3. Product Specs

Product Name 2D LiDAR

Model UGM-50LAP

Supply voltage DC 24V +/-10%

Supply current Steady state current: 1A or less, Starting Current: 1.5A or less, without Heater *1

Power Consumption 24W or less (Steady state and current)

Heater Voltage DC24V

Heater Current Steady state and Starting current : 2A or less, Only Heater*2

Heater Power Consumption 48W or less

Measurement resolution 1mm

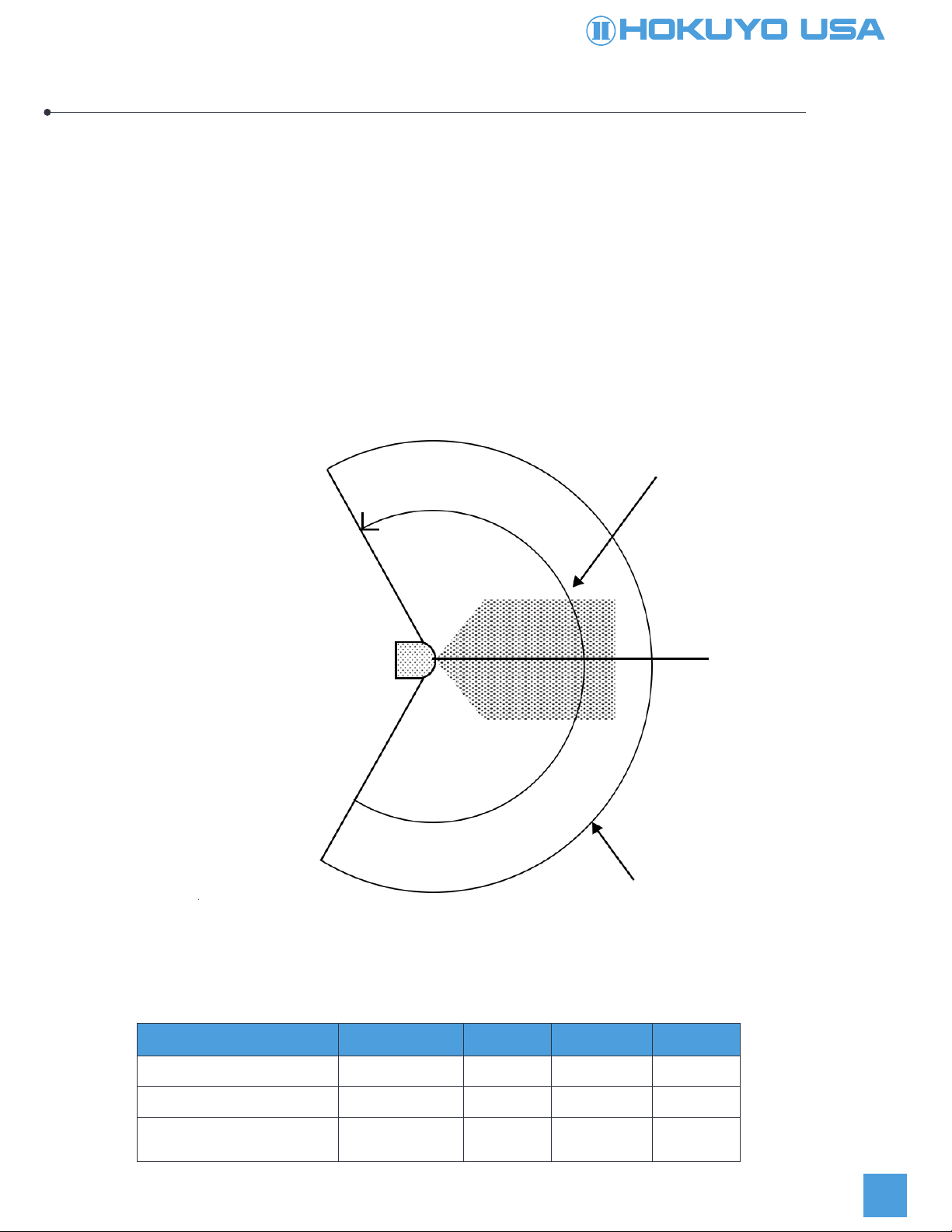

190*

Detection range and object Guarantee detection range:

0.1m to 50m*3 (10% Reflectance Black paper 500mm×500mm)

0.1m to 120m*4 (90% Reflectance white Kent paper1400mm×1400mm)

Maximum area setting : 120m (Distance output range 160m)

Minimum detectable size

Normal mode : 65mm (5m), 130mm (10m), 260mm (30m)

High resolution mode : 33mm (5m), 65mm (10m), 130mm (30m)

Average Accuracy by distance 10% Reflectance Black paper

0.1m to 30m:±30mm (Indoor 1,000lx or less)

30m to 50m:±40mmm (Indoor 1,000lx or less)

0.1m to 50m:±50mm*5 (Outdoor 100,000lx or less)

90% Reflectance white Kent paper

0.1m to 50m:±30mm

0.1m to 50m:±50mm*5 Ambient illuminance : 100,000lx or less

Repeat accuracy

Scanning angle

Within 30 sec after power supply

Start up time

Ethernet 100BASE-TX(Auto-negotiation)

