INSTRUCTION MANUAL FOR

DODGE®S-2000 SPHERICAL ROLLER BEARINGS

GENERAL INFORMATION

DODGE S-2000 Spherical Roller Bearing mounted units incor-

porate a unique way of sealing the internal components of the

bearing while still allowing a full + or - 1 degree of misalignment.

The patented sealing system (Pat. #5,908,249) has proven

effective, due to its constant contact pressure, in protecting the

internal bearing components under maximum allowable misaligned

conditions.

INSTALLATION INSTRUCTIONS

NON-EXPANSION BEARING

WARNING

TO ENSURE THAT DRIVE IS NOT UNEXPECTEDLY

STARTED, TURN OFF AND LOCK OUT OR TAG POWER

SOURCE BEFORE PROCEEDING. FAILURE TO

OBSERVE THESE PRECAUTIONS MAY RESULT IN

BODILY INJURY.

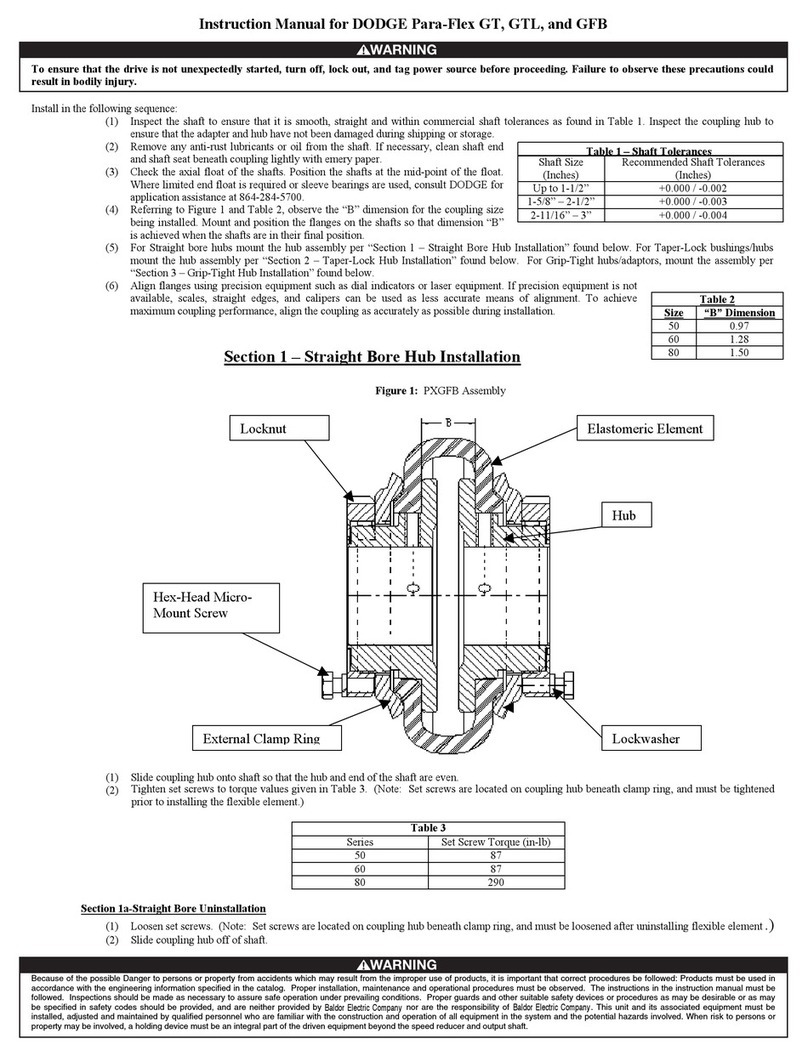

1. Clean shaft and bore of bearing. The shaft should be

straight, free of burrs and nicks, and correct size (see

shaft tolerance table). If used shafting is utilized, then

the bearing should be mounted on unworn section of

shafting.

2. Lubricate shaft and bearing bore with grease or oil to

facilitate assembly. Slip bearing into position. When light

press fit is required, press against the end of the inner

ring of bearing. Do not strike or exert pressure on the

housing or seals.

3. Bolt bearing to support, using shims where necessary to

align bearing so inner ring does not rub on seal carrier.

Use full shims which extend across the entire housing

base.

4. Determine final shaft postion and tighten setscrews in the

locking collar(s) of non-expansion bearing to recom-

mended torque while the other bearings remain free.

Rotate the shaft slowly under load, if possible, to prop-

erly center the rolling elements with respect to the

raceways. Then tighten setscrews into the locking collar

of the remaining bearings to the recommended torque.

5. Check rotation. If there is any strain, irregular rotational

torque or vibration, it could be due to incorrect

alignment, bent shaft or bent supports. Installation

should be rechecked and correction made where

necessary.

EXPANSION BEARING

Steps (1, 2, 3) Same as Non-Expansion Bearing.

4. Position expansion bearing in the housing. For normal

expansion conditions, the bearing insert should be posi-

tioned in the center of the housing. To center bearing

insert in housing, move bearing insert to extreme posi-

tion and mark shaft. Then using bearing maximum total

expansion table, move bearing insert in opposite direc-

tion one-half the total expansion to center bearing in the

housing. If maximum expansion is required, move

bearing insert to the extreme position in the housing to

permit full movement in direction of expansion. After

expansion bearing has been positioned in the housing,

tighten the setscrews in the locking collar to the

recommended torque.

