CHAIN

TENSION

1.

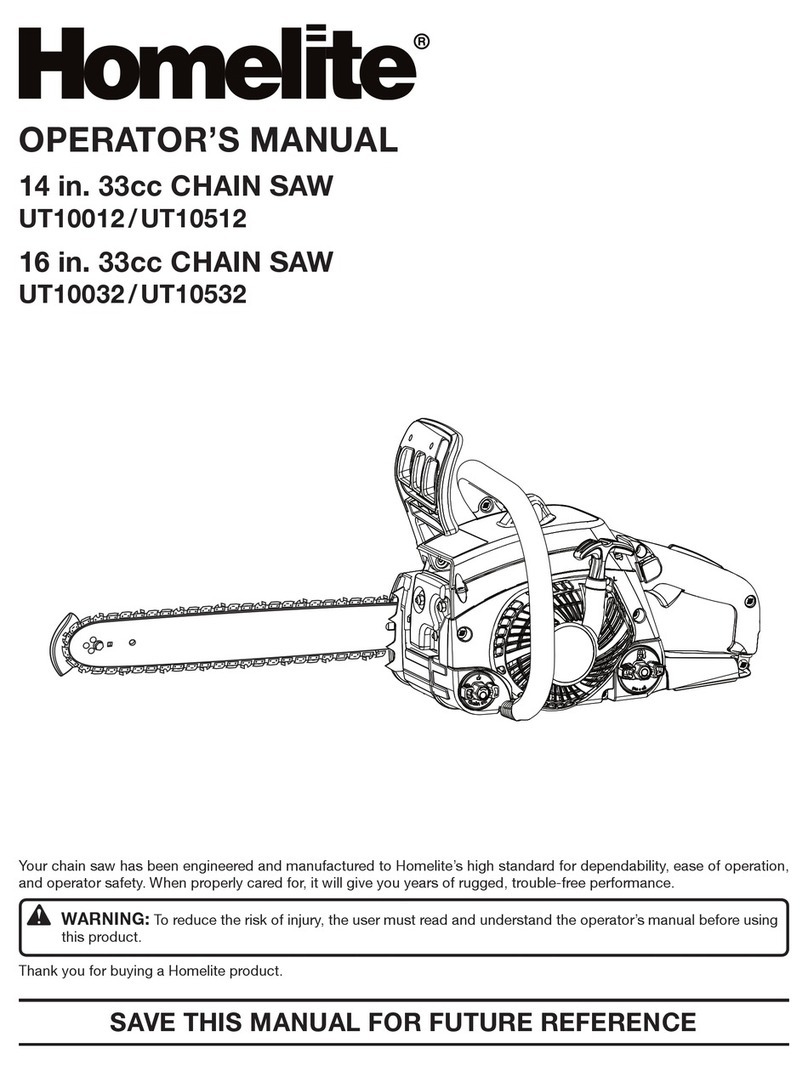

Proper tension is extremely important. The mounting

nutshould be loose enoughto permitmovementof the

guide bar tension adjustment. Holdupthe noseof the

barduringtheadjustment stepsand untilthemounting

nut has been tightened completely. This will take up

any clearance between the bar mounting slot and the

mounting pins in the direction in which pressure is

most often applied during cutting.

2. "Snap" the chain to remove any kinks (pullchain away

from bar and let go several times).

Proper cold tension: As tight as possible without

causing binding. Chain tie-straps should remain in

contact with bar along bottom rails.

Adjustment of warm chain: Tighten until tangs move

halfway upintobargroove. Checktensionafterbarhas

cooled, because only a cool chain can be tensioned

accurately.

3. Because steel expands as its temperature rises, you

will be concerned with two conditions.

a) The first is "cold tension". When first mounted on

the bar, the chain is cool and should be "snug" or

taut

-

As much tension as possible without your

feeling any bindingas you pull the chain along the

bar byhand.We callthissetting"coldtension."You

should notseeanyclearancebetweenthetie-straps

andthebar railsalongthebottomof thebar.Tighten

the mounting nut to lock the assembly at this ten-

sion. Now you are ready to fill the saw with chain

oil and fuel and make some cuts.

b) ThesecondconditionisUwarmtension." Asyouop-

erate the saw, the chain will heat up and expand,

developing "droop" (too little tension). Operating

with adroopingchain isdamagingtothe chain, bar

and engine. Itisalsodangeroustocutwithadroop-

ing chain which can catch in the wood and pull or

throw you. When wearing in a new chain and bar,

youshouldstoptoadjustthetensionaftereachfour

or five cuts for the first tankful of fuel consumed.

During this period, the droop will be due partly to

warming of the steel and partly to looseningof the

chain joints. After the joints are worn in,the chain

will stretch from heat, butwill returntothe original

tension when it has cooled.

