3

TABLE OF CONTENTS

INTRODUCTION & SYSTEM REQUIREMENTS...........................................................................................................5

Engine Requirements................................................................................................................................................5

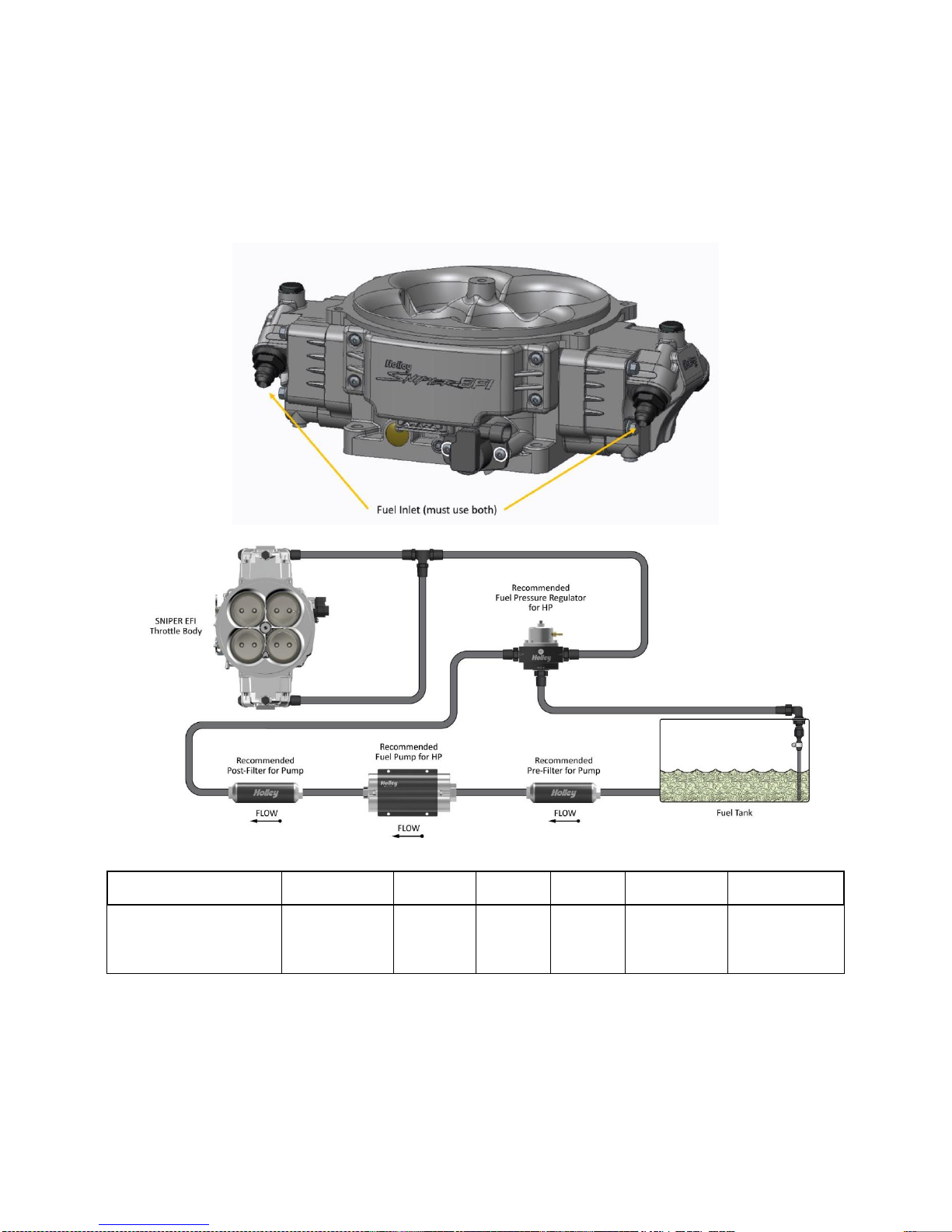

Fuel System Requirements .......................................................................................................................................5

TOOLS REQUIRED FOR INSTALLATION....................................................................................................................5

PARTS IDENTIFICATION..............................................................................................................................................6

