r

I

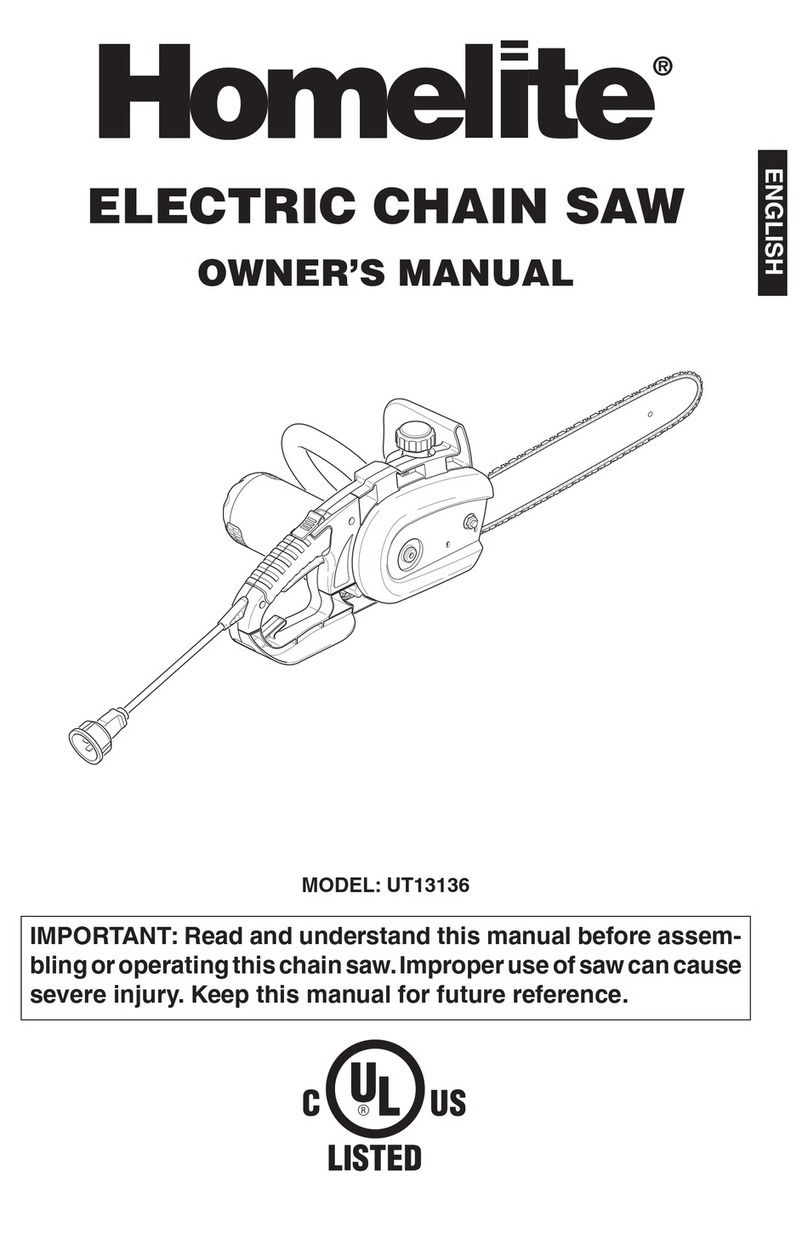

I Gmp ANDBALANoE

1. The

only

way

tohold

the

saw

so

that

you-

can

maintain

'- control'in iase it jumps or kicks back toward you

durinq

operation

isio u-se

thegripshown'

Always

us-e

ilriJqiip ina hold

onto

the

saw

tiimly

withboth

hands

*nei tfieengine

is running.

Wear

non'slip

glovesfor

maximum

griP

andProtection.

']

USE

PROPER

GRIP-

ALWAYS

KEEP

BOTHHANDS

FIRMLY

ON

THE

SAW

Durinq

startinq,

hold the saw downlirmly on a level

Jurfic.e

with t66 bar and chainin the clear.Use

the

iiCe of one knee to hotd down the rear handle,

anaonehand

to holddownthefronthandle.

Use

the

other handfor crankingthe engine'Do not,useany

technique

which would bring your foot or leg near

thebarand

chain.

