Page 7 Revision 2.2 P/N: 201827

Honey Bee Manufacturing Ltd.

AirFLEX Header - Quick Start Guide

Header Calibraon Overview

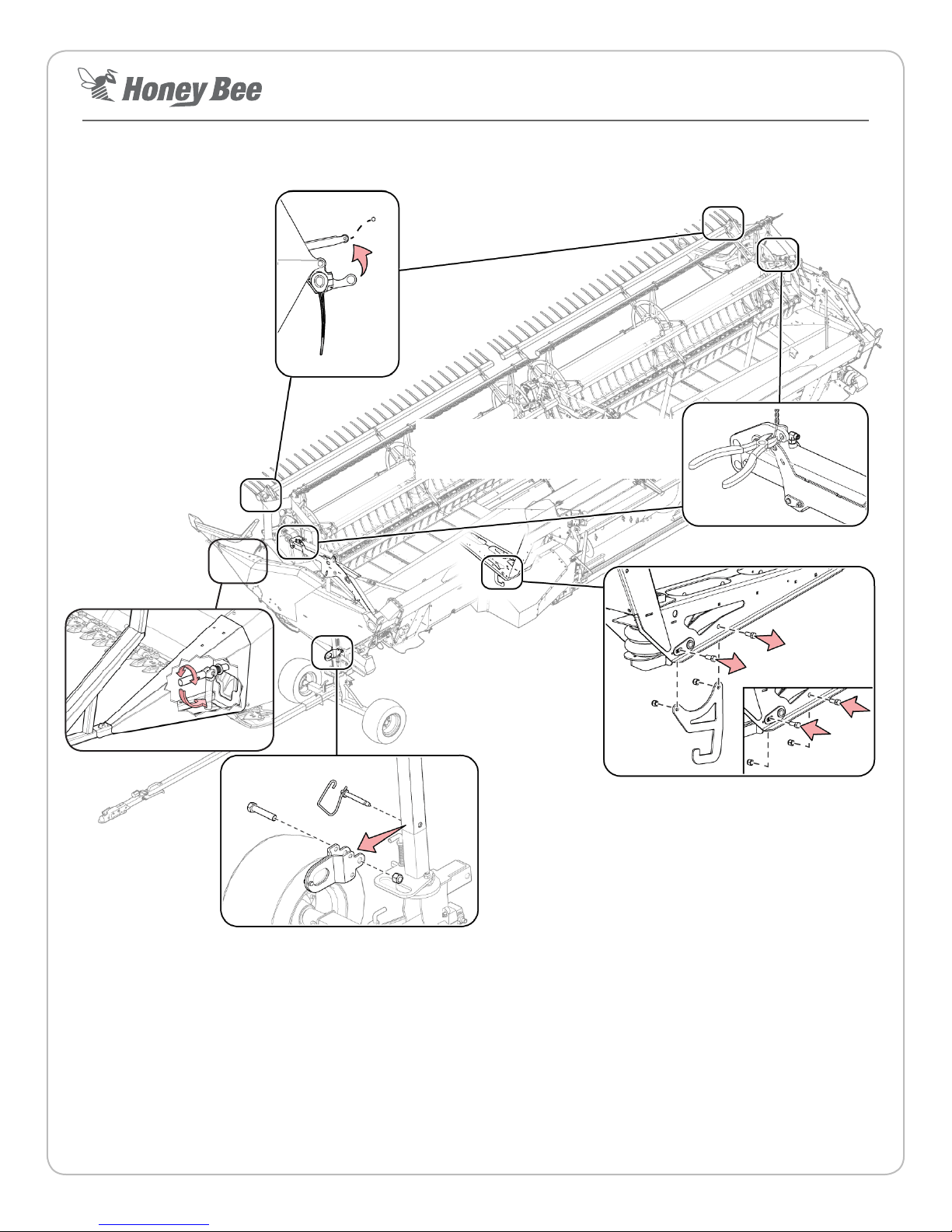

1. Tighten/Loosen the indicated adjuster bolt on the le and

right hand dividers so the dividers are ‘heavy’ enough to

rest at the boom of their travel with the divider extensions

removed. Reinstall the extensions.

2. Ensure the center sensor(s) are lowered to their eld

posions and dividers are secured and capable of their full

range of moon.

3. Ensure each sensor ‘ag’ contacts its roller at the ‘heel’ of

each strut at the rear of the header.