EXCESSIVE DROOP

4. Any time the chain droops to where the chain tangs

hang outor almost outthe bargroove (asillustrated in

the picture labeled "excessive droop") you must shut

off the engine immediately and do the following:

a) Take off your glove and feelthechain.Ifyoucannot

holdchain inyour fingerswithoutdiscomfortwhile

counting to20, the chain is too hottoadjust accu-

rately. If you try toadjust an overheatedchain, you

will fail because

thechainwill becontracting rapidly

as you proceed.Letthechain cooltowhereyoucan

hold it comfortably before making the adjustment.

b) A warm chain should not be adjusted to the same

tension as a coldchain.When chain iswarm adjust

to where the clearance between the tie-straps and

bar rails at bottom, center of bar is about

1/8"

(3,2mm) or to half the depth of the tangs (see

"Proper Warm Chain Tension" illustration).

CAREFUL

Uponcooling, the chain maybecome too tight onthe bar.

Before next use, the tension should always be adjusted

for proper "cold tension" after it has cooled.

5.

A chain will get too hot if it is underoiled, improperly

sharpened or dull,or if youarecutting hard,seasoned

wood. Make ita habit to knowwhether yourchain is in

good cutting condition and is getting enough lubri-

cation. An underoiled chain will get so hot that the

joints willstiffenandthechainwillthen bindonthe bar.

Ifthis occurs let barandchaincool,then removethem.

Cleanallsawdustfromtheguidebar mountingpadand

clutch area of the engine. Clean out the oil discharge

hole inthe guide bar pad,and all the sawdust from the

guide bar. Reassemble and tension the chain on the

saw. Fill the chain oiler with oil. Start up and run the

engine for

30

seconds at full throttle. Shut off the en-

gineand examine the chain drive linksandjoints.They

should appear moist with oil. If dry, have the saw

checked by your dealer.

CHAIN OIL AND

THE

OIL

SYSTEM

1.

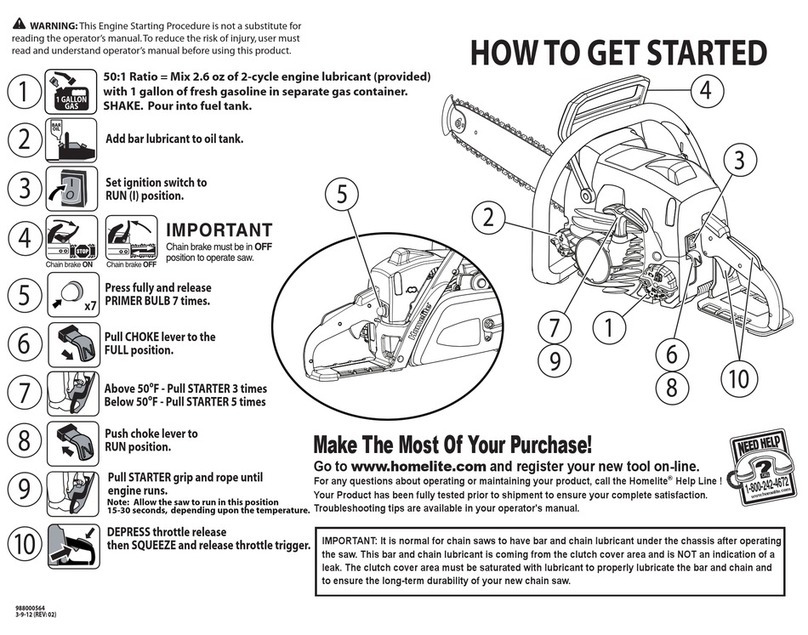

Thechain oiland fuel mix tanks are identified inraised

letters onthe left side of the saw.Thefuel cap isRED.

Thechain oilcap is BLACK. Be suretofill the chain oil

tank with oileverytimeyoufuelthesaw,butalways be-

low the check valve.

CHAIN OIL

PRESSURE LINE

AND CHECK VALVE.

DO NOT FILL TANK

ABOVE VALVE

LEVEL.

NOTE

Constant jiggling ina vehicle, or upside-down storage of

a saw having a full tank of chain oil, can force oil back

through the oilpressure lineintothe cylinder. Thisoilmay

lock the engine hydraulically, preventing cranking. To

avoid this occurance, be sure to fill the oil tank only to

just below the oil pressure line and check valve. This as-

sembly can beseen in the neck of the oil tank. Whenever

the engine refuses to turn over, remove the spark plug to

break the hydraulic lock. Then crank the engine several

times to dispel the oil. Clean the spark plug thoroughly

before you reinstall it.

Wipe down the saw if any oil or fuel is spilled on it. Keep

the saw handles clean.

2.

Type of oil:

HOMELITEB Bar and Chain Oil

should be used just

as itcomes fromthecontainer, as it isformulated with

"viscosity improvers" which render it free-flowing

even at below zero temperatures. It has the property

of clinging to the chain to minimize "throw-off".

Any brand of clean motoroil includingreprocessedoil

may be used as a substitute chain oil. However, inex-

tremely cold weather, SAE

30

weight oil should be

diluted inthe proportionof

1

partkeroseneto4 partsof

oil to restore free-flowing properties. Never use dirty

oil or used oil inthe chain oiler system as itmay dam-

age the oil pump.