IM-246

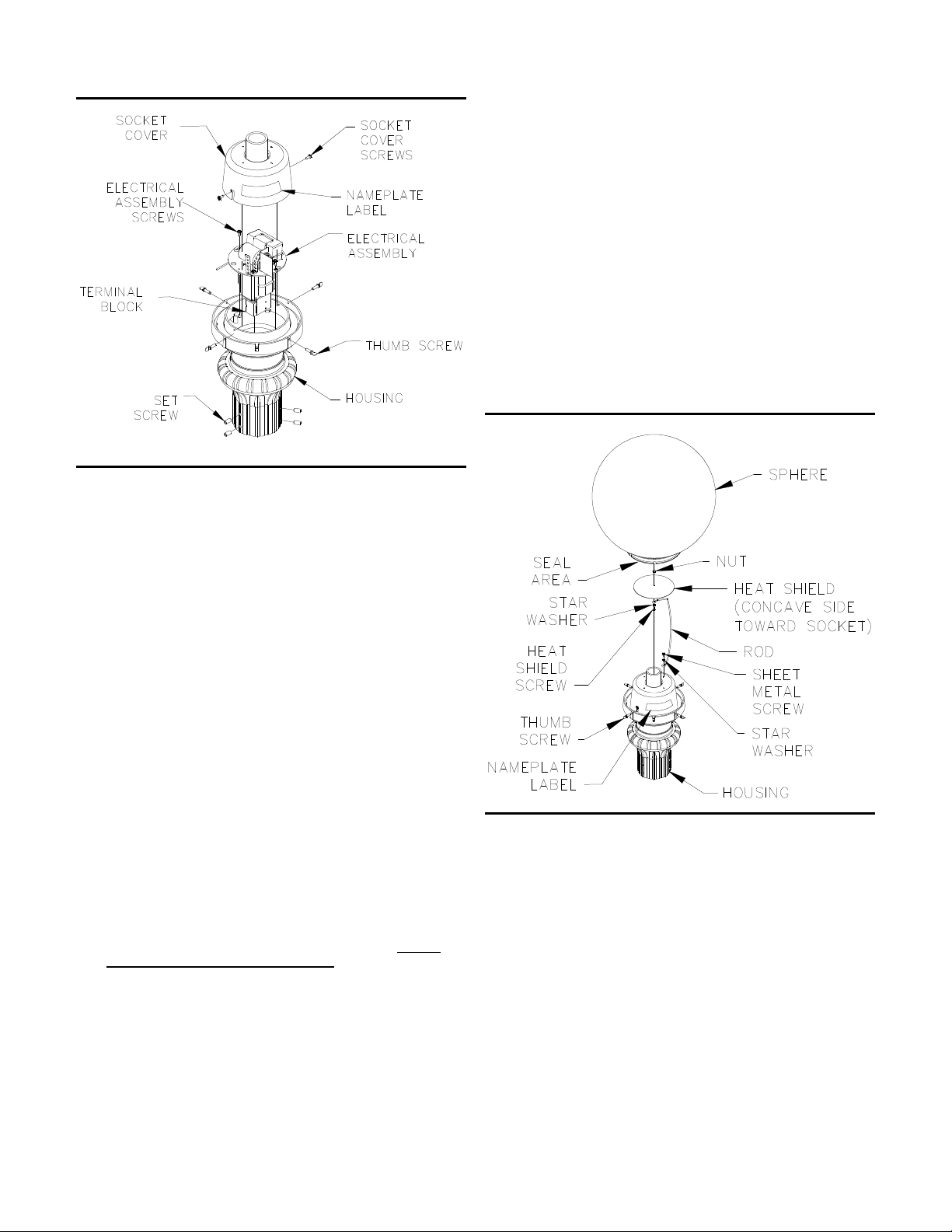

Figure 1

GR1455

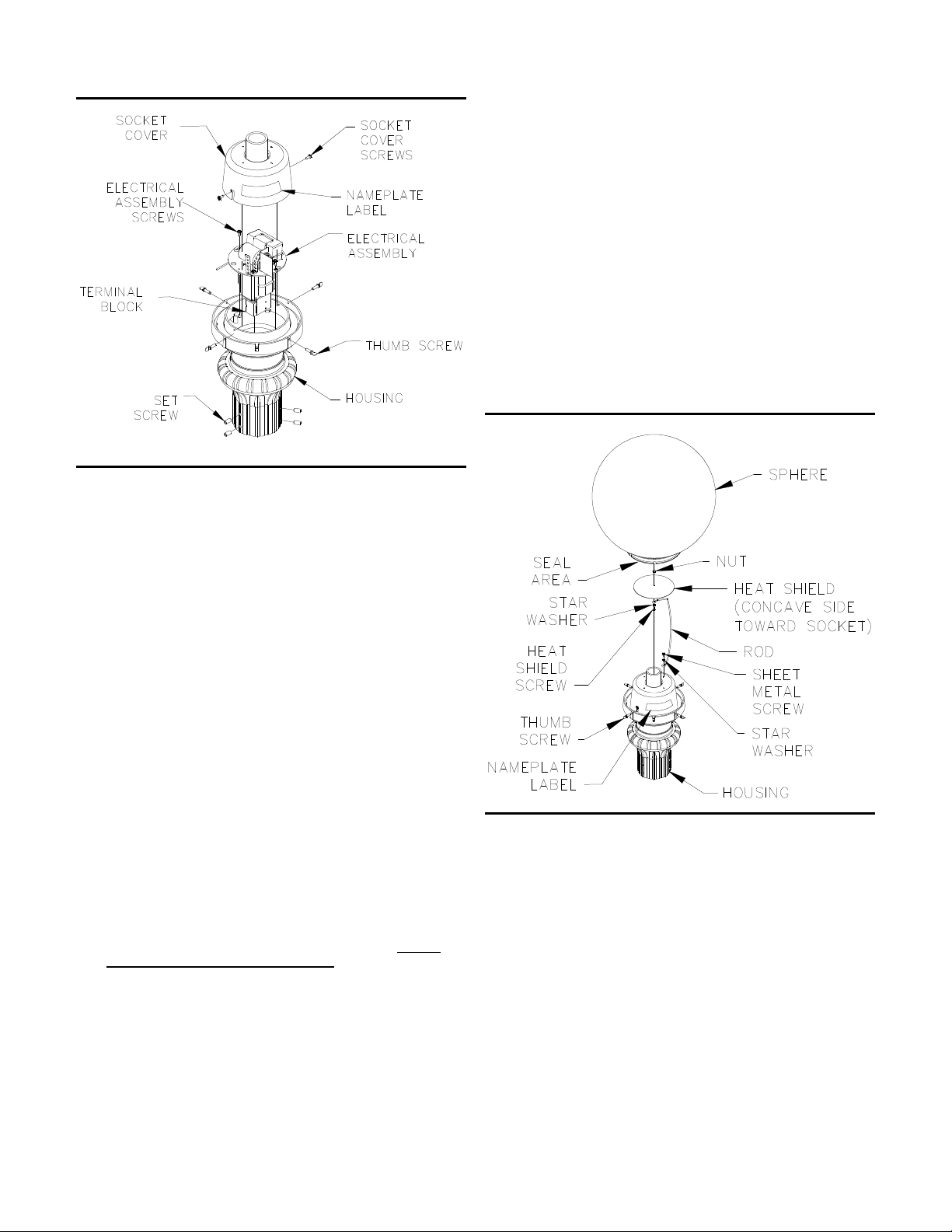

2.3 Prismasphere Optic Assembly Installation

2.3.1 Once housing has been installed according to instructions

in Section 2.2 and before placing the Sphere optics onto the

housing, the heat shield must be assembled onto the socket

cover.

2.3.2 Attach heat shield to rod using washer, nut and machine

screw as shown in Figure 2. (Note, the concave side of heat

shield must be toward socket.) Mount opposite end of rod to any

hole on top of socket cover using sheet metal screw and washer.

Rod, washers, shield, nut and screws are shipped in a plastic

bag with the housing assembly.

2.3.3 Install the proper lamp as specified on Nameplate Label.

Tighten the lamp carefully but securely.

2.3.4 Wipe the gasket and seating area of the optics with a clean

dry cloth to ensure a proper seal.

2.3.5 Install optics onto housing and center. Alternate tightening

thumb screws until each screw is tightened all the way seating

flat portion the screw head with housing side. It may be helpful to

use pliers to tighten these screws.

2.3.6 Energize the luminaire and check for proper operation.

2.4 Acrylic Washington Optic Assembly with

House Side Shield Installation

2.4.1 Once housing has been installed according to instructions

in Section 2.2 and before placing the Acrylic Washington Optics

onto the housing, the house side shield must be assembled on to

the socket cover.