Roller

Flag

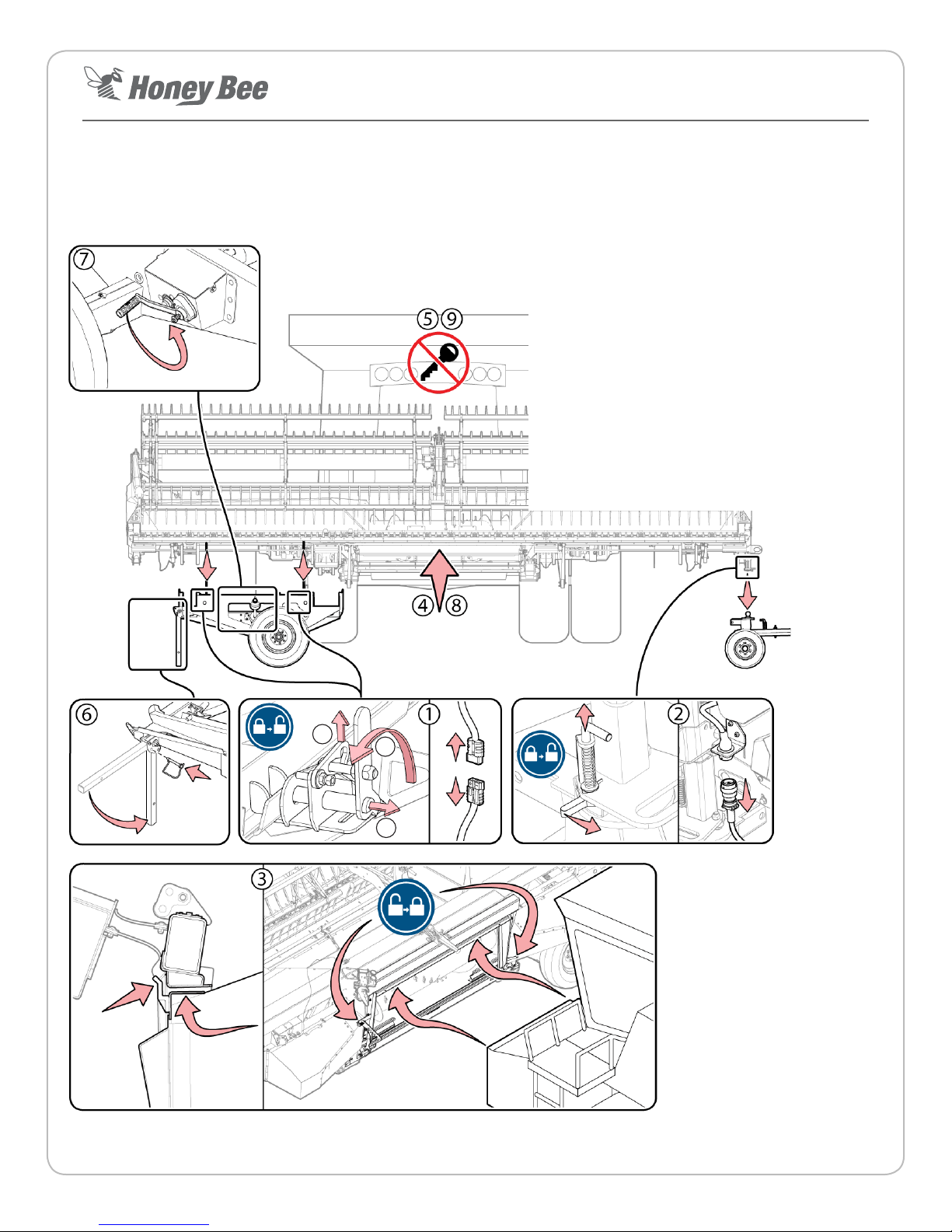

4. Set combine sengs required for header calibraon.

• FLOAT - Set to OFF

• HEADER TYPE - Draper, Rigid, Plaorm (or similar), do

not select Flex type unless specically instructed.

• AUTO HEADER HEIGHT - Set to ON

• AUTO TILT/LATERAL/CONTOUR - Set to ON

5. Park the combine in a ditch with

the header in the air over the road.

Engage the parking brake. (Remain

in this posion through header &

combine calibraon)

6. Select combine make via the

Automax menu (last opon).

7. Set header to FLEX mode prior to calibrang (this calibrates

both RIGID & FLEX modes).

8. Fully extend the hydraulic lt cylinder.

9. Select ‘H/H CALIBRATION’ via Automax main menu.

Follow onscreen instrucons.