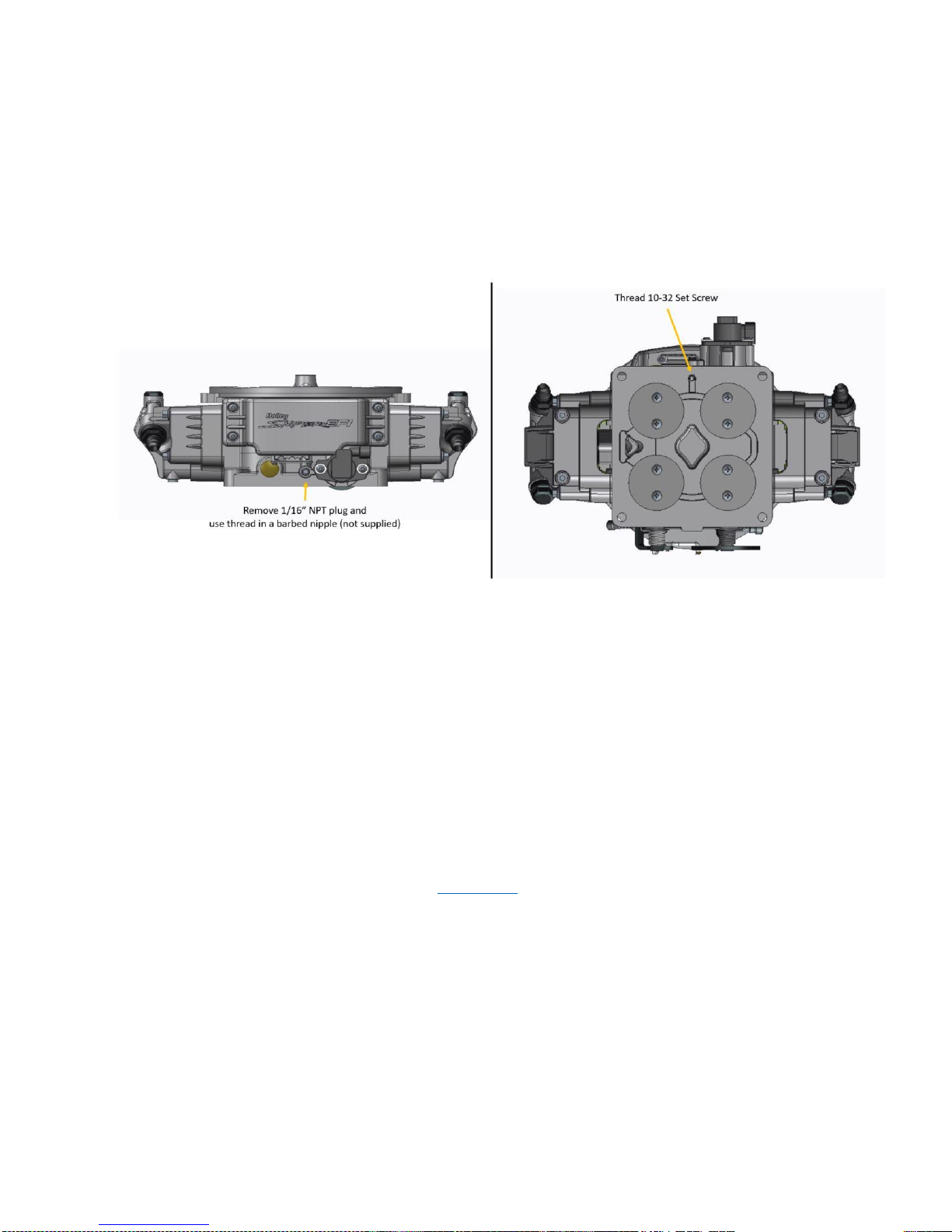

PREPARING THE THROTTLE BODY FOR INSTALLATION........................................................................................7

THROTTLE BODY INSTALLATION...............................................................................................................................7