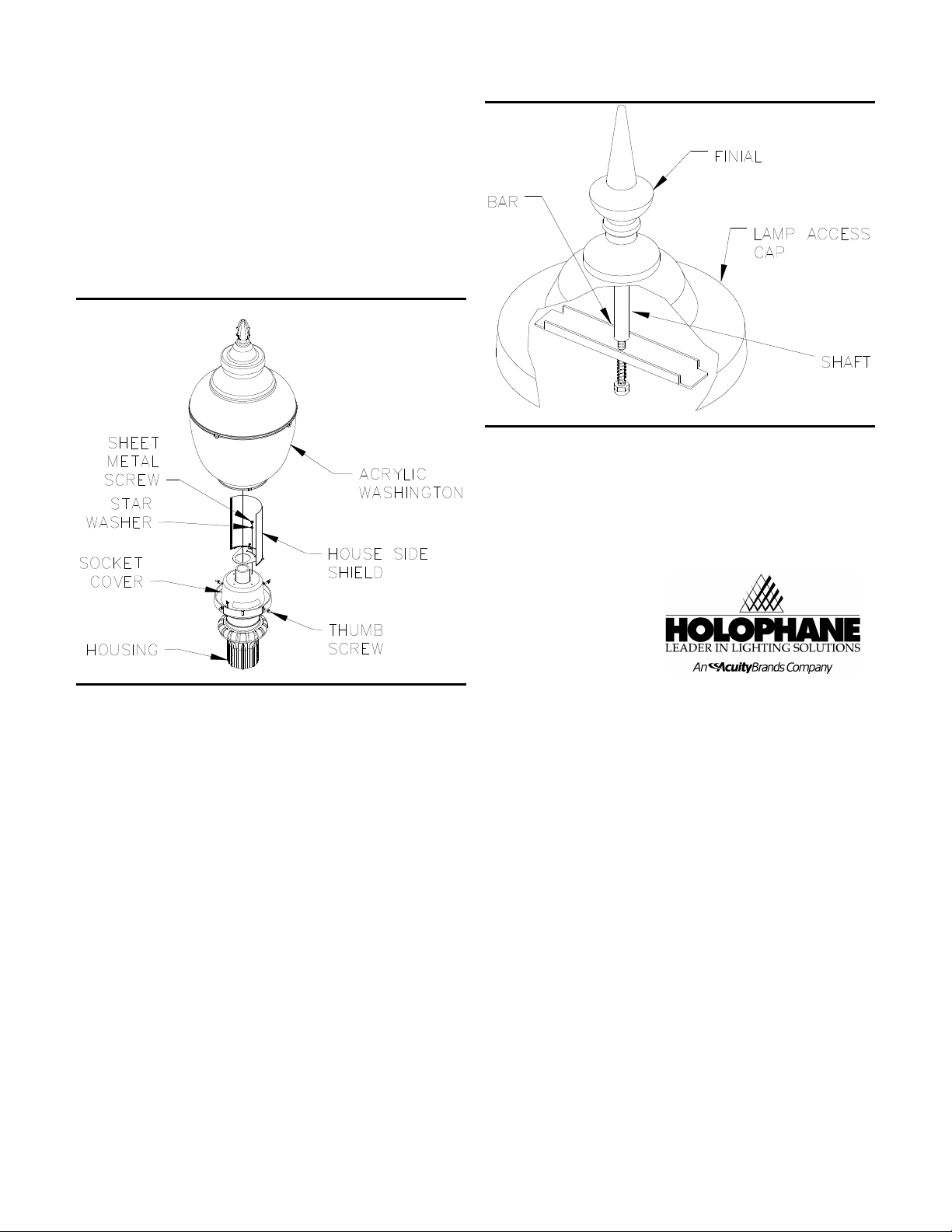

2.4.2 Attach heat shield to socket cover using sheet metal screw

and washer as shown in Figure 3. Mount house side shield to

any hole on top of socket cover to achieve the desired position

for house shielding using sheet metal screw and washer. Utilize

the slot in the base of the shield for better positioning. House

side shield must be installed before lamp. House side shield,

washer and screws are shipped in a plastic bag with the housing

assembly.

2.4.3 Install the proper lamp as specified on Nameplate Label.

Tighten the lamp carefully but securely.

2.4.4 Wipe the gasket and seating area of the optics with a clean

dry cloth to ensure a proper seal.

2.4.5 Install optics onto housing and center. Alternate tightening

thumb screws until each screw is tightened all the way seating

flat portion the screw head with housing side. It may be helpful to

use pliers to tighten these screws.

2.4.6 Energize the luminaire and check for proper operation.

3

MAINTENANCE

Electrical Component Replacement

.

3.1.1 Wipe off exterior dirt and debris.

3.1.2 Remove the four mounting thumb screws holding refractor

assembly to electrical housing.

3.1.3 Remove the refractor by lifting it from the housing.

3.1.4 Remove screws holding socket cover in place. Disconnect

socket connection and set aside socket cover. (See Figure 1)

3.1.5 Loosen the two screws to the electrical assembly. Firmly grasp

electrical assembly, rotate and lift out thru the keyhole slots. Set

electrical assembly aside. If luminaire has the button photocontrol,

disconnect it’s connection before setting aside.

3.1.6 Tag and disconnect common and line leads.

3.1.7 Remove and retain component mounting hardware.

3.1.8 Tag associated electrical leads, and remove involved

component.

3.1.9 Install new component using existing mounting hardware.

3.1.10 Make electrical connections in accordance with tags and

approved wiring practices.

3.1.11 Reconnect incoming lead lines and install optics as instructed

in Section 2.2.

Figure 2

GR1456

4 RELAMPING AND CLEANING.

4.1. Lamp Access

4.1.1 Standard Units:

Note the orientation of the “Street Side” marking on the refractor.

Loosen the optic mounting thumb screws. Lift the refractor off of the

housing.

Units with Top re-lamping access:

Grip the finial on top of the fixture, rotate it counter clockwise until the

bar is free from threads on shaft. Lift up on finial, shift bar to one side

and remove lamp access cap. See Figure 4

4.1.2 Remove the lamp and dispose of it in a safe and proper

manner.

4.1.3 Install the proper lamp type as specified on Nameplate Label.

Tighten the lamp carefully but securely.