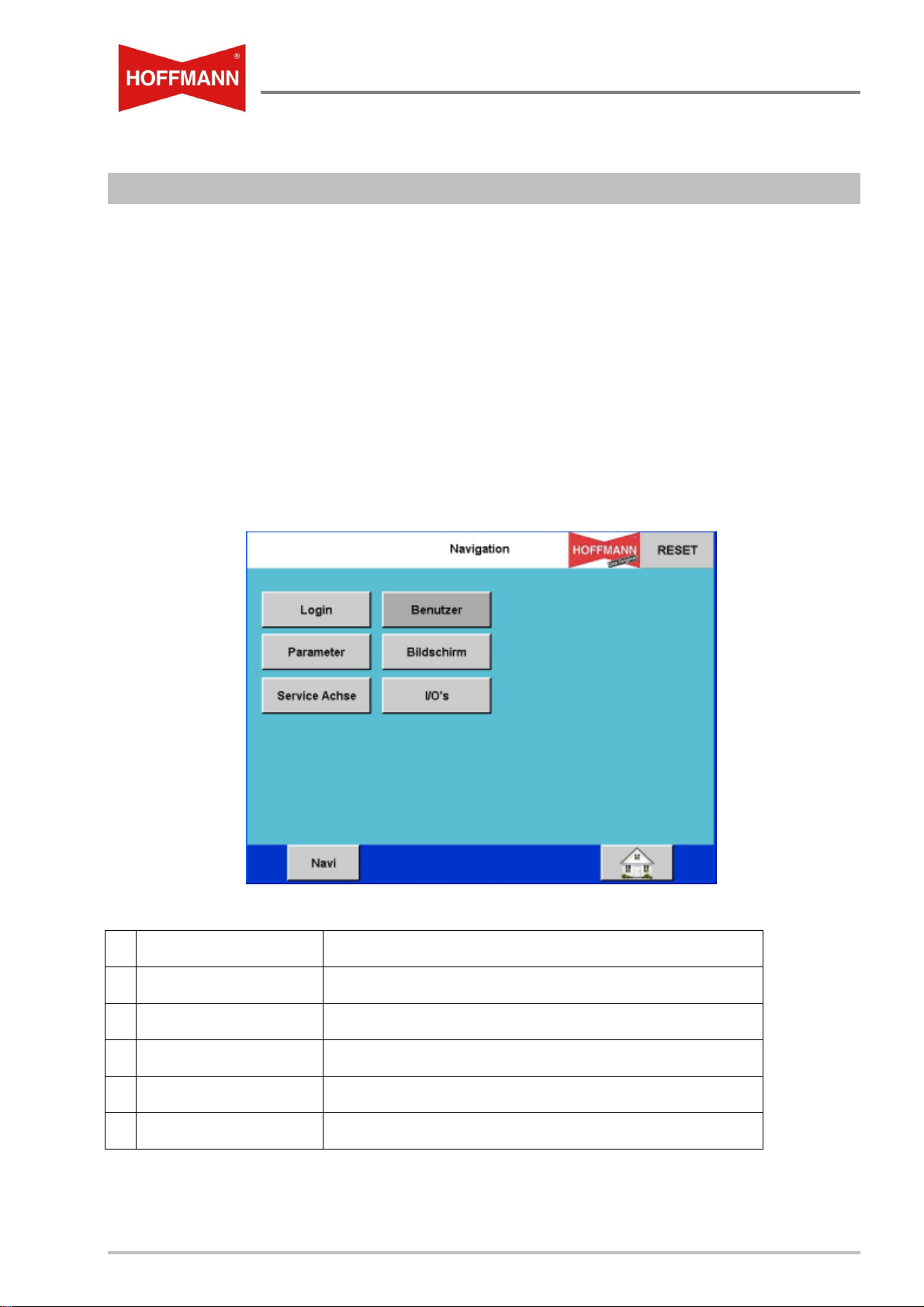

3SUB MENU NAVIGATION.......................................................................................................................5

