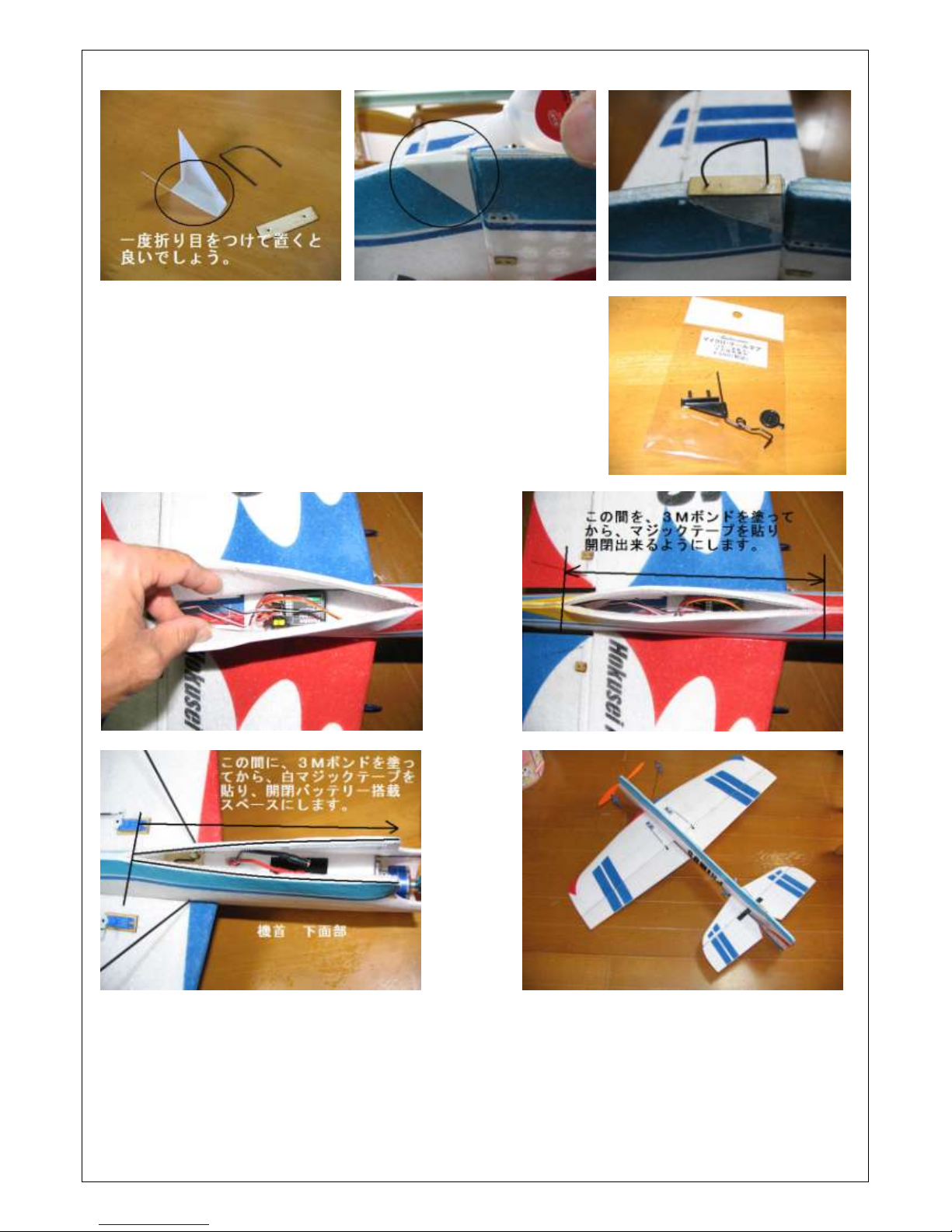

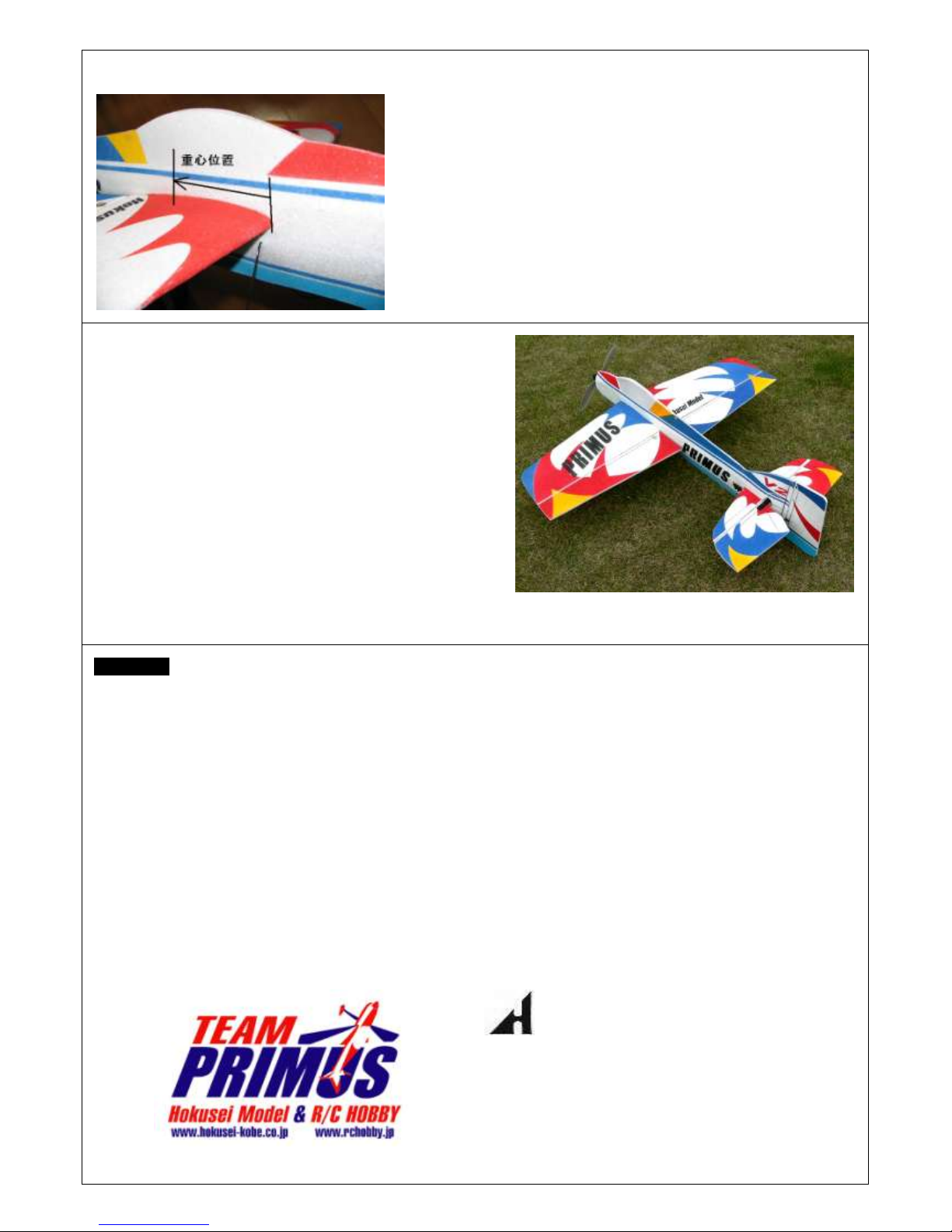

9. The Position of Center of Gravity

The Center of Gravity (CG) should be measured when everything (including the battery

pack) is put on the plane.

The suggested position of the CG for the plane is 100-110 mm behind the point where

the leading edge of the main wing meets the fuselage.

The suggested position of the CG is only meant to provide as a starting point to explore

the “best”position of the CG. The “best”position is different for different pilots and

different flying styles.

Please adjust the position of the CG by moving the position of your battery forward or

backward to find the most desirable position of the CG for your plane.

You may use batteries of different types, sizes, and weights. Find the right position for

your particular battery to get the optimum CG by experimenting.

Now your Primus EPP is ready to fly!

This plane is made of EPP (expanded polypropylene) material with carbon

fiber reinforcement. As a result, it is much more durable than balsa planes.

Minor crashes will normally not cause any damage to the airframe; and more

serious ones mostly create cracks, which are often easily repairable with glue

such as 3M Scotch 6225n glue in the flying field, in the airframe. Therefore,

this plane can be a wonderful trainer for practicing new maneuvers.

This plane is designed for slow acrobatic flying. Please do not stress the

airframe with high-speed acrobatic maneuvers.

Handling lithium polymer (LiPo) batteries

Electric acrobatic model planes are becoming more and more popular with the

advancement of LiPo battery technology. However, LiPo batteries can be a fire

hazard if they are handled properly.

Please read the instruction from your LiPo battery vendor or manufacturer carefully, and only use LiPo battery chargers to charge LiPo batteries.

Never overcharge or over-discharge your LiPo batteries.

Warnings:

This plane is designed for advanced hobbyist. Beginners please seek help from those who are experienced in acrobatic model airplanes.

This plane is designed for slow acrobatic flying using a 350-400 class brushless motor powered by an 11.1v LiPo battery pack. Please do not

