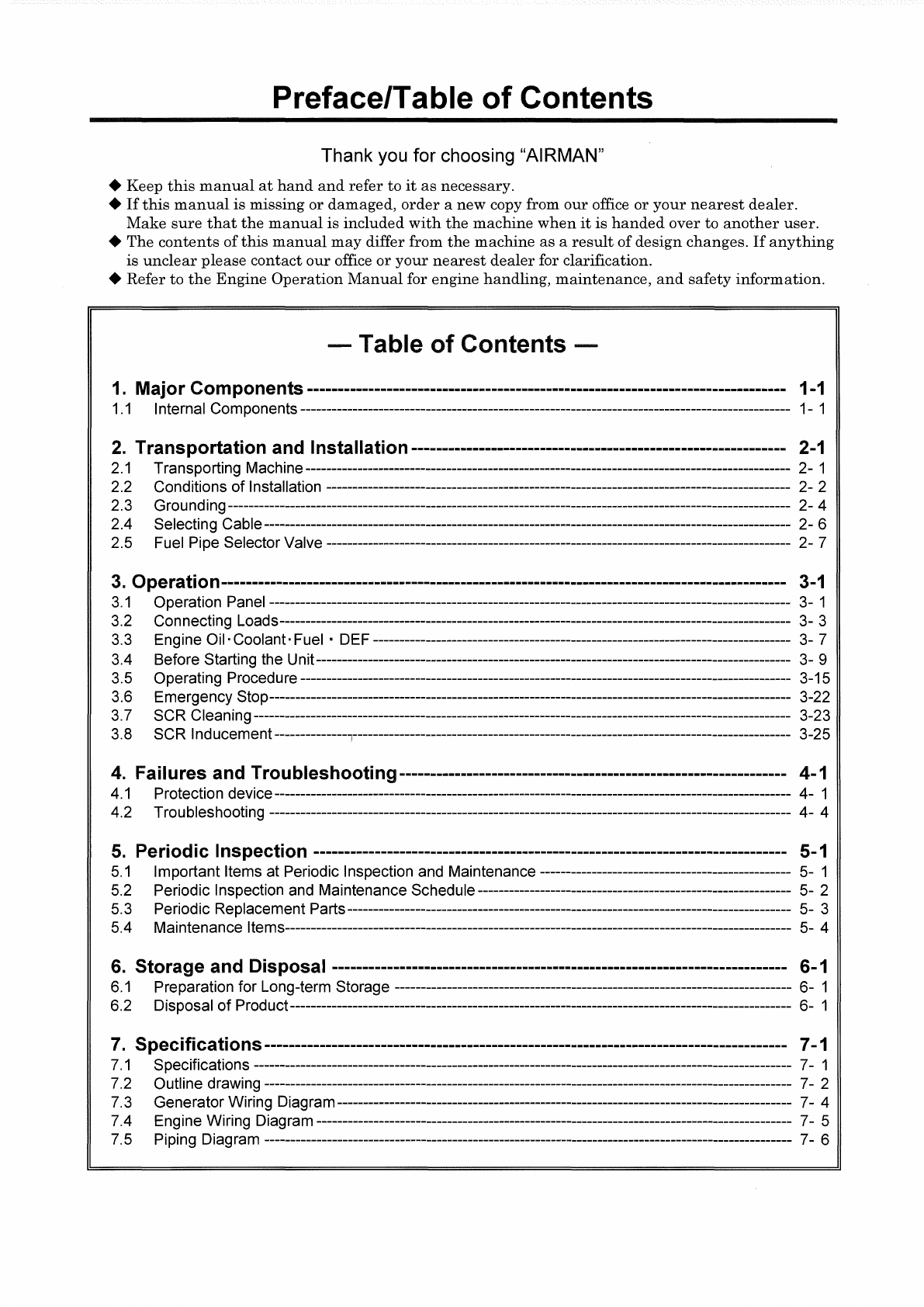

Preface/Table

of

Contents

Thank you for choosing "Al

RMAN"