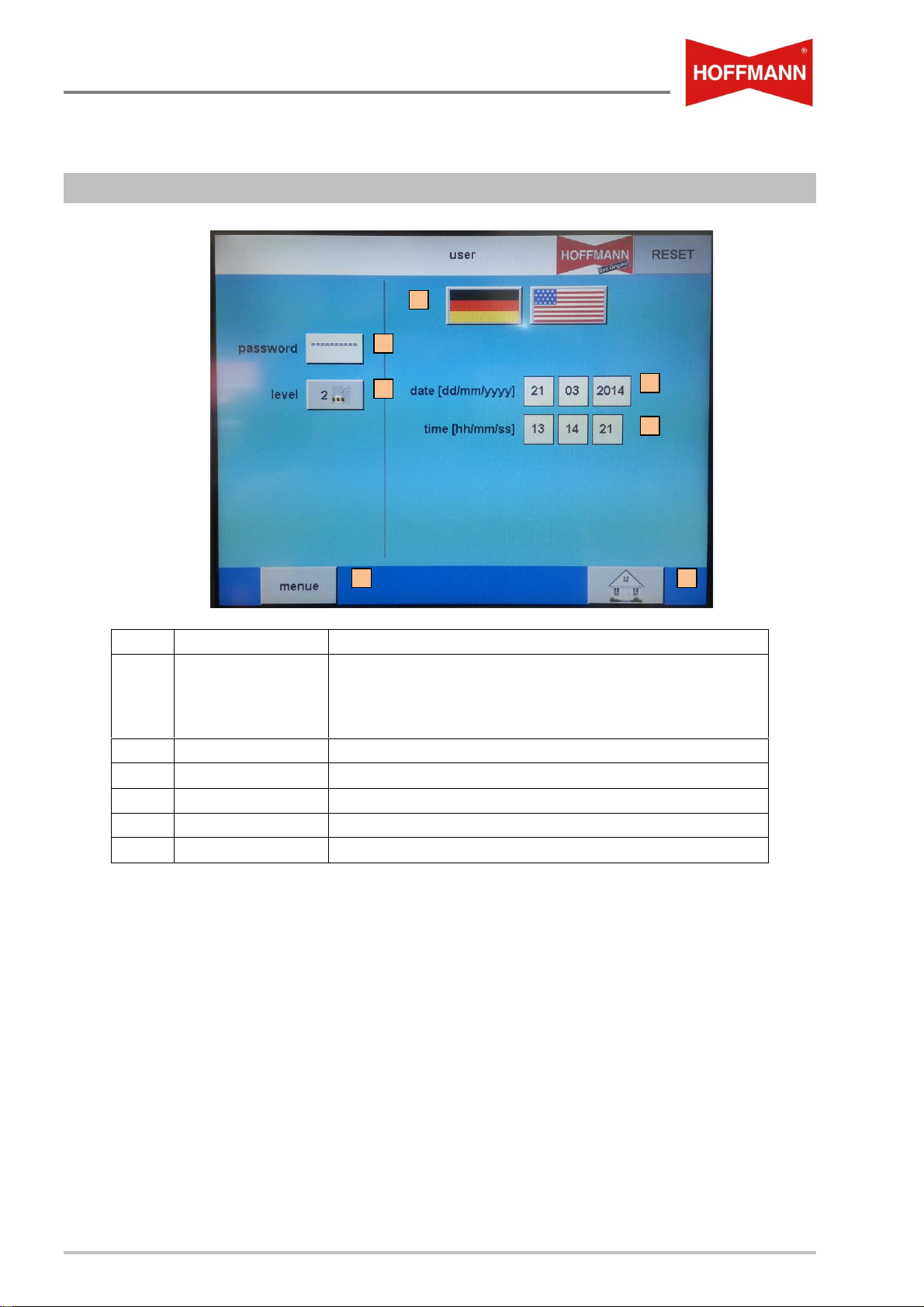

3.1 SUB MENU USER ...................................................................................................................................6

