2

Table of Contents

NOTICE TO INSTALLERS........................................................................................................................................................... 3

PACKING NOTE........................................................................................................................................................................ 3

PRODUCT FEATURES ............................................................................................................................................................... 4

TECHNICAL INFORMATION ..................................................................................................................................................... 4

PUMBING REQUIREMENTS ..................................................................................................................................................... 4

GENERAL INFO ........................................................................................................................................................................ 4

PARTS LIST............................................................................................................................................................................... 5

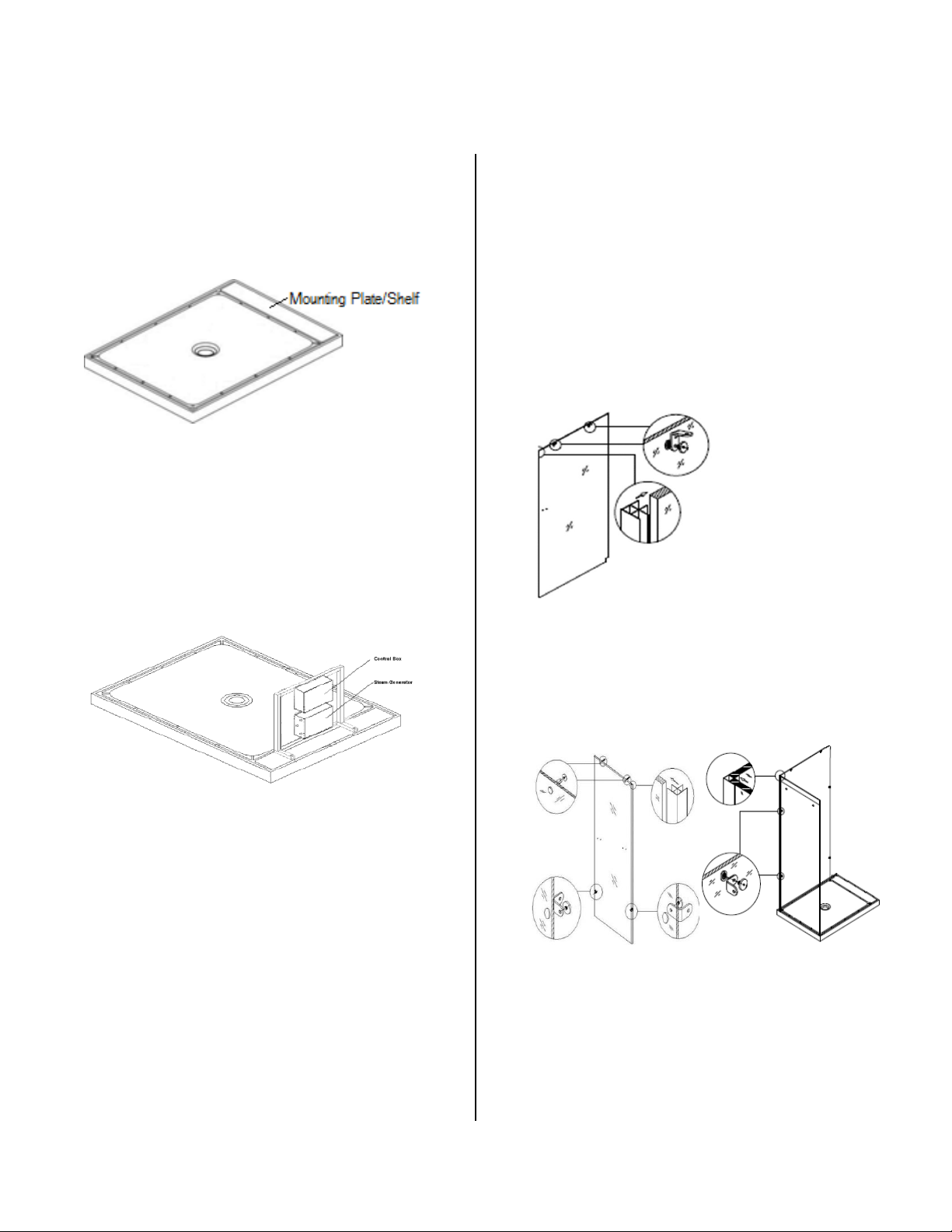

GLASS ANGLE BRACKET INSTALLATION INSTRUCTION ....................................................................................................... 5

SECTION PICTURE OF RUBBER SEAL.................................................................................................................................... 5