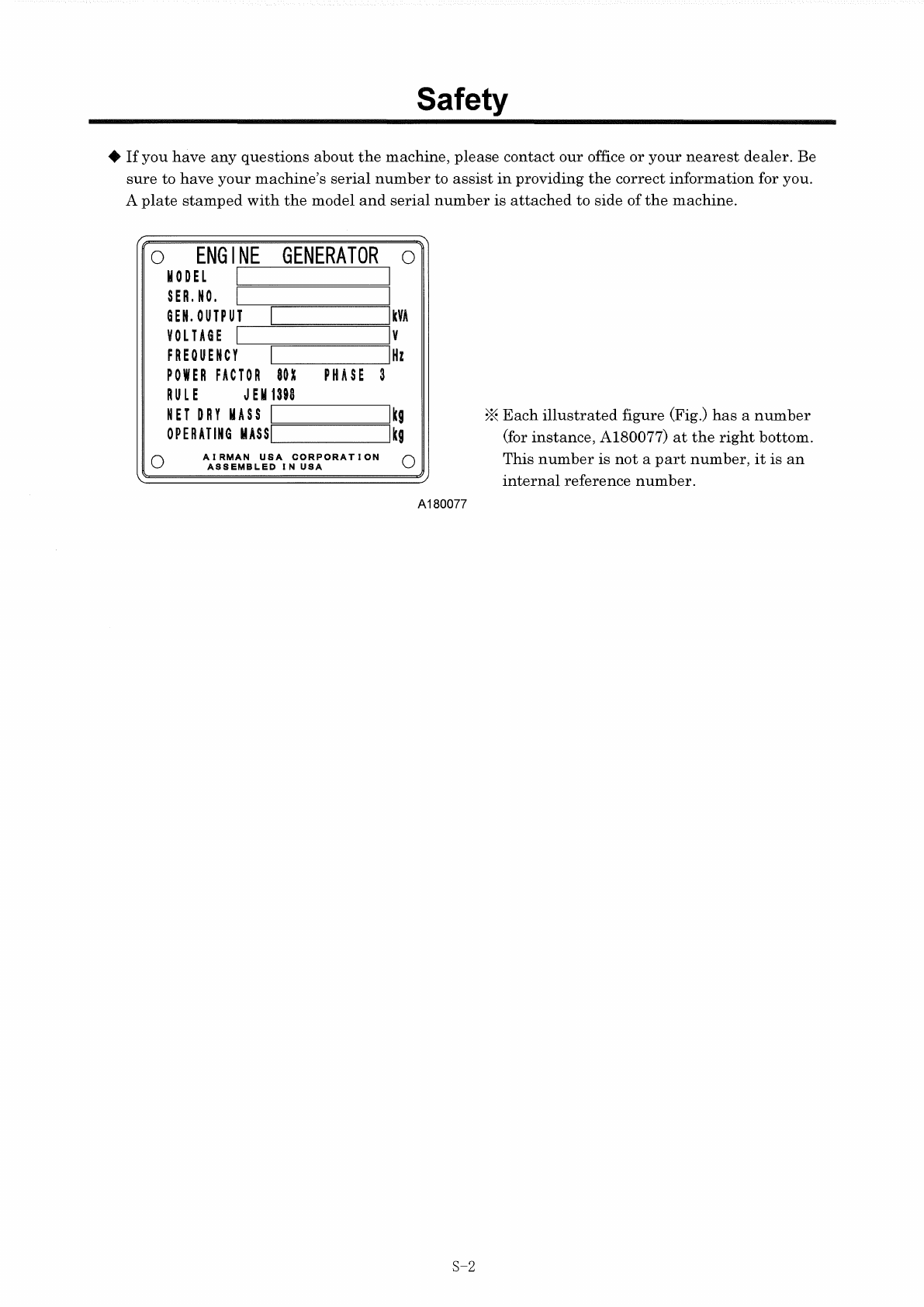

♦

Keep

this

manual

at

hand

and

refer

to

it

as

necessary.

♦

If

this

manual

is

missing

or

damaged,

order

a

new

copy from

our

office

or

your

nearest

dealer.

Make

sure

that

the

manual

is

included

with

the

machine

when

it

is

handed

over

to

another

user.

♦

The

contents

of

this

manual

may

differ from

the

machine

as

a

result

of

design

changes.

If

anything

is

unclear

please

contact

our

office

or

your

nearest

dealer

for clarification.

♦

Refer

to

the

Engine

Operation

Manual

for

engine

handling,

maintenance,

and

safety

information.

-Table

of

Contents -

1.

Major Components------------------------------------------------------------------------------

1-1

1.1

Internal

Components-------------------------

1- 1

2.

Transportation and Installation-------------------------------------------------------------

2-1

2.1

Transporting

Machine-------------------------

2-1

2.2

Conditions of Installation 2- 2

2.3 Grounding 2- 4

2.4 Selecting Cable 2- 6

2.5 Fuel Pipe Selector Valve 2- 7

3.

0 peration--------------------------------------------------------------------------------------------

3-1

3.1

Operation

Panel---------------------------

3- 1

3.2

Connecting Loads 3- 3

3.3

Engine Oil·Coolant· Fuel · DEF 3- 7

3.4 Before Starting the Unit 3- 9

3.5 Operating Procedure 3-15

3.6 Emergency Stop 3-22

3.

7 SCR Cleaning 3-23

3.8 SCR Inducement 3-25

4.

Fa

iIures and Troubleshooting--------------------------------------------------------------- 4-1

4.1

Protection

device--------------------------

4- 1

4.2

Troubleshooting---------------------------

4- 4

5.

Periodic Inspection ----------------------------------------------------------------------------- 5-1

5.1

Important Items at Periodic Inspection and

Maintenance-------------

5- 1

5.2

Periodic Inspection

and

Maintenance

Schedule----------------

5- 2

5.3

Periodic Replacement

Parts-----------------------

5- 3

5.4 Maintenance

Items--------------------------

5- 4

6.

Storage and Disposal -------------------------------------------------------------------------- 6-1

6.1

Preparation for Long-term Storage

--------------------

6- 1

6.2 Disposal of

Product-------------------------

6- 1

7.

Specifications------------------------------------------------------------------------------------- 7-1

7.1

Specifications---------------------------

7- 1

7.2

Outline

drawing---------------------------

7- 2

7.3

Generator Wiring

Diagram-----------------------

7- 4

7.4 Engine Wiring

Diagram------------------------

7- 5

7.5 Piping

Diagram--------------------------

7- 6