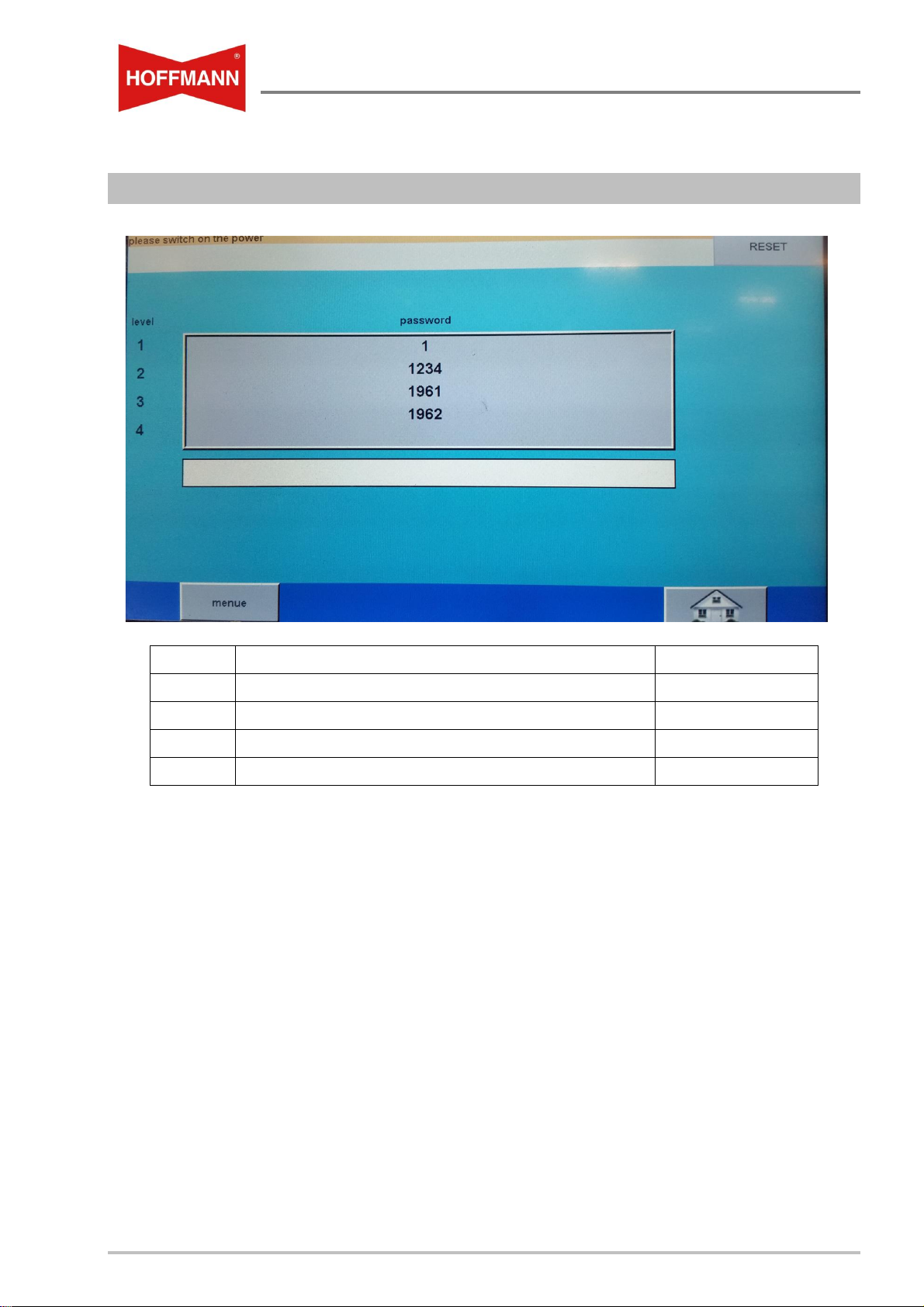

4SUB MENU USER (ACCESS LEVELS)..................................................................................................7

