1

XL-FW10054UM-en-US Rev C· 2018-01-29 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Contents

Content Page

Introduction..............................................1

Notes, Cautions, and Warnings ..................1

Section 1 – Model Identification................2

Section 2 – General Safety Instructions .....3

Section 3 – Fifth Wheel Intended Use ........4

Section 4 – Fifth Wheel NON-Intended Use...4

Section 5 – Coupling Preparation ..............4

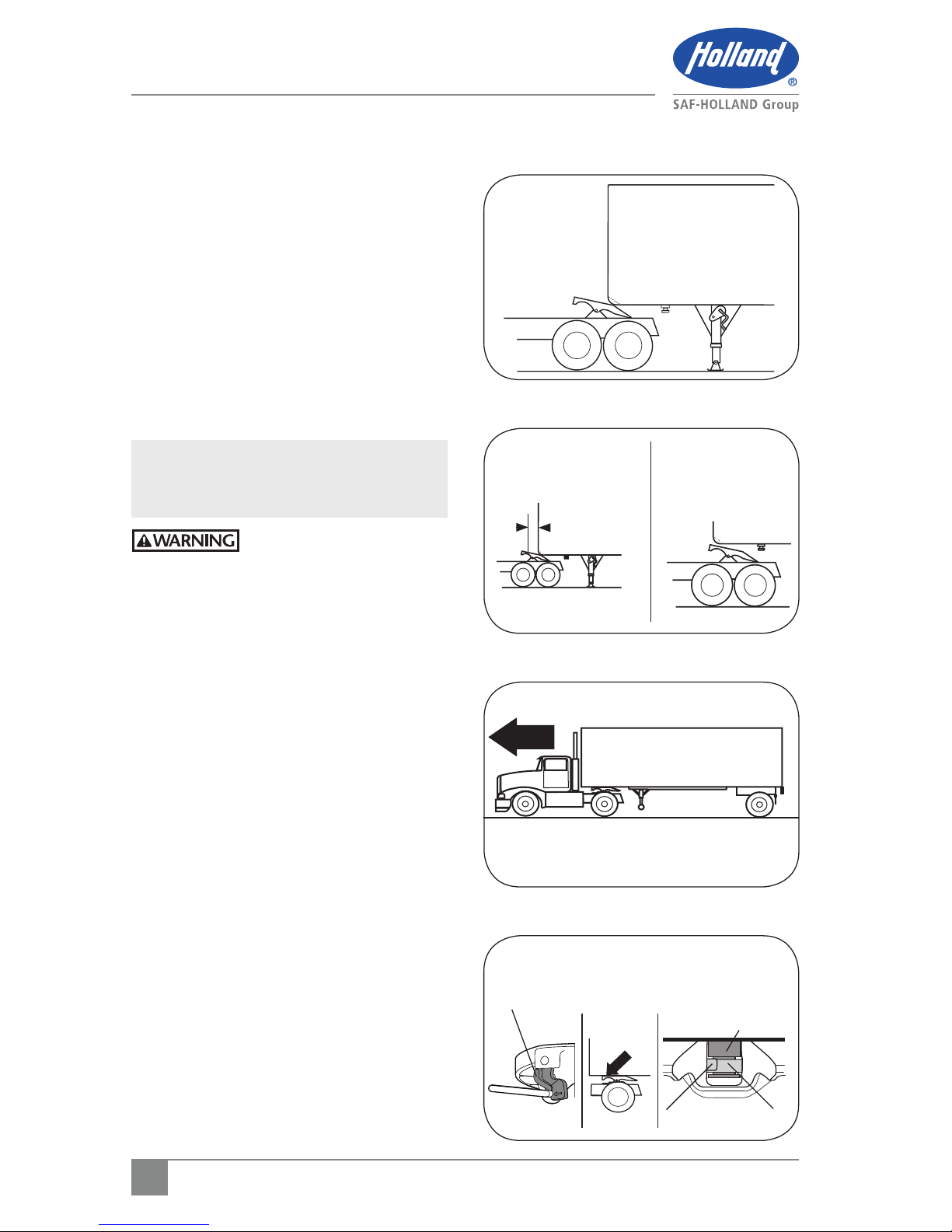

Section 6 – Coupling Procedures ...............5

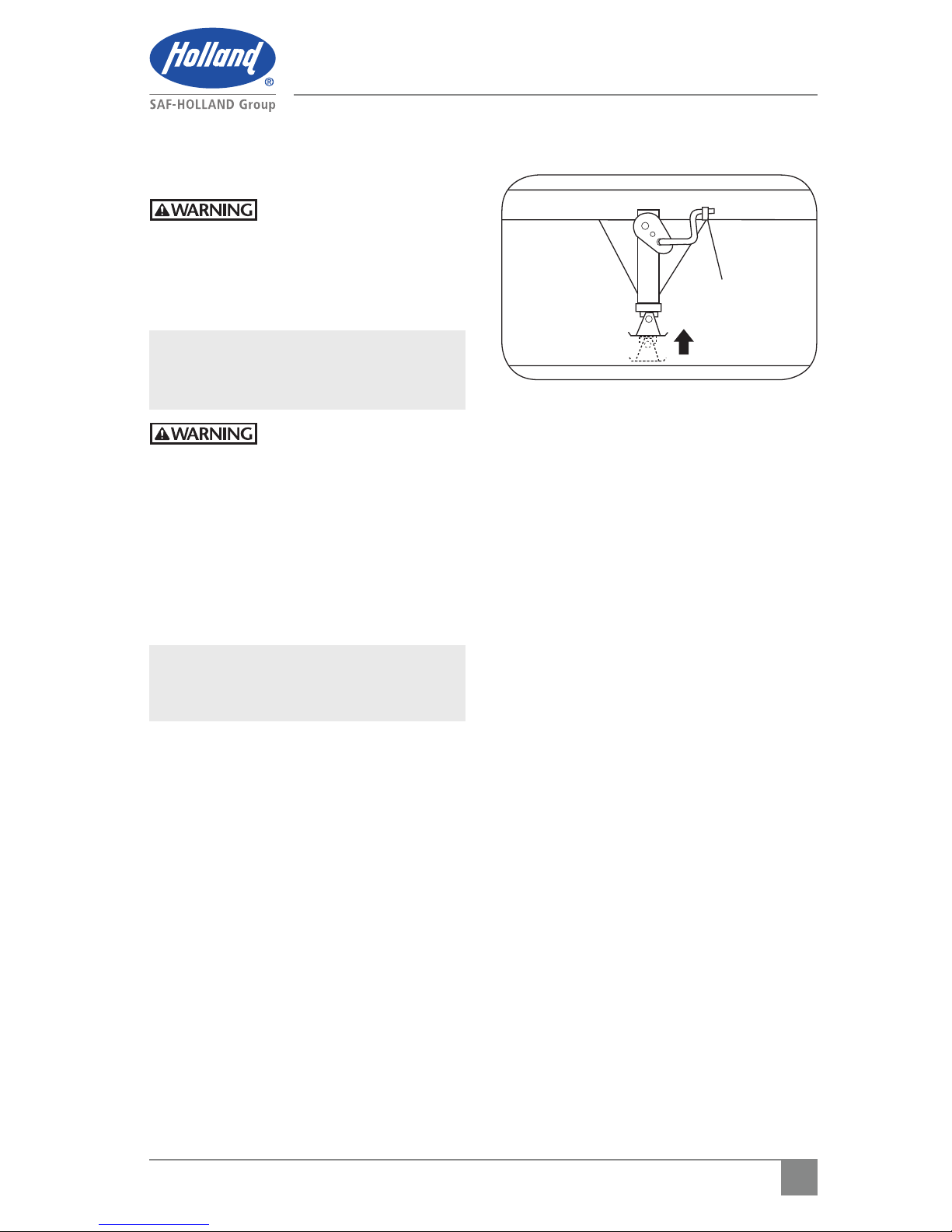

Section 7 – Uncoupling Procedures ...........7

Section 8 – Positioning Sliding Fifth Wheels....8

Content Page

Section 9 – Fifth Wheel Maintenance ........9

Section 10 – Top Plate Removal...............10

Section 11 – Fifth Wheel Lubrication .......10

Section 12 – Slide Base Lubrication.........12

Section 13 – Fifth Wheel Adjustment .......13

Section 14 – Pocket Insert Inspection ......15

Section 15 – Top Plate Installation ..........16

Section 16 – Troubleshooting ..................17

Section 17 – Rebuild and Replacement Kits..19

Introduction

This manual provides the information necessary

for the proper operation and maintenance of

HOLLAND®FWS1 and FWS2 series fifth wheels.

NOTE: For HOLLAND replacement

components contact SAF-HOLLAND

Customer Service: 888-396-6501.

Notes, Cautions, and Warnings

You must read and understand all of the

procedures presented in this manual

before operating or starting work on any

HOLLAND FWS1 or FWS2 series fifth wheel.

IMPORTANT: Keep this manual in

a safe location for

future reference.

Proper tools must be used to perform the

maintenance and repair procedures described

in this manual.

