XL-FW1114-01 1

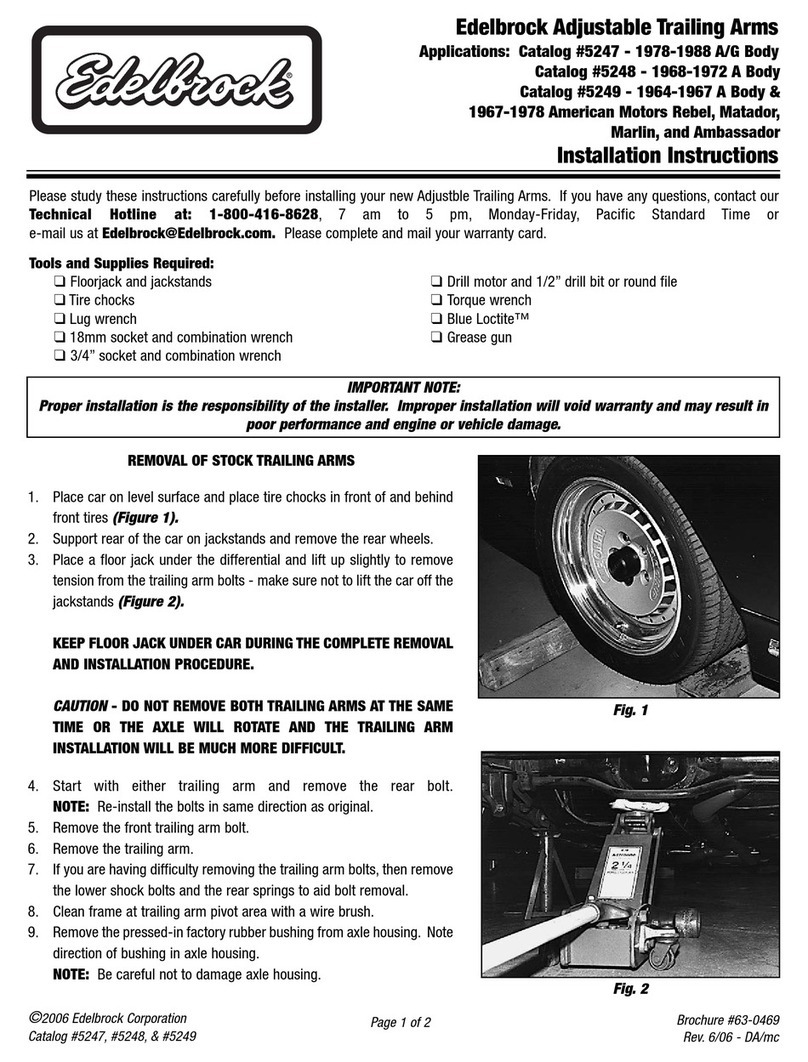

FW3510

FW3510/FW3410 &

FW3110

FIFTH WHEEL

OPERATING MANUAL

WARNING

You must read and understand

the instructions in this

manual before operating

your fifth wheel.

Failure to follow all of the

important operating procedures

contained in these instructions

may result in a hazardous

condition or cause a hazardous

condition to develop.

These instructions apply to the

proper operation of your fifth

wheel only. There are other

important checks, inspections,

and procedures not listed here

that arenecessary,prudent,

and/or required by law.