Always

keep

your

weight

wellbalanced

on both

feet'

CinC,ivou wi'll oe ex-eriing

pressureto cut,-

guard

ioainsf loss

ol balance

bybeing ready

to hold up on

th-e

saw

as

itcuts

through

the

material.

3.

.+

PTTT ATARTER STRAIGHT UP TO CRANK ENGINE

1

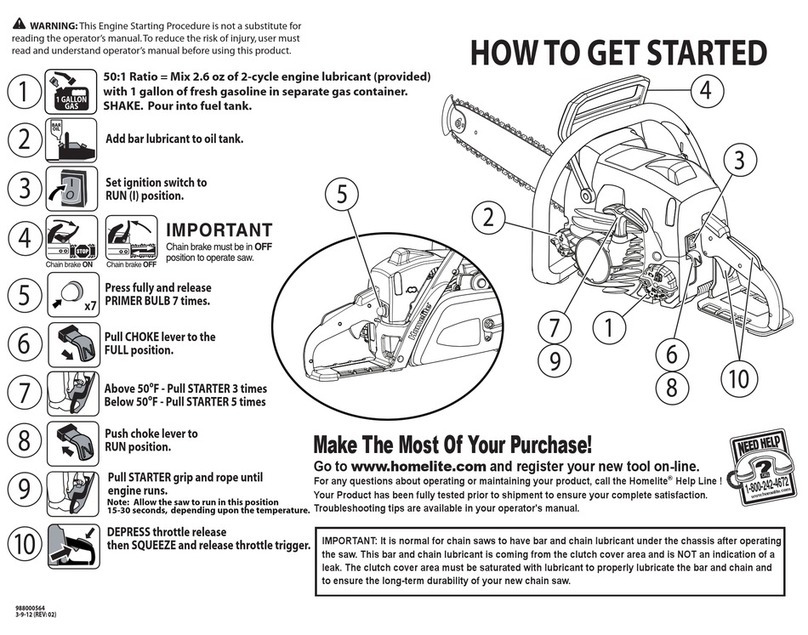

START'NG

ANDSTOPPTNG

The triqqer latch is on the top of the rear handle,

the

choke d6ntrol bulton is on top lelt of the engine cover.

The rocker type positive ON/OFF control (ignition) 6

switch is loca[ddoh the rearhandlewhere the operator

can pushit lo "OFF" without releasing-his..grip

on the

handle.

Push

front end of switchfor "RUN", push rear

endfor "STOP". - 6.

1. Slide choke control button as far back as it will go

(for cold start), and push down the front end of

the ignition

switch

tor "RUN".

2. Holdsaw down firmty

on a cleansurface

with guide

barand

chain

inthe

clear. 7.

3. For cold starling, pull the trigger latch back to ope.n

the throtlte part-iaily.

CAUTION:when-the trigger is

depressedail or pdrt way during starting, the chain a

wiil turn when the engine starts. A warm engine

shouldrequireneither

choking nor trigger latching.

4. Pullthestarter

grip asbriskly

as

youcanto give

the

engine

a rapid

spii. XOte: Toprevent

damage-to

the

stalter,do-not lank cord out to the very end; hold

grip and let cord rewindevenlyinstead

of,letting

il

snap

back.

Crank

untilengine

starts

up or-fires

- if it doesnot

ie-p golng, niove thc ch6ke button to a half-way

position

belore

crankang

agaln.

IMPORTANT:

As soon as engine runs' use throttle

iriqqer to releaselrigger latCh

and control engine

sp66A:

at the same

timl, ease

the chokebuttonfor-

rriardio open the choke as the engine warms up'

do notop6rate

withengine

choked

or partlychoked

except

brielly

during

warm'uP.

Pick saw up,assume

balanced-

cytting stance,

and

iqueezetriller toopen

throttle

lullybefore

thechain

contacts

thewood.

Aoolv lioht pressureon the saw to make it leed

srhbdttrti

and rapidly'Alwaysdo the cutting at full

throttle,'but

throitle

back whenthe loadis removed.

]DLE

SAW

WHEN

NOT

ACTUALLY

CUTTING

WOOD.

Do notcut at part throttle

or force the sawto cut as

this

allows

the-clutch

toslipand

overheat'

7