The header calibraon is complete when the calibraon done

message appears on the screen with no errors.

Note: Refer to operator manual for detailed instrucons.

IMPORTANT: Don’t make assumpons, don’t skip steps, x all

errors that occur before connuing.

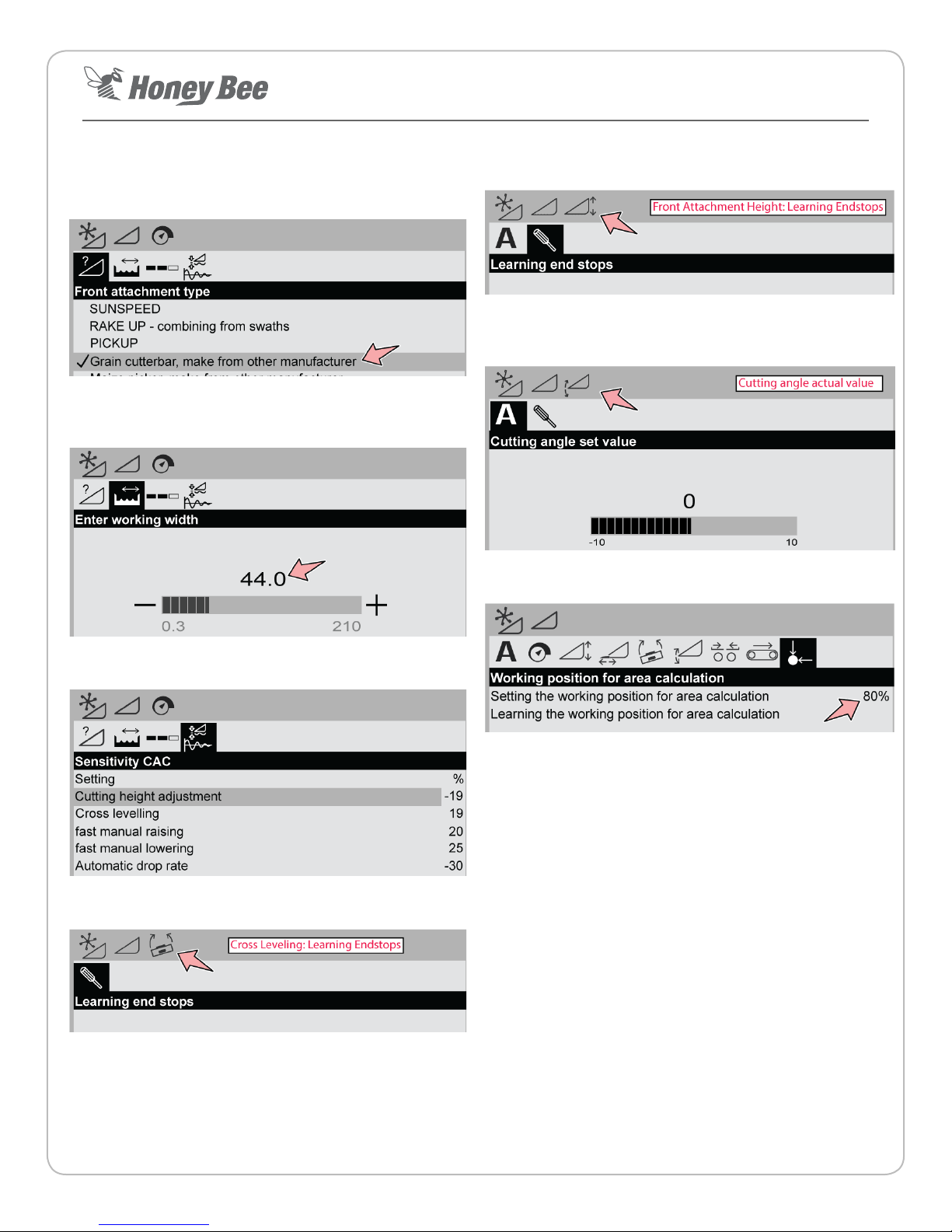

Combine Calibraon

Ensure the combine-specic sengs are entered as described

in the make-specic secons at the end of this document.