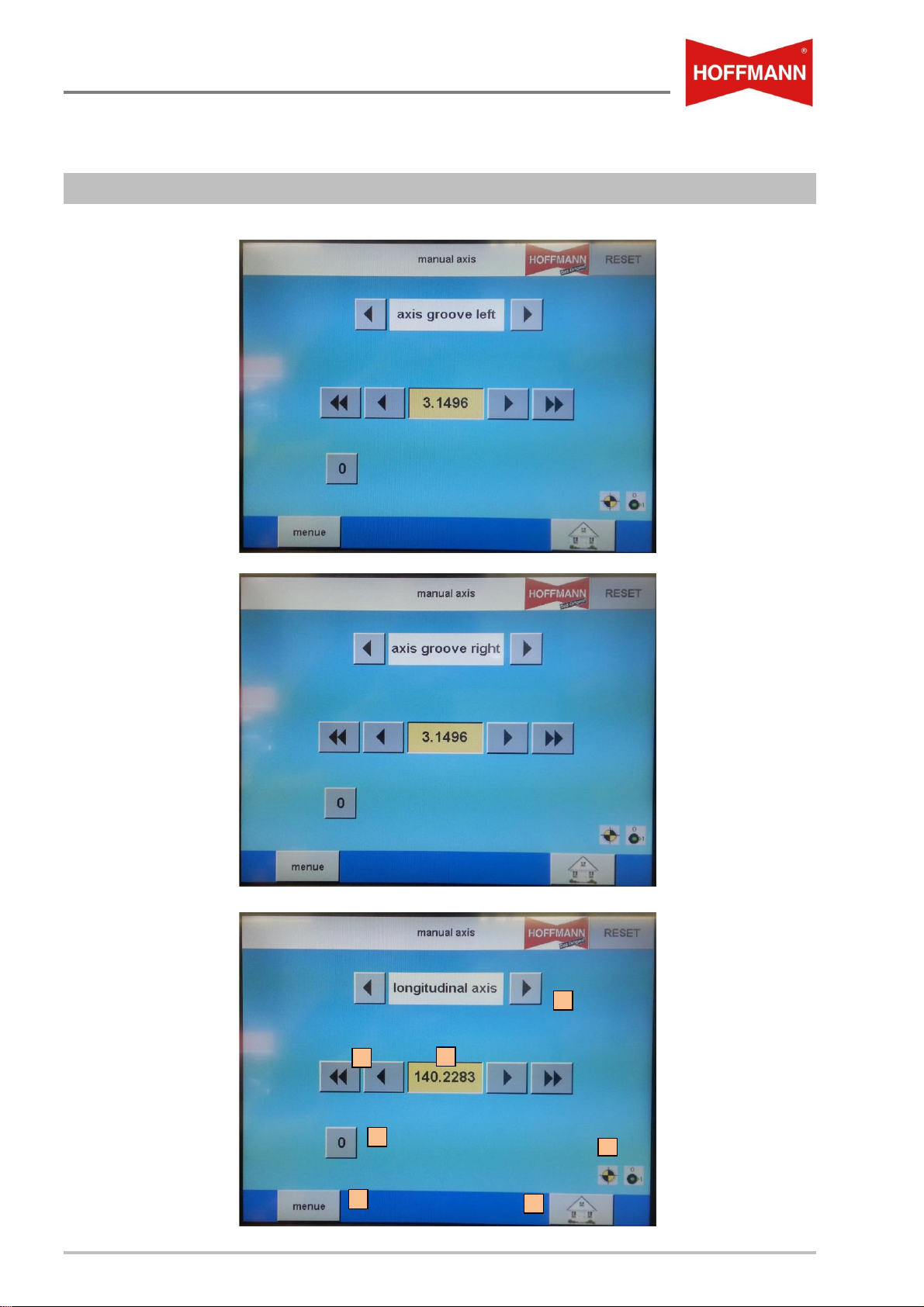

5SUB MENU MANUAL AXIS ....................................................................................................................8