NOTE: In the United States, workshop

safety requirements are defined by

federal and/or state Occupational

Safety and Health Acts. Equivalent

laws may exist in other countries.

This manual is written based

on the assumption that OSHA

or other applicable employee

safety regulations are followed

by the location where the work

is performed.

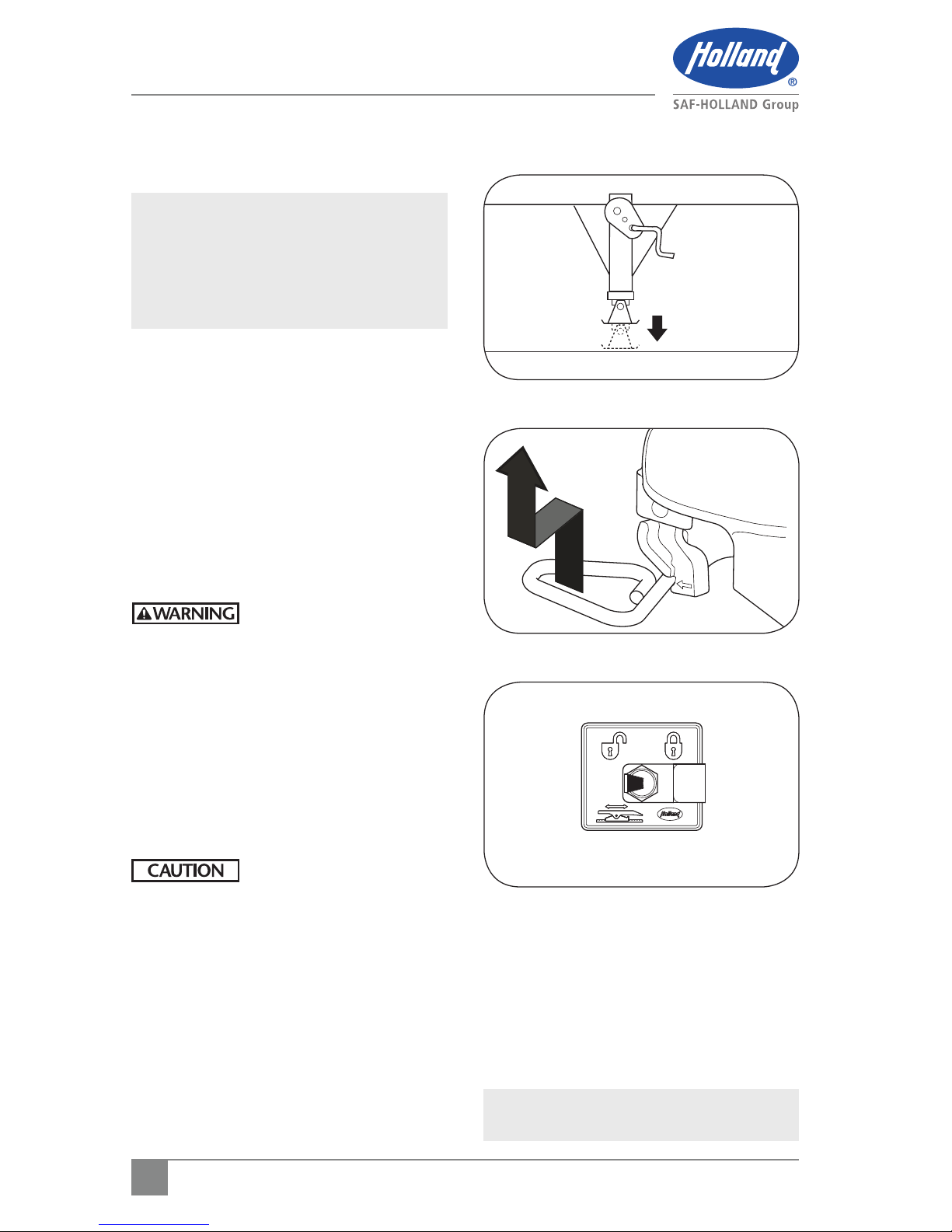

Throughout this manual, you will notice the

terms, “NOTE,” “IMPORTANT,” “CAUTION,”

and “WARNING” followed by product

information. So that you may better understand

the manual, those terms are defined as follows:

NOTE: Includes additional information

to enable accurate and easy

performance of procedures.

IMPORTANT: Includes additional

information that if

not followed could

lead to hindered

product performance.

Used without the safety

alert symbol, indicates

a potentially hazardous

situation which, if not

avoided, may result in

property damage.

Indicates a potentially

hazardous situation which,

if not avoided, may result

in minor or moderate injury.

Indicates a potentially

hazardous situation which,

if not avoided, could result

in death or serious injury.