Table of Contents

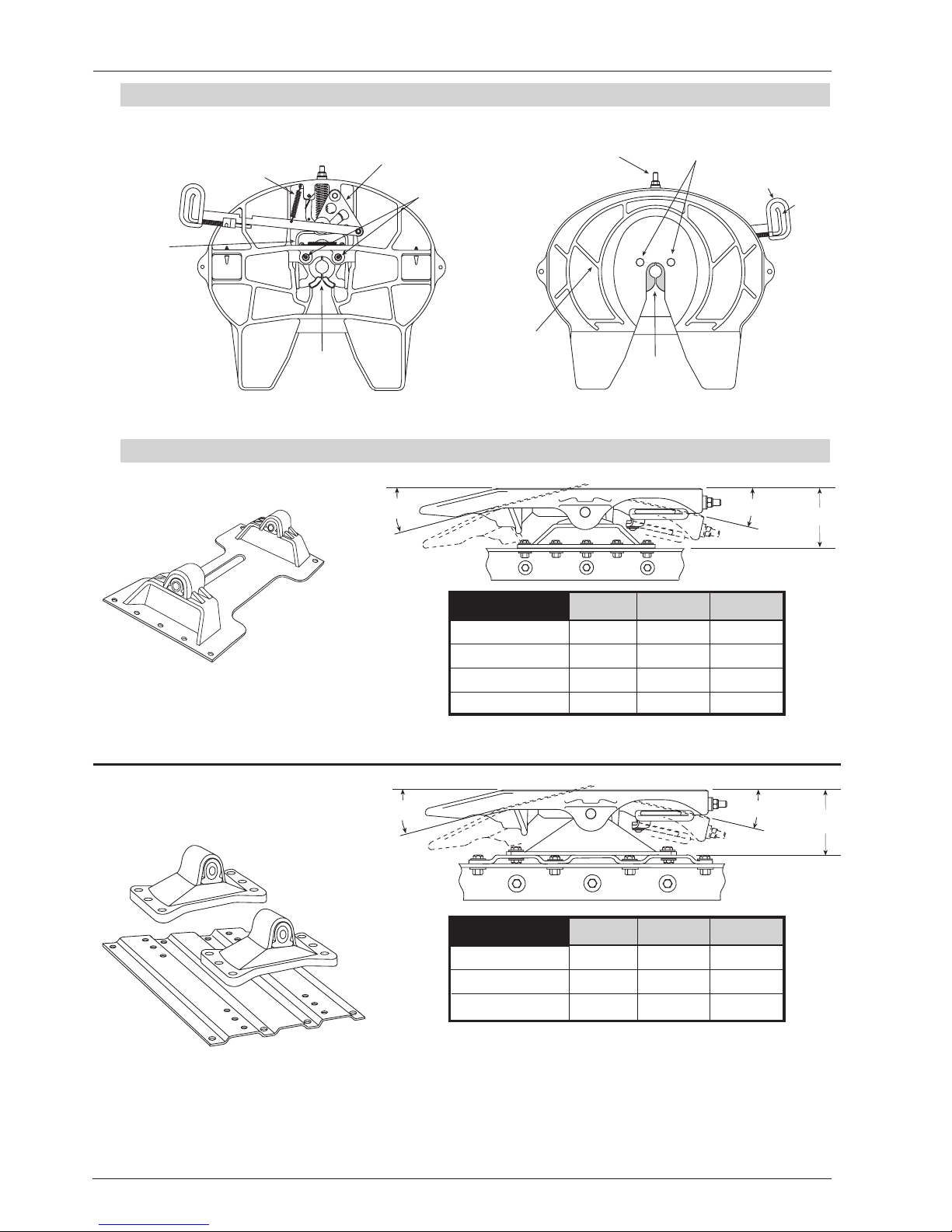

1. Component Part Identification and Specifications

1.1 Identification of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2 Important specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

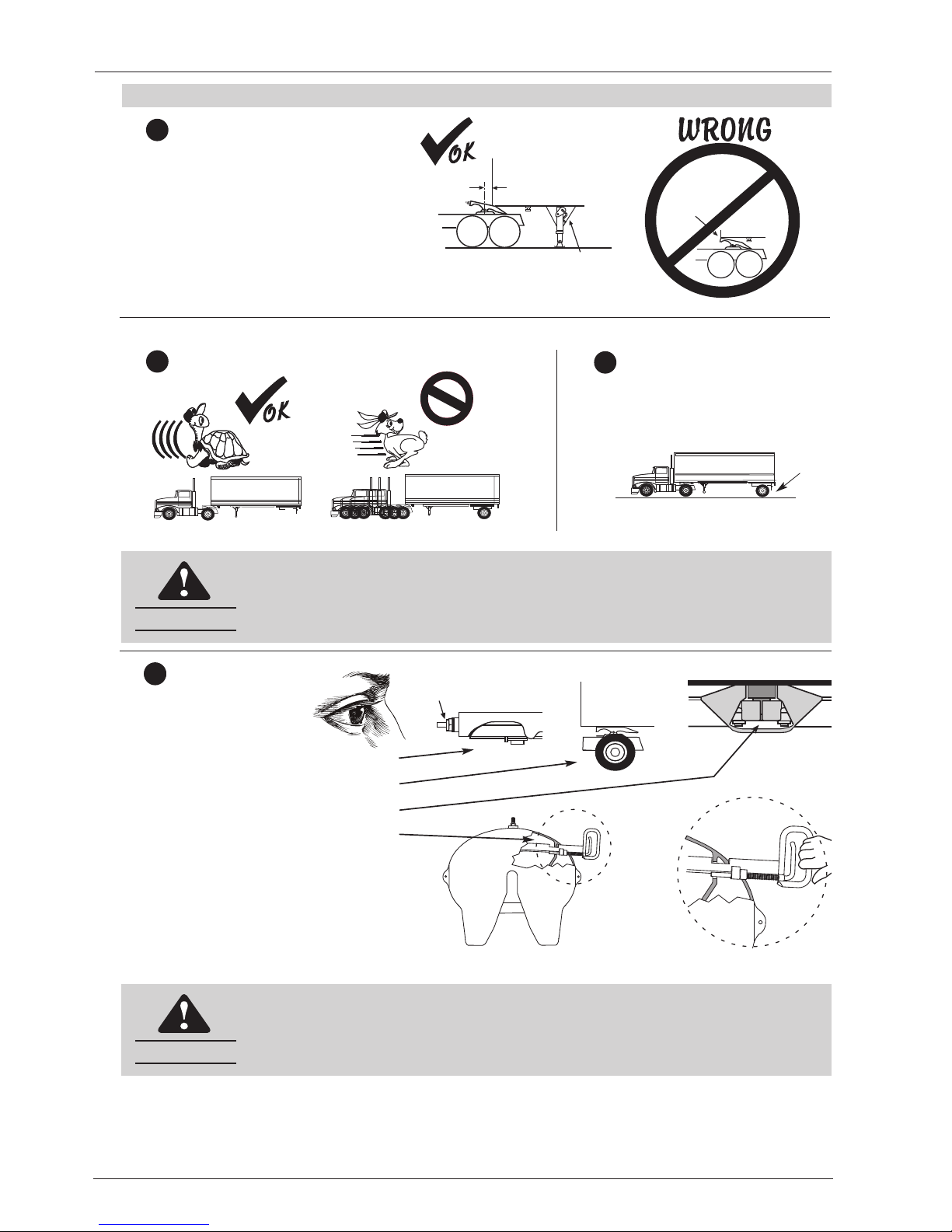

2. Operating Instructions

2.1 Pre-service inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Trailer coupling procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

2.3 Trailer uncoupling procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3. Routine Inspection and Maintenance

3.1 As Needed Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2 Required Inspections and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

3.2.1 General fifth wheel inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2.2 Inspection of locking mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2.3 Lock adjustment procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7