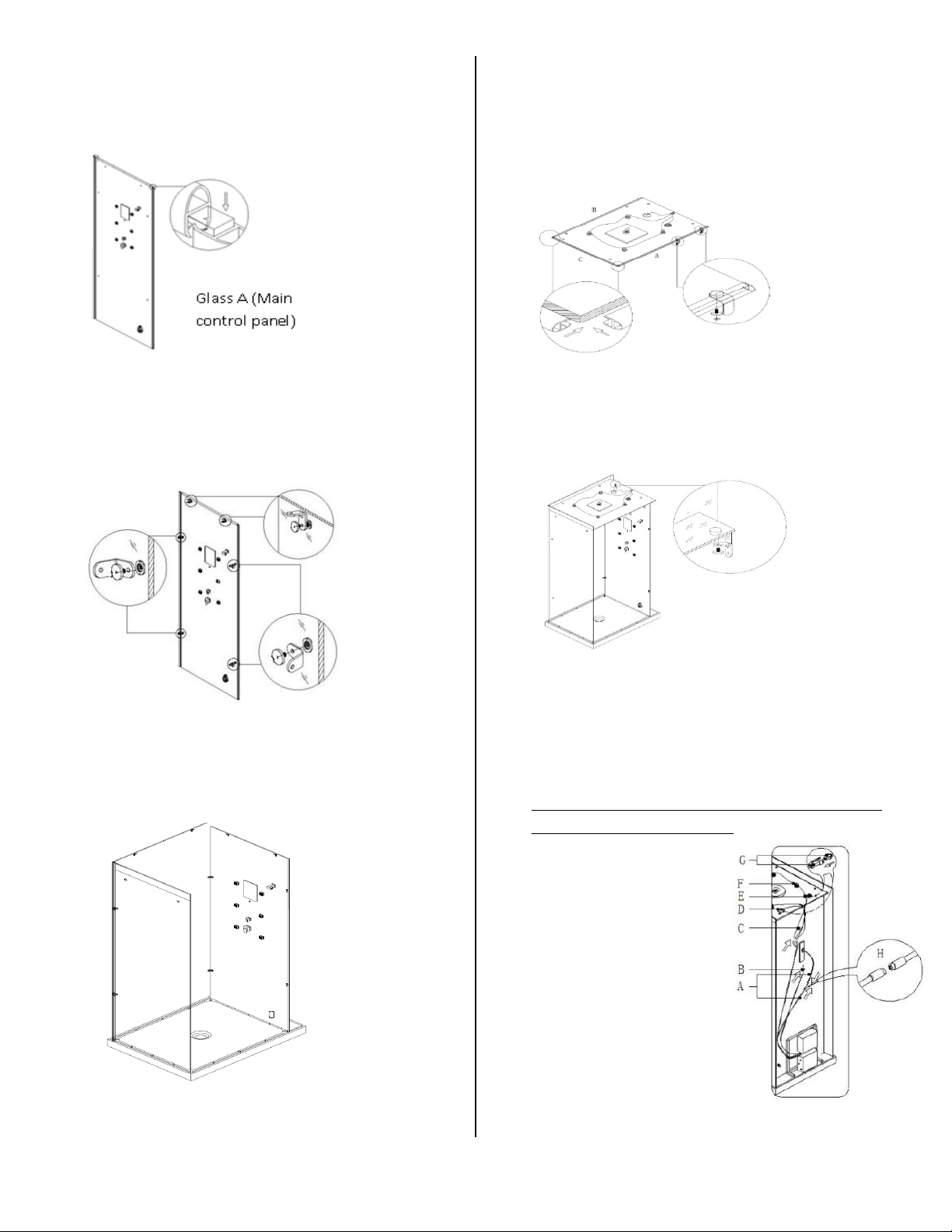

INSTALLATION INSTRUCTIONS................................................................................................................................................ 6

PFISTER HANDLE ASSEMBLY ................................................................................................................................................... 9

