3

DRIVER ASSISTANCE FEATURES

LANE KEEP ASSIST (LKA)

• Detects lane markings and evaluates relative vehicle

position

• Recognizes when the vehicle begins to drift towards

the lane markings

• Distinguishes between planned lane changes and

lane drifting

• Intervenes before the vehicle reaches the lane markings

• Automatically applies a correction torque to the steering

wheel

• Smoothly releases steering torque as soon as the

vehicle trajectory is re-established

• The system enables the driver to suppress or override

steering torque

• LKA is activated at 37 mph / 60 kph

STEERING ASSIST

• Speed Dependent Steering Assist - Provides variable

steering assist based on vehicle speed. It helps the

driver experience easier steering at low speeds and

a rmer steering response at higher speeds. It also

aids the driver by reducing fatigue and helps the driver

maintain better control of the vehicle.

• Active Return - Helps to reduce driver fatigue through

easier maneuvering by returning the steering wheel to

the center position at lower vehicle speeds.

• Crown/Side-Wind Compensation - Helps to reduce

driver fatigue, or steering eort, by helping keep the

vehicle straight during heavy side winds, crowned

roads, or some alignment issues.

• Road Disturbance Compensation - Helps improve

driver comfort by reducing steering wheel vibration

typically caused by road disturbances like potholes,

road debris, or other bumps in the road.

SYSTEM COMPONENTS

BENDIX®AUTOVUE®FLC-20™CAMERA

• The forward-facing camera tracks the lane markers and

provides the lane characteristics for the left and right

marker to the Sheppard®Active Steering System by

Bendix CVS system over the vehicle communication

network. In addition, the system also provides

information on when the lane departure warnings

will be suppressed, allowing the LKA feature to be

suppressed at the same time. See Figure 3.

• For additional information, see the Bendix®AutoVue®

FLC-20™ Camera Service Data sheet SD-64-20124

available for download on bendix.com.

• Is compatible with later versions of Bendix®Wingman®

Fusion™systems.

LDW WINDSHIELD MOUNTING BRACKET

• The bracket that holds the camera secure and keeps

it facing the correct direction to successfully determine

lane width and position. See Figure 3.

Figure 3 – Bendix®

AutoVue® FLC-20™Camera & Bracket

Bendix®AutoVue®

FLC-20™Camera

Camera

Bracket

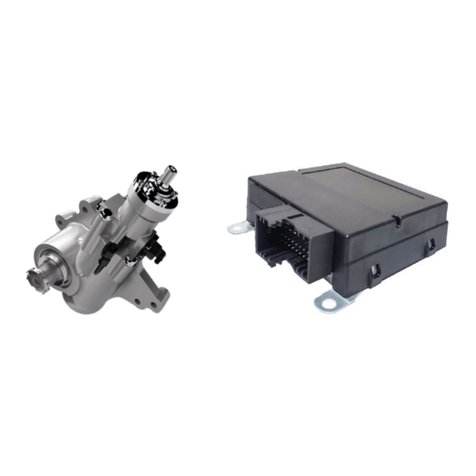

ACTIVE STEERING ECU

• The Electronic Control Unit (ECU) for the Sheppard

Active Steering System by Bendix CVS is a standalone

unit designed to work with J1939 Vehicle CAN and a

forward-facing lane sensing camera. See Figure 4.

Figure 4 – Lane Keep Assist Electronic Control Unit (ECU)

ECU

Connector