Interface

4 LEDs (Yellow green, Orange, Blue, Red)

LED display

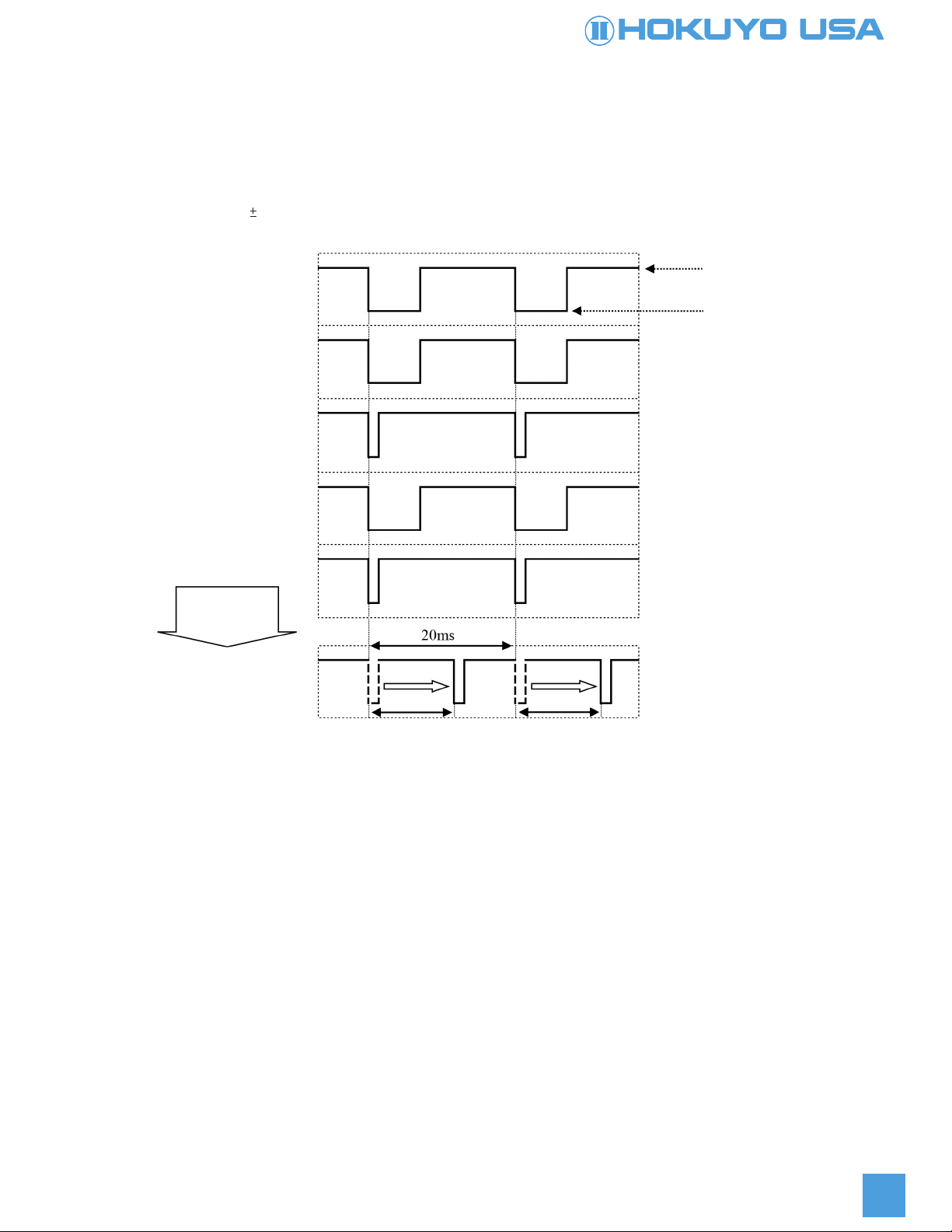

20ms*6(Normal mode 3000rpm)/ approx. 0.32°(360°/1125)

40ms*6(Low speed mode 1500rpm)/ approx.0.16°(360°/2250)

80ms*6(High resolution mode 750rpm)/ approx.0.08°(360°/4500)

Scan speed/ Angular resolution

7 PNP OUTPUTS : Synchronization master output, Synchronization output

Malfunction output, Contamination output, Area detection 1 to 3

(Open collector output DC30V 50mA MAX.)

Outputs

40msec or less (Normal mode)

80msec or less (Low speed mode)

160msec or less (High resolution mode)

In either case, change depending upon the delay setting

Output response time

7 INPUTS : Synchronous input, IP Reset input, Reboot input, Area input 1 to 4

(All 15 patterns)

(Photocoupler input, Cathode common, Input ON current 2mA)

Inputs

10% Reflectance Black paper

0.1m to 30m:σ<9mm (Indoor 1,000lx or less)

30m to 50m:σ<15mm (Indoor 1,000lx or less)

0.1m to 50m:σ<15mm*5 (Outdoor 100,000lx or less)

90% Reflectance white Kent paper

0.1m to 50m:σ<9mm (Indoor 1,000lx or less)

0.1m to 50m:σ<15mm*5 (Outdoor 100,000lx or less)

UGM-50LAP

4

Light source Laser semiconductor (905nm), FDA Laser Safety Class 1 (IEC60825-1:2014)