overpower your plane with a much larger motor powered by a higher-voltage battery pack.

This plane is designed to have just enough strength required by slow acrobatic flying so as to keep the total weight down for high

performance. If you want to use the plane for high-speed acrobatic flying, please reinforce it with carbon fiber materials and glass fiber

tapes.

EPP material can change its shape under stress, especially in high temperature. Therefore, care must be applied in transporting and storing

your EPP planes to avoid their distorting. Do not, for example, leave your EPP planes in a vehicle for a long time on a hot summer day. The

best way to store an EPP plane is probably hanging it vertically with the nose up.

Be a responsible RC pilot. Check the power system, batteries, radio control equipment, all of the control surfaces, and the flying field before

flying. Always fly safely.

The product is an ARF kit, which needs further cutting to make all the components fit together.

Although this plane is much more durable than a typical balsa plane, it is not indestructible in a crash. The building material and parts can be

ruined if they are handled with excessive force or incorrectly. Care is still needed during either building or flying the plane

Flying the plane with wide-open throttle in level or dive flight may cause its wing to twist or flutter, which may lead to disintegration of the

plane in the air. Similarly, violent maneuvers such as blenders and snap-rolls may also lead to disintegration of the plane in the air. Please

manage the throttle and flying speed wisely. Hokusei will not be held liable for such disintegration.

Read the manual for your ESC carefully before using it for the first time. It is a good idea not to install a prop onto your motor when trying a

new power configuration for you motor start spinning unexpectedly.

Read instruction for your LiPo batteries carefully and handle them with caution.

Contact Info:

International Division, Hokusei Model

916 Shenye Mansion, 1027 Wenjin Zhong Road Luohu District,

Shenzhen, China 518001

Tel: (86)755-82253767 Fax: (86)755-82203767

Authorized International Dealer:

http://www.BestValueRC.com