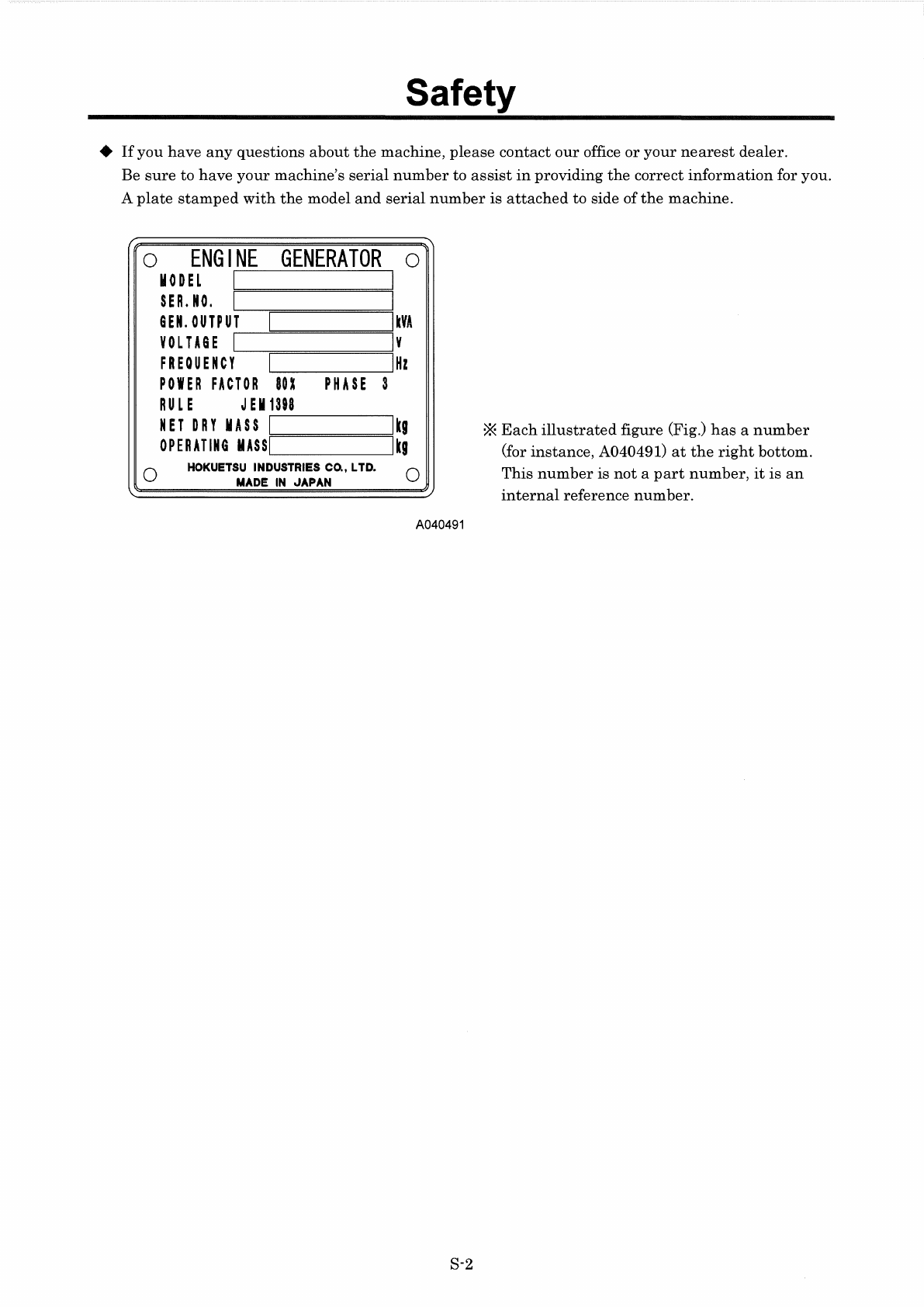

A

CAUT

H990432

Safety

•

Be

sure to stop the engine and let the coolant water sufficiently cool

down before draining

it.

• If the drain valve is opened before the coolant water is cool enough, hot

scalding water could jet out, causing burns.

• When washing the machine, cover the control panel, generator and its electric parts to prevent them

from being exposed to splashing water and avoid possible decrease

in

electrical insulation or other

troubles

to

the machine.

• Dust, sand, and dirt accumulated inside the control panel could cause malfunction or issues with the

instrumentation. Clean them using compressed air.

A100285

• Waste liquid from the machine contains harmful material. Do not

discharge it onto the ground or into the river, lake or sea. Such material

will pollute the environment.

•

Be

sure to use a container to hold waste liquid from the machine.

•

Be

sure

to

follow the designated regulations when disposing of oil, fuel,

coolant (antifreeze), filter, battery or other harmful materials.

• The engine of this machine contains many electrical and electronic parts. Before welding, be sure

to disconnect all electronic control equipment (specifically the ECM).

Failure to do so could result

in

equipment malfunction due to excessive current.

S-6