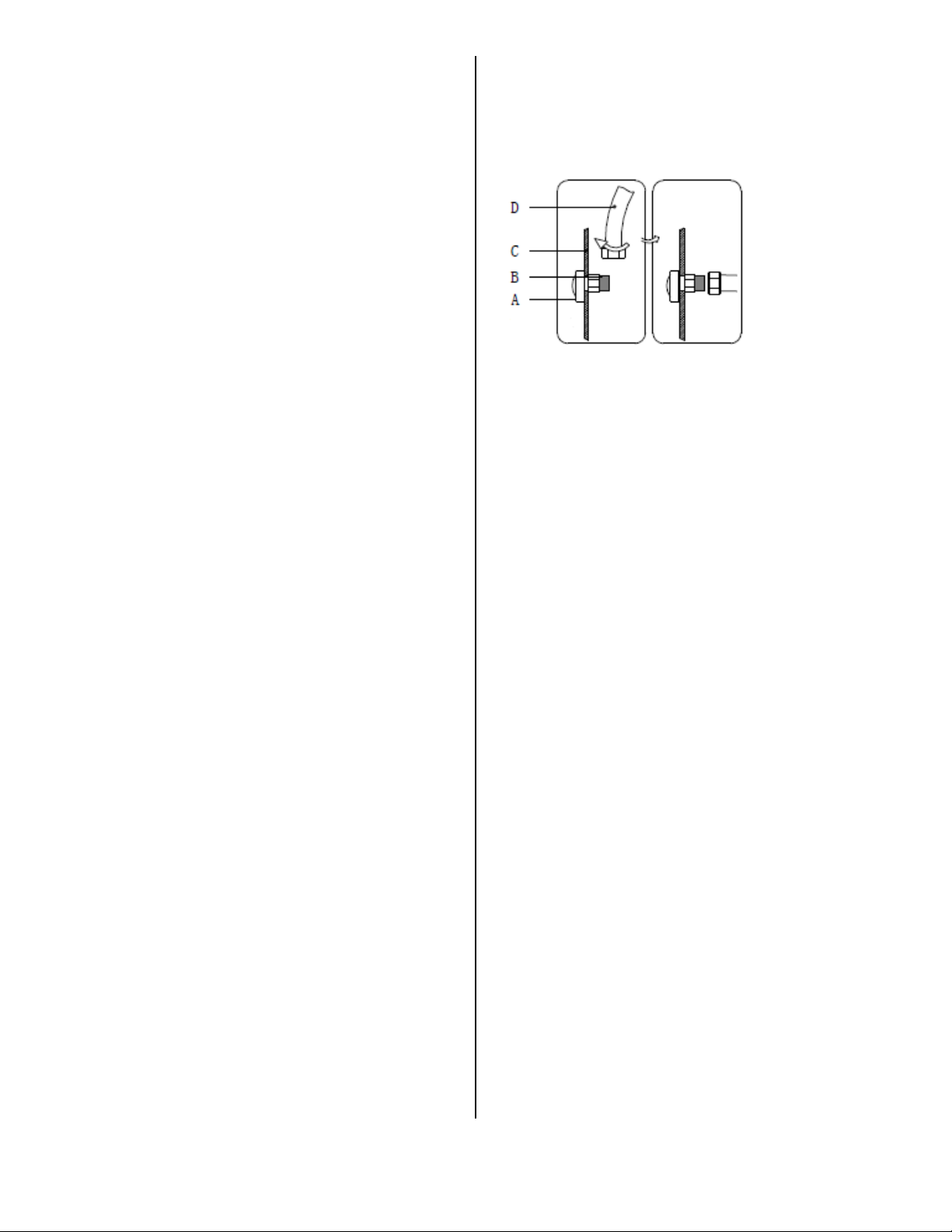

TRIM FLANGE ATTACHMENT .............................................................................................................................................. 9

HANDLE ATTACHMENT ....................................................................................................................................................... 9

TEMPERATURE ADJUSTMENTS ............................................................................................................................................... 9

FAUCET FUNCTION AND USAGE ........................................................................................................................................... 10

S198E KEYPAD USER MANUAL.............................................................................................................................................. 10

KEYPAD DIAGRAM............................................................................................................................................................. 10

KEYPAD OPERATIONS INSTRUCTIONS................................................................................................................................... 11

FAUCET CLEANING AND MAINTENANCE .............................................................................................................................. 12

GENERATOR CLEANING......................................................................................................................................................... 12

PFISTER MAINTENANCE & CARE ........................................................................................................................................... 13

DISASSEMBLY: ............................................................................................................................................................... 13

TRIM CARE: ................................................................................................................................................................... 13

TROUBLESHOOTING TIPS .................................................................................................................................................. 13

CLEANING CARTRIDGE ...................................................................................................................................................... 13

ADDITIONAL INFORMATION ................................................................................................................................................. 14

WARRANTY INFORMATION & REGISTRATION ...................................................................................................................... 14

NOTES.................................................................................................................................................................................... 14