Table of Contents

4EXACT06/2010 Hohner Maschinenbau GmbH

Table of Contents

1 Basic safety precautions.................................................................................. 5

1.1 Purpose of this document .............................................................................................. 5

1.2 The operator .................................................................................................................. 5

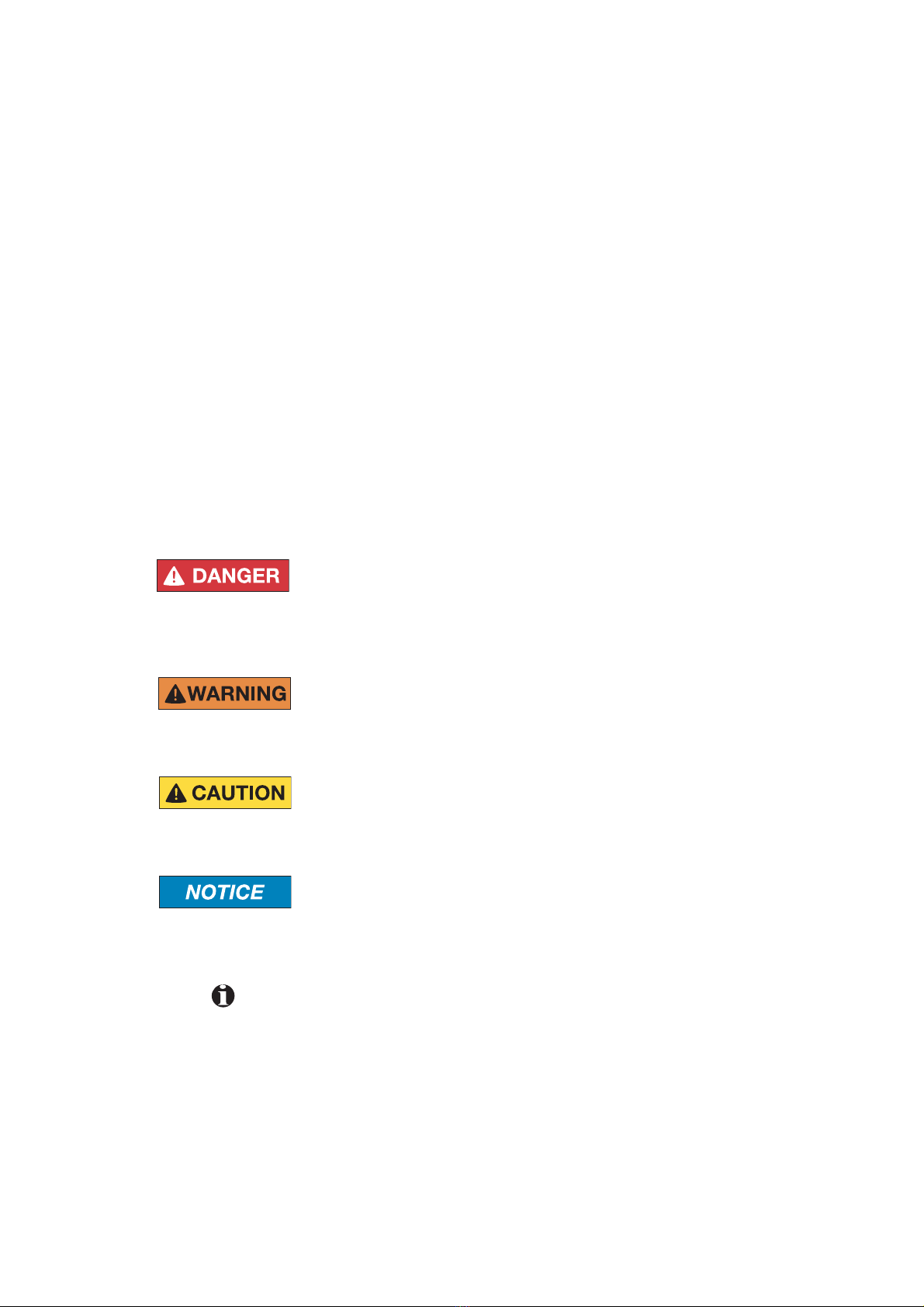

1.3 Safety symbols and the displays in use......................................................................... 5

1.4 Duty and liability............................................................................................................. 5

1.5 Correct use of the machine............................................................................................ 6

1.6 User requirements ......................................................................................................... 6

1.7 Safety and protective systems....................................................................................... 6

1.8 Informal safety measures .............................................................................................. 6

1.9 Personnel training.......................................................................................................... 6

1.10 Parts of the machine that are particularly dangerous .................................................... 7

1.11 Servicing and repair work, elimination of faults ............................................................. 7

1.12 Structural modifications to the machine......................................................................... 7

1.13 Cleaning the machine and the removal of waste products ............................................ 7

1.14 Noise levels produced by the machine .......................................................................... 7

2 Description of the Saddle Binder EXACT ........................................................ 8

2.1 Dimensions .................................................................................................................... 9

2.2 Conformity ..................................................................................................................... 9

2.3 Marking and type plate .................................................................................................. 9

2.4 Technical data ............................................................................................................... 9

3 Structure and function of the machine ........................................................... 10

3.1 Safety-related components.......................................................................................... 11

3.2 Mounting of the finger guard........................................................................................ 11

3.3 Electrical connection and motor protective relay ........................................................ 13

3.4 Installation of the stitching table.................................................................................. 15

3.4.1 Installation of stitching table: flat stitching................................................................ 15

3.4.2 Installation of stitching table for brochures stitching ................................................ 15

3.5 Installation - Stitching head......................................................................................... 17

3.6 Installation of the clincher box ..................................................................................... 17

3.7 Fine adjustment of the clincher box ............................................................................. 17

3.8 Pressure adjustment for clincher back press............................................................... 19

3.9 Installation of centering device and rider for stitching brochures................................. 19

3.10 Adjustment for stitching thickness ............................................................................... 21

4 Flow diagrams ............................................................................................... 22