5. Same as Non-Expansion Bearing.

FIELD CONVERSION (RE-OP) OF A NON-EXPANSION

BEARING INTO AN EXPANSION BEARING

All non-expansion bearing sizes can be re-oped to become

expansion bearings. To re-op a non-expansion to an

expansion bearing follow these steps:

1. Move the snap ring, opposite from the collar side of

bearing, to the outermost snap ring groove.

2. Install bearing per Expansion Bearing instructions listed

above.

NOTE: Bearing nameplate has a non-expansion Part

Number. When bearing is re-oped the bearing should be

marked as expansion for future reference.

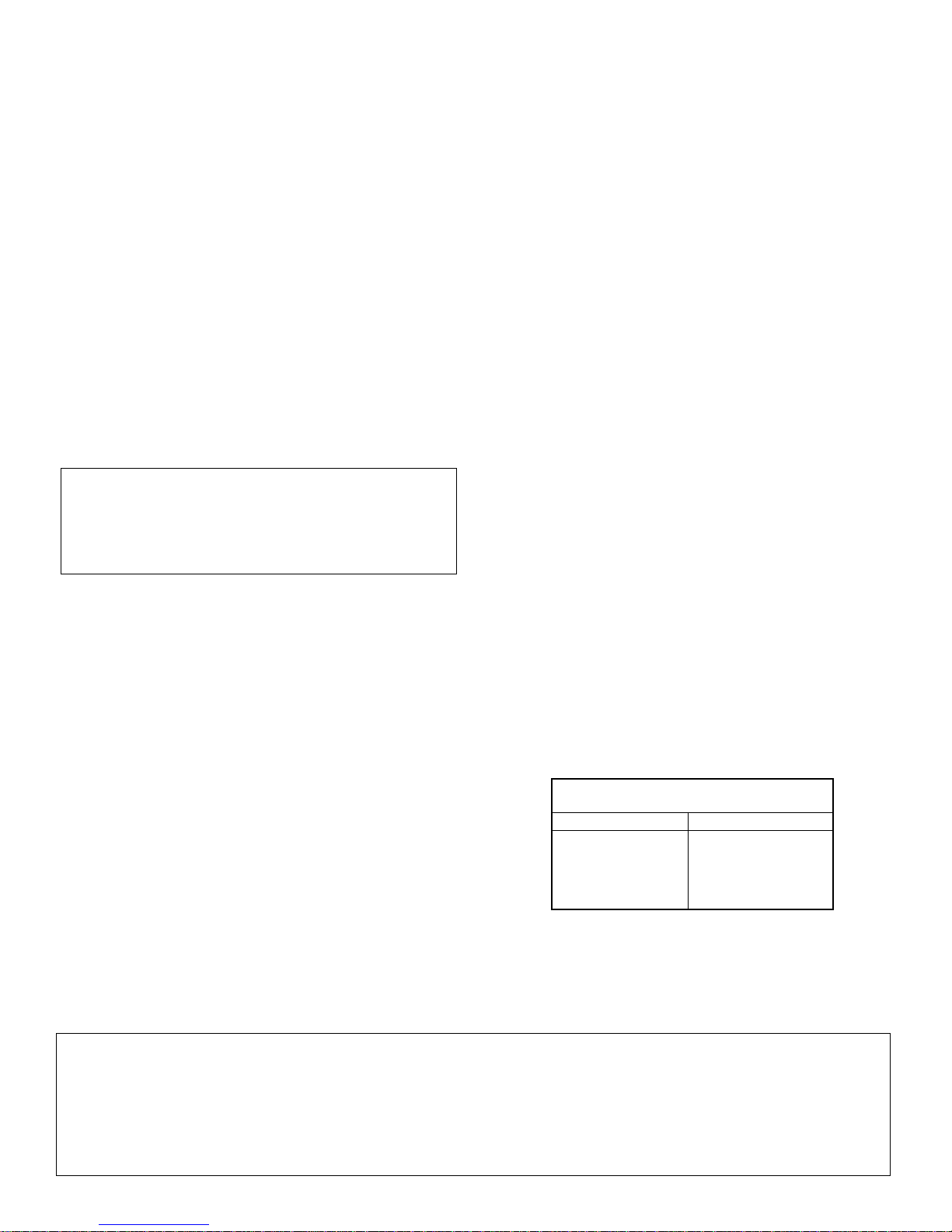

BEARING MAXIMUM TOTAL EXPANSION TABLE

SHAFT SIZE TOTAL

EXPANSION

in. in.

13/8- 11/2 3/16

111/16 - 37/16 1/4

315/16 5/16

47/16 - 415/16 3/8

WARNING: Because of the possible danger to persons(s) or property from accidents which may result from the improper use of products, it is

important that correct procedures be followed: Products must be used in accordance with the engineering information specified in the catalog.

Proper installation, maintenance and operation procedures must be observed. The instructions in the instruction manuals must be followed.

Inspections should be made as necessary to assure safe operation under prevailing conditions. Proper guards and other suitable safety devices or

procedures as may be desirable or as may be specified in safety codes should be provided, and are neither provided by Baldor Electric Company

nor are the responsibility of Baldor Electric Company. This unit and its associated equipment must be installed, adjusted and maintained by

qualified personnel who are familiar with the construction and operation of all equipment in the system and the potential hazards involved. When

risk to persons or property may be involved, a holding device must be an integral part of the driven equipment beyond the speed reducer output

shaft.