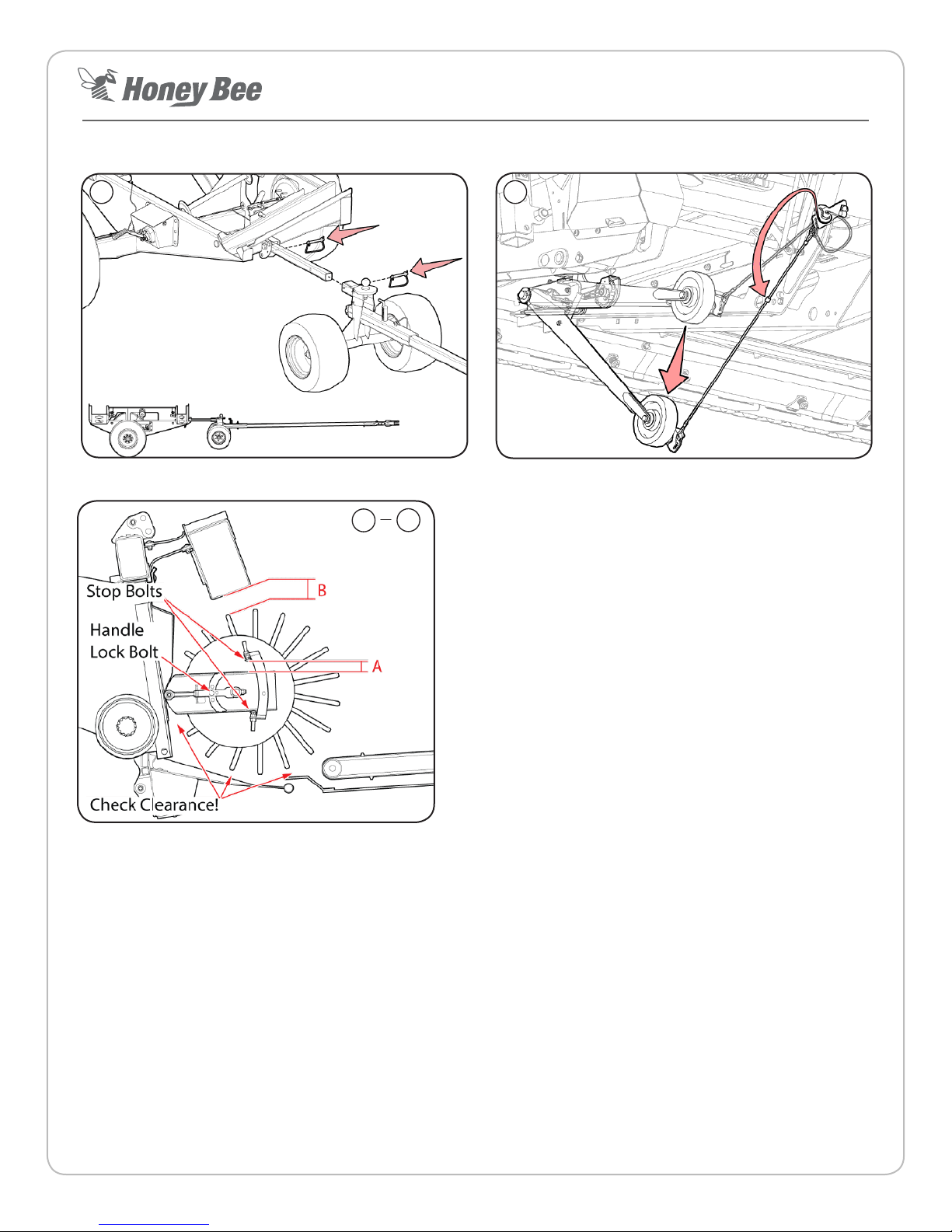

1. The combine must be run at maximum RPM (harvest

speed) and the hydraulic oil must be up to operang

temperatures during calibraon.

2. Check the oil level to ensure there is no air in the system

(normally heard as a whining noise).

3. Set the AirFLEX to RIGID mode via the Automax control

panel.

4. Set combine hydraulic header raise rate so it takes 5

seconds to li the header from the lowest posion to the

highest posion.

5. Set combine hydraulic header drop rate so it takes 7

seconds to lower the header from the highest posion to

the lowest posion.