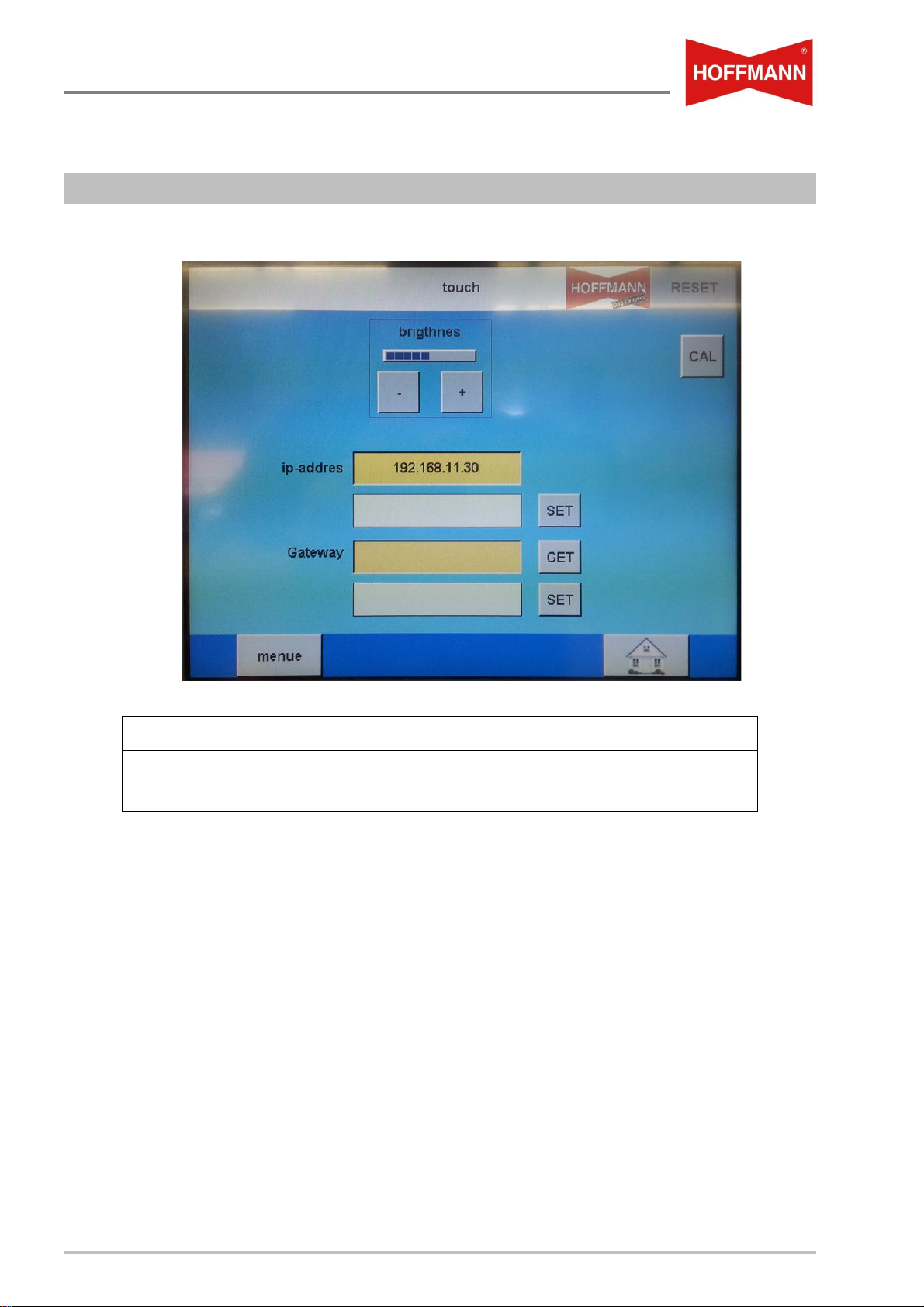

6SUB MENU TOUCH (SCREEN)............................................................................................................10