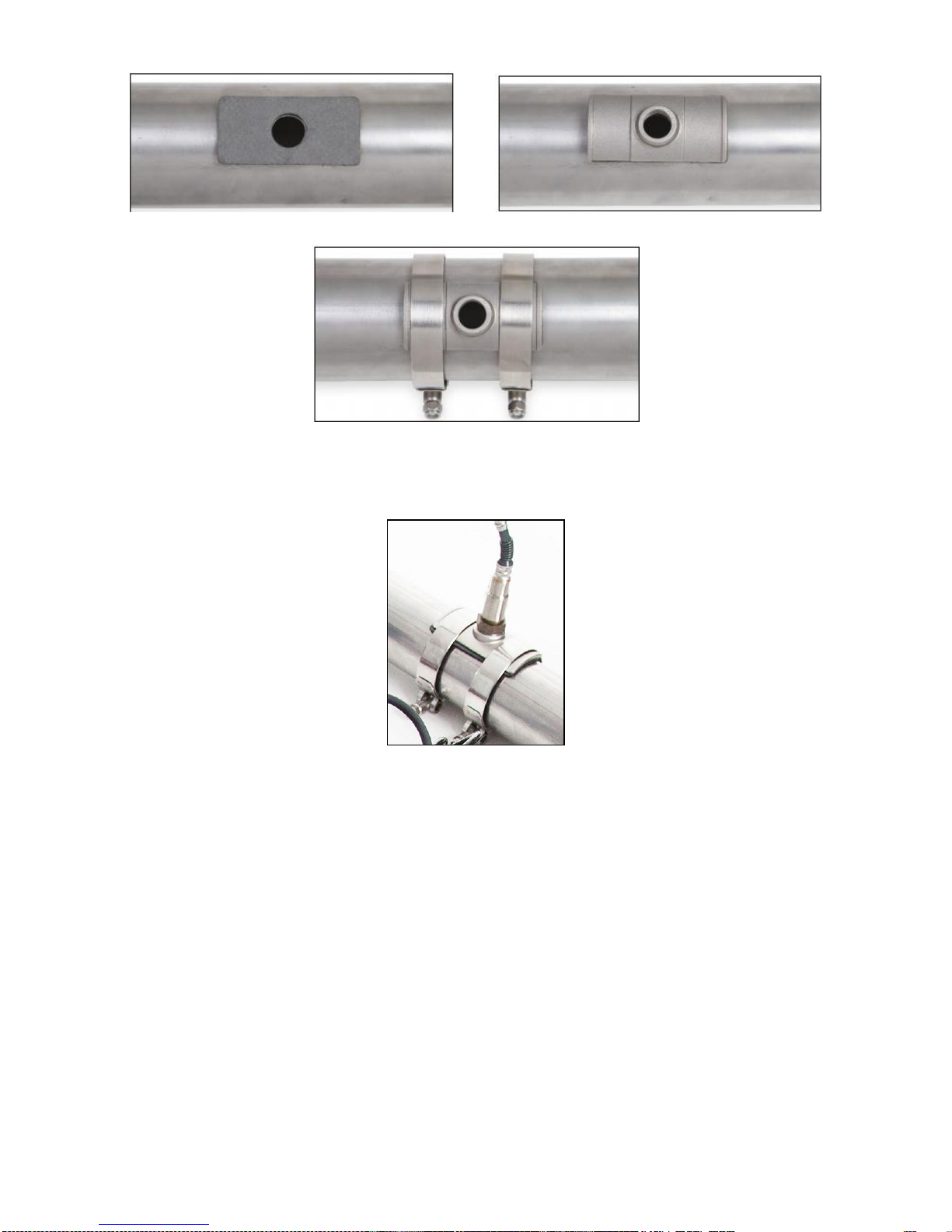

OXYGEN SENSOR INSTALLATION.............................................................................................................................8

COOLANT TEMPATURE SENSOR INSTALLATION....................................................................................................9

FUEL SYSTEM CONNECTIONS.................................................................................................................................10

ECU WIRING OVERVIEW...........................................................................................................................................11

BASIC WIRING INSTALLATION..................................................................................................................................12

GENERAL WIRING REFERENCE...............................................................................................................................13

Throttle Body Connections ......................................................................................................................................13

Pigtail & Loose Wire Connections............................................................................................................................13

Connecting Sniper EFI Touchscreen LCD to Sniper EFI.........................................................................................14

NON TIMING CONTROLLED IGNITION SYSTEM WIRING .......................................................................................17

Coil (-) [no timing control].........................................................................................................................................17

Ignition Box Tach Output (No Timing Control).........................................................................................................18

TIMING CONTROLLED IGNITION SYSYEM WIRING................................................................................................20

Timing Control Preface:...........................................................................................................................................20

MSD (Magnetic) Distributor [Timing Control] ...........................................................................................................20

Holley Dual Sync Distributor [Timing Control]..........................................................................................................25

Sniper EFI HyperSpark Distributor [Timing Control] ................................................................................................31

HANDHELD NAVIGATION ..........................................................................................................................................32

Possible Screens.....................................................................................................................................................32

INITIAL EFI SETUP .....................................................................................................................................................34

Calibration Wizards..................................................................................................................................................34

Sensor Verification...................................................................................................................................................38

Prestart Checklist.....................................................................................................................................................39

First Startup.............................................................................................................................................................39

After Startup.............................................................................................................................................................39

Ignition Timing Check (without Timing Control) .......................................................................................................40

Ignition Timing Check (ECU Controlling Timing)......................................................................................................41

THROTTLE BLADE ADJUSTMENT ............................................................................................................................42

SYSTEM SETUP .........................................................................................................................................................43

Ignition System Setup..............................................................................................................................................43

BASIC TUNING............................................................................................................................................................44

Basic Fuel................................................................................................................................................................44

Target AFR..............................................................................................................................................................45

Acceleration Enrichment..........................................................................................................................................45

Fuel Prime ...............................................................................................................................................................46

Closed Loop Enable/Disable ...................................................................................................................................46

Learn Enable/Disable ..............................................................................................................................................47