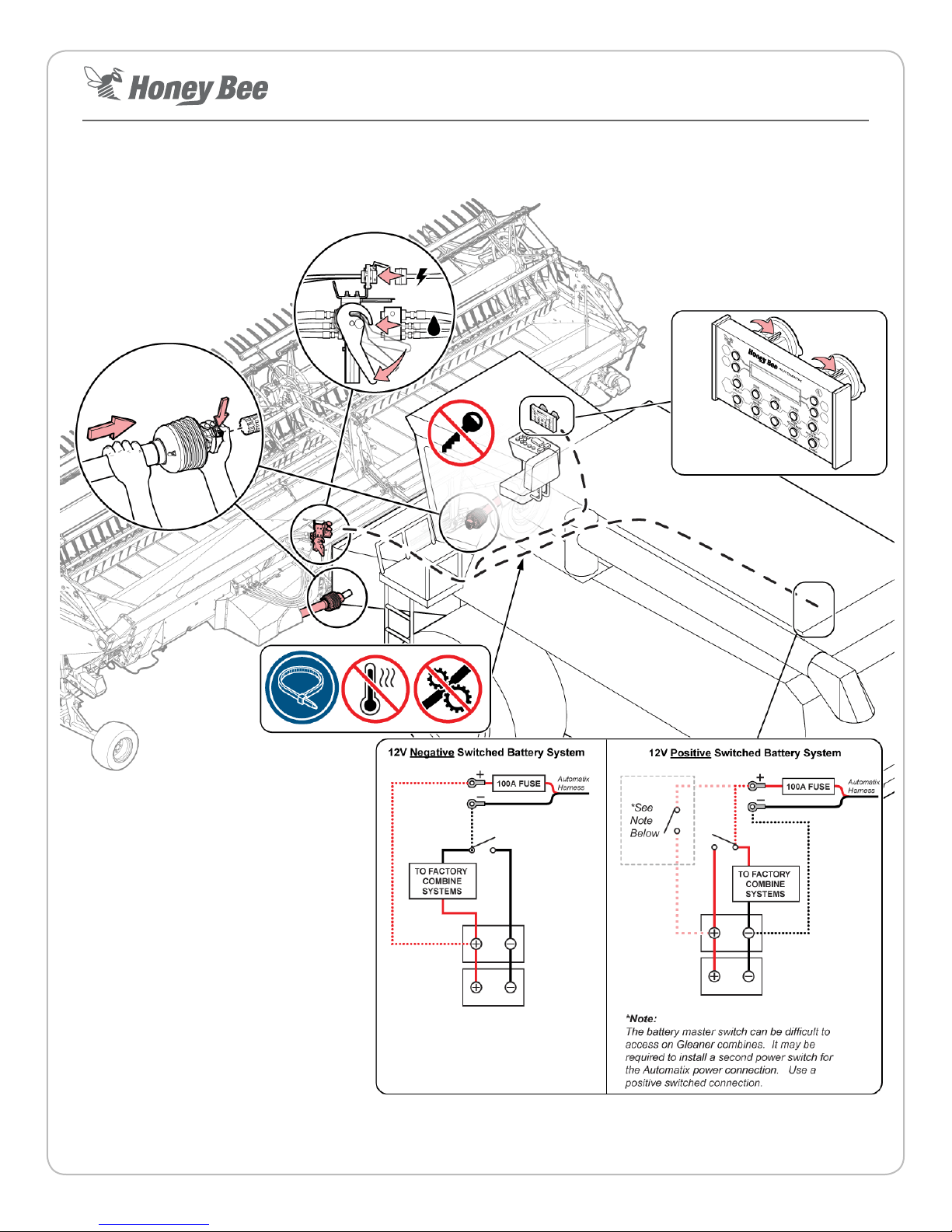

6. Calibrate the combines header height sengs as described

in the combine’s operator manual.

7. Slowly increase header height sensivity via combine

controls unl the header starts hunng up and down.

Decrease sensivity by 10-20% unl the header stops

hunng. Set the lt sensivity to hal the height sensivity

minus 10%, so if the header height sensivity is set to 200,

the lt sensivity should be set to approximately 90 (200/2

= 100, 100 - 10% = 90).

8. When the combine calibraon is done, lower and run

the header and combine rotor so automac header

height is enabled. Record a set-point for header height

on the combine (i.e. 4” (10 cm)). Raise the table all the

way up and laterally lt it all the way to the le or right.

Press the return to set point buon on the combine.

The header should lower back to the set point AND level

out automacally. If this fails, it may indicate a combine

soware problem.

The combine specic sengs listed on the following

pages are recommendaons only. Opmal sengs will

vary by equipment conguraon and condions. It is

the equipment operator’s responsibility to ensure they

operate their equipment in a safe, ecient manner.

The header must be in RIGID mode.for this step!