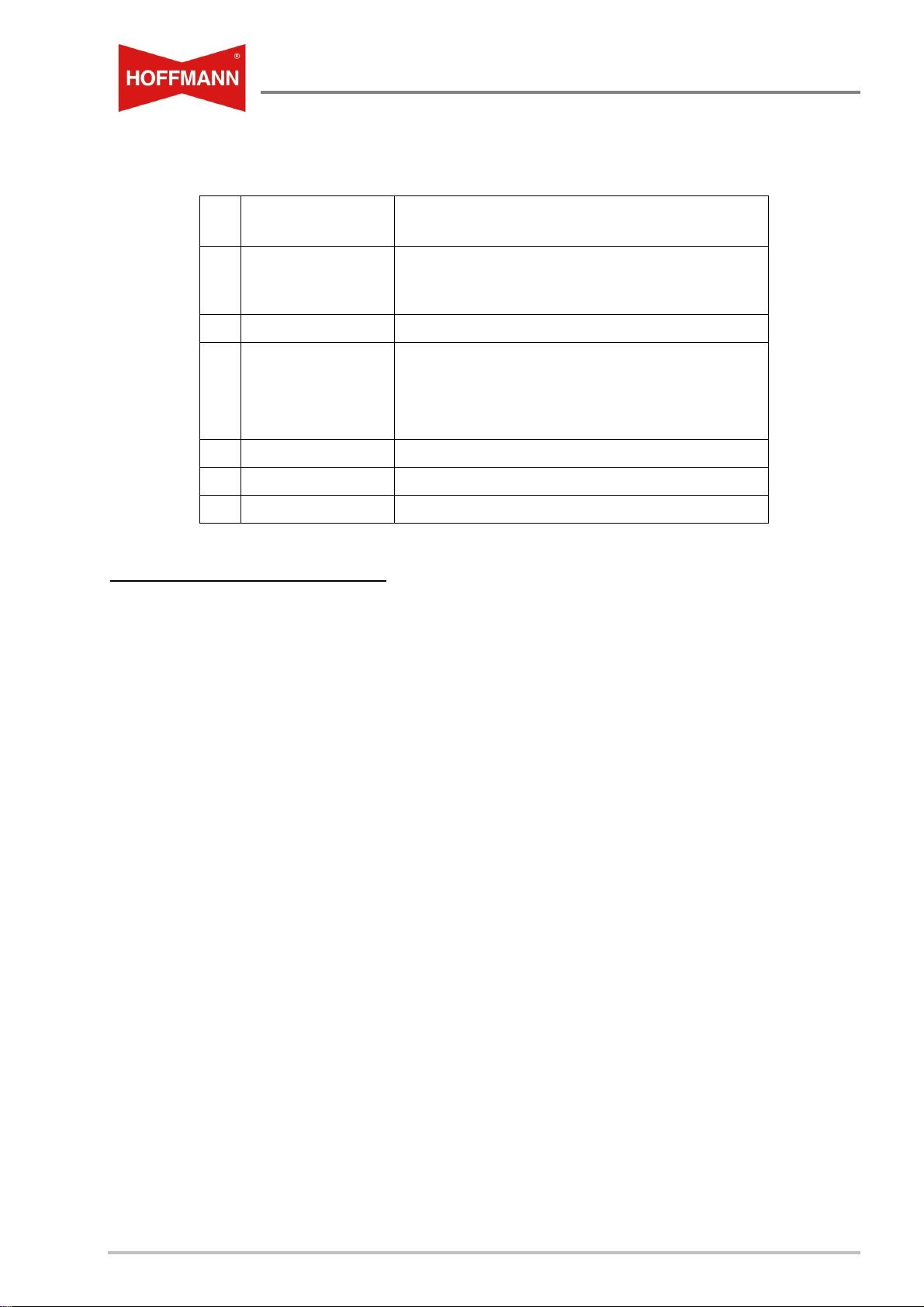

7SUB MENU PARAMETER.....................................................................................................................11

8SUB MENU DIGITAL INPUTS AND OUTPUTS (I/OS).........................................................................12

9MANUAL ENTRY OF FRAME DIMENSIONS.......................................................................................17

10 SCANNING QR CODES........................................................................................................................18

11 ADDING AND DELETING IMAGES......................................................................................................19

12 QR- CODE STRUCTURE ......................................................................................................................20

IMPORTANT:

THIS MANUAL ONLY COVERS DATA ENTRY, I/O AND

ERROR MESSAGES AND QR CODE DETAILS FOR

MS40SF

OPERATOR MUST HAVE ACCESS TO AND BE

THOROUGHLY FAMILIAR WITH THE MAIN OPERATING

AND MAINTENANCE MANUAL FOR THIS MACHINE AS

WELL AS THE SEPARATE MANUAL FOR THE ELA-2

POSITIONING SYSTEM.

ALL THREE MANUALS MUST BE KEPT WITH MACHINE